文章编号:1004-0609(2010)S1-s0303-06

粉末冶金钛合金的制备与力学性能

肖代红, 袁铁锤,贺跃辉,王守仁

(中南大学 粉末冶金国家重点实验室,长沙410083)

摘 要:采用元素混合法制备粉末冶金Ti-Al-Mo-V-Ag合金。通过X射线衍射、金相观察、扫描电镜及力学性能测试等方法,研究Ag的添加及烧结温度对基体合金的显微组织与力学性能影响,并对其作用机制进行探讨。结果表明:添加5%~10% Ag(质量分数)可提高基体合金的压坯成型性,最终使烧结合金的致密度与力学性能得到提高;Ti-5Al-4Mo-4V-5Ag合金经过1 250 ℃真空烧结4 h后,抗压缩强度及相对密度分别达到1 656 MPa及96.3%。

关键词:钛合金;烧结;显微组织;力学性能

中图分类号:TG 146.23 文献标志码:A

Synthesis and mechanical properties of

powder metallurgy titanium alloy

XIAO Dai-hong, YUAN Tie-chui, HE Yue-hui, WANG Shou-ren

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The Ti-Al-Mo-V-Ag alloys were prepared by powder metallurgy using the blended elemental (BE) technique. The effects of Ag additions and sintering temperature on microstructure and properties of the based alloys were investigated using X-ray diffractometry, optical microscopy, scanning electron microscopy and mechanical properties tests. The results show that adding Ag element increases the relative density and improve the mechanical properties of powder metallurgy (P/M) Ti-5Al-4Mo-4V alloy. After sintering at 1 250 ℃ for 4 h, the relative density and compression strength of P/M Ti-5Al-4Mo-4V-5Ag alloy are 96.3% and 1 656 MPa, respectively.

Key words: titanium alloys; sintering; microstructure; properties

钛合金具有密度低、比强度高、屈强比高、塑韧性和耐腐蚀性好等优点,在军工、民用等领域具有广阔的应用前景[1-2]。扩大钛合金市场的瓶颈是钛的提取、熔炼、机加工很难,从而导致生产成本高[3-4]。粉末冶金技术由于在零部件近净形具有优势,能大大提高材料利用率,降低加工成本,并能获得均匀细小的显微组织,因此成为降低钛合金成本的重要技术[3-6]。粉末冶金钛合金的研究主要集中在混合元素法(BE)、预合金法(PA)、快速凝固法(RS)等3种方法上,其中混合元素法无论是经济效益、成分选择及微观组织设计上,都比其它两种方法优越[7-8]。BE法钛合金产品的主要应用是工业钛过滤器、叶轮或整体叶盘等形状复杂的零件,如俄罗斯的伊尔114飞机发动机高压压气离心机叶轮和发动机轴支撑件。

由于铝具有密度低、在钛中的固溶大(质量分数超过6%)等特点,使得其成为钛合金中的主要合金化元素之一。目前已研制的低铝含量(2%~6%)的粉末冶金钛合金因具有较高强度、良好的耐热抗蠕变性能,而受到广泛的关注[9-12]。由于合金化元素对粉末冶金钛合金具有重要影响[13],为此,本文作者拟采用元素混合法制备Ti-5Al-4Mo-4V基合金,通过真空烧结,研究Ag元素及烧结温度对基体合金组织与性能影响,为实际工业生产提供可行性参考。

1 实验

试验用钛合金的名义成分如表1所列,原料为氢化钛粉、钼粉、铝粉、银粉、铝-钒中间合金粉,平均晶粒尺寸分别为48、1.5、2.6、0.7及74 μm。按照配比称取粉末质量后,在行星式球磨机中通过氩气保护进行湿磨48 h后,在真空干燥箱干燥处理。干燥后的粉末采用钢模压制成型,压力为300 MPa。压坯在钼片式真空烧结炉进行烧结4 h,烧结温度分别为 1 150、1 250及1 350 ℃,烧结后随炉冷却至室温。烧结样品的密度采用阿基米德排水法测量。试样抛光后采用Kroll试剂腐蚀后,进行金相观察。压缩性能测试在INSTRON 3356型全数字电液伺服力学性能试验机进行,样品尺寸采用d 6 mm×7 mm,加载速率为1mm/min。压缩测试后的合金断口在FEI-Nano230型场发射扫描电镜上分析。合金的物相分析在D/max2550全自动转扒靶X射线衍射仪上进行。

表1 试验合金的名义成分

Table 1 Nominal compositions of experimental alloys

2 结果与分析

2.1 物相分析

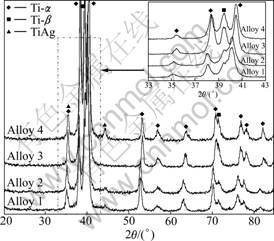

对1 250 ℃烧结的样品进行X射线衍射分析(见图1),结果显示4种合金中均含有α相与β相的衍射峰,其中β相的衍射峰的强度随着Ag的增加而提高,表明β相增加。从图1中也看到,α相的衍射峰向高角度方向移动,显示出Ag的添加改变其晶格参数。另外合金4中,除了α相与β相的衍射峰外,还出现了TiAg峰,这是由Ag的含量较高,部分Ag与Ti发生了反应,生成了TiAg化合物。

2.2 相对密度及压缩性能

烧结样品的性能测试结果如图2所示。由图2可看出,经1 150 ℃烧结后,合金的相对密度随着Ag含量的增加而提高,从82.5%(合金1)提高到93.6%(合金4)。压缩性能测试显示,无Ag合金1的抗压缩强度为1 002 MPa,压缩率只有2.1%;当添加2%Ag后,合金2的抗压缩强度提高到1 244 MPa,压缩率提高到6.2%;当Ag含量增加到5%时,合金3的抗压缩强度相对合金1提高578 MPa,而压缩率也达到25%;进一步增加Ag到10%时,抗压缩强度与压缩率相对合金3略有降低,但也分别达到1 476 MPa与21%,大大超过合金1的。

图1 合金在1250℃烧结后的XRD谱

Fig.1 XRD patterns of alloys after being sintered at 1 250 ℃

4种合金在1 250 ℃烧结后,相对1 150 ℃烧结时,试样的相对密度均有所提高,分别为85.%、88%、95%和96%。同时,Ag含量的增加对基体合金的相对密度的影响趋势与1 150 ℃相类似。压缩性能测试表明,随着Ag含量的增加,基体合金的抗压缩强度明显提高,从1 134 MPa提高到1 568 MPa;压缩率从1.5%提高19.2%。另外与1 150 ℃的比较也表明,提高烧结温度时,抗压缩强度也提高,而压缩率略有降低。

对1 350 ℃烧结的试样进行密度测试显示,4种合金的相对密度均超过92%,表明烧结温度的提高有助于合金致密度的改善。随着Ag含量的增加,基体合金的相对密度分别提高到93.6%(合金2)、95.3%(合金3)及97.1%(合金4)。而压缩性能测试显示,合金1的压缩强度为1 231 MPa,比1 250 ℃烧结后略有提高;而添加Ag含量其他3种合金的压缩强度尽管均高于合金1的,且合金4的强度超过合金3的。但相对1 250 ℃烧结后的样品,同一成分合金的抗压缩强度及压缩率却有所降低,表明过高的烧结温度对粉末冶金钛合金的压缩性能不利。

2.3 显微组织

对不同烧结温度下的试样进行金相观察(见图3~5),并结合XRD结果可知, 4种合金均为典型的α+β型双相组织,其中还含有细小片状的α组织及α晶团。但Ag含量不同时,合金的显微组织有明显的差别。

图2 试样在不同温度烧结后的性能比较

Fig.2 Comparison of properties of samples after being sintered at different temperatures: (a) Relative density; (b) Compression strength; (c) Compressive rate

图3 试样在1 150 ℃烧结后的金相组织

Fig.3 Optical microstructures of alloys after being sintered at 1 150 ℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4

图4 试样在1 250 ℃烧结后的金相组织

Fig.4 Optical microstructures of alloys after being sintered at 1 250 ℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4

图5 试样在1 350 ℃烧结后的金相组织

Fig.5 Optical microstructures of alloys after being sintered at 1 350 ℃: (a) Alloy 1; (b) Alloy 2; (c) Alloy 3; (d) Alloy 4

经1 150 ℃烧结后(见图3),随着Ag含量的增加,合金中孔隙数量减少,晶粒尺寸略有增大。合金2与合金1的显微组织差别不是很明显,均为α+β型双态组织,其中等轴α相较多(见图3(a)与(b)中白色部分),表明添加2%Ag对合金的组织影响较小。当Ag含量达到5%时,合金3(见图3(c))的主要组织为魏德曼组织(Widmanstaetten structure),这种组织由原始β晶粒、片状α相及α晶团组成,等轴α相减少。进一步增加Ag的含量时;合金4的组织为魏德曼组织,该组织由原始β晶粒、β晶粒内的片状α相及α晶团组成。

经1 250 ℃烧结后(见图4),合金1与2的组织与1 150 ℃烧结后相类似,均为α+β型双态组织,其中等轴α相为主要相。相对1 150 ℃烧结态,合金3中等轴α相明显减少,组织主要为魏德曼组织,这种组织也由初始β晶粒、片状α相及α晶团组成。而合金4中并未出现等轴α相,而是魏德曼组织,组织中的片状α相的厚度相对合金3更小。

经1 350 ℃烧结后(见图5),合金1与2的组织与 1 150 ℃及1 250 ℃烧结后相类似,均为α+β型双态组织,其中等轴α相为主要相,但晶粒尺寸却增大,片状α相增多。而合金3为明显的魏德曼组织,组织由原始β晶粒、片状α相及α晶团组成,其中片状α相厚度较大。合金4的组织与1 250 ℃烧结样品的相类似,但原始β晶粒晶界上的α相厚度及α晶团尺寸减小。

同时,对合金3在1 250 ℃烧结后的压缩断口进行SEM观察,显示出合金的断裂方式主要为穿晶断裂,而对其中的α晶团进行高倍扫描电镜观察(见图6),表明α晶团由平均尺寸120 nm的层片状组成,在层片之间有纳米级的球状TiAg化合物,这些化合物可起到弥散强化的作用。

3 分析与讨论

粉末冶金钛合金的性能受合金成分、孔隙率及显微组织影响。Ti-5Al-4Mo-4V合金是一种含高合金元素含量的α+β型合金。其中Al元素为α相稳定元素,而Mo和V为β相稳定元素,这些元素溶解在α相和β相中,均能起到固溶强化的作用,同时也改变粉末冶金钛合金中相的比例。当在Ti-5Al-4Mo-4V中添加Ag元素时,因Ag元素是一种β相共析型稳定元素,其固溶到基体中时,可起到固溶强化作用,而当Ag的含量超过一定量时,过量的银与钛会发生共析转变,生成TiAg化合物相(见图1),强烈降低(α+β)/β相点,使得合金中易生成片状组织[14]。而图3~6的实验结果表明,添加5%~10%Ag时,合金中的主要组织是原始β晶粒、β晶粒中的片状α相及α晶团。

Ti-5Al-4Mo-4V-(5-10)Ag合金系中,位于两相区的合金自β相区随炉冷却过程中,由于产生的过冷度小,晶核一方面在晶界上形成,并且在晶界区长大为晶界α,而后许多在晶界区的晶核从晶界向晶内生长,形成位向相同、相互平行的片状α相。另一方面,在晶粒内部也可形核,并长成α晶团。α晶团的大小与数量受许多因素影响,加热温度越高,保温时间越长,β稳定元素越多,β相变点越低,冷却速度越慢,则α晶团越大。试验合金4中的α晶团数量明显超过合金3与合金2的,这主要是由于β稳定元素Ag的含量较高。由图3~5中可知,合金3中的等轴α相减少,而魏德曼组织增多,这是因为随着烧结温度的提高,β稳定元素Mo、V和Ag的扩散速率增大,固溶更充分,在随后的炉冷过程中,α相会从β初晶里析出形成细小的魏德曼层片组织。

另外,从图2中也看到,所着烧结温度的提高,烧结体的相对密度也提高,最终能达到97%。这是因为烧结温度越高,粉末活性越高,β稳定元素Mo、V和Ag的扩散速率越大,烧结体收缩增大,孔隙减少,使烧结体合金的相对密度增大。同时添加Ag元素,可降低(α+β)/β相转变点温度,从而可降低复合粉末的烧结温度,烧结过程中形成的纳米级TiAg化合物也可起到阻碍晶粒长大的作用,最终提高含Ag烧结体合金的相对密度。

图6 合金3经过1 250 ℃烧结后压缩断口的SEM像

Fig.6 SEM images of fracture surface of alloy 3 after being sintered at 1 250 ℃

从图2中也看到,不同Ag含量的烧结态合金的性能不一样。随着Ag含量的增加,相同烧结工艺下,合金的相对密度提高(见图2),表明合金中孔隙减少。而抗压缩强度与塑性变形能力随着Ag含量的增加也提高,特别是含5%~10%Ag元素时,1 250~1 350 ℃烧结下的合金的抗压缩强度超过了1 400 MPa,压缩率也达到19%以上。合金的强度与致密度的关系可表示为[15]

σm=σ0exp(–bm) (1)

式中:σm是修正后的拉伸强度;σ0是具有一定孔隙率m的合金的真实拉伸强度;b是常数,约为4~7。由此可以看出,随着孔隙度m的减小,烧结钛合金的σm呈指数增大趋势。另外,从图1和6中也可看到,高含量Ag的添加,一方面提高烧结合金的致密度,另一方面改变基体合金的相组成,合金的显微组织由(α+β)双态组织转变为魏德曼组织,同时还生成纳米级的TiAg化合物,这种组织的变化促进了压缩强度的提高。

4 结论

1) 在粉末Ti-5Al-4Mo-4V复合粉中添加5%~10% Ag,可改善烧结体合金的相对密度,提高其压缩性能。

2) 提高烧结温度,含Ag烧结体钛合金的相对密度能达到96%,抗压缩强度超过1 500 MPa,而压缩率可达到19%以上。

3) 基体合金中添加5%~10%Ag时,烧结体合金的显微组织由(α+β)双态组织转变为魏德曼组织,同时在基体合金中生成纳米级的具有弥散强化作用的TiAg化合物。

REFERENCES

[1] MOISEYEV V N. Titanium alloys Russian aircraft and aerospace applications [M]. Taylor & Fraccis Group, LLC, 2008: 147-153.

[2] LEYENS C, PETERS M. Titanium and titanium alloys [M]. Weinheim: Wiley-VCH Verlag GmbH & Co. KGaA, 2003: 351- 368.

[3] 汤慧萍, 刘 咏, 韦伟峰, 陈丽芳. 添加稀土元素对粉末冶金Ti合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2004, 14(2): 244-249.

TANG Hui-min, LIU Yong, WEI Wei-feng, CHEN Li-fang. Effect of rare-earth element addition on microstructure and mechanical properties of P/M titanium alloys [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(2): 244-249.

[4] HANSON A D, RUNKLE J C, WIDMER R, HEBEISSEN J C. Titanium near net shapes from elemental powder blends [J]. International Journal of Powder Metallurgy, 1990, 26(2): 157-64.

[5] ROBERTSON I M, SCHAFFER G B. Design of titanium alloy for efficient sintering to low porosity [J]. Powder Metallurgy, 2009, 52(4): 311-315.

[6] 汤慧萍, 黄伯云, 刘 咏, 欧阳洪武. 粉末冶金钛合金致密化研究的进展[J]. 稀有金属材料与工程, 2003, 32(9): 677-680.

TANG Hui-ping, HUANG Bai-yun, LIU Yong, OUYANG Hong-wu. Progress in the densification of powder metallurgical titanium alloys [J]. Rare Metal Materials and Engineering, 2003, 32(9): 677-680.

[7] TAKAHIRO F, OGAWA A, OUCHI C, TAJIMA H. Microstructure and properties of titanium alloy produced in the newly developed blended elemental powder metallurgy process [J]. Materials Science and Engineering A, 1996, 213(1/2): 148- 153.

[8] SUN F S, YU K OSOURCE. Development of cost effective blended elemental powder metallurgy Ti alloys [C]// ORLANDOF L. Innovations in Titanium Technology, TMS 2007 Annual Meeting & Exhibition. Warrendale (PA): TMS. 2007: 19-27.

[9] 赵 瑶, 贺跃辉, 江 垚.粉末冶金Ti6Al4V合金的研制进展[J].粉末冶金材料科学与工程, 2008, 13(2):70-78.

ZHAO Yao, HE Yue-hui, JIANG Yao. Progress of powder metallurgy Ti6Al4V alloy [J]. Powder Metallurgy Materials Science and Engineering, 2008, 13(2):70-78.

[10] TAMIRISAKANDALA S. BHAT R B, RAVI V A. Powder metallurgy Ti-6Al-4V-xB alloys: Processing, microstructure, and properties [J]. JOM, 2004, 56(5): 60-63.

[11] AZEVEDO C R F, RODRIGUES D, NETO F B. Ti-Al-V powder metallurgy (PM) via the hydrogenation dehydrogenation (HDH) process [J]. Journal of Alloys and Compounds, 2003, 353(1/2): 217-227.

[12] IVASISHIN O M, SAVVAKIN DG, FROES F, MOKSON V C. Synthesis of alloy Ti-6Al-4V with low residual porosity by a powder metallurgy method [J]. Powder Metallurgy and Metal Ceramics, 2002, 41(7/8): 382-90.

[13] LIU Yong, CHEN Li-fang, WEI Wei-feng, TANG Hui-ping. Improvement of ductility of powder metallurgy titanium alloys by addition of rare earth element [J]. Journal of Materials Science and Technology, 2006, 22(4): 465-469.

[14] 莫 畏. 钛[M]. 北京: 冶金工业出版社, 2008: 252-257.

MO Wei. Titanium [M]. Beijing: Metallurgical Industry Press, 2008: 252-257.

[15] DUCKWORTH W. Discussion of ryshkewitch paper [J]. J Amer Ceramic Soc, 1953, 36: 68-75.

(编辑 李艳红)

基金项目:国家杰出青年科学基金资助项目(50825102);湖南省科技计划博士后专项基金资助项目(2009RS3025);粉末冶金国家重点实验室创新基金资助项目(PM2010)

通信作者:肖代红,副教授,博士; 电话:0731-88877880; E-mail: xdh0615@163.com