DOI: 10.11817/j.issn.1672-7207.2020.11.014

PZT陶瓷冷烧结工艺的优化与压电性能研究

郭茹1,马玉鹏1,张妍1,ROSCOW James2,BOWEN R. Chris2,张斗1

(1. 中南大学 粉末冶金国家重点实验室,湖南 长沙,410083;

2. 巴斯大学 机械工程学院,英国 巴斯,BA2 7AY)

摘要:为了提高冷烧结工艺制备的样品致密度,进而其增强压电性能,通过对PZT粉体进行表面修饰、优化PZT颗粒粒径搭配等手段室温化制备高压电系数PZT陶瓷,对PZT陶瓷冷烧结工艺进行优化。研究结果表明:通过Li2MoO4溶液对PZT原料粉体进行表面修饰,形成了厚度为150 nm的Li2MoO4包覆层,有利于冷烧结过程中颗粒重排和溶解-沉淀;采用[63,200) μm的粗颗粒和1~3 μm的细颗粒搭配,使得细颗粒流动到粗颗粒桥接产生的缝隙和孔洞中,实现颗粒间紧密的连接,获得最高的密度(6.49 g/cm3)和相对致密度(85.40%);致密度的提高使样品获得优异的介电和压电性能,在1 kHz时,相对介电常数和介电损耗分别为66.8和0.288;在110 Hz时,压电系数d33为71 pC/N。

关键词:冷烧结;颗粒尺寸分布;致密度;压电系数;锆钛酸铅

中图分类号:TB34 文献标志码:A

文章编号:1672-7207(2020)11-3119-09

Optimization of cold sintering process and piezoelectric properties of PZT ceramics

GUO Ru1, MA Yupeng1, ZHANG Yan1, ROSCOW James2, BOWEN R. Chris2, ZHANG Dou1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Department of Mechanical Engineering, University of Bath, Bath, BA2 7AY, UK)

Abstract: To improve the density of samples in cold sintering process and enhance the piezoelectric properties, the high piezoelectric coefficient PZT ceramics at room temperature were prepared by surface modification of a lead zirconate titanate PZT powder and optimization of PZT particle size. The cold sintering process of PZT ceramics was optimized. The results show that a Li2MoO4 coating with a thickness of 150 nm is formed on the surface of the PZT powder, which is beneficial to the particle rearrangement and the dissolution-precipitation process during cold sintering. A combination of coarse particles [63, 200) μm and fine particles 1-3 μm provides a close connection between the particles due to the fine particles flowing into the gaps and holes between the coarse particles, so as to obtain a high density (6.49 g/cm3) and relative density (85.40%). This increase in density allows the samples to obtain excellent dielectric and piezoelectric properties. For example, the relative permittivity εr and loss tangent tanδ at 1 kHz are 66.8 and 0.288, respectively; and the piezoelectric coefficient d33 at 110 Hz is 71 pC/N.

Key words: cold sintering; particle size distribution; relative density; piezoelectric coefficient; lead zirconate titanate

锆钛酸铅(Pb(Zr1-xTix)O3,PZT)等压电陶瓷具有压电系数高、机电耦合性能好、响应速度快、激励功率小、精度高、稳定性好等优点,被广泛应用于压电传感及驱动领域,如驱动器、换能器、变压器、电容器和传感器等压电器件[1-3]。目前,压电陶瓷主要制备方法为固相烧结法,采用高于1 000 ℃的温度烧结成型,但传统的高温烧结工艺仍然存在一些困难和局限性。例如,对含有易挥发元素(如Pb,Bi,Na,K等)的材料体系,难以保持精准的化学计量比;对于不同材料的共烧(如电极/陶瓷多层电容器),容易由晶体缺陷引起结构、浓度偏差或晶间扩散;除此之外,烧结熔点高的材料耗时长,实验装置复杂[4]。因此高温烧结使得陶瓷材料在材料合成、物相稳定性、能源节约等方面受到了限制。为了降低陶瓷粉体的烧结致密化温度,微波烧结、液相烧结、两步烧结、场辅助烧结等新型烧结技术逐渐被开发应用。然而,这些温度仍远高于400 ℃,并没有将烧结温度降低到“低温范畴”。2016年,美国宾夕法尼亚大学Randall课题组发明了一种“冷烧结(cold sintering process, CSP)”新技术,该工艺通过向陶瓷粉体中添加少量瞬态液相(如V2O5,Na2Mo2O7,K2Mo2O7,Li2MoO4),并施加高压(350~500 MPa)促进颗粒间的扩散和重排,使得陶瓷粉体在较低的温度(室温~300 ℃)和较短时间(30~60 min)实现致密化[5]。与传统高温烧结工艺不同,冷烧结工艺中机械力-化学力耦合增强的传质作用为烧结致密化提供了驱动力[6]。目前,冷烧结工艺已被应用到多种高性能结构陶瓷(ZrO2陶瓷[7])、功能陶瓷(BaTiO3[5],SrTiO3[8],Pb(Zr1-xTix)O3[9]等)、锂离子正极(LiFePO4)[10]、金属氧化物(ZnO[11],Bi2O3[12])及NASICON型固态电解质[13]等材料的制备中。提高冷烧结工艺制备的样品致密度有助于增强压电性能。NELO等[9,14]提出采用双峰尺寸分布的粉体搭配,制备了PZT陶瓷和BST(Ba0.55Sr0.45TiO3,钛酸锶钡)陶瓷,表现出良好的介电和压电性能[14]。这是由于单一粒度的粉体使得松装密度和压制密度较低,而当粗细粉末按照一定比例混匀后,粗颗粒间的大孔隙可被一部分细颗粒所填充,可显著提高样品致密度。因此,采用粗细颗粒混合,优化粒径搭配效果,有望显著改善冷烧结样品致密度,进而提高压电系数。为此,本文作者通过探究不同PZT粉体颗粒的粒径搭配,且对PZT粉体进行表面修饰,进一步优化了冷烧结制备工艺,获得了高致密度和压电系数的PZT陶瓷,为开发高性能压电陶瓷室温化制备技术提供参考。

1 材料和方法

1.1 实验材料

锆钛酸铅粉体(Pb(ZrTi)O3,PZT,NCE55),1,2-丁二醇(纯度98%),钼酸锂(Li2MoO4,LMO,纯度99.9%)。其中,PZT粉体分为粗、细2种粒度,其中,粗粒径粉体粒径分别为[38, 63),[63, 200)和[200, 450) μm,细粒径粉体粒径为1~3 μm。粗细粒径粉体按照质量比9:1混合作为原料。

1.2 PZT混合粉体的表面修饰

首先,将0.654 g LMO溶解在10 mL去离子水中,随后加入10 mL,1,2-丁二醇混合搅拌5 min,将10 g PZT混合原料粉体加入上述溶液中,在90 ℃下继续搅拌蒸发,得到黏稠粉浆,在120 ℃下继续干燥18 h,研磨过筛后得到PZT表面包覆LMO层的粉体(PZT@LMO粉体)。

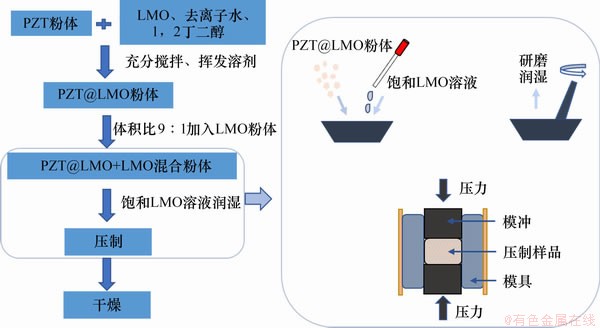

1.3 PZT陶瓷块体的制备

PZT陶瓷冷烧结制备工艺示意图如图1所示。以表面修饰后的PZT@LMO为原料,与LMO按照体积比9:1混料。称取1 g混合物料,加入0.2 mL饱和LMO溶液,在研钵中充分研磨润湿、混合均匀后,转移至直径为13 mm的模具中,在室温下采取190 MPa的压力压制5 min(Carver 3851-0手动压片机),最后,将样品在80 ℃下干燥24 h。采用粒径[38, 63),[63, 200)和[200, 450) μm的粗颗粒与细粒径(1~3 μm)搭配制备的PZT陶瓷分别命名为样品1,2,3。同时采用传统固相烧结法制备PZT陶瓷作为对照。

图1 PZT陶瓷冷烧结制备工艺示意图

Fig. 1 Schematic diagram of cold sintering process of PZT ceramics

1.4 表征与测试方法

采用X射线衍射仪分析PZT粉体物相组成;使用Nova Nano SEM 230场发射扫描电镜(SEM)对PZT粉体、陶瓷断面等进行微观形貌的表征;采用Titan G2 60-300透射电镜(TEM)对PZT@LMO粉体核壳结构进行表征;采用AUW120D电子分析天平和千分尺分析测量陶瓷样品的密度与致密度。采用阻抗分析仪(Solartron 1296)测量PZT陶瓷介电性能;样品在120 ℃,1.3 kV/mm下电晕极化30 min,放置24 h后使用准静态压电系数d33测量仪测量PZT陶瓷的压电常数。

2 实验结果与分析

2.1 PZT粉体的表征

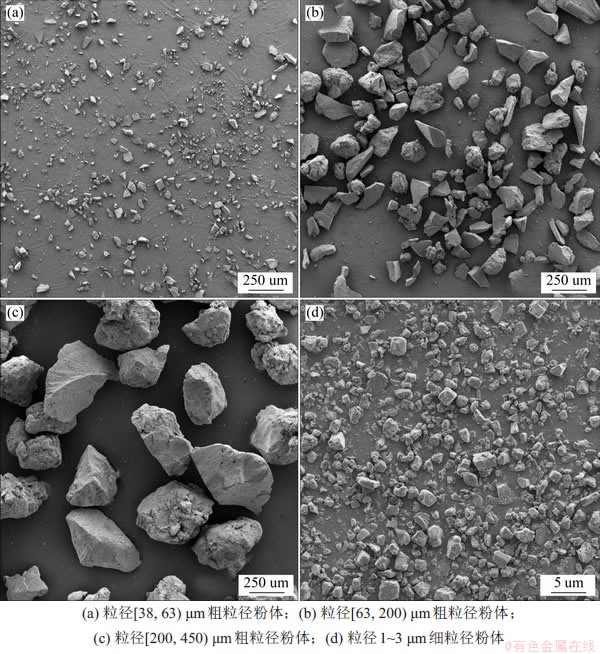

2.1.1 PZT原料的微观形貌

图2所示为PZT原料粉体的SEM照片。由图2可见:粗粒径的PZT颗粒形状不规则,流动性差;细粉体颗粒形状相对较规则,粒径范围为1~3 μm。原料粉体的粒径和形貌会影响其流动性,从而影响压制时坯体内部的压力及密度分布,进而对冷烧结样品的致密度和压电性能产生影响。样品1、样品2和样品3分别采用不同粒度等级搭配的PZT粉体,在机械压力作用下,细粒径可流动填充到粗粒径产生的孔洞、缝隙中,可有效提高压制样品的堆积和压制密度,进而提高样品的致密度。

图2 PZT原料粉体的SEM照片

Fig. 2 SEM images of PZT raw material powder

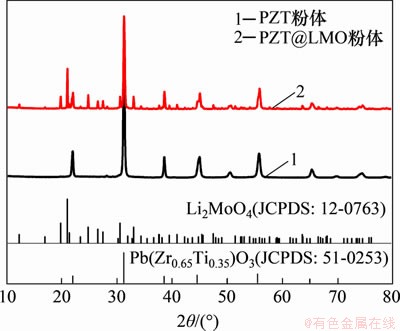

2.1.2 PZT及PZT@LMO粉体的物相分析

图3所示为PZT和PZT@LMO粉体的X射线衍射图。由图3可知,PZT粉体XRD图谱中2θ为22.0°,31.2°,38.6°,44.5°,49.9°,55.5°和64.9°,分别对应(100),(110),(111),(200),(210),(211)和(220)衍射晶面,这与Pb(Zr0.65Ti0.35)O3(JCPDS:51-0253)晶体结构完全匹配。PZT@LMO粉体的XRD图谱中除PZT物相之外,还可以明显观察到LMO物相,如2θ分别为12.3°,19.8°,21.0°,24.8°,30.6°,33.1°和37.6°,对应(110),(012),(211),(220),(113),(410)和(330)衍射晶面,与Li2MoO4(JCPDS:12-0763)匹配,证明了LMO物相与PZT物相复合存在。

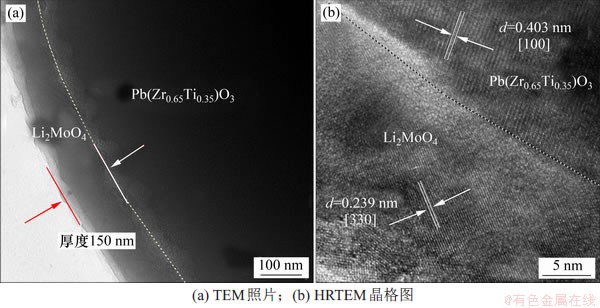

2.1.3 PZT@LMO粉体核壳结构分析

图4所示为PZT@LMO粉体的TEM照片。从图4(a)可以看出:PZT颗粒表面形成了一层均匀的、厚度约为150 nm的LMO修饰层。在HRTEM晶格图中标定其中一个明显的晶格条纹的晶面间距为0.403 nm,对应PZT的(100)晶面,标定另一个晶面间距为0.239 nm,与LMO的(330)晶面相匹配,证实了在PZT表面LMO物相的存在。

图3 PZT和PZT@LMO粉体的X射线衍射图

Fig. 3 XRD patterns of PZT and PZT@LMO powders

图4 PZT@LMO粉体的TEM照片和HRTEM晶格图

Fig. 4 TEM and HRTEM images of PZT@LMO powders

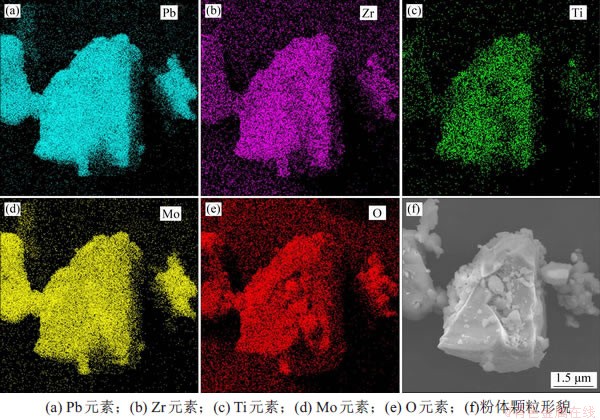

图5所示为PZT@LMO粉体的EDS图。从图5可以看出:PZT和LMO两物相中的Pb,Zr,Ti,Mo和O元素均匀分布,进一步证明了LMO在PZT颗粒表面包覆的均匀性,形成了PZT@LMO核壳结构,该EDS结果与XRD,TEM表征结果相一致。由于冷烧结过程需借助水溶性LMO的溶解,在每个颗粒周围形成一层薄薄的过饱和溶液,PZT颗粒接触的区域溶解在其周围的LMO液相中。外部压力使包裹水膜的颗粒产生流动滑移,促进颗粒重排,形成高度压实的生坯,然后在机械力作用下溶液中水分蒸发,溶质析出形成沉淀相,最终再次沉淀、填充颗粒之间的空隙中完成致密化。因此,LMO层均匀包覆于PZT颗粒表面,有利于冷烧结过程中颗粒重排和溶解-沉淀,进而有助于形成高度致密的陶瓷,提高材料的压电性能。

图5 PZT@LMO粉体的EDS图

Fig. 5 EDS elemental maps of PZT@LMO powders

2.2 PZT陶瓷样品的表征

2.2.1 PZT陶瓷块体的微观形貌

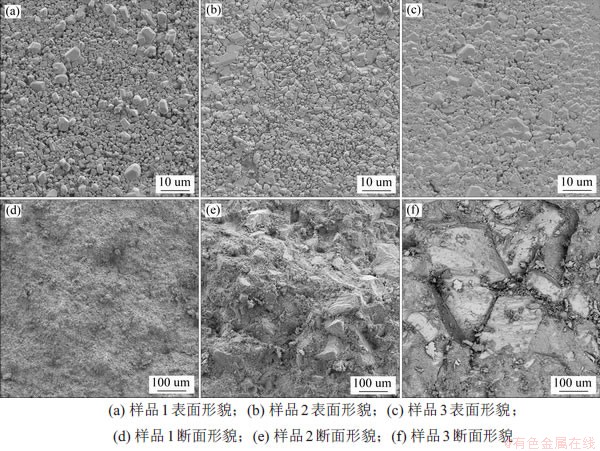

图6所示为不同粒径搭配下的PZT陶瓷的表面及断面形貌SEM照片。从图6可以看出,样品1存在较多微小的孔洞,这是因为粗颗粒粒径较小,产生的缝隙较小,细颗粒较难流动填充至孔隙中。样品3由于粗颗粒粒径较大,相互桥接产生较大的孔隙,导致细颗粒不能完全将其填充致密。而样品2粗细颗粒粒径搭配合理,之间形成了较紧密的连接,整体表现出较高的致密性。

图6 不同粒径搭配下的PZT陶瓷的表面及断面形貌SEM照片

Fig. 6 SEM images of top-view and cross section morphology of PZT ceramics with different particle size distribution

2.2.2 密度与致密度

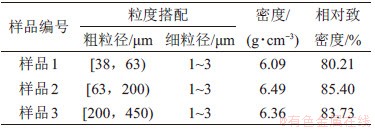

表1所示为不同粒径搭配下的PZT陶瓷的密度与致密度。由表1可知,随着粗颗粒粒径的增加,样品1,2,3获得的密度分别为6.09,6.49和6.36 g/cm3,相应的致密度分别为80.31%,85.40%和83.73%,密度和致密度均呈现先增加后减小的趋势。样品致密度的变化与粉体颗粒粒径搭配有关,这与PZT陶瓷块体的显微形貌规律一致。

表1 不同粒径搭配下的PZT陶瓷的密度与致密度

Table 1 Density and relative density of PZT ceramics with different particle size distribution

2.2.3 介电性能分析

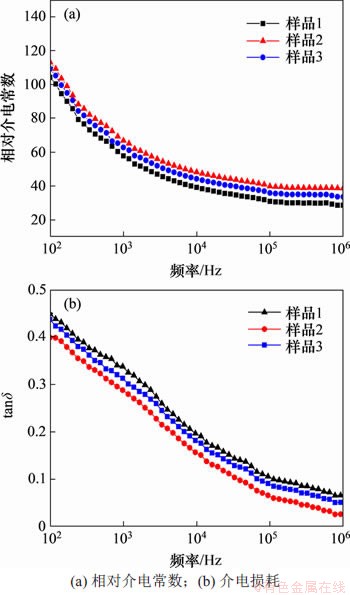

图7所示为不同样品随频率变化的相对介电常数及介电损耗。

由图7(a)可见,随着频率从100 Hz升高至1 MHz,相对介电常数在整个频率范围内呈下降趋势,这是PZT陶瓷的电介质弛豫极化引起的,由于内部转向极化建立时间较长,当外电场频率增加,电畴翻转来跟不上电场变化而产生极化滞后现象。当频率为1 kHz时,样品1,2,3的相对介电常数分别为57.7,66.8和62.8。由图7(b)可知:当频率为1 kHz时,样品1,2,3的介电损耗分别为0.339,0.288和0.313。样品2的致密度最高,因而表现出最优的介电性能。

图7 不同样品的相对介电常数和介电损耗随频率的变化

Fig. 7 Relative permittivity and loss tangent of different samples as a function of frequency

2.2.4 压电性能分析

图8所示为采用准静态压电系数d33测试仪对极化样品测量的随频率变化的压电系数d33。

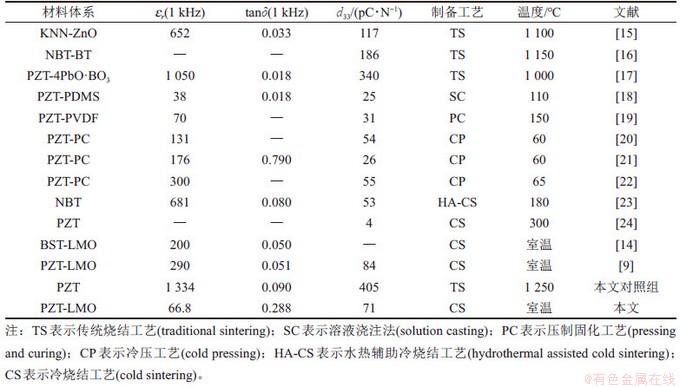

表2 几种典型的压电陶瓷、复合材料的性能及其制备温度对比

Table 2 Performance comparisons of some typical piezoelectric ceramic and composites and its fabrication temperature

由图8可知,当测试频率从5 Hz增加到250 Hz时,PZT陶瓷样品的压电系数d33呈下降趋势。当频率为110 Hz时,样品1,2,3的d33分别为41,71和50 pC/N。样品2的压电性能最优,这与其样品晶粒间结合紧密,孔隙率低,致密度最高有关。

此外,表2所示为几种典型的压电陶瓷、复合材料的性能及其制备温度。例如,常见的KNN(K0.5Na0.5NbO3),NBT(Na0.5Bi0.5TiO3),PZT基陶瓷压电系数d33可高达100~400 pC/N,但制备工艺往往是基于1 000 ℃以上的烧结温度。PZT-PDMS(聚二甲基硅氧烷)和PZT-PVDF(聚偏氟乙烯)等陶瓷-聚合物复合材料可以在低温110~150 ℃下制备,但由于低压电性能聚合物的加入,复合材料整体获得的压电系数d33较低(20~30 pC/N)。PZT-PC(portland cement硅酸盐水泥)等无机复合物进一步降低制备温度至60~65 ℃,压电系数d33维持在25~55 pC/N。与以上几种压电材料的制备条件及获得的压电性能对比发现本文采用的冷烧结工艺获得的PZT陶瓷表现了明显的优异性,不仅完全实现了室温制备工艺,同时获得相对较高的压电系数d33为71 pC/N,为低温化制造新型高性能压电陶瓷及传感器件提供了广阔的应用潜力。

图8 不同样品随频率变化的压电系数d33

Fig. 8 Piezoelectric coefficient d33 of different samples as a function of frequency

3 结论

1) 通过Li2MoO4溶液对PZT原料粉体进行表面修饰,形成厚度为150 nm的Li2MoO4包覆层,PZT@LMO粉体的制备有利于冷烧结过程中颗粒重排和溶解-沉淀。

2) PZT颗粒不同粒径搭配可有效提高PZT陶瓷样品的致密度,采用[63, 200) μm的粗颗粒和1~3 μm的细颗粒搭配时,可获得最高的密度(6.49 g/cm3)和致密度(85.40%),这是因为细颗粒既可流动到粗颗粒桥接产生的缝隙和孔洞中,又可以实现颗粒间紧密的连接,充分填充致密。

3) PZT陶瓷样品的介电性能和压电性能受致密度影响。当频率为1 kHz时,致密度最高的样品的相对介电常数和介电损耗分别为66.8和0.288。在频率为110 Hz时,获得最高的压电系数d33为71 pC/N,实现了高压电系数PZT陶瓷的室温制备。

参考文献:

[1] JASIM A, WANG H, YESNER G, et al. Optimized design of layered bridge transducer for piezoelectric energy harvesting from roadway[J]. Energy, 2017, 141: 1133-1145.

[2] SEBASTIAN T, KOZIELSKI L, ERHART J. Co-sintered PZT ceramics for the piezoelectric transformers[J]. Ceramics International, 2015, 41(8): 9321-9327.

[3] GUPTA R, RANA L, TOMAR M, et al. Characterization of lead zirconium titanate thin films based multifunctional energy harvesters[J]. Thin Solid Films, 2018, 652: 39-42.

[4] GUO Hanzheng, BAKER A, GUO Jing, et al. Cold sintering process: a novel technique for low-temperature ceramic processing of ferroelectrics[J]. Journal of the American Ceramic Society, 2016, 99(11): 3489-3507.

[5] GUO Hanzheng, BAKER A, GUO J, et al. Protocol for ultralow-temperature ceramic sintering: an integration of nanotechnology and the cold sintering process[J]. ACS Nano, 2016, 10(11): 10606-10614.

[6] GUO Jing, BERBANO S S, GUO Hanzheng, et al. Cold sintering process of composites: bridging the processing temperature gap of ceramic and polymer materials[J]. Advanced Functional Materials, 2016, 26(39): 7115-7121.

[7] GUO Hanzheng, GUO Jing, BAKER A, et al. Cold sintering process for ZrO2-based ceramics: significantly enhanced densification evolution in yttria-doped ZrO2[J]. Journal of the American Ceramic Society, 2017, 100(2): 491-495.

[8] BOSTON R, GUO J, FUNAHASHI S, et al. Reactive intermediate phase cold sintering in strontium titanate[J]. RSC Advances, 2018, 8(36): 20372-20378.

[9] NELO M, SIPONKOSKI T, KAHARI H, et al. Upside - down composites: fabricating piezoceramics at room temperature[J]. Journal of the European Ceramic Society, 2019, 39(11): 3301-3306.

[10] SEO J H, GUO J, GUO Hanzheng, et al. Cold sintering of a Li-ion cathode: LiFePO4-composite with high volumetric capacity[J]. Ceramics International, 2017, 43(17): 15370-15374.

[11] FUNAHASHI S, GUO Jing, GUO Hanzheng, et al. Demonstration of the cold sintering process study for the densification and grain growth of ZnO ceramics[J]. Journal of the American Ceramic Society, 2017, 100(2): 546-553.

[12] SONG Jinjie, ZHU Guisheng, XU Huarui, et al. Preparation and properties of high-density Bi2O3 ceramics by cold sintering[J]. Ceramics International, 2020, 46(9): 13848-13853.

[13] LENG Haoyang, HUANG Jiajia, NIE Jiuyuan, et al. Cold sintering and ionic conductivities of Na3.256Mg0.128Zr1.872Si2PO12 solid electrolytes[J]. Journal of Power Sources, 2018, 391: 170-179.

[14] NELO M, PERANTIE J, SIPONKOSKI T, et al. Upside-down composites: electroceramics without sintering[J]. Applied Materials Today, 2019, 15: 83-86.

[15] ZUO Ruzhong, RODEL J, CHEN Renzheng, et al. Sintering and electrical properties of lead-free Na0.5K0.5NbO3 piezoelectric ceramics[J]. Journal of the American Ceramic Society, 2006, 89(6): 2010-2015.

[16] ANTHONIAPPEN J, LIN C H, TU C S, et al. Enhanced piezoelectric and dielectric responses in 92.5%(Bi0.5Na0.5) TiO3-7.5%BaTiO3 ceramics[J]. Journal of the American Ceramic Society, 2014, 97(6): 1890-1894.

[17] TANDON R P, SINGH V, NARAYANASWAMI N, et al. Low temperature sintering of PZT ceramics using a glass additive[J]. Ferroelectrics, 1997, 196(1): 117-120.

[18] BABU I, DE WITH G. Highly flexible piezoelectric 0-3 PZT-PDMS composites with high filler content[J]. Composites Science and Technology, 2014, 91: 91-97.

[19] ZHANG Deqing, WANG Dawei, YUAN Jie, et al. Structural and electrical properties of PZT/PVDF piezoelectric nanocomposites prepared by cold-press and hot-press routes[J]. Chinese Physics Letters, 2008, 25(12): 4410-4413.

[20] LI Zongjin, GONG Hongyu, ZHANG Yujun. Fabrication and piezoelectricity of 0-3 cement based composite with nano-PZT powder[J]. Current Applied Physics, 2009, 9(3): 588-591.

[21] CHAIPANICH A. Effect of PZT particle size on dielectric and piezoelectric properties of PZT-cement composites[J]. Current Applied Physics, 2007, 7(5): 574-577.

[22] DONG Biqin, LI Zongjin. Cement-based piezoelectric ceramic smart composites[J]. Composites Science and Technology, 2005, 65(9): 1363-1371.

[23] HUANG Huanqi, TANG Jian, LIU Jun. Preparation of Na0.5Bi0.5TiO3 ceramics by hydrothermal-assisted cold sintering[J]. Ceramics International, 2019, 45(6): 6753-6758.

[24] WANG Dixiong, GUO Hanzheng, MORANDI C S, et al. Cold sintering and electrical characterization of lead zirconate titanate piezoelectric ceramics[J]. APL Materials, 2018, 6(1): 016101.

(编辑 赵俊)

收稿日期: 2020 -07 -29; 修回日期: 2020 -09 -13

基金项目(Foundation item):国家自然科学基金资助项目(51672311, U19A2087);湖南省自然科学基金资助项目(2019JJ40349) (Projects(51672311, U19A2087) supported by the National Natural Science Foundation of China; Project(2019JJ40349) supported by the Natural Science Foundation of Hunan Province)

通信作者:张斗,博士,教授,从事电子陶瓷与器件,介电复合材料与器件,无铅压电铁电陶瓷、铁电薄膜、3D直写以及多孔生物陶瓷研究;E-mail:dzhang@csu.edu.cn