文章编号:1004-0609(2007)11-1750-05

铝铸锭凝固边界热交换规律及温度场模拟

杜凤山,张 沛,许志强,赵玲玲

(燕山大学 机械工程学院,秦皇岛 066004)

摘 要:研究铝铸锭凝固边界热交换的变化规律及数学模型,并对不同浇注温度下凝固过程的温度场进行模拟。利用实时数据采集系统获得凝固过程中铸锭和金属模温度变化历史数据,采用非线性反算法和一维传热差分法对试验数据处理,建立界面换热模型并将其应用于凝固温度场模拟中。结果表明:在铸锭表面凝固前后凝固界面热流密度可分段用指数函数来描述其变化规律,而所建立的热交换系数与边界温度的对应关系可更好地反映实际的传热情况。模拟结果与实验测温结果相符,验证了该铸件/铸型边界热交换规律的可靠性。

关键词:铝铸锭;热交换系数;凝固;温度场

中图分类号:TG 244.1; O 242.1 文献标识码:A

Law of heat transfer and simulation of temperature field for aluminum ingot solidification

DU Feng-shan, ZHANG Pei, XU Zhi-qiang, ZHAO Ling-ling

(College of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China)

Abstract: The rules of heat exchange on the interface of casting and model were set up, and the solidification temperature fields were simulated. In the solidification process, the temperature history data of ingot and mold were recorded with a data acquirement system. Based on the experimental data, nonlinear estimation method and finite difference method of one dimensional heat transfer were adopted to form the model of interface heat transfer. With this model, the temperature field of the casting system was simulated. The results indicate that the heat flow in the interface of ingot and mold can be described by exponential function. The heat transfer coefficient related with boundary temperature is better reflecting the true state. The results of the simulation agree well with the measured values, which indicates that the models of the coefficient of interface heat transfer are reliability.

Key words: aluminum ingot; coefficient of heat transfer; solidification; temperature field

铸件与铸型间的热交换是整个凝固传热过程的控制环节,影响铸件表面乃至内部质量[1?4],它也是计算机模拟中的重要物性参数,对模拟精度产生重要影 响[5?6]。边界热交换系数是界面接触状况、物理条件、化学条件以及界面温度等因素综合作用的体现,其中接触状况起决定作用[7?8]。由于铸件和铸型间的接触状况在凝固过程中发生复杂的变化,这就使界面换热系数很难确定。为获得精确的边界热交换系数,长期以来许多学者从不同角度进行了研究,针对在涂有涂料的铁模中离心铸造铸钢件的情况,Ebisu[9]提出铸件和铸型之间气隙产生后的有效传热量随铸件凝固层的增厚而按指数函数衰减。朱宪华等[10]参考这一思路,导出了灰铸铁和砂型之间气隙产生后有效传热量与凝固时间的关系。严卫东等[11]沿用这一方法针对Al- 4%Cu(质量分数)合金砂型铸造情况,通过实验得出铸造试样在凝固过程中界面向砂型中导出的热流随凝固时间的关系式。也有些学者对铸件和铸型之间气隙传热系数的实测和计算作了不少研究[5, 12]。目前对界面热交换的一般处理方法是假定截面热阻或截面传热系数为时间[10, 13?14]、温度[2, 15]或凝固层厚度[9]的函 数,归纳起来主要有间隙跟踪法、反算法及多因素回归法[16]等。上述方法在应用中都有不同程度的局限性,而且界面换热复杂多样,任子平等[1]和王芹[17]在凝固过程模拟中将界面换热系数假设为常数,这势必将影响模拟结果的精度。

铸件和铸型的材质对界面换热系数的影响也是不容忽视的,目前有关铝铸件与金属型铸模的界面换热系数可供参考的数据比较少。为了提供模拟凝固过程所需参数及提高计算精度,本文作者分别采取非线性反算法和利用并拓展了朱宪华等[5]的函数关系式,获取铝铸锭与金属型铸模的界面换热系数,并应用于温度场的模拟中。

1 边界热交换系数实验

1.1 实验条件

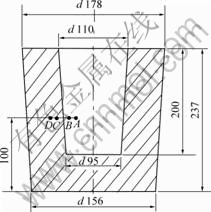

实验铸锭材料采用铝合金A356,化学成分Si7%,Mg0.3%,其热物性能参见文献[18]。金属型铸模材质为灰铸铁HT13,化学成分为:C 3.42%,Si 2.3%,Mn 0.67%,其物理性能参数由实验测得。锭模尺寸见图1。浇注温度为700 ℃。

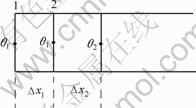

图1 锭模尺寸及测温点分布示意图

Fig.1 Model dimension and distribution of points for measuring temperature (mm)

1.2 测温条件

温度测量采用多通道测温系统,使用Labview测试软件,通过微机实时监测和记录温度变化过程。采用镍铬?镍硅热电偶,测温点位置如图1所示。为了减少温度响应的衰减与延迟,也即提高测点温度对表面换热系数变化的敏感性,测温位置尽可能接近铸锭与锭模的边界面。铸锭内A、B点距铸锭外表面5 mm、2 mm,锭模内C、D点距锭模内表面2 mm和5 mm。

1.3 结果与分析

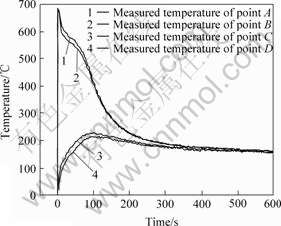

测温结果如图2所示。由于金属型铸模较大的热导率及较高的蓄热能力,从图2中曲线3和4可见,在最初的100 s内测量点温度急剧升高,距界面不同距离的温差也愈大。当达到最大值后温差又急剧减小,200 s后两测温点温差极小并几乎保持恒定值,温度下降较平稳。铸件内的测量点温度在最高点后急剧下降,这是由于金属型铸模的极冷作用,使得界面附近液态金属快速凝固。在近界面处两测温点温差在凝固阶段稍大,而其它时间内不大并且基本保持稳定。200 s后温度下降平稳缓慢。从图中也可看出在后期存在稳定阶段,从铸锭到锭模温差几乎不再变化,温度也基本呈线性下降。

图2 温度测量结果

Fig.2 Results of measuring temperature

在实验数据基础上,采用非线性反算法[19]计算界面热交换系数(h)。其原理就是通过多次迭代寻求h值使各时刻的计算值与测定值逼近。各时间计算值与测定值的差方和计算式如下:

令差方和S对热交换系数h求导,满足下式

由式(2)求得hm,即所求m时刻的热交换系数。为保证计算的收敛,应保证时间步长?t≤?x2/(2a),其中?x为网格尺寸,a为材料导温系数。计算过程中在凝固阶段?t取0.05 s,凝固结束后取0.1 s。

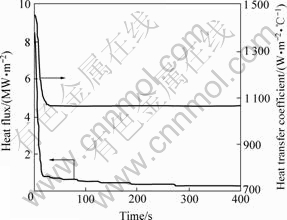

分别计算热交换系数随时间(h—t)和铸锭界面温度(h—θe)的变化,计算结果如图3所示。

图3 界面热交换系数

Fig.3 Heat transfer coefficient at interface

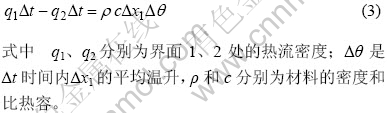

当测温点在近表面处,沿热流方向把锭模截面简化为一维传热系统,根据图4所示的差分形式按一维热传导能量守恒可得:

在t=ti时刻则:

图4 一维差分示意图

Fig.4 Schematic plan of one dimension difference

将式(2)~(6)代入式(3)可得界面温度θif,由式(4)得到时间ti时刻所对应的界面1处热流qi1,朱宪华等[5]认为热量从界面向铸型传输随时间呈指数衰减,本文作者根据这一思路假设界面热流密度与凝固时间满足关系式q=Aexp(-BtC),进行数据拟合,得到热流密度随时间(q—t)变化曲线,结果如图5所示。其中A为热流密度幅值;B为热流密度衰减系数;C为时间调节系数;t为凝固时间。

图5 铸锭/锭模热流密度/换热系数与时间的关系

Fig.5 Relationship between heat flux heat transfer coefficient at interface and time

以上关系曲线分别描述了铸型/铸件界面的热交换随时间或界面温度的变化规律。界面热流密度值q在界面合金凝固前后都可用指数形式来描述不同的衰减程度,凝固过程中快速下降,而凝固结束后将随时间逐渐衰减,幅度平稳;界面热交换系数h先平稳下降,当界面液态金属开始凝固后,h值快速下降,随界面状态逐渐稳定后,h值又平稳下降至一基本恒定值。

2 温度场的模拟

2.1 有限元建模

模拟计算采用的铸锭/锭模轴对称有限元模型如图6所示。用八节点六面体单元和楔形单元进行网格划分。单元数为5 788,节点数为1 783。

图6 铸锭/锭模有限元模型

Fig.6 FEM of casting ingot and model

初始条件和边界条件根据实际实验工况确定,锭模未经预热处理,其初始温度与环境温度均为25 ℃,考虑浇注充型过程对温度场的影响,浇注温度700 ℃,浇注速度1 m/s。凝固过程中所涉及到的各种边界条件包括锭模与空气、铸锭顶部与空气、铸锭与锭模间的对流和辐射边界,为了计算方便,都统一为对流换热边界的形式

2.2 模拟计算结果分析

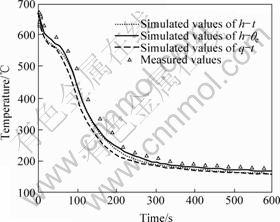

比较铸锭内测温点的模拟和实测结果,A点的温度变化如图7所示。图中列出采用不同的铸锭/锭模间热交换模型所得的结果。从图7可以看出,由反算法所得出的界面热交换系数使模拟结果与实验测量值相符的较好,虽然反算法的结果能较准确地反映真实情况,但是反算法对数据的处理过程较繁锁。

采用界面热流密度与凝固时间的关系,在模拟中的应用也能使温度场模拟结果与实测值相符。在浇注阶段,由于温度变化剧烈,液面波动较大,靠近界面锭模内的温度值有所起伏,使得模拟结果与实测值有所差异,在稳定凝固后,尤其温度变化平缓后,模拟结果与实验值相差减小。

图7 铸锭内测温点实测值和模拟值

Fig.7 Temperatures of measure and simulation at measured point in ingot

以上界面热交换系数的确定是以浇注温度700 ℃时的实测温度为依据,为了不失一般性,在界面状况不变的情况下,使用以上的界面热交换系数,而浇注温度改为650 ℃,模拟结果与实测值的温度变化曲线如图8所示。从图中可看出二者能基本相符,其规律性与浇注温度700 ℃时相类似。尤其采用h—θe曲线作为界面热交换的边界条件,模拟值与实测值相符的更好。可见基于界面温度变化的热交换系数能更好的反应界面的热传输变化规律,因为在界面材质不发生明显物理和化学变化时,界面温度场的变化直接作用界面的接触状况,界面接触状况是决定热交换规律的关键因素。因此本文所确定的铸锭/锭模的界面热交换系数能够在铸件材料铝合金A356与金属型铸模的凝固模拟过程中进行使用,能够保证模拟计算结果的精度。

图8 铸锭内测温点实测值和模拟值

Fig.8 Temperatures of measure and simulation at measured point in ingot

REFERENCES

[1] 任子平, 刘 坤, 刘 鹏. 大型圆台钢锭定向凝固的数值模拟[J]. 冶金能源, 2006, 25(6): 20?24.

REN Zi-ping, LIU Kun, LIU Peng. The numerical simulation of directional solidification process for large-scale frustum of a cone ingot[J]. Energy for Metallurgical Industry, 2006, 25(6): 20?24.

[2] 郭 鹏, 张兴国, 郝 海, 金俊泽. AZ31镁合金圆锭连铸过程温度场的数值模拟[J]. 中国有色金属学报, 2006, 16(9): 1570?1576.

GUO Peng, ZHANG Xing-guo, HAO Hai, JIN Jun-ze. Temperature simulation of direct chill casting of AZ31 magnesium alloy billets[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1570?1576.

[3] Hao H, Maijer D M, W ells M A, Cockcroft S L, Rogge R. Prediction and measurement of residual stresses/strains in a direct chill casting magnesium alloy billet[C]//Magnesium Technology 2005. Warrendale, PA: TM S, 2005: 223?228.

[4] Harste K, Schwerdtfeger K. Shrinkage of round iron-carbon ingots during solidification and subsequent cooling[J]. ISIJ International, 2003, 43(7): 1011?1020.

[5] 陈海清, 李华基, 曹 阳. 铸件凝固过程数值模拟[M]. 重庆: 重庆大学出版社, 1991: 75?86.

CHEN Hai-yang, LI Hua-ji, CAO Yang. Numerical simulation of the solidification of castings[M]. Chongqing: Chongqing University Press, 1991: 75?86.

[6] 徐 宏, 侯 华, 赵宇宏, 陈 铮. 铝铸件凝固模拟边界热交换系数及缩孔缩松预测研究[J]. 材料制备工艺模拟, 1986, 20(2): 1583?1561.

XU Hong, HOU Hua, ZHAO Yu-hong, CHEN Zheng. Research on interface heat transfer coefficient and shrink porous of solidification of aluminum casting[J]. Material Preparation Technology Simulation, 1986, 20(2): 1583?1561.

[7] 陈国权, 林家骝. 影响铸件/铸型界面热交换因素综述[J]. 铸造技术, 1992, 13(5): 36?37.

CHEN Guo-quan, LIN Jia-liu. Survey of the factors influencing metal/mold interfacial heat transfer[J]. Foundry Technology, 1992, 13(5): 36?37.

[8] 章四琪, 黄劲松. 有色金属熔炼与铸锭[M]. 北京: 化学工业出版社, 2006: 105?112.

ZHANG Si-qi, HUANG Jin-song. Nonferrous alloys fusion metallurgy and casting ingot[M]. Beijing: Chemical Industry Press, 2006: 105?112.

[9] Ebisu Y. Computer simulations on the macrostructures in centrifugal casting[C]//AFS Trans, 1977, 85: 85.

[10] 朱宪华, 杨秉俭, 苏俊义. 离心铸造大型气缸套凝固过程的数值模拟及试验研究[J]. 西安交通大学学报, 1986, 20(2): 36?37.

ZHU Xian-hua, YAN Bing-jian, SU Jun-yi. Numerical simulation and experimental nethodology during centrifugal casting of large cylinder liner[J]. Sian Traffic University Traction, 1986, 20(2): 36?37.

[11] 严卫东. 铝合金及高温合金铸件凝固过程中晶粒组织形成的计算机模拟[D]. 西安: 西北工业大学, 2002.

YAN Wei-dong. Computer simulation of grain structure during casting solidification of aluminum alloy and refractory alloy[D]. Xi’an: Northwestern Polytechnical University, 2002.

[12] 张向琨, 石 伟, 蔡临宁. 空心钢锭芯部换热条件的确定[J]. 大型铸锻件, 2000, 20(3): 10?13.

ZHANG Xiang-kun, SHI Wei, CAI Lin-ning. Study on the heat transfer boundary conditions of core in hollow ingot[J]. Large-scale Founding and Forging, 2000, 20(3): 10?13.

[13] Spinelli J E, Rosa D M, Ferreira I L, Garcia A. Influence of melt convection on dendritic spacings of downward unsteady-state directionally solidified Al-Cu alloys[J]. Mater Sci Eng A, 2004, 383: 271?282.

[14] Meloa M L N M, Rizzo E M S, Santos R G. Numerical model to predict the position, amount and size of microporosity formation in Al-Cu alloys by dissolved gas and solidification shrinkage[J]. Mater Sci Eng A, 2004, 374: 351?361.

[15] 李建超, 谢麒麟, 王宝峰, 麻永林, 崔健忠. 铸造铝合金圆锭温度场试验研究和数值模拟[J]. 特种铸造及有色合金, 2006, 26(6): 337?339.

LI Jian-chao, XIE Qi-lin, WANG Bao-feng, CUI Jian-zhongl. Experiment and numerical simulation of the temperature field in aluminum alloy ingot in semi-continuous casting[J]. SpecialCasting and Nonferrous Alloys, 2006, 26(6): 337?339.

[16] Hwang J C, Chuang H T, Jong S H, Hwang W S. Measurement of heat transfer coefficient at metal/mold interface during casting[J]. AFS Trans, 1994, 102: 877?883.

[17] 王 芹. 锻造用钢锭凝固过程温度场数值模拟及其应用[D]. 西安: 西安建筑科技大学, 2004.

WANG Qin. Numerical simulation of temperature field and application of solidification process of forged steel ingot[D]. Xi’an: Xi’an Architecture Science and Technology University, 2004.

[18] Conley J G, Huang J, Asada J, et al. Modeling the effects of cooling rate, hydrogen content, grain refiner and modifier on microporosity formation in Al A356 alloys[J]. Mater Sci Eng A, 2000, 285: 49?55.

[19] 刘 庄. 热处理过程的数值模拟[M]. 北京: 科学出版社, 1996: 14?19.

LIU Zhuang. Numerical simulation of the heat treatment process[M]. Beijing: Science Press, 1996: 14?19.

基金项目:国家自然科学基金重点资助项目(50435010,50534020);国家重点基础规划研究资助项目(2004CCA066000)

收稿日期:2007-03-30;修订日期:2007-07-05

通讯作者:杜凤山,教授;电话:0335-8057040;E-mail: fsdu@ysu.edu.cn

(编辑 龙怀中)