DOI: 10.11817/j.issn.1672-7207.2016.04.031

外错高抽巷高位钻孔卸压瓦斯抽采技术

王红胜1, 2,李树刚1, 2,双海清1,杜政贤1,由临东1,刘浪1, 2

(1. 西安科技大学 能源学院,陕西 西安,710054;

2. 西部矿井开采及灾害防治教育部重点实验室,陕西 西安,710054)

摘要:为解决相邻两工作面上隅角瓦斯超限难题和实现高抽巷“一巷两用”,提出外错高抽巷布置方式:沿上工作面回风顺槽侧,在煤层顶板内外错布置走向高抽巷;在高抽巷服务前期,在其内采用高位钻孔抽采上工作面采动卸压瓦斯;在高抽巷服务后期,直接采用高抽巷抽采下工作面采动卸压瓦斯;实现1条高抽巷服务于相邻两工作面,提高高抽巷利用效率。基于山西霍州煤电集团李雅庄煤矿2-603工作面地质条件,建立外错高抽巷围岩结构力学模型,采用理论分析、数值模拟、相似材料模拟及现场实测等研究方法系统分析工作面覆岩采动裂隙发育特征,研究覆岩采动裂隙分布规律,确定外错高抽巷和高位抽采钻孔布置参数;基于高位钻孔测斜结果,提出角度补偿纠偏方法及纠偏效果评价指标。高抽巷位于2煤层顶板25.0 m处,外错2-603工作面25.0 m;高位钻孔终孔位于顶板44.0 m处,水平及倾斜方向上的纠偏角分别为-3°和-2°。研究结果表明:高抽巷受2-603工作面采动影响较小,巷道断面能满足下区段2-605工作面抽采要求;高位钻孔终孔位置合理,高位钻孔抽采瓦斯体积分数高,且持续抽采时间长;采用角度补偿纠偏方法后钻孔瓦斯体积分数的最大值和平均值较纠偏前分别提高15.3%和11.6%,2-603工作面生产班、检修班上隅角瓦斯体积分数分别为0.504%~0.951%和0.467%~0.893%,解决了工作面隅角瓦斯超限难题,保障了工作面安全高效开采。

关键词:外错高抽巷;采动裂隙;卸压瓦斯;一巷两用;钻孔测斜;钻孔纠偏;角度补偿

中图分类号:TD712.6 文献标志码:A 文章编号:1672-7207(2016)04-1319-08

Pressure-relief gas drainage technique by high level borehole in lateral high drainage roadway

WANG Hongsheng1, 2, LI Shugang1, 2, SHUANG Haiqing1, DU Zhengxian1, YOU Lindong1, LIU Lang1, 2

(1. School of Energy Engineering, Xi’an University of Science and Technology, Xi’an 710054,China;

2. Key Laboratory of Western Mine Exploitation and Hazard Prevention of the Ministry of Education, Xi’an 710054, China)

Abstract: To solve the problems of the gas consistence exceeding limit at the upper corner of the two adjacent coalfaces and to realize the high drainage roadway with two utilizations, the arrangement mode and the connotation of the lateral high drainage roadway (LHDR) were proposed. Along the air return way of the upper coalface, strike high-bleeding roadway in roof was laid on lateral upper coalface, pressure relief gas in fractured zone of the upper coalface’s overlying strata was extracted by boreholes in high drainage roadway at the earlier stage of service, pressure relief gas in fractured zone of the next coalface’s overlying strata was extracted by the roadway at the later stage of service, the LHDR could serve two coalfaces, and the utilization ratio of the LHDR was improved. Based on the geological conditions of No.2-603 coalface of Liyazhuang coal mine in Huozhou, Shanxi Province, mechanical model of the LHDR was established. The overlying strata’s mining-induced fracture development features were analyzed by the methods of the theoretical analysis, numerical simulation, similar material simulation and field measurement, the overlying strata’s mining-induced fracture distribution law was obtained, and the layout parameters of the LHDR and drainage boreholes were determined. Based on the borehole inclination survey results, borehole angle compensation correction method and the evaluation index of borehole correction effect were proposed. The high drainage roadway was located at 25.0 m to the roof of No.2 coal seam, and 25.0 m to the No.2-603 coalface. The borehole’s final hole location was 44.0 m in height over the roof, and the correction angles of the horizontal direction and inclined direction were -3° and -2° respectively. The results show that, mining of the No.2-603 coalface has little influence on the lateral high drainage gateway, the roadway section can meet the drainage requirements of No.2-605 coalface, the borehole’s final hole location is reasonable, and the maximum and average value of the gas concentration is improved by 15.3% and 11.6%, and the gas consistence at the upper corner is 0.504%-0.953% and 0.467%-0.893%.The problem of the gas consistence exceeding limit is solved, and the coalface is mined safely and effectively.

Key words: lateral high drainage roadway; mining-induced fracture; pressure-relief gas; one gateway with two utilizations; borehole inclination survey; borehole correction; angle compensation

工作面回采后,采场上覆岩层会发生运移和破断,覆岩层内将产生大量裂隙,这些裂隙是瓦斯储存、流动的场所和通道[1-4]。受采动影响,煤层卸压后大量瓦斯沿顶板裂隙进入裂隙带,若将抽采钻孔或巷道布置在裂隙带内,则将有效提高卸压瓦斯抽采效果[5-8],避免工作面隅角瓦斯超限。目前,卸压瓦斯抽采方法主要有巷道抽采和钻孔抽采。合理的高抽巷层位及钻孔终孔位置决定了卸压瓦斯抽采效果[9-11],但确定高抽巷层位及钻孔终孔位置要考虑岩层岩性、采动影响强弱程度、覆岩采动裂隙发育程度及分布特征等因素影响,若高抽巷层位及钻孔终孔位置不合理,则形成抽采盲区,降低抽采效果,易致使工作面上隅角瓦斯超限。李雅庄煤矿为山西霍州煤电集团唯一高瓦斯矿井,在2-603工作面回采巷道形成后,在上下顺槽内向煤层布置顺层平行钻孔预抽煤层瓦斯,预抽时间约为2 a。由于煤层透气性低,顺层平行钻孔预抽效果差,回采2-603工作面时,上隅角瓦斯易超限。为解决上隅角瓦斯超限难题和提高高抽巷利用效率,提出了相邻2个工作面共用外错高抽巷卸压瓦斯抽采技术,即沿2-603工作面回风顺槽侧,在煤层顶板内外错(内错2-605工作面)布置走向高抽巷。在高抽巷服务前期,在其内采用高位钻孔抽采2-603工作面采动卸压瓦斯;在高抽巷服务后期,直接采用高抽巷抽采2-605工作面采动卸压瓦斯。本文作者对覆岩采动裂隙发育特征、高抽巷合理层位、抽采钻孔终孔位置及钻孔测斜与纠偏等关键问题进行较系统分析,以便解决相邻2个工作面隅角瓦斯超限难题,实现高抽巷的“一巷两用”。

1 外错高抽巷“一巷两用”布置方式

1.1 工作面概况

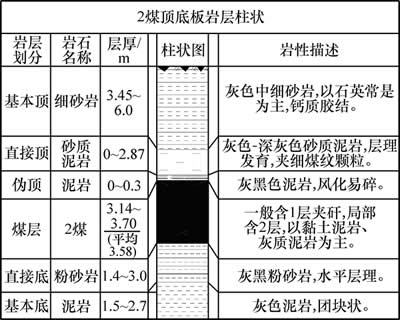

李雅庄煤矿2-603工作面井下标高为+190.0~+250.0 m,埋深为+628.0~+650.0 m。井下位于六采区西翼,西南部紧邻井田边界,西部为2-226采空区,西北部为未开采2-605工作面。工作面沿煤层倾向布置,倾斜长度为230.0 m;沿走向推进,推进长度为2 168.0 m。采用综合机械化开采、全部垮落法管理采空区顶板。煤层倾角为5°~16°,平均为8°。工作面顶底板岩层柱状见图1。

图1 工作面岩层柱状

Fig. 1 Rock column of coalface

1.2 瓦斯赋存条件

2煤瓦斯压力为0.68 MPa,放散初速度ΔP= 7.5 mL/s。原始瓦斯含量为7.32 m3/t,可解吸瓦斯量为5.70 m3/t,不可解吸量为1.62 m3/t。煤层极限吸附常数a=18.03~45.05 m3/t,b=0.409~0.638 MPa-1。煤层孔隙率为6.45%~8.05%,透气性系数为0.137 1 m2/(MPa2·d),钻孔瓦斯流量衰减系数为0.006 5~0.008 9 d-1,属于可抽采煤层。

1.3 工作面抽采现状及抽采效果

在2-6031和2-6032巷内施工本煤层顺层平行钻孔,钻孔间距分别为2.4 m和1.6 m。钻孔水平角垂直于煤壁,钻孔倾角平行于煤层倾角,采用ZDY-3200型钻机施工,孔深为150.0~180.0 m。2-6032巷由切眼往外,在巷道顶板间隔80.0 m施工1组低位裂隙钻孔,每组5个孔,孔深为120.0 m。在2-603工作面上隅角埋管抽放,采用两趟Φ280抽放管路迈步交替抽放方式,始终保持1趟管路伸入上隅角12.0~20.0 m,工作面每推进60.0 m,断管1次;上隅角瓦斯抽放管路通过六采区轨道巷移动抽放泵站抽采。工作面采用瓦斯综合抽采技术,但抽采效果差,工作面回采时上隅角瓦斯易发生超限事故。

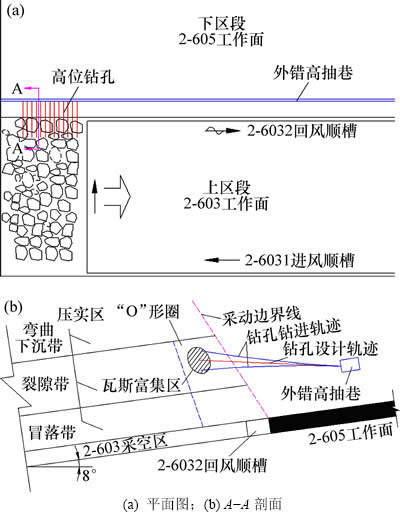

1.4 外错高抽巷布置方式的提出

为解决2-603工作面上隅角瓦斯超限难题,也为实现高抽巷的“一巷两用”,基于2-603和2-605相邻2个工作面地质条件,提出外错高抽巷布置方式,见图2。由图2可知:沿2-603工作面回风顺槽侧,在煤层顶板内外错(内错2-605工作面)布置走向高抽巷。在高抽巷服务前期,在其内采用高位钻孔抽采2-603工作面采动卸压瓦斯;在高抽巷服务后期,直接采用高抽巷抽采2-605工作面采动卸压瓦斯。高抽巷这种布置方式可达到降低2-603和2-605相邻2个工作面隅角瓦斯体积分数,避免工作面瓦斯超限事故发生。

图2 外错高抽巷布置方式

Fig. 2 Layout of lateral high drainage roadway

由图2(b)可知:受2-603工作面采动影响,大量卸压瓦斯聚集到2-6032回风顺槽侧覆岩裂隙带内,形成瓦斯富集区,在外错高抽巷内向瓦斯富集区布置高位抽采钻孔,抽采裂隙带内卸压瓦斯,能有效降低工作面上隅角瓦斯体积分数,避免瓦斯超限事故发生。

2 采场覆岩采动裂隙分布规律

2.1 “二带”高度理论分析

根据2-603工作面顶板岩性、采煤方法、采空区顶板管理方法确定“两带”高度理论计算公式[12]如下。

冒落带最大高度(Hk)的统计经验公式为

(1)

(1)

裂隙带最大高度(Hd)的统计经验公式为

(2)

(2)

式中:∑M为采高,m;Hk为冒落带最大高度,m;Hd为裂隙带最大高度,m。2煤厚为3.14~3.70 m,平均为3.58 m。经计算,冒落带高度最大为11.5~12.4 m,平均为12.2 m;最小为7.1~8.0 m,平均为7.8 m。裂隙带高度最大为42.0~44.5 m,平均为44.0 m;最小为30.8~33.3 m,平均为32.8 m。

2.2 覆岩采动裂隙发育特征UDEC2D数值模拟分析

2.2.1 模型建立

参照L-70钻孔(位于2-603工作面内)柱状图,采用离散单元数值模拟分析软件UDEC2D4.0建立数值模型,模型长×高为400.0 m×190.0 m,工作面采高为3.0 m,开挖步距为15.0 m。固定模型下部边界的垂直位移和左、右边界的水平位移。水平地应力、垂直应力分别为9.22 MPa和14.49 MPa,水平地应力与垂直应力的比值为0.636 3。煤层及顶底板岩层均采用Mohr-Coulumb本构关系模型。

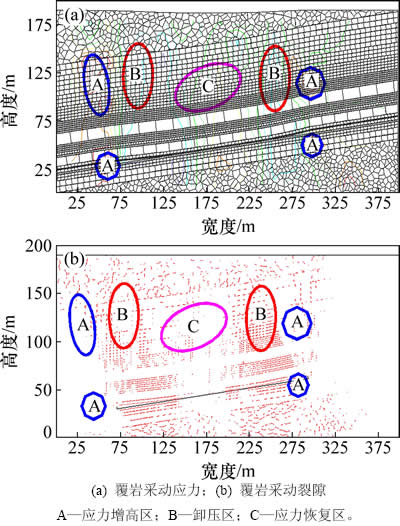

2.2.2 采场覆岩采动应力及裂隙分布规律

工作面开挖后,覆岩采动应力及裂隙分布规律见图3。由图3可知:工作面上端头底板12.0 m处、下端头底板外错10.0 m处处于应力增高区,应力分别达到35 MPa和45 MPa;工作面上端头顶板51.0 m处、下端头顶板62.0 m处处于应力增高区,应力达到45 MPa。这些区域裂隙不发育。工作面中部没有支撑,煤层回采后,直接顶发生冒落,导致基本顶大面积垮落,冒落岩石被上覆岩层逐渐压实,导致裂隙逐渐闭合,应力逐渐恢复,这些区域裂隙较发育。工作面开挖后,因工作面上、下端头煤层的支撑作用,导致上、下端头处覆岩不能充分垮落,形成了“砌体梁”结构,这些区域处于卸压区,裂隙发育。

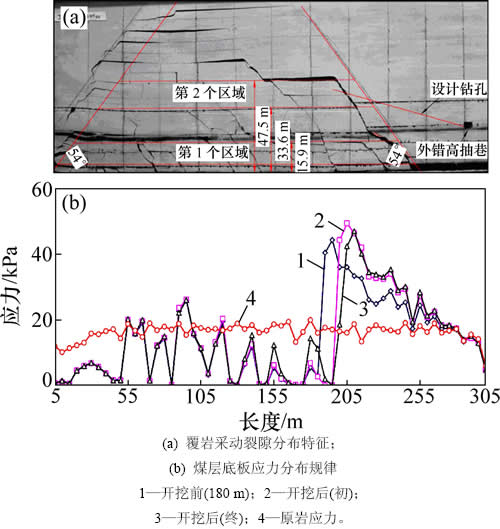

2.2.3 上端头覆岩采动裂隙分布特征

开挖后采场覆岩采动裂隙呈“分区”集中分布特征见图4。垂直方向上集中分布在2个区域即第1和第2区域,分别距离底板13.0~25.0 m和38.6~50.0 m,裂隙带宽度分别约为65.0 m和50.0 m,裂隙带距采空区边界分别为12.0 m和28.0 m,且在上山采动角62°以内。

图3 工作面覆岩采动应力及裂隙分布规律

Fig. 3 Distribution caws of mining-induced stress and fracture

图4 上端头覆岩采动裂隙“分区”特征

Fig. 4 Mining-induced fracture distribution law

2.3 覆岩采动裂隙发育特征物理模拟分析

2.3.1 模型建立

参照L-70钻孔柱状图,采用长×宽×高为3.0 m×0.2 m×2.0 m的平面应力模型试验台[13]模拟工作面开挖,模型铺设规格为2.0 m×0.2 m×1.0 m。根据相似三定理[14],确定模型几何相似比α1=100,容重相似比αγ=1.69,时间相似比αt=10,强度相似比为αR=169。煤层采高为3.0 m,由左向右开挖,开挖步距为15.0 m,在煤层底板铺设60个应力计。

2.3.2 覆岩采动裂隙分布规律

2-603工作面开挖195 m时,覆岩采动裂隙分布规律及煤层底板应力分布规律见图5。

图5 2-603工作面开挖195 m时的裂隙分布与应力分布

Fig. 5 Distribution of crack and stress of excavation 195 m of No.2-603 coal face

由图5(a)可知:采空区中部覆岩逐渐被压实,导致离层裂隙和穿层裂隙逐渐闭合;工作面2个端头上方岩层因形成了“砌体梁”结构而不能充分垮落,这些区域裂隙发育。裂隙主要分布在2个区域:第1个区域位于顶板15.9 m以下范围内,第2个区域距离底板33.6~47.5 m的范围内,且在上山采动角54°以内。

由图5(b)可知:采空区上方岩层已充分垮落,采空区中部应力开始恢复。模型右侧端头附近,因煤壁支撑作用,上方覆岩不能充分冒落,形成了“砌体梁”结构,在煤壁内形成了固定支承压力,其中煤壁内0~5.0 m为应力降低区,5.0~25.0 m为压力增高区,25.0 m以上应力逐渐恢复到原岩应力。

3 外错高抽巷布置参数

3.1 高抽巷层位的确定

外错高抽巷位置应避开应力增高区,同时兼顾抽采钻孔施工长度和高抽巷后期抽采效果,在水平方向上高抽巷外错25 m,在垂直方向上布置在裂隙带下部或冒落带顶部,距离煤层顶板为20.0~25.0 m,见图5(a)。

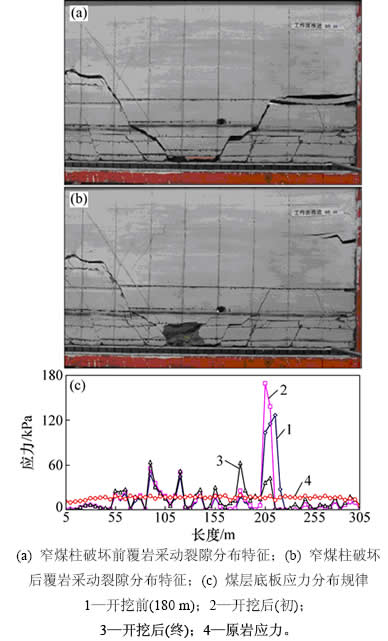

2-605工作面开挖100.0 m时,剩下宽为5.0 m窄煤柱,覆岩采动裂隙分布特征及煤层底板应力分布规律见图6。由图6可知:窄煤柱受压破坏后,覆岩采动裂隙贯通高抽巷,有利于后期高抽巷抽采2-605工作面下端头覆岩采动卸压瓦斯。

图6 2-605工作面开挖100 m裂隙分布与应力分布

Fig. 6 Distribution of crack and stress of excavation 100 m of No.2-605 coal face

3.2 高抽巷布置参数

外错2-603工作面24.5~26.4 m布置高抽巷,高抽巷为矩形断面,其高×宽为3.0 m×3.5 m。高抽巷开口位置从2-6032回风顺槽12号导线点前2.2 m处沿306.7°方位角水平施工7.7 m,到位后左拐沿216.7°方位角4°上山施工20.0 m,再按20°上山施工43.0 m,到位后沿3‰坡度施工。高抽巷与2-6032回风顺槽平行掘进,设计长度为1 422.4 m。受2煤起伏变化影响,高抽巷底板距2煤顶板为17~29 m,平均约为25.0 m。在高抽巷内铺设瓦斯抽采系统,铺设直径为280.0 mm的螺纹管路,铺设长度为1 420.0 m。为便于数据测量及分析,在管路起始端安设控制阀门和孔板流量计各1组。

4 高位钻孔终孔位置的确定

4.1 布置区域确定

工作面上端头覆岩采动裂隙分布主要集中在2个区域。第1区域距离工作面较近,漏风严重,由瓦斯升浮特性可知,瓦斯主要聚集在第2区域,因此,钻孔终孔位置应布置在第2区域内,以确保钻孔持续、有效抽采工作面覆岩采动卸压瓦斯。

4.2 钻孔终孔位置优化

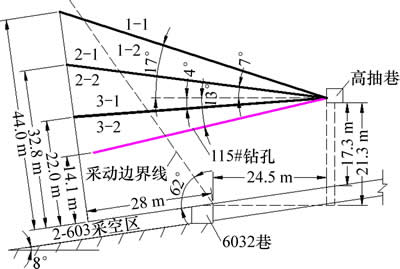

为确定钻孔终孔合理位置,滞后工作面15.0 m,在115号钻孔附近,沿工作面推进方向,依次布置3组共计6个试验钻孔。1-1和1-2钻孔孔深为61.0 m,倾角为17°,终孔位置距煤层顶板44.0 m;2-1和2-2钻孔孔深为57.0 m,倾角为7°,终孔位置煤层顶板 32.8 m;3-1和3-2钻孔孔深为55.0 m,倾角为-4°,终孔位置煤层顶板22.0 m。6个钻孔呈扇形布置,钻孔直径为113.0 mm,孔口间距为5.0 m,开孔位置距巷道底板1.0 m,在采空区内钻孔投影长度不小于28.0 m。试验钻孔布置参数见图7。

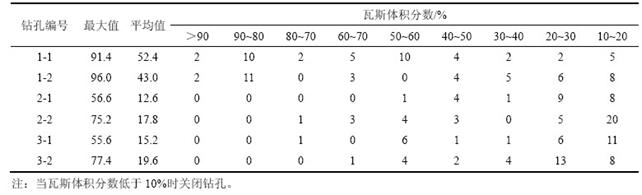

6个试验钻孔瓦斯体积分数监测结果见表1。由表1可知:1-1和1-2钻孔抽采时间长,抽采体积分数高,表明1-1和1-2钻孔抽采效果好,其布置参数合理可行。

图7 试验钻孔布置参数

Fig. 7 Borehole layout parameters

表1 试验钻孔抽采时间

Table 1 Drainage results of the test boreholes d

5 角度补偿纠偏方法及效果评价

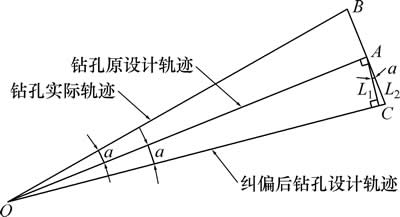

5.1 角度补偿纠偏方法

角度补偿纠偏原理见图8。由图8可知:OA为钻孔原设计轨迹,OB为钻孔实际轨迹;钻孔偏斜距离为D1,偏斜角度为 ;纠偏后钻孔设计轨迹为OC。在钻孔倾角变化较小时,钻孔偏斜也较小,可通过镜像原理实现角度补偿。在钻机、地质条件、钻孔施工技术及工艺水平等因素[15]不变前提下,纠偏后钻孔仍然向上偏斜D1,纠偏后钻孔设计终孔与钻孔原设计终孔距离为D2。D1与D2关系为

;纠偏后钻孔设计轨迹为OC。在钻孔倾角变化较小时,钻孔偏斜也较小,可通过镜像原理实现角度补偿。在钻机、地质条件、钻孔施工技术及工艺水平等因素[15]不变前提下,纠偏后钻孔仍然向上偏斜D1,纠偏后钻孔设计终孔与钻孔原设计终孔距离为D2。D1与D2关系为

(3)

(3)

当钻孔偏斜角度 <10°时,因为cos

<10°时,因为cos ≥0.984 8,钻孔纠偏精度至少可达到0.984 8,所以,D1与D2偏差小,钻孔纠偏精度高。当钻孔偏斜角度10°<

≥0.984 8,钻孔纠偏精度至少可达到0.984 8,所以,D1与D2偏差小,钻孔纠偏精度高。当钻孔偏斜角度10°< <25°时,因为0.906 4≤cos

<25°时,因为0.906 4≤cos ≤0.984 8,所以,D1与D2偏差较大,但在对钻孔纠偏精度要求不高时也可满足施工要求。因此,钻孔偏斜角度越小,钻孔实际轨迹越接近钻孔设计轨迹。

≤0.984 8,所以,D1与D2偏差较大,但在对钻孔纠偏精度要求不高时也可满足施工要求。因此,钻孔偏斜角度越小,钻孔实际轨迹越接近钻孔设计轨迹。

图8 角度补偿纠偏原理

Fig. 8 Principle of angle compensation correction

5.2 纠偏效果评价

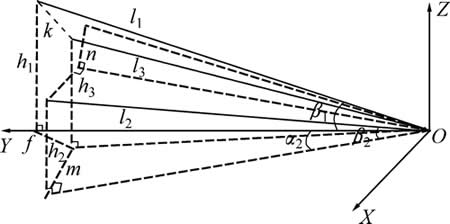

钻孔轨迹简化为直线,见图9。图9中:l1,l2和l3分别为钻孔原设计轨迹、纠偏后钻孔设计轨迹、纠偏后钻孔钻进轨迹;l1与l3终孔水平投影为f,倾向投影高度差为△h;l1至l3终孔距离为f与△h矢量和。由空间几何及余弦定理可得:

图9 钻孔轨迹及投影

Fig. 9 Borehole track and its projection

(4)

(4)

(5)

(5)

(6)

(6)

式中:l1为钻孔原设计孔深,m;l2为纠偏后钻孔设计孔深,m;l3为纠偏后钻孔钻进孔深,m;α2为纠偏后钻孔设计水平投影角,(°);β1为钻孔原设计倾角,(°);β2为纠偏后钻孔设计倾角,(°);m为纠偏后钻孔设计水平偏斜距离,m;n为纠偏后钻孔设计上、下偏斜距离,m;k为l1与l3终孔距离,m。

图10 上隅角瓦斯体积分数监测结果

Fig. 10 Gas concentration variation law of the upper corner

当纠偏后钻孔钻进轨迹距其设计轨迹越近,k就越小,故k可以用于衡量钻孔纠偏效果。

5.3 纠偏效果

采用YHX7.2矿用回转钻机测斜仪对外错高抽巷内151号和152号钻孔进行测斜,得到钻孔的偏斜程度。基于测斜结果,通过纠偏方案对比分析,确定纠偏参数为水平方向上钻孔右偏3°,倾斜方向上下偏2°。纠偏前后高位钻孔瓦斯抽采体积分数的最大值、平均值分别提高15.3%和11.6%,且抽采时间延长1~6 d,表明纠偏前后钻孔抽采效果有明显提高。有关钻孔测斜与纠偏内容见文献[15]。

6 工程应用分析

综合以上分析,自159号钻孔以后,布置高位钻孔,其布置参数参照1-1和1-2试验钻孔参数进行设计,且高位钻孔在施工时进行角度补偿纠偏,并对钻孔进行瓦斯体积分数监测。

6.1 高位钻孔布置参数

在外错高抽巷内,滞后2-603工作面15.0 m由内向外施工高位钻孔,间距为1.8 m,孔口距高抽巷底板为1.0 m。根据2-6032回风顺槽与外错高抽巷相对高差,实时变更钻孔角度,使高位钻孔终孔位于2煤顶板44.0 m处,且在采空区内投影长度不小于28.0 m。

6.2 钻孔纠偏参数

钻孔施工时进行纠偏,水平方向上钻孔右偏3°,倾斜方向上下偏2°。由于钻孔偏斜程度受地质条件、施工技术、钻孔角度等因素影响,因此,每班都要进行1个钻孔测斜分析,根据测斜结果及时调整补偿角度,以保证钻孔实际轨迹达到设计要求。

6.3 应用效果

2-603工作面已回采结束,回采期间安排专人检测高抽巷支管路、高位钻孔和工作面上隅角瓦斯体积分数。结果表明:

1) 高抽巷抽放支管路同时连接15~20个钻孔,每个钻孔可抽采20~40 d,瓦斯抽采体积分数为10%~65%。其中,瓦斯抽采体积分数≥50%和30%~50%的时间分别占总抽采时间的16%~36%和23%~50%。支管路流量为90 m3/min,瓦斯抽采体积分数为18.4%~31.4%,平均为24.8%;纯瓦斯流量为16.6~28.3 m3/min,平均为22.3 m3/min。

2) 自2014-04项目实施后,生产班、检修班的2-603工作面上隅角瓦斯体积分数分别为0.50%~0.95%和0.47%~0.89%,见图10。应用效果表明:采用高位钻孔有效抽采了2-603工作面覆岩采动卸压瓦斯,避免了上隅角瓦斯超限事故发生,有效保障了工作面安全高效开采。

7 结论

1) 提出了外错高抽巷布置方式及其内涵。沿上工作面回风顺槽侧,在煤层顶板内外错布置走向高抽巷;高抽巷服务前期,在其内采用高位钻孔抽采上工作面采动卸压瓦斯;高抽巷服务后期,直接采用高抽巷抽采下工作面采动卸压瓦斯;实现了1条高抽巷服务于相邻两工作面,提高了高抽巷利用效率,实现了“一巷两用”。

2) 1-1和1-2钻孔终孔位于覆岩采动裂隙瓦斯富集区内,其终孔位置合理可行。

3) 提出了角度补偿纠偏方法和纠偏效果评价指标。纠偏前后高位钻孔瓦斯抽采体积分数的最大值、平均值分别提高15.3%和11.6%,且抽采时间延长了1~6 d,表明纠偏前后钻孔抽采效果有明显提高。

4) 工作面生产班、检修班上隅角瓦斯体积分数分别为0.504%~0.951%和0.467%~0.893%;外错高抽巷高位钻孔卸压瓦斯抽采技术的成功实施,有效抽采了2-603工作面覆岩采动卸压瓦斯,避免了工作面上隅角瓦斯超限。

参考文献:

[1] 郭玉森, 林柏泉, 吴传始. 围岩裂隙演化与采动卸压瓦斯储运的耦合关系[J]. 采矿与安全工程学报, 2007, 24(4): 414-417.

GUO Yusen, LIN Baiquan, WU Chuanshi. Coupling relation of crack evolvement in surrounding rocks with the storage and migration of mining induced releasing gas[J]. Journal of Mining & Safety Engineering, 2007, 24(4): 414-417.

[2] 林海飞, 李树刚, 成连华. 覆岩采动裂隙带动态演化模型的实验分析[J]. 采矿与安全工程学报, 2011, 28(2): 298-303.

LIN Haifei, LI Shugang, CHENG Lianhua. Experimental analysis of dynamic evolution model of mining-induced fissure zone in overlying strata[J]. Journal of Mining & Safety Engineering, 2011, 28(2): 298-303.

[3] 李树刚, 林海飞, 赵鹏翔, 等. 采动裂隙椭抛带动态演化及煤与甲烷共采[J]. 煤炭学报, 2014, 39(8): 1455-1462.

LI Shugang, LIN Haifei, ZHAO Pengxiang, et al. Dynamic evolution of mining fissure elliptic paraboloid zone and extraction coal and gas[J]. Journal of China Coal Society, 2014, 39(8): 1455-1462.

[4] 马占国, 赵国贞, 龚鹏, 等. 采动岩体瓦斯渗流规律[J]. 辽宁工程技术大学学报, 2011, 30(4): 497-500.

MA Zhanguo, ZHAO Guozhen, GONG Peng, et al. Gas seepage in mined rock mass[J]. Journal of Liaoning Technical University (Natural Science), 2011, 30(4): 497-500.

[5] 袁亮. 卸压开采抽采瓦斯理论及煤与瓦斯共采技术体系[J]. 煤炭学报, 2009, 34(1): 1-8.

YUAN Liang. Theory of pressure-relieved gas extraction and technique system of integrated coal production and gas extraction[J]. Journal of China Coal Society, 2009, 34(1): 1-8.

[6] 卢平, 袁亮, 程桦, 等. 低透气性煤层群高瓦斯采煤工作面强化抽采卸压瓦斯机理及试验[J]. 煤炭学报, 2010, 35(4): 580-585.

LU Ping, YUAN Liang, CHENG Hua, et al. Theory and experimental studies of enhanced gas drainage in the high gas face fo low permeability coal multi-seams[J]. Journal of China Coal Society, 2010, 35(4): 580-585.

[7] 程远平, 俞启香, 袁亮, 等. 煤与远程卸压瓦斯安全高效共采试验研究[J]. 中国矿业大学学报, 2004, 33(2): 132-136.

CHENG Yuanping, YU Qixiang, YUAN Liang, et al. Experimental research of safe and high-efficient exploitation of coal and pressure relief gas in long distance[J]. Journal of China University of Mining & Technology, 2004, 33(2): 132-136.

[8] 方良才. 淮南矿区瓦斯卸压抽采理论与应用技术[J]. 煤炭科学技术, 2010, 38(8): 56-62.

FANG Liangcai. Gas pressure releasing and drainage theory and application technology in Huainan mining area[J]. Coal Science and Technology, 2010, 38(8): 56-62.

[9] 王兆丰, 田富超, 赵彬, 等. 羽状千米长钻孔抽采效果考察试验[J]. 煤炭学报, 2010, 35(1): 76-79.

WANG Zaofeng, TIAN Fuchao, ZHAO Bin, et al. The testing of gas drainage efficiency about feather-veined 1 000 m length-drill hole[J]. Journal of China Coal Society, 2010, 35(1): 76-79.

[10] 尹光志, 李铭辉, 李生舟, 等. 基于含瓦斯煤岩固气耦合模型的钻孔抽采瓦斯三维数值模拟[J]. 煤炭学报, 2013, 38(4): 535-541.

YIN Guangzhi, LI Minghui, LI Shengzhou, et al. 3D numerical simulation of gas drainage from boreholes based on solid-gas coupling model of coal containing gas[J]. Journal of China Coal Society, 2013, 38(4): 535-541.

[11] 朱红青, 张民波, 王宁, 等. Y型通风高位钻孔抽采被保护层卸压瓦斯研究[J]. 煤炭科学技术, 2013, 41(2): 56-59.

ZHU Hongqing, ZHANG Minbo, WANG Ning, et al. Study on pressure released gas drainage in protected seam with high level borehole under Y type ventilation[J]. Coal Science and Technology, 2013, 41(2): 56-59.

[12] 钱鸣高, 石平五, 许家林. 矿山压力与岩层控制[M]. 徐州: 中国矿业大学出版社, 2010: 70-84.

QIAN Minggao, SHI Pingwu, XU Jialin. Rock pressure and strata control[M]. Xuzhou: China University of Mining and Technology Press, 2010: 70-84.

[13] 王红胜, 李树刚, 由临东, 等. 一种可实现机械加载和液压加载相似材料模拟实验装置, 201420425478.4[P]. 2014-12.

WANG Hongsheng, LI Shugang, YOU Lindong, et al. A similar material simulation experiment equipment by mechanism and hydraulic stressing, 201420425478.4[P]. 2014-12.

[14] 顾大钊. 相似材料与相似模型[M]. 徐州: 中国矿业大学出版社, 1995: 11-13.

GU Dazhao. Similar material and similar model[M]. Xuzhou: China University of Mining and Technology Press, 1995: 11-13.

王红胜, 杜政贤, 樊启文, 等. 外错高抽巷卸压瓦斯抽采钻孔测斜与纠偏技术[J]. 煤炭科学技术, 2015, 43(8): 77-81.

WANG Hongsheng, DU Zhengxian, FAN Qiwen, et al. Inclination measuring and deviation correction technology of pressure released gas drainage borehole in external dislocated high level gateway[J]. Coal Science and Technology, 2015, 43(8):77-81.

(编辑 陈灿华)

收稿日期:2015-05-28;修回日期:2015-07-26

基金项目(Foundation item):国家重点基础研究计划(973计划)项目(2015CB251600)(Project (2015CB251600) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:王红胜,博士,副教授,从事矿山压力与岩层控制研究;E-mail:cumtwhs@xust.edu.cn