文章编号: 1004-0609(2005)03-0463-08

镁合金在镀液中的腐蚀行为

胡波年1, 2, 陈珏伶1, 余 刚1, 刘 正3, 叶立元1

(1. 湖南大学 化学化工学院, 长沙 410082;

2. 湖南高等建材专科学校 化学化工系, 衡阳 421008;

3. 沈阳工业大学 材料科学与工程学院, 沈阳 110023)

摘 要: 通过腐蚀实验和阳极极化曲线研究了硫酸镍主盐配制的化学镀镍液成分和温度对AZ91D镁合金的腐蚀行为的影响, 比较了碱式碳酸镍主盐和硫酸镍主盐两种镀镍液的腐蚀性以及施镀后的镀层质量。 结果表明: 硫酸镍镀液的腐蚀性比碱式碳酸镍镀液大, 在低温下, 镁合金在硫酸镍镀液中表面的氟化镁膜不致密, 镀液对基材的腐蚀性高; 而在高温下, Mg2+与F-的反应性增强, 氟化反应完全, 形成的氟化镁钝化膜致密性高, 可保护镁合金基体免遭镀液的腐蚀。 在施镀温度下, 镀液中F-的缓蚀作用, 可使SO2-4离子对镁合金的腐蚀速率大大降低。

关键词: AZ91D镁合金; 镀液腐蚀; 化学镀镍; 硫酸镍

中图分类号: TQ153.1 文献标识码: A

Corrosion behavior of magnesium alloy in

electroless nickel plating bath

HU Bo-nian1, 2, CHEN Jue-ling1, YU Gang1, LIU Zheng3, YE Li-yuan1

(1. School of Chemistry and Chemical Engineering, Hunan University,

Changsha 410082, China;

2. Department of Chemistry and Chemical Engineering, Hunan College of Building Materials,

Hengyang 421008, China;

3. School of Materials Science and Engineering, Shenyang University of Technology,

Shenyang 110023, China)

Abstract: Through the corrosion experiments and the anodic polarization curves, the effects of composition of plating bath and temperature on corrosion behavior of magnesium alloy AZ91D in electroless nickel plating bath composed of nickel sulfate were studied. The corrosion behavior of AZ91D in the baths with nickel sulfate or with basic nickel carbonate and the quality of the coating obtained in both baths, were compared. The results show that corrosion of magnesium alloy in the bath with nickel sulfate is suffered more seriously than that in the bath with basic nickel carbonate. At low temperature, MgF2 film on the surface of magnesium alloy in the bath with nickel sulfate is not compact and the coupons of magnesium alloy have a big corrosion rate, but at high temperature, the reactive of Mg2+ and F- increases, and MgF2 film on the surface of magnesium alloy becomes more compact. So MgF2 film can prevent magnesium alloy from further corrosion. At the plating temperature beyond 70℃, the corrosion rate of magnesium alloy caused by SO2-4 in the bath is reduced in presence of F-.

Key words: AZ91D magnesium alloy; bath corrosion; electroless nickel plating; nickel sulfate

镁合金是一种应用范围越来越广的轻金属材料。 由于其本身耐蚀性差, 通常可通过化学镀镍来提高其耐蚀性。 在镁合金化学镀镍的工艺中, Cl-、 SO2-4的存在会对镁合金基体造成腐蚀, 因此广泛应用的是碱式碳酸镍主盐的镀镍液系统, 回避镀液中过多的Cl-、 SO2-4的使用[1]。 碱式碳酸镍作为镍源有两个缺点: 一是由于碱式碳酸镍水溶性不好, 一般采用氢氟酸使之溶解来补充镍的消耗, 这样必然造成镀液中F-浓度增加, 次亚磷酸钠的补充又造成镀液中Na+浓度增加, 随着使用周期的增加则会产生NiF2和NaF沉淀, 从而影响镀层的质量和寿命[2]; 二是碱式碳酸镍价格是硫酸镍的两倍, 成本高[3]。 硫酸镍的价格低廉, 容易制成纯度较高的产品, 且易溶解, 被认为是镍源的最佳选择[4]。 如果硫酸镍为主盐镀镍体系在工艺条件下对镁合金基体无明显腐蚀, 不影响施镀的效果, 那么可改善镀液的成分、 降低成本、 提高经济效益。

镀液对镁合金的腐蚀, 将直接影响镀层的性能, 因此这是一个不可忽视的问题。 本文作者分析了硫酸镍主盐镀镍液成分对镁合金腐蚀的原因, 并验证了硫酸镍主盐镀镍液的化学镀效果, 为镁合金化学镀镍提供了一种切实可行、 高效、 经济的施镀工艺。

1 实验

1.1 镁合金的前处理

选用镁合金AZ91D为研究材料, 其化学成分(质量分数, %)为8.500%~9.500%Al, 0.450%~0.900%Zn, 0.170%~0.400%Mn, 〈0.050%Si, 〈0.025%Cu, 〈0.004%Fe, 〈0.001%Ni, 其他〈0.010%, 余量Mg。

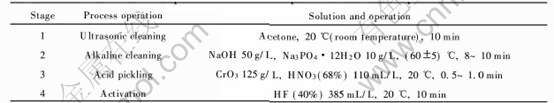

镁合金试样的表面处理流程为: 镁合金→打磨抛光→超声波丙酮清洗→碱洗→酸洗→活化(各步间水洗)[5-7]。 表面处理的溶液配方及操作条件列于表1。

1.2 镀液的腐蚀实验及腐蚀的评定方法

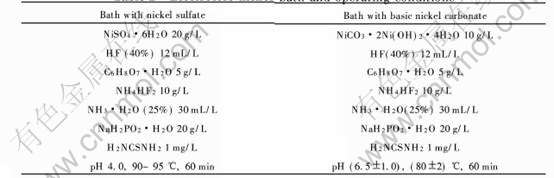

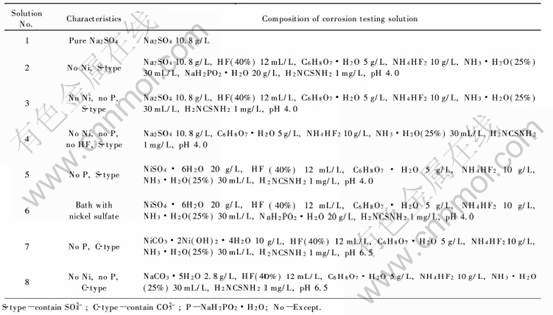

表2所列为硫酸镍主盐化学镀镍液与碱式碳酸镍主盐化学镀镍液的配方及施镀工艺[6-8]。 依据表2中的化学镀镍溶液的组成特点配制了表3的腐蚀溶液, 通过1~8号溶液的腐蚀实验来考察硫酸镍主盐镀镍液中各组分及温度对镁合金腐蚀的影响, 并与镁合金在碳酸镍镀液中的腐蚀性进行对比。

将镁合金试样按表1工艺进行表面处理, 然后放入表3所列的各腐蚀溶液中室温浸泡进行腐蚀实验, 时间分别为4和15h。

对于镀液腐蚀性的评定, 因镁合金基体的溶解和各种复杂的腐蚀反应产物粘附在镁合金的表面上, 试样质量的变化规律复杂, 采用质量法来评定镁合金的腐蚀程度, 准确性低。 本文作者采用肉眼观察得到单位面积腐蚀点数和表面腐蚀形貌来评定镁合金的腐蚀程度。

镀层腐蚀实验的具体操作如下: 在5%的NaCl溶液中室温浸泡2h, 通过单位面积上的腐蚀点来比较获得的镀层耐蚀性。

表1 表面处理的溶液组成及操作条件

Table 1 Solution composition of surface pretreatment and operation conditions

表2 化学镀镍的镀液及施镀工艺

Table 2 Electroless nickel bath and operating conditions

表3 腐蚀溶液的成分

Table 3 Composition of corrosion solution

同时, 通过测定不同成分溶液的阳极极化曲线来分析镁合金表面的钝化状态。

2 结果与讨论

2.1 硫酸镍镀液中各成分对镁合金耐蚀性的影响

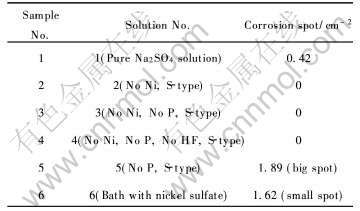

通过实验发现, 在室温(20℃)下镁合金在依据硫酸镍主盐镀镍液配制的腐蚀液中, 腐蚀情况不同, 因此在室温(20℃)下将经过活化处理的镁合金试样在1~6号溶液中浸泡15h来考察镀液各成分对镁合金耐蚀性的影响, 实验结果列于表4。

表4 Mg合金在镀液中的腐蚀速率

Table 4 Corrosion rate of magnesium alloy in electroless nickel bath

从表4可以看出, 1、 5、 6号试样被腐蚀, 2~4号试样无明显腐蚀痕迹。

1) 由1号试样可知, 在室温(20℃)下, 只有SO2-4离子存在, 经过活化处理的镁合金遭受一定的腐蚀。 而在含SO2-4离子溶液中并含有HF或NH4HF2时, 如2~4号试样受到腐蚀的程度低, 这说明F-对镁合金有保护作用。

2) 2~6号试样所浸的溶液都含有SO2-4和F-离子, 2~4号试样所浸的溶液无Ni2+离子则未观察到腐蚀点, 而5、 6号试样浸在含Ni2+溶液中则遭受腐蚀, Ni2+是一种强氧化剂, 能与金属镁发生直接置换反应, Ni2+离子可以加剧镁合金的腐蚀。

3) 5号试样比6号试样的腐蚀更加严重, 说明具有一定还原性的NaH2PO2·H2O有减缓镁合金的腐蚀作用, 反应产物中的磷酸盐对镁合金有部分磷化缓蚀作用。 在室温状态下, 硫酸镍镀液对镁合金基材有腐蚀作用。

2.2 温度对硫酸盐镀镍液腐蚀性影响

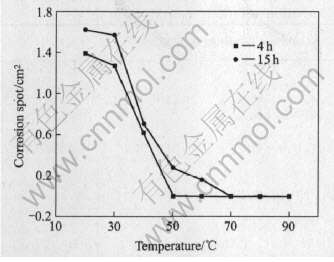

选用含SO2-4的5号溶液在不同温度下进行腐蚀实验, 考察SO2-4对镁合金的腐蚀性能, 腐蚀结果如图1所示。

图1 不同温度下5号溶液对镁合金基体的腐蚀

Fig.1 Corrosion of magnesium alloy in solution of No.5 at various temperatures

在20℃时腐蚀较严重, 温度低于40℃腐蚀明显, 当达到50℃以上时无明显腐蚀。 温度提高会增强Mg2+与F-的反应性, 在镁合金表面生成更多的MgF2, 减少与溶液的接触面积, 保护镁合金免遭腐蚀。

在70~95℃的施镀温度下, 硫酸镍主盐镀镍液对镁合金基体同样有较好的保护作用, 因此施镀的过程中也不会造成镀件的腐蚀, 可以用硫酸镍作主盐配制化学镀液在镁合金上施镀。

2.3 镁合金在碱式碳酸镍为主盐的镀液中的腐蚀

选用不加还原剂NaH2PO2·H2O的碱式碳酸镍主盐镀镍液(7号溶液)进行腐蚀实验, 时间15 h。 结果发现在20~90℃下镁合金均无腐蚀点。

在依据碳酸镍镀液配制的腐蚀溶液(7、 8号溶液)中未发现试样被腐蚀, 由于溶液中的CO2-3对镁合金无腐蚀性, 并能与Mg2+形成水溶性小的MgCO3沉淀保护镁合金。 即使有腐蚀性很强的Ni2+存在, 在施镀的短时间范围内也不会使镁合金发生严重的腐蚀作用, 故碱式碳酸镍镀液对镁合金的腐蚀性低于硫酸镍镀液的, 能使镁合金处于保护的状态下施镀。

2.4 镁合金在各溶液中的阳极极化行为

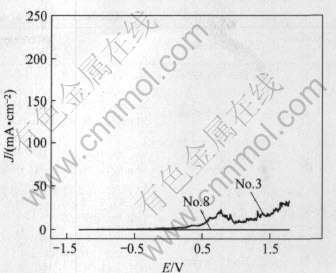

图2所示为将经过活化处理的镁合金在3号和8号溶液中作的阳极极化曲线。 目的是比较在镀液中不加Ni2+和NaH2PO2的条件下, SO2-4和CO2-3对镁合金表面钝化膜的影响。 在30℃时镁合金在含SO2-4的3号溶液中由0.25V后开始有较大的溶解电流, 而在含CO2-3的8号溶液中, 镁合金在-1.50~1.75V的电势区内阳极电流很小, 处于钝化状态。 说明在低温下, SO2-4比CO2-3对镁合金的 腐蚀性强, 对镁合金在镀液中形成钝化膜的破坏性较大。

图2 30℃时AZ91D镁合金在3号和8号溶液中的阳极极化曲线

Fig.2 Anodic polarization curves of AZ91D magnesium alloy in solutions of No.3 and No.8 at 30℃

图3所示为30℃下AZ91D镁合金在3、 5号和6号溶液中的阳极极化曲线、 在5号溶液中Ni2+存在时能产生典型的阳极极化曲线, -0.15V的致钝电势、 -0.25~-0.05V的钝化区、 0.75V后二次溶解和二次钝化。 溶液中镍离子被锌或镁置换, 镁合金表面沉积少量不致密的电势较高的镍点, 有较强的局部电偶腐蚀趋势, 因此又会加速镁合金的 腐蚀。 在电势高于1.6V时, 有Ni2+存在的5号溶液比没有Ni2+存在时的3号溶液的阳极化电流大, 溶解速度更快。

图3 30℃时AZ91D镁合金在3、 5号和6号溶液中的阳极极化曲线

Fig.3 Anodic polarization curves of AZ91D magnesium alloy in solutions of No.3, 5 and No.6 at 30℃

在6号溶液中, 同时存在Ni2+和NaH2PO2·H2O时, 阳极溶解电流比在5号溶液中减小, 说明NaH2PO2的氧化产物磷酸盐对镁合金基体部分磷化效果, 起到一定的缓蚀作用。

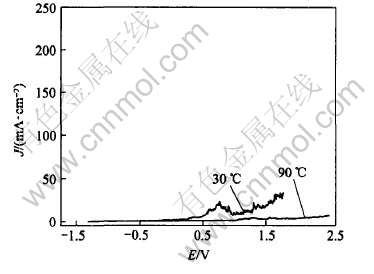

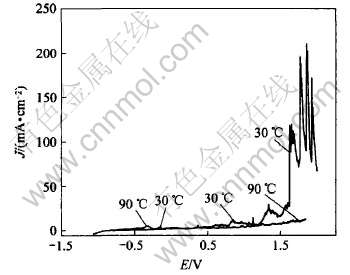

图4和5表明, 在30℃时无论溶液中是否含有Ni2+, 当电势达到一定的数值后, 都有相对较大的溶解电流, 而在90℃时, 可以看到在-1.0~ 2.0V左右有相对较低的溶解电流。 对于硫酸镍为 主盐的镀液来说, 高温时钝化特性好, 腐蚀性要小。

图4 AZ91D镁合金于30℃和90℃时在3号溶液中的阳极极化曲线

Fig.4 Anodic polarization curves of AZ91D magnesium alloy in solution of No.3 at 30℃ and 90℃

图5 AZ91D镁合金于30℃和90℃时在5号溶液中的阳极极化曲线

Fig.5 Anodic polarization curves of AZ91D magnesium alloy in solution of No.5 at 30℃ and 90℃

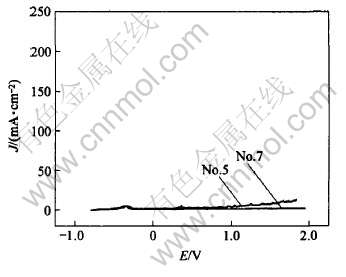

在90℃时, 从含SO2-4的5号溶液和含CO2-3的7号溶液中的阳极极化曲线发现(图6), 5号溶液中的阳极极化曲线电势达到0.75V后有相对较大的溶解电流, 而在含CO2-3的7号溶液中, 镁合金在-0.75~2.00V的电势区内的阳极溶解电流都很小, 处于钝态。 说明90℃下, SO2-4比CO2-3对镁合金的腐蚀性更强, 对镁合金在镀液中形成钝化膜的破坏性更大。 但镁合金在两种镀液体系中的维钝电流相差并不十分明显, 那么, 硫酸镍主盐镀镍液对镁合金基体在施镀温度下有较好的保护作用, 防止了因镀件的剧烈腐蚀造成的施镀困难, 因此可以用硫酸镍作主盐配制化学镀液在镁合金上施镀。

图6 90℃时AZ91D镁合金在5号和7号溶液中的阳极极化曲线

Fig.6 Anodic polarization curves of AZ91D magnesium alloy in solutions of No.3 and No.7 at 90℃

在图2~6中, 5~7号溶液含有Ni2+离子, 镁合金在其中的阳极曲线都会出现一次溶解峰, 而3号、 8号溶液无Ni2+离子, 无一次溶解峰。 这是因为因置换反应Ni沉积在试样表面造成的局部电偶腐蚀导致电流增大, 而电流降低和在3、 8号溶液中无一次溶解峰则反应了溶液具有钝化能力。 进一步证明Ni2+离子加速腐蚀, 镀液除Ni2+离子外其他成分具有钝化作用。

由此可见, 镁合金在1~8号溶液阳极极化行为与腐蚀试验的结果一致。

2.5 镀液腐蚀性分析

由以上实验证明, 镁合金在碱式碳酸镍主盐的镀液中腐蚀性很小, 而在硫酸镍做主盐的镀液中确有一定的腐蚀作用。

通过实验证明活化对镀液的腐蚀性影响很大。 当改变活化条件(如温度、 时间)可使镀液在室温下15h无明显腐蚀点。 做好表面前处理可使镁合金在硫酸镍主盐镀镍液中的腐蚀速率很低。 因此对于硫酸镍主盐镀镍液, 在低温出现腐蚀, 不是由于SO2-4离子破坏了MgF2膜, 因为MgF2的溶解度(7.3×10-2g/L)远远小于MgSO4的溶解度(278g/L), 不可能进行SO2-4+MgF2[FY]MgSO4+F-的反应, 出现腐蚀的最根本是因为活化后MgF2的不连续, 不完整。 活化步骤使镁合金表面沉积黏附力较强的MgF2膜, 使得表面电势分布更均匀, 减小了腐蚀微电池的影响[9], 但试样表面的氟化物膜不连续处或空隙的位置与腐蚀性物质接触生成无保护能力的MgO[10]。 MgO在镀液pH值范围内(4.0~6.5)是不稳定的, 将会溶解, 使得镁合金基体暴露而与镀液接触, 硫酸镍镀液中的H+和活性阴离子SO2-4, 均可与Mg反应, 结合成可溶性物质, 结果在新露出的镁合金基底的特定点上由于沿Mg17Al12网状结构选择性腐蚀形成孔蚀核[11]。 在自然腐蚀条件下, 含活性阴离子的介质中有阳离子氧化剂时能促使蚀核长大成蚀孔[12]。 而镀液中Ni2+离子为强氧化剂, 它能促进阳极过程, 金属镁的腐蚀电势上升至孔蚀临界电势以上, 蚀核会发展成蚀孔。 因此在含有Ni2+离子的溶液中, 腐蚀明显。 如果蚀核形成后, 在无Ni2+离子而有F-离子和其他保护性离子溶液中, 再钝化阻力小, 该特定点仍有再钝化能力, 蚀核就不再长大, 在无Ni2+离子溶液无明显腐蚀现象的原因就在此。 而在碱式碳酸镍主盐镀镍液中, MgCO3、 NiCO3等难溶盐在MgF2不连续的位置形成了一层膜, 阻碍镁合金暴露, Ni2+离子与镁基体接触的机会减小, 所以镁合金的腐蚀速率很低。

随着温度升高, 硫酸镍主盐镀镍液的钝化能力进一步增强。 由于镀液中含有F-离子, 高温下Mg2+与F-的反应活性增强, 又有新的MgF2在原来MgF2不连续处生成, 或是镀液的其他成分的影响, 使得表面不溶性膜更加致密, 使腐蚀速度大大降低, 所以, 温度越高, 在含氟的镀液中镁的腐蚀速度越小。

一般认为, 酸性含SO2-4的镀液会使镁合金基体腐蚀, 形成多孔的表面, 并且伴有大量置换反应发生, 这样沉积在镁合金表面的镍层结合力差, 耐蚀性不好。 通过以上实验可以说明高温下镀液的腐蚀性小, 而氟化物膜的再生成可以限制置换反应, 用硫酸镍主盐镀镍液也得到良好性能的镀层。 况且在化学镀镍前还有浸锌步骤, 锌层可进一步保护镁合金。 浸锌后可再进行电镀锌或锡[13,14]。 电镀锌时使得锌层的厚度达到0.6μm或锌的沉积达到0.43mg/cm2以上时, 将得到良好结合力的镀层[13], 那么, 采用含硫酸根的镀液就不必担心化学镀过程中的镀件腐蚀而施镀困难的问题。

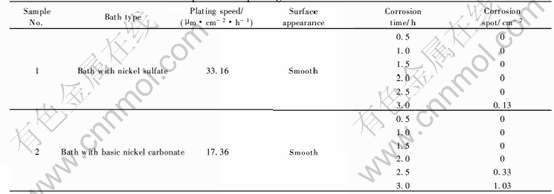

2.6 两种镀液的施镀效果比较

镁合金在硫酸镍主盐和碱式碳酸镍主盐两种镀液中施镀后镀层性能比较列于表5。 通过5%NaCl溶液的浸泡实验可以看出, 2h内在两种镀液中得到的镀层均无表观腐蚀点。 而随着时间的延长2号试样在2.5h出现明显腐蚀, 3.0h时腐蚀更严重。

表5 两种镀液获得的镀层性能对比

Table 5 Comparison of plating of two electroless nickel baths

3号试样在3.0h时也出现了腐蚀。 说明从耐蚀性来讲, 在以硫酸镍为镀液主盐的工艺获得的镀层略优于在碱式碳酸镍为镀液主盐的工艺获得的镀层。

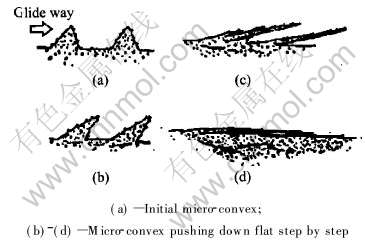

两种镀层的微观形貌如图7所示。 图7(a)和7(b)所示为试样分别在硫酸镍主盐镀镍液和碱式碳酸镍主盐镀镍液中施镀1h后镀层的金相照片。 可以看出图7(a)中与图7(b)中镀层镀层形貌差别不大, Ni-P沉积层致密, 无明显孔洞和缺陷, 均有胞状突起。 镀层积量较多, 为镀层提供了良好的耐蚀性。 图7(a)中的胞状突起略大于图7(b), 这是由于局部粗糙度过大或施镀过程中气泡未能及时脱逸而造成的尺寸增大[15]。

图7 不同镀液中施镀1h后镀层的微观形貌

Fig.7 Microcosmic morphologies of coating plated in different solutions for 1h

由此看出采用硫酸镍主盐镀镍工艺施镀获得的镁合金镀件的镀层性能良好。

3 结论

1) 碱式碳酸盐镀镍液不论在低温还是施镀温度下对镁合金基体的腐蚀性均很低。

2) SO2-4离子本身不会破坏MgF2钝化膜而造成镁合金的腐蚀。 低温下在硫酸镍主盐镀镍液有明显腐蚀主要是因为MgF2膜的不致密和Ni2+离子加速镁合金腐蚀造成的。

3) 在施镀温度下镁合金基体表面在镀液中再钝化, 使不溶性MgF2膜更加致密, 阻止镁合金基体进一步腐蚀, 因此在高温下, 镀液对镁合金的腐蚀比常温下低。

4) 阳极极化曲线表明, 镁合金在低温时含SO2-4镀液的溶解电流大, 但在高温时溶解电流小, 说明含SO2-4镀液在高温的钝化特性好。

5) 由于高温时硫酸镍主盐镀液中的腐蚀性小, 采用该工艺获得的化学镀镍层的施镀质量较高, 镀层耐蚀性能好, 结合力强。

REFERENCES

[1]叶宏, 冯燕熹, 王希山, 等. 镁合金的化学镀镍工艺研究[J]. 表面技术, 2002, 31(6): 32-36.

YE Hong, FENG Yan-xi, WANG Xi-shan, et al. Technology of electroless nickel plating on magnesium alloy [J]. Surface Technology, 2002, 31(6): 32-36.

[2]刘正, 张奎, 曾小勤. 镁基轻质合金理论基础及其应用[M]. 北京: 机械工业出版社, 2002. 167.

LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory and Application of Magnesium Alloys [M]. Beijing: Mechanical Industry Press, 2002. 167.

[3]刘新宽, 向阳辉, 胡文彬, 等. 镁合金化学镀镍溶液的老化[J]. 中国有色金属学报, 2003, 13(4): 1046-1050.

LIU Xin-kuan, XIANG Yang-hui, HU Wen-bin, et al. Ageing of electroless nickel bath of magnesium alloys [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(4): 1046-1050.

[4]李宁, 袁国伟, 黎德育, 等. 化学镀镍基合金理论与技术[M]. 哈尔滨: 哈尔滨工业大学出版社, 2000. 32.

LI Ning, YUAN Guo-wei, LI De-yu, et al. Theory and Technology of Electroless Nickel planting[M]. Harbin: Harbin Institute of Technology Press, 2000. 32.

[5]Delong H K. Plating on magnesium[J]. Metal Finishing Guidebook, 1978, 76(1): 175-83.

[6]Sharma A K, Suresh M R, Bhojraj H, et al. Electroless nickel plating on magnesium alloy[J]. Metal Finishing, 1998, 96(3): 10-18.

[7]Fairweather W A. Electroless nickel plating of magnesium[J]. Trans IMF, 1997, 75(3): 113-117.

[8]李瑛, 余刚, 刘跃龙, 等. 镁合金上硫酸镍体系化学镀镍工艺[J]. 材料保护, 2003, 36(10): 30-32.

LI Ying, YU Gang, LIU Yue-long, et al. Electroless nickel plating technology of AZ91D magnesium alloy in nikel sulfate bath [J]. Materials Protection, 2003, 36(10): 30-32.

[9]郭洪飞, 安茂忠. 镁及镁合金电镀与化学镀[J]. 电镀与环保, 2004, 24(2): 1-5.

GUO Hong-fei, AN Mao-zhong. Electroplating and electroless nickel plating on magnesium alloy[J]. Electroplating & Pollution Control, 2004, 24(2): 1-5.

[10]曾荣昌, 柯为伟, 徐永波, 等. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei-wei, XU Yong-bo, et al. Recent development and application of magnesium alloys [J]. Acta Metallurgica Sinica, 2001, 37(7): 673-685.

[11]向阳辉, 胡文彬, 沈彬, 等. 镁合金直接化学镀镍活化表面状态对镀速的影响[J]. 电镀与环保, 2000, 20(2): 21-23.

XIANG Yang-hui, HU Wen-bin, SHEN Bin, et al. Effect of surface state after activation on deposition rate of direct electroless nickel plating on magnesium alloy [J]. Electroplating & Pollution Control, 2000, 20(2): 21-23.

[12]魏宝明. 金属腐蚀理论及应用[M]. 北京: 化学工业出版社, 1986. 149.

WEI Bao-ming. Theory and Application of Metal Corrosion[M]. Beijing: Chemistry Industry Press, 1986. 149.

[13]Kato J, Urushihata W, Nakayama T. Magnesium Based Alloys Article and a Method Thereof[P]. US 6068938, 2000.

[14]Ogata M. Electroplating on magnesium alloy[J]. Surf Fin Soc of Japan, 1998, 49(1): 51-56.

[15]霍宏伟, 李瑛, 王福会. AZ91D镁合金化学镀镍[J]. 中国腐蚀与防护学报, 2002, 22(1): 14-17.

HUO Hong-wei, LI Ying, WANG Fu-hui. Electroless nickel plating on AZ91D magnesium alloy [J]. Journal of Chinese Society for Corrosion and Protection, 2002, 22(1): 14-17.

(编辑陈爱华)

基金项目: 国家科技攻关计划资助项目(2001BA311A03)

收稿日期: 2004-09-29; 修订日期: 2004-12-03

作者简介: 胡波年(1957-), 男, 副教授.

通讯作者: 余 刚, 博士; 电话: 0731-8821770; E-mail: yuganghnu@sina.com