Structure and magnetic properties of columnar Fe-N thin films deposited by direct current magnetron sputtering

JIA Hui(贾 辉)1, 2, WANG Xin(王 欣)2, PANG Shao-ping(庞绍平)3,

ZHENG Wei-tao(郑伟涛)2, LONG Bei-hong(龙北红)2, LI Bo(李 博)2

1. College of Physics, Beihua University, Jilin 132021, China;

2. Department of Materials Science, Key Laboratory of Automobile Materials of Ministry of Education,

Jilin University, Changchun 130012, China;

3. Yancheng Institute of Technology, Yancheng 224003, China

Received 22 April 2008; accepted 10 October 2008

Abstract: Columnar Fe-N thin films with thickness ranging from 30 to 150 nm were deposited by direct current magnetron sputtering using an Ar/N2 gas mixture (V(N2)/V(N2+Ar)=5%) on corning glass substrates. The structure, surface morphology and magnetic properties were investigated using X-ray diffractometry(XRD), scanning electron microscopy, atomic force microscopy, transmission electron microscopy(TEM) and superconducting quantum interference magnetometry. XRD investigation shows that Fe-N films exhibit amorphous-like structures; however, TEM measurements indicate the synthesis of mixture phases of α-Fe+ζ-Fe2N+ε-Fe3N in these films. The magnetic anisotropy and coercivity of Fe-N thin films exhibit strong dependence on the film growth behavior and surface morphology. With increasing the height of Fe-N films with column structures, the coercivity increases from 7.96 kA/m to 22.28 kA/m in the direction parallel to the film surface. In perpendicular direction the coercivity only increases slightly from 39.79 kA/m to 43.77 kA/m. However, the values of anisotropy field increase from 0.79×106 to 1.44×106 A/m, which is mainly attributed to the shape anisotropy of elongated columns due to the fact that the difference of magneto-crystalline anisotropy among these Fe-N films is small. The saturation magnetizations of Fe-N films vary with increasing film thickness from 23.5 to 85.1 A?m2/kg.

Key words: Fe-N thin film; coercivity; magnetic anisotropy; saturation magnetization

1 Introduction

Iron nitride thin films have attracted a great deal of attention for many years due to their variety of structural and magnetic properties for the potential applications as magnetic functional materials[1-8]. All nitrides with the composition of FexN (x≥3) are ferromagnetics at room temperature. Among them, α″-Fe16N2 (bct) has higher saturation magnetization (298 A?m2/kg) than that of bulk α-Fe (210 A?m2/kg) and γ′-Fe4N (fcc, 188 A?m2/kg) [9-10]. In addition, paramagnetic ξ-Fe2N (orthorhombic) and nonmagnetic phases FeN (γ″′-NaCl and γ″-ZnS) also have been paid much attention in these years[11-12]. Compared with the crystalline structures, amorphous magnetic Fe-N thin films are expected to have several advantages over crystalline Fe-N films such as lower magnetic anisotropy because of the isotropic nature of the amorphous structure[13-14]. Some reports have been given on the synthesis of amorphous Fe-N films by sputtering technique. However, the synthesis conditions must be controlled carefully to avoid forming other Fe-N crystalline structures[15-17].

In this work, using DC magnetron sputtering technique, Fe-N thin films were deposited with various thicknesses on corning glasses substrate. The relationship of surface morphology and structure with magnetic properties including coercivity, saturation magnetization and magnetic anisotropy for synthesized Fe-N thin films was studied.

2 Experimental

Fe-N films with thickness ranging from 30 to 150 nm were deposited on corning glass substrates in mixed Ar/N2 gas (V(N2)/V(Ar+N2)=5%) using DC magnetron sputtering with high purity (99.99%) α-Fe target. The distance between the fixed substrate holder and the target was 6.5 cm. The base pressure was 5×10-5 Pa. Prior to deposition, the substrates were cleaned ultrasonically in acetone and ethanol consecutively, then baked in a vacuum chamber at 250 ℃ for 2 h and cooled down to room temperature. During sputtering, the DC power and the magnet exciting power were kept constant at 100 W and 37.5 W (I=2.50 A, U=15 V) respectively, and the total pressure was fixed at 2.0 Pa. The deposition rate was about 0.1 nm/s.

The structure of the films was analyzed using X-ray diffractometer(XRD) with Cu Kα radiation using a current of 150 mA and voltage of 40 kV (Rigaku, D/MAX-rA) and JEM-2000EX TEM operated at 180 kV and 160 kV. The surface morphology of the films was characterized using scanning electron microscope (SEM) (JOEL JSM-6700F) and non-contacted atomic force microscope(AFM) (Digital Instrument Nanoscope Ⅲ scanning probe microscope). The radius of the Si3N4 tip was about 10 nm. The scan area was 1-5 μm, the scan speed was 1 Hz and the sampling rate was 256 points per line. Magnetic properties of the films were measured by superconducting quantum interference device (SQUIDS) magnetometer (MPMS-5S, Quantum Design, San Diego, CA, USA) in magnetic fields up to 5 T. The mass of the samples was measured using analytical balance (Sartorius BS210S).

3 Results and discussion

3.1 Film structures and surface morphology

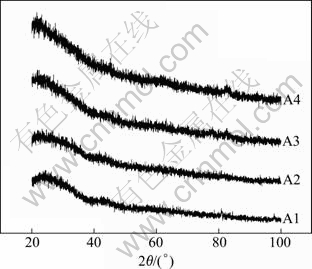

Structures of the Fe-N thin films were analyzed using XRD. Fig.1 shows the XRD patterns of the Fe-N film samples (A1, A2, A3 and A4 corresponding to film with thickness of 30, 90, 120 and 150 nm, respectively) deposited on glass substrates. No obvious strong diffraction peak can be observed for these films, which indicates that the synthesized films are amorphous or crystal Fe-N films containing small crystalline grains without showing any preferred orientation growth. In order to well understand the crystal phases in samples A1, A2, A3 and A4, the structures of Fe-N films were investigated by means of TEM.

Fig.1 X-ray diffraction patterns for Fe-N film samples with various film thicknesses: (a) A1, 30 nm; (b) A2, 90 nm; (c) A3, 120 nm; (d) A4, 150 nm

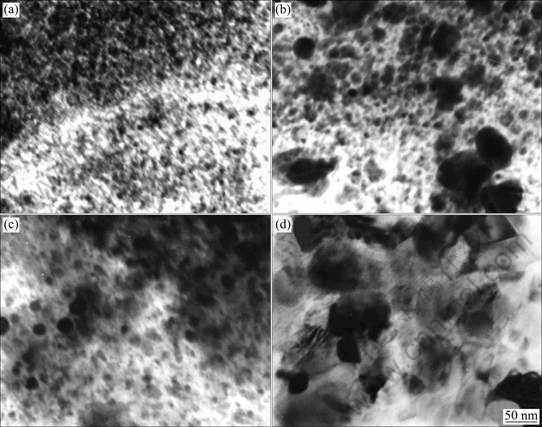

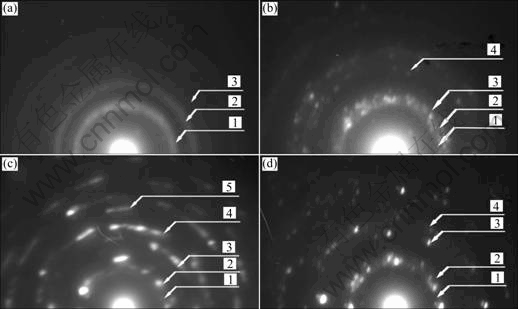

The TEM bright-field images shown in Fig.2 reveal that the nanocrystalline grain sizes increase from 5 nm to 50 nm with increasing film thickness. Compared with the analysis of XRD, it can be concluded that the broadened peaks should come from the reflections of Fe-N nanocrystalline, not from the amorphous structures. The diffraction patterns of selected area for these Fe-N films are shown in Fig.3. The obtained diffraction rings in these figures attribute to reflections of ζ-Fe2N+ε-Fe3N (Fig.3(a), for sample A1), ζ-Fe2N+α-Fe+ε-Fe3N (Fig.3(b), for sample A2), and ε-Fe3N+α-Fe+ζ-Fe2N (Figs.3(c), (d), for sample A3, A4, respectively). The broader diffraction rings in Fig.3(a) indicate that the size of grains for Fe-N film deposited for 5 min is much smaller than that of the others.

Fig.2 Bright-field SEM images for Fe-N film samples: (a) A1; (b) A2; (c) A3; (d) A4

Fig.3 Electron diffraction patterns for corresponding samples: (a) A1, diffraction rings 1 to 3 belonging to z-Fe2N (200), e-Fe3N (210) and z-Fe2N (042), respectively; (b) A2, diffraction rings 1 to 4 belonging to z-Fe2N (200), α-Fe (110), e-Fe3N (210) and z-Fe2N (042), respectively; (c) A3, diffraction rings 1 to 5 belonging to z-Fe2N (200), α-Fe (110), e-Fe3N (103) and z-Fe2N (042), (240), respectively; (d) A4, diffraction rings 1 to 4 belonging to e-Fe3N (110), α-Fe (110), e-Fe3N (300) and z-Fe2N (240), respectively

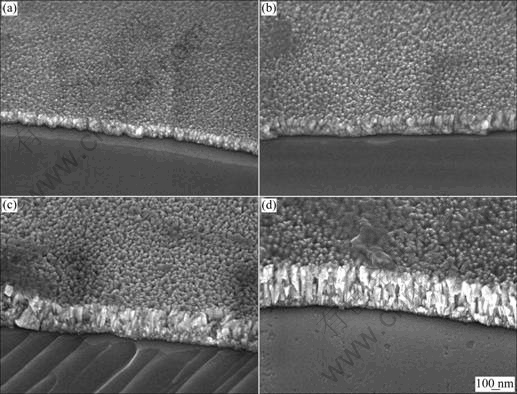

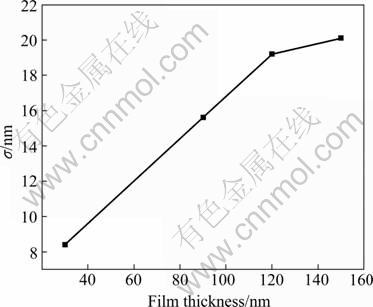

Fig.4 exhibits the cross-sectional SEM images for the Fe-N films. After initial random nucleation of islands, the dominant columns are formed and grow vertically as a function of film thickness. In addition, it is shown that the column structures become denser and column edges become smoother with the increase of deposition time, which may be related to the growth mechanism of Fe-N thin film[11]. In order to further characterize the surface morphology and evaluate the surface roughness (σ), the AFM was used. The roughness for Fe-N films as a function of the film thickness is shown in Fig.5. It can be seen that with increasing Fe-N film thickness, the surface roughness increases from about 12.5 to 20.1 nm.

Fig.4 Cross-sectional SEM images for Fe-N films with various film thicknesses: (a) 30 nm; (b) 90 nm; (c) 120 nm; (d) 150 nm

Fig.5 Surface roughness of Fe-N films vs thicknesses obtained from AFM data

3.2 Magnetic properties

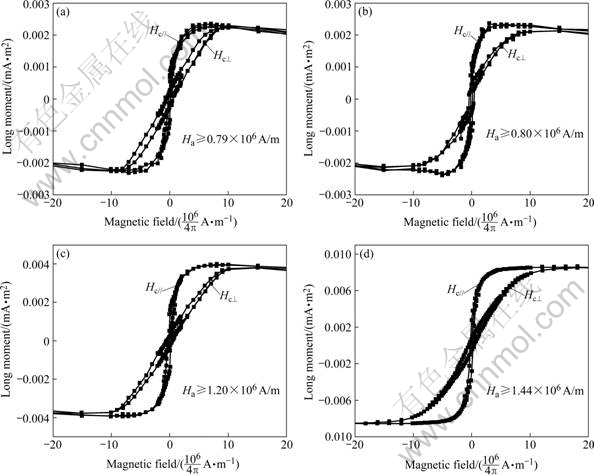

Fig.6 shows the magnetization curves of Fe-N films with various thicknesses. The H// lines indicate the hysteresis loops when a magnetic field is applied parallel to the substrate. When the magnetic field is applied normal to the substrate, the H^ lines are obtained. In this case, the magnetic field is in the longitudinal direction of the column structures. All the magnetic hysteresis loops were measured without considering the diamagnetic component of the substrate background signal. The differences in Hc and the distinct loop shapes along two

magnetic directions imply that magnetic anisotropy exists for columns grown at different deposition times. The value of magnetic anisotropy field increases from 0.79×106 to 1.44×106 A/m with increasing film thickness. As no obvious anisotropy growth of grains is observed by XRD, magneto-crystalline anisotropy can be

expected to have few attribute to the magnetic anisotropy. Therefore, the shape anisotropy is supposed to play a key role in the magnetic anisotropy of these Fe-N films, which shows the increasing tendency with increasing film thickness. The easy axis of magnetization is found to be parallel to the substrate. The coercivities Hc// and Hc^ vs film thickness are plotted in Fig.7. With increasing deposition time, the coercivity Hc// increases obviously from 7.96 to 22.28 kA/m; however, Hc^ increases only slightly in the range of 39.79-43.77 kA/m. The influence of microstructures, such as grain size, surface roughness, on the magnetic properties of thin films is extremely complicated. In this work, with increasing film thickness, nanocrystalline size of Fe-N thin film increased from 5 nm to 50 nm; consequently, Hc// increased, which indicates that the critical size of single domain particle for Fe-N thin films might be above 50 nm[18-19]. The calculated saturation magnetizations for these Fe-N thin films are also shown in Fig.7, which are about 23.5, 41.8, 79.2 and 85.1 A?m2/kg, respectively.

Fig.6 Magnetization curves for Fe-N films with various film thicknesses: (a) 30 nm; (b) 90 nm; (c) 120 nm; (d) 150 nm

Fig.7 Coercivity(Hc) and saturation magnetization(Ms) for Fe-N films with various film thicknesses

3.3 Discussion

As mentioned above, the synthesized Fe-N films exhibit in-plane anisotropy. In addition to the possible influence of grain size on the coercivity of the synthesized Fe-N thin films, Hc// also exhibits the same tendency with increasing surface roughness. According to Ref.[20], this tendency can be partly attributed to the increase of demagnetizing factor. Many magnetic properties including coercivity are each a function of the demagnetizing factor that depends on the surface roughness and type of magnetic domain walls. It is well known that there are mainly two kinds of magnetic domain walls: Bloch wall for bulk magnetic materials or thick films and Néel wall for thin films in which the magnetization rotates within the film plane when crossing the wall. In the case of Néel wall, the demagnetizing factor increases in the direction parallel to the film surface with increasing surface roughness as

nxx—σ2, where nxx is the demagnetizing factor, and σ is the surface roughness. In this work, with increasing demagnetizing factor in the direction parallel to the film, Hc// increased from 7.96 to 22.28 kA/m. However, the coercivity in the perpendicular direction Hc^ increased slightly from 39.79 to 43.77 kA/m. Saturation magnetization of Fe-N films exhibits a dependence on the synthesized phases. With increasing deposition times for these Fe-N film samples, the amount of rich-Fe phase (ε-Fe3N and α-Fe) in the films increases. Consequently, saturation magnetization increases.

4 Conclusions

1) Fe-N thin films, with various film thicknesses deposited at low N2 fraction (V(N2)/V(N2+Ar)=5%) exhibit columnar growth in the directions parallel and vertical to the film surface. With increasing film thickness from 30 to 150 nm, the surface roughness and grain size increase and those columns vertical to the substrates are elongated, which results in an increase of shape magnetic anisotropy for these films.

2) In the direction of magnetic field parallel to the substrate, Hc// increases from 7.96 to 22.28 kA/m. In the direction of magnetic field perpendicular to the substrate, the value of Hc^ changes mildly from 39.79 to 43.77 kA/m with increasing film thickness.

3) The saturation magnetization(Ms) of Fe-N films exhibits a strong dependence on the synthesized Fe-N phases. The types of Fe-N phases in these films change little with increasing deposition time; however, the amount of Fe-rich ferromagnetic phases increases after longer deposition time, which attributes to the increase of Ms.

Acknowledgements

The authors gratefully appreciate the financial support by the Development of Science and Technology Program of Jilin Province, China (Grant No. 20070501).

References

[1] KIM T K, TAKAHASHI M. New magnetic material having ultrahigh magnetic moment [J]. Appl Phys Lett, 1972, 20(12): 492-494.

[2] KITA E, SHIBATA K, YANAGIHARA H, SASAKI Y, KISHIMOTO M. Magnetic properties of core-shell type Fe16N2 nanoparticles [J]. Magn Magn Mater, 2007, 310: 2411-2413.

[3] BAO X H, METZGER R M, DOYLE W D. Synthesis of high moment and high coercivity iron nitride particles [J]. Appl Phys, 1993, 73(10): 6734-6736.

[4] COEY J M D, SMITH P A I. Magnetic nitrides [J]. Magn Magn Mater, 1999, 200: 405-424.

[5] BABONNEAU D, JAOUEN M, DENANOT M F, GUERIN P. Nanostructure and magnetic properties of BN-encapsulated Fe(b) and Fe2N nanoparticles prepared by dual ion-beam sputtering [J]. Appl Phys Lett, 2003, 82(18): 3056-3058.

[6] KOYANOA T, NOMIYAMA T, KANOH N, NUMATA H, OHBA T, KITA E, OHTSUKA H. Magnetization of α? iron nitride produced through the fcc→bcc martensitic transformation in high magnetic field [J]. Appl Phys, 2006, 100: 033906.

[7] WANG X, ZHENG W T, TIAN H W, YU S S, XU W, MENG S H, HE X D, HAN J C, SUN C Q, TAY B K. Growth, structural, and magnetic properties of iron nitride thin films deposited by dc magnetron sputtering, [J]. Appl Sruf Sci, 2003, 220: 30-39.

[8] ZHENG W T, SUN C Q. Electronic process of nitriding: Mechanism and applications [J]. Prog Solid State Chem, 2006, 34 (1): 1-20.

[9] COEHOORN R, DAALDEROP G H O, JANSEN H J F. Full calculations of the magnetization of Fe16N2 and Fe4N [J]. Physical Review B, 1993, 48(6): 3830-3834.

[10] JIANG E Y, SUN C Q, LI J E, LIU Y G. The structures and magnetic properties of FeN films prepared by the facing targets sputtering method [J]. J Appl Phys, 1989, 65(4): 1659-1663.

[11] WANG X, ZHENG W T, GAO L J, GUO W, BAI Y B, FEI W D, MENG S H, HE X D, HAN J C. Surface morphology and dynamic scaling in growth of iron nitride thin films deposited by dc magnetron sputtering [J]. Vac Sci Technol A, 2003, 21(4): 983-987.

[12] GUPTA M, GUPTA A, BHATTACHARYA P, MISRA P, KUKREJA L M. Study of iron nitride thin films deposited by pulsed laser deposition [J]. J Alloys Comp, 2001, 326: 265-269.

[13] DUBEY R, GUPTA A, PIVIN J C. Amorphization in iron nitride thin films prepared by reactive ion-beam sputtering [J]. Physical Review B, 2006, 74: 214110-1-214110-8.

[14] KIM Y K, NARAYAN P B. Magnetic, microstructural, and compositional characterization of Fe-N thin films for recording sensor applications [J]. Vac Sci Technol A, 1995, 13(3): 1040-1043.

[15] BOBO J F, VERGNAT M, CHATBI H, HENNET L, LENOBLE O, BAUER P H, PIECUCH M. Magnetic and structural properties of sputtered Fe-N thin films [J]. Magn Magn Mater, 1995, 140/144: 717-718.

[16] TELLING N D, JONES G A, GRUNDY P J, BLYTHE H J. Fe-N alloy films prepared using nitrogen atom source [J]. Magn Magn Mater, 2001, 226/230: 1659-1661.

[17] DUBEY R, GUPTA A. Magnetic properties of amorphous iron nitride films by ion-beam sputtering [J]. Appl Phys, 2005, 98: 083903.

[18] TANG G D, HOU L, ZHANG M, LIU LH, YANG L X, PAN C F, NIE X F, LUO H L. Influence of preparing condition on magnetic properties of the FeCoNi-SiO2 granular alloy solids [J]. Magn Magn Mater, 2002, 251: 42-49.

[19] HERZER G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets [J]. IEEE Trans Magn, 1990, 26(5): 1397-1402.

[20] ZHAO Y P, GAMACHE R M, WANG G C, LU T M. Effect of surface roughness on magnetic domain wall thickness, domain size, and coercivity [J]. Appl Phys, 2001, 89: 1325-1330.

Foundation item: Project(20070501) supported by the Development of Science and Technology Program of Jilin Province, China

Corresponding author: WANG Xin; Tel: +86-431-82468444; E-mail: wang_xin@jlu.edu.cn

DOI: 10.1016/S1003-6326(08)60277-0

(Edited by YANG Hua)