Effects of ratio of hydrogen flow on microstructure of hydrogenated microcrystalline silicon films deposited by magnetron sputtering at 100 °C

来源期刊:中南大学学报(英文版)2019年第10期

论文作者:王军军 王林青 周永涛 刘雪芹

文章页码:2661 - 2667

Key words:hydrogenated microcrystalline silicon films; radio frequency magnetron sputtering; ratio of hydrogen flow; low temperature; microstructure

Abstract: Hydrogenated microcrystalline silicon (μc-Si:H) films were prepared on glass and silicon substrates by radio frequency magnetron sputtering at 100 °C using a mixture of argon (Ar) and hydrogen (H2) gasses as precursor gas. The effects of the ratio of hydrogen flow (H2/(Ar+H2)%)) on the microstructure were evaluated. Results show that the microstructure, bonding structure, and surface morphology of the μc-Si:H films can be tailored based on the ratio of hydrogen flow. An amorphous to crystalline phase transition occurred when the ratio of hydrogen flow increased up to 50%. The crystallinity increased and tended to stabilize with the increase in ratio of hydrogen flow from 40% to 70%. The surface roughness of thin films increased, and total hydrogen content decreased as the ratio of hydrogen flow increased. All μc-Si:H films have a preferred (111) orientation, independent of the ratio of hydrogen flow. And the μc-Si:H films had a dense structure, which shows their excellent resistance to post-oxidation.

Cite this article as: WANG Lin-qing, ZHOU Yong-tao, WANG Jun-jun, LIU Xue-qin. Effects of ratio of hydrogen flow on microstructure of hydrogenated microcrystalline silicon films deposited by magnetron sputtering at 100 °C [J]. Journal of Central South University, 2019, 26(10): 2661-2667. DOI: https://doi.org/10.1007/s11771-019-4203-7.

J. Cent. South Univ. (2019) 26: 2661-2667

DOI: https://doi.org/10.1007/s11771-019-4203-7

WANG Lin-qing(王林青)1, 2, ZHOU Yong-tao(周永涛)3, 4,WANG Jun-jun(王军军)3, 4, LIU Xue-qin(刘雪芹)3, 4

1. School of Science, Chongqing University of Technology, Chongqing 400054, China;

2. Chongqing Key Laboratory of Green Energy Materials Technology and Systems,Chongqing 400054, China

3. College of Materials Science and Engineering, Chongqing University of Technology,Chongqing 400054, China;

4. Chongqing Collaborative Innovation Center for Brake Tribological Materials, Chongqing 400054, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2019

Abstract: Hydrogenated microcrystalline silicon (μc-Si:H) films were prepared on glass and silicon substrates by radio frequency magnetron sputtering at 100 °C using a mixture of argon (Ar) and hydrogen (H2) gasses as precursor gas. The effects of the ratio of hydrogen flow (H2/(Ar+H2)%)) on the microstructure were evaluated. Results show that the microstructure, bonding structure, and surface morphology of the μc-Si:H films can be tailored based on the ratio of hydrogen flow. An amorphous to crystalline phase transition occurred when the ratio of hydrogen flow increased up to 50%. The crystallinity increased and tended to stabilize with the increase in ratio of hydrogen flow from 40% to 70%. The surface roughness of thin films increased, and total hydrogen content decreased as the ratio of hydrogen flow increased. All μc-Si:H films have a preferred (111) orientation, independent of the ratio of hydrogen flow. And the μc-Si:H films had a dense structure, which shows their excellent resistance to post-oxidation.

Key words: hydrogenated microcrystalline silicon films; radio frequency magnetron sputtering; ratio of hydrogen flow; low temperature; microstructure

Cite this article as: WANG Lin-qing, ZHOU Yong-tao, WANG Jun-jun, LIU Xue-qin. Effects of ratio of hydrogen flow on microstructure of hydrogenated microcrystalline silicon films deposited by magnetron sputtering at 100 °C [J]. Journal of Central South University, 2019, 26(10): 2661-2667. DOI: https://doi.org/10.1007/s11771-019-4203-7.

1 Introduction

Hydrogenated microcrystalline silicon (μc-Si:H) films exhibit excellent properties such as high charge carrier mobility, high electrical conductivity, and good stability. Because of these properties, they have attracted considerable attention for use in transistors, solar cells, and image sensors [1-6]. Many deposition techniques, including hot wire chemical vapor deposition, plasma-enhanced chemical vapor deposition, and magnetron sputtering, have been used to grow μc-Si:H films at a typical substrate temperature ranging from 200 °C to 400 °C [1, 4, 7-11]. Growing μc-Si:H films at a low substrate temperature (<200 °C) has a strong practical incentive because low temperature enables the use of substrates, such as glass or plastic, that have low softening or decomposition temperatures [12-15]. Recently, many studies have reported on low temperature growth of μc-Si:H films [14, 16-18], where many assistant processes, including applying a very high pressure to the plasma [16], adding helium/chlorinated silanes to the plasma [17, 18], and using high flux ion bombardment to magnetron sputtering [14], were adopted to facilitate the nucleation of nanocrystallite. In our previous work, μc-Si:H films were obtained at a low substrate temperature (100 °C) via magnetron sputtering without any assistant process [19]. However, the μc-Si:H films had a complex microstructure, consisting of crystalline and amorphous silicon phases, and grain boundaries. The photoelectric properties can be tailored by the microstructure. Thus, studying microstructure evolution is important [1]. The microstructure of μc-Si:H films strongly depends on the ratio of hydrogen flow (H2/(Ar+H2)%) in a magnetron sputtering at the substrate temperature ranging from 200 °C to 400 °C [11, 20-22]. However, few studies have investigated the microstructure of μc-Si:H films grown by magnetron sputtering at 100 °C.

In this study, a series of μc-Si:H films was deposited on glass and silicon substrates via magnetron sputtering at 100 °C under different H2/(Ar+H2) flow ratios ranging from 40% to 70%. The effects of the ratio of hydrogen flow on the microstructure were evaluated using spectroscopic ellipsometry, Raman spectroscopy, X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), and atomic force microscopy (AFM).

2 Experimental

Glass with dimensions of 3 cm×2 cm×0.1 cm and Si (100) wafer were used as substrates. The substrates were ultrasonically cleaned in acetone and ethanol baths in succession for 20 min, followed by rinsing in deionized water. The μc-Si:H films were deposited on cleaned substrate by using radio frequency (13.56 MHz) magnetron sputtering technique, which was configured with a Si (99.999%) targets. The surface of substrates was cleaned by sputtering with argon (Ar) for 30 min before deposition process. The base pressure was approximately 3×10-5 Pa, and the pressure in the sputtering process was approximately 1.5 Pa. Deposition was performed at 0.2 Pa with Ar flow rate of 30 sccm and H2 flow rate of 20–70 sccm, corresponding to the ratio of hydrogen flow in the range of 40%-70%. The radio frequency power was fixed at 200 W.

The thickness of the μc-Si:H films was determined by a spectroscopic ellipsometer (SE, M-2000DI), and the thickness of all as-deposited films was approximately 200 nm. The crystallinity of the μc-Si:H films was analyzed by confocal micro-Raman spectroscopy measurements (Renishaw inVia Reflex) operated at an argon laser wavelength of 488 nm. In order to avoid the surface damage, the powder of laser light was kept at 5 mW. The diameter of the laser spot was 2.5 μm. The crystal structure of the μc-Si:H films was measured by grazing incidence XRD (Bruker AXS D8) using a Cu Kα radiation source operating at 45 kV and 40 mA. The incident angle was 0.5°. The hydrogen bonding information and hydrogen content were obtained using FT-IR (Thermo Nicolet 6700). For easy detection of IR absorption, the μc-Si:H films were deposited at (100) silicon wafer. The spectra were recorded in transmittance mode (400-2500 cm-1) with 4 cm-1 resolution. Surface roughness and morphology were observed using CSPM 5500 AFM with a contact mode.

3 Results and discussion

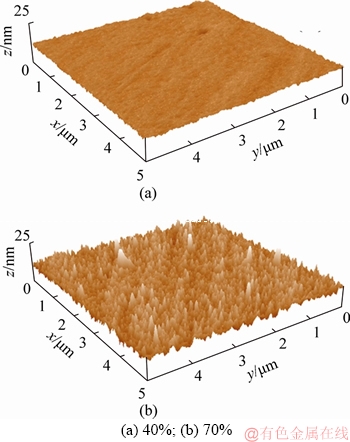

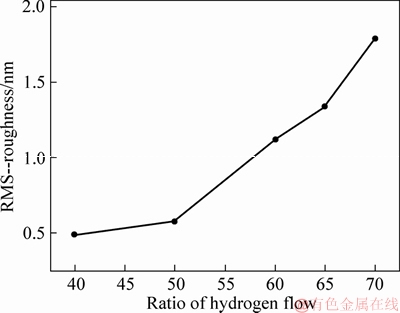

Figure 1 shows the AFM images of the μc-Si:H films under the different ratios of hydrogen flows ranging from 40% and 70%. The surface of the films deposited at a ratio of hydrogen flow of 40% was relatively smooth. Meanwhile, the surface became rough when the ratio of hydrogen flow increased up to 70%. This result indicated that the structure of films was changed with increasing ratio of hydrogen flow [23, 24]. The RMS roughness of the films is shown in Figure 2. The figure shows that RMS roughness increased with the increase in ratio of hydrogen flow. This is in some way related to the incorporation of crystallites in the amorphous matrix, thereby leading to an increase in the surface roughness [23].

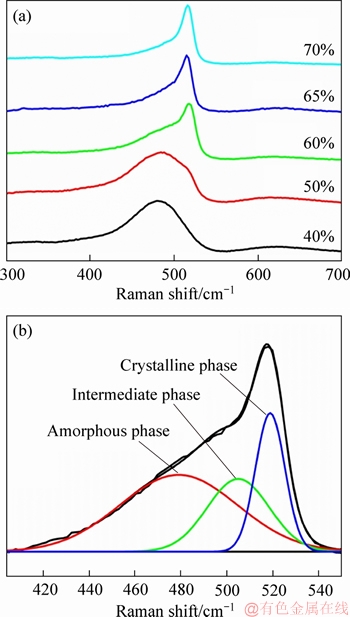

The Raman spectra of μc-Si:H films as a function of ratio of hydrogen flow were measured (Figure 3(a)). The figure shows that only a single peak was present at 480 cm-1 when the ratio of hydrogen flow was 40%, indicating that the as-deposited Si:H films are in the amorphous phase [25]. When the ratio of hydrogen flow increased up to 50%, a weak peak at approximately 520 cm-1 was observed, which corresponds to the transverse optical (TO) mode of the crystalline silicon. This finding revealed that μc-Si:H films can be formed under this situation. With a further increase in the ratio of hydrogen flow, the intensities of the peak at approximately 520 cm-1 gradually increased, and the 480 cm-1 peak gradually decreased at the same time. These results indicated that in the as-deposited μc-Si:H films, an amorphous to crystalline phase transition occurred when the ratio of hydrogen flow increased up to 50%.

Figure 1 AFM micrographs of μc-Si:H thin films deposited at various flow rate ratios of hydrogen:

Figure 2 RMS-roughness of μc-Si:H film as function of ratio of hydrogen flow

Figure 3 Raman spectra of Si:H thin films deposited under different hydrogen flow ratios (a), Gaussian fitting of μc-Si:H films prepared with 60% hydrogen flow ratio (b)

The Gaussian fitting of μc-Si:H films deposited at a ratio of hydrogen flow of 60% is shown in Figure 3(b). The Raman spectrum can be deconvoluted into three peaks located at 520, 510, and 480 cm-1, which belong to the TO mode of the crystalline silicon, defective part of the crystalline phase, and the amorphous silicon phase, respectively [1, 17, 20, 21, 25, 26]. Generally, the approximate fraction of crystalline volume (Xc) of μc-Si:H films follows the relation [11,20]:

Xc=(I510+I520)/(I480+I510+I520) (1)

where the subscript number is wavenumber, and I is the integrated area of the related peak.

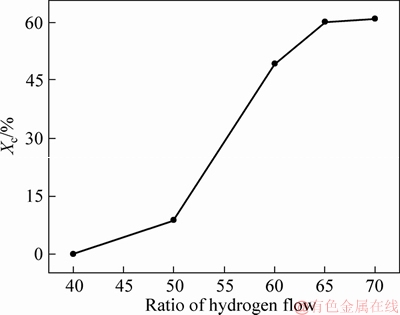

Figure 4 shows the Xc of the as-deposited μc-Si:H films at various ratios of hydrogen flow. Xc increased and tended to stabilize with the increase in ratio of hydrogen flow from 40% to 70%. This phenomenon is caused by various reasons. First, the atomic hydrogen covered on the growing surface can promote μc-Si:H growth [11, 20, 27]. The increase in the ratio of hydrogen flow indicates an increase in the atomic hydrogen on the growing surface. Second, Ar ion creates hydrogen radicals during the magnetron sputtering deposition of μc-Si:H. The decrease in Ar ion leads to the decrease in hydrogen radicals [20]. In this work, the Ar flow rate was kept constant. Consequently, hydrogen radicals would be limited by the Ar flow rate. Thus, Xc tended to stabilize when the ratio of hydrogen flow further increased.

Figure 4 Crystal volume fraction (Xc) of μc-Si:H thin films deposited under different hydrogen flow ratio

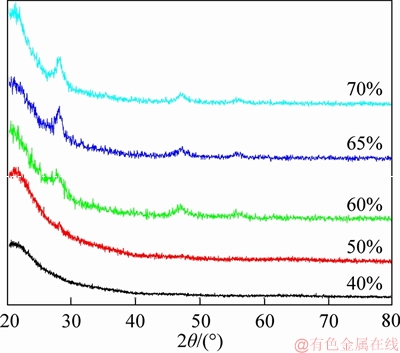

Figure 5 shows the XRD patterns of the μc-Si:H films as a function of the ratio of hydrogen flow. There is no obvious crystalline diffraction peaks at the ratio of hydrogen flow of 40%, indicating that the as-deposited μc-Si:H films were amorphous or nearly amorphous. When the ratio of hydrogen flow increased up to 50%, a very weak diffraction peak appeared at approximately 2θ=28.4°, corresponding to the Si (111) diffraction peak [1, 18, 28, 29], revealing that the crystal formed under such conditions. With the further increase in ratio of hydrogen flow, the intensities of the peak at approximately 2θ=28.4° gradually increased, and two other small diffraction peaks appeared at approximately 47.3° and 56.1°, which corresponded to the Si diffraction peaks of (220) and (311) [1, 18, 28, 29], respectively. These results indicated that a transition from the amorphous phase to microcrystalline phase occurred when the ratio of hydrogen flow increased up to 50%. The XRD results were in accordance with the Raman results. Moreover, one could notice that the intensity of the (111) peak became stronger, while the intensities of two other peaks hardly changed with increasing ratio of hydrogen flow. This result indicated that the crystallinity increased with the increase in ratio of hydrogen flow. And all μc-Si:H films have a preferred (111) orientation, independent of the ratio of hydrogen flow.

Figure 5 XRD patterns of μc-Si:H films deposited in various ratios of hydrogen flow

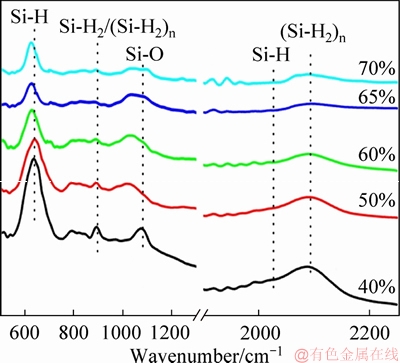

Figure 6 shows the FT-IR spectra of the μc-Si:H films deposited at various ratios of hydrogen flow. The figure shows that the peak was related to the Si-H wagging/rocking mode located at 640 cm-1 when the ratio of hydrogen flow was <60%. Meanwhile, this peak shifted to ~630 cm-1 for the μc-Si:H films deposited at the ratio of hydrogen flow of 60%-70%. In addition, the peak related to the stretching absorption band was decomposed into two Gaussian components, ~2010 and ~2090 cm-1. Meanwhile, no absorption band was found at ~2010 cm-1, and the peak at~2090 cm-1 shifted to a higher frequency at the ratio of hydrogen flow of 60%–70% [14, 22]. The presence of the 630 cm-1 wagging/rocking mode and the high-frequency stretching modes can be attributed either to the presence of Si-H2 and (Si-H2)n complexes at the grain boundaries or to Si-H or Si-H2 bonds located at the (111) and (220) surfaces of the Si crystallites [26, 27]. Furthermore, the peak intensity related to Si-O stretching mode, an indication of materials with low density, was very weak. This indicated that μc-Si:H films had a dense structure. The dense μc-Si:H films showed excellent resistance to post-oxidation [14, 22].

Figure 6 FT-IR absorption spectra of μc-Si:H films deposited in various ratios of hydrogen flow

Generally, the incorporated hydrogen content in μc-Si:H films can be estimated from the wagging/rocking mode on the FT-IR absorption spectrum [26, 28, 29]. The total bonded hydrogen concentration (CH) can be calculated using the following relation:

(2)

(2)

where A640 is the area of the absorption band at 640 cm-1; N is the atomic density of the crystalline silicon (5.0×1022 cm-3); α(ω) is the absorption coefficient [27, 28]. Figure 7 shows the variation of CH for the as-prepared Si:H films. Clearly, CH decreased from 12.0 at% to 4.2 at% when the ratio of hydrogen flow increased from 40% to 70%. This change may be caused by the decrease in the amorphous phase during the growth processes because H mainly bonds with the amorphous matrix [17, 30].

Figure 7 Hydrogen content (CH ) of μc-Si:H thin films as a function of ratio of hydrogen flow

4 Conclusions

The microstructure of the μc-Si:H films deposited by RF (13.56 MHz) magnetron sputtering at the low substrate temperature of 100 °C under different ratios of hydrogen flow was investigated. Amorphous to crystalline phase transition occurs when the ratio of hydrogen flow is approximately 50%. When the ratio of hydrogen flow increases from 40% to 70%, the crystallinity of the μc-Si:H films increases and tends to stabilize. The surface roughness of thin films increased, and total hydrogen content decreased as the ratio of hydrogen flow increased. These phenomena may be attributed to the increase in atomic hydrogen flux on the growing surface. Moreover, the as-deposited Si:H films had a (111) preferred orientation, independent of the ratio of hydrogen flow. And the μc-Si:H films had a dense structure, which shows an excellent resistance to post-oxidation.

References

[1] LI T T, XU S Z, HUANG Q, REN H Z, NI J, LI B Z, ZHANG D K, WEI C C, AMANATIDES E, MATARAS D, ZHAO Y, ZHANG X. SiH4 enhanced dissociation via argon plasma assistance for hydrogenated microcrystalline silicon thin-film deposition and application in tandem solar cells [J]. Sol Energ Mat Sol C, 2018, 180: 110–117. DOI: 10.1016/ j.solmat.2018.02.024.

[2] LIU B, BAI L, LI T, WEI C, LI B, HUANG Q, ZHANG D, WANG G, ZHAO Y, ZHANG X. High efficiency and high open-circuit voltage quadruple-junction silicon thin film solar cells for future electronic applications [J]. Energy Environ Sci, 2017, 10: 1134–1141. DOI: 10.1039/C7EE00332C.

[3] ZHONG C L, GENG K W, LUO L E, YANG D W. An analytical model to explore open-circuit voltage of a-Si:H/c-Si heterojunction solar cells [J]. Journal of Central South University, 2016, 23: 598–603. DOI: 10.1007/s11771-016- 3106-0.

[4] SU Y J, DOND C, ZHU M, XU J, FAN P H. Effects of growth temperature on μc-Si:H films prepared by plasma assistant magnetron sputtering [J]. Rare Metals, 2012, 31(2): 193–197. DOI: 10.1007/s12598-012-0490-y.

[5] PYTHON M, MADANI O, DOMINE D, MEILLAUD F, VALLAT-SAUVAIN E, BALLIF C. Influence of the substrate geometrical parameters on microcrystalline silicon growth for thin-film solar cells [J]. Sol Energ Mat Sol C, 2009, 93(10): 1714–1720. DOI: 10.1016/j.solmat. 2009.05.025.

[6] BUGNON G, FELTRIN A, MEILLAUD F, BAILAT J, BALLIF C. Influence of pressure and silane depletion on microcrystalline silicon material quality and solar cell performance [J]. J Appl Phys, 2009, 105(6): 064507. DOI: 10.1063/1.3095488.

[7] ADHIKARI D, JUNDA M M, MARSILLAC S X, COLLINS R W, PODRAZA N J. Nanostructure evolution of magnetron sputtered hydrogenated silicon thin films [J]. J Appl Phys, 2017, 122(7): 075302. DOI: 10.1063/1.4998455.

[8] WANG L Q, WANG W Y, HUANG J H, TAN R Q, SONG W J, CHEN J M. Growth and properties of hydrogenated microcrystalline silicon thin films prepared by magnetron sputtering with different substrate temperatures [J]. Rare Metals, 2015. DOI: 10.1007/s12598-015-0510-9.

[9] DUSHAQ G, NAYFEH A, RASRAS M. Tuning the optical properties of RF-PECVD grown μc-Si:H thin films using different hydrogen flow rate [J]. Superlattice Microst, 2017, 107: 172–177. DOI: 10.1016/j.spmi.2017.03.052.

[10] KLEIN S, REPMANN T, BRAMMER T. Microcrystalline silicon films and solar cells deposited by PECVD and HWCVD [J]. Sol Energy, 2004, 77(6): 893–908. DOI: 10.1016/ j.solener.2004.08.029.

[11] FUKAYA K, TABATA A, SASAKI K. Mechanism of hydrogenated microcrystalline Si film deposition by magnetron sputtering employing a Si target and H2/Ar gas mixture [J]. Jpn J Appl Phys, 2014, 48(3): 035507. DOI: 10.1143/JJAP.48.035507.

[12] MELLOS A, KANDYLA M, PALLES D, KOMPITSAS M. Effects of hydrogen pressure on hydrogenated amorphous silicon thin films prepared by low-temperature reactive pulsed laser deposition [J]. Phys Status Solidi C, 2017, 14(1, 2): 1600088. DOI: 10.1002/pssc.201600088.

[13] ALPUIM P, CHU V, CONDE J P. Amorphous and microcrystalline silicon films grown at low temperatures by radio-frequency and hot-wire chemical vapor deposition [J]. Jpn J Appl Phys, 1999, 86(7): 3812. DOI: 10.1063/1.371292.

[14] GERBI J E, ABELSON J R. Low temperature magnetron sputter deposition of polycrystalline silicon thin films using high flux ion bombardment [J]. Jpn J Appl Phys, 2007, 101(6): 063508. DOI: 10.1063/1.2710301.

[15] WADIBHASME N A, DUSANE R O. Low temperature deposition of device-quality silicon thin films for flexible PV application [C]// 40th IEEE Photovoltaic Specialist Conference. Denvor: IEEE 2014: 3060-3064. DOI: 10.1109/PVSC.2014.6925581.

[16] DAVIS W A, LEWIN G, DAVIS T M E, BRUCE D G. Nanocrystalline Si:H thin films grown at room temperature with plasma-enhanced chemical vapour deposition at a very high pressure [J]. J Phys D Appl Phys, 2012, 45(33): 335104. DOI: 10.1088/0022-3727/45/33/335104.

[17] ZHANG L, GAO J H, XIAO J Q, WEN L S, GONG J, SUN C. Low-temperature (120 °C) growth of nanocrystalline silicon films prepared by plasma enhanced chemical vapor deposition from SiCl4/H2 gases: Microstructure characterization [J]. Appl Surf Sci, 2012, 258(7): 3221–3226. DOI: 10.1016/j.apsusc.2011.11.068.

[18] BHATTACHARYA K, DAS D. Effect of deposition temperature on the growth of nanocrystalline silicon network from helium diluted silane plasma [J]. J Phys D Appl Phys, 2008, 41(15): 155420. DOI: 10.1088/0022-3727/ 41/15/155420.

[19] WANG L, WANG W, HUANG J, ZENG Y, TAN R, SONG W, CHEN J. Low temperature magnetron sputtering deposition of hydrogenated microcrystalline silicon thin films without amorphous incubation layers on glass [J]. J Non-Cryst Solids, 2014, 388(3): 86–90. DOI: 10.1016/ j.jnoncrysol.2014.01.038.

[20] MAKIHARA H, TABATA A, SUZUOKI Y, MIZUTANI T. Effect of the hydrogen partial pressure ratio on the properties of μc-Si:H films prepared by rf magnetron sputtering [J]. Vacuum, 2000, 59(2): 785–791. DOI: 10.1016/S0042- 207X(00)00348-1.

[21] GONCALVES C, CHARVET S, ZEINERT A, CLIN M, ZELLAMA K. Nanocrystalline silicon thin films prepared by radiofrequency magnetron sputtering [J]. Thin Solid Films, 2002, 403-404: 91–96. DOI: 10.1016/s0040-6090(01)01553-x.

[22] FUKAYA K, TABATA A, MIZUTANI T. Dependence on gas pressure of μc-Si:H prepared by RF magnetron sputtering [J]. Vacuum, 2004, 74(3, 4): 561–565. DOI: 10.1016/j.vacuum.2004. 01.027.

[23] GOPE J, KUMAR S, SUDHAKAR S, RAUTHAN C M S, SRIVASTAVA P C. Effect of silane flow rate on structural, electrical and optical properties of silicon thin films grown by VHF PECVD technique [J]. Mater Chem Phys, 2013, 141(1): 89–94. DOI: 10.1016/j.matchemphys.2013.04.028.

[24] GUO L, DING J, YANG J, CHENG G, LING Z. Effects of high hydrogen dilution ratio on surface topography and mechanical properties of hydrogenated nanocrystalline silicon thin films [J]. Thin Solid Films, 2011, 519(18): 6039–6043. DOI: 10.1016/j.tsf.2011.04.117.

[25] CHENG Q, XU S, OSTRIKOV K K. Structural evolution of nanocrystalline silicon thin films synthesized in high-density, low-temperature reactive plasmas [J]. Nanotechnology, 2009, 20-21: 215606. DOI: 10.1088/0957-4484/20/21/215606.

[26] CHENG Q, XU S, HUANG S, OSTRIKOV K. Effective control of nanostructured phases in rapid, room-temperature synthesis of nanocrystalline Si in high-density plasmas [J]. Cryst Growth Des, 2009, 9(6): 2863–2867. DOI: 10.1021/ cg900176c.

[27] MATSUDA A. Microcrystalline silicon: Growth and device application [J]. J Non-Cryst Solids, 2004, 338(1): 1–12. DOI: 10.1016/j.jnoncrysol.2004.02.012.

[28] WEI D Y, XIAO S Q, HUANG S Y, CHAN C S, ZHOU H P, XU L X, GUO Y N, CHAI J W, WANG S J, XU S. Low-temperature deposition of μc-Si:H thin films by a low-frequency inductively coupled plasma for photovoltaic applications [J]. J Phys D Appl Phys, 2013, 46(21): 215501. DOI: 10.1088/0022-3727/46/21/215501.

[29] XIAO S Q, XU S, WEI D Y, HUANG S Y, ZHOU H P, XU Y. From amorphous to microcrystalline: Phase transition in rapid synthesis of hydrogenated silicon thin film in low frequency inductively coupled plasmas [J]. J Appl Phys, 2010, 108(11): 113520. DOI: 10.1063/1.3514006.

[30] CHENG Q, XU S, OSTRIKOV K. Rapid, low-temperature synthesis of nc-Si in high-density, non-equilibrium plasmas: Enabling nanocrystallinity at very low hydrogen dilution [J]. J Mater Chem, 2009,19(29): 5134–5140. DOI: 10.1039/b904227j.

(Edited by HE Yun-bin)

中文导读

氢稀释比对磁控溅射低温(100 °C)沉积氢化微晶硅薄膜微结构特性的影响

摘要:在低温(100 °C)条件下采用磁控溅射在玻璃和硅(100)衬底上沉积氢化微晶硅(μc-Si:H)薄膜,研究不同氢稀释比对微晶硅薄膜微结构特性的影响。结果表明:薄膜从非晶相过渡到了微晶相当氢稀释比增加到约50%,氢化微晶硅薄膜的结晶率随氢稀释比从40%增加到70%先增加后趋于稳定;薄膜的表面粗糙度随着氢稀释比的增加而增加,氢含量的变化趋势与之相反;所制备的氢化微晶硅薄膜都具有 (111)择优取向,与氢稀释比无关,且薄膜结构致密。

关键词:微晶硅薄膜;射频磁控溅射;氢稀释比例;低温;微结构

Foundation item: Projects(51505050, 51805063) supported by the National Natural Science Foundation of China for Young Scholars; Projects(KJ1500942, KJQN201801134) supported by the Scientific and Technological Research Program of Chongqing Education Commission of China; Projects(cstc2017jcyjAX0075, cstc2015jcyjA50033) supported by the Chongqing Research Program of Basic Research and Frontier Technology, China

Received date: 2018-09-02; Accepted date: 2019-02-27

Corresponding author: WANG Jun-jun, PhD, Associate Professor; Tel: +86-2362563175; E-mail: wangjunjun@cqut.edu.cn; ORCID: 0000-0001-5796-8926