稀有金属 2013,37(05),681-686

两种超高强度合金的应力腐蚀开裂行为研究

刘建华 文陈 于美 赵阔 陈亚争 许广兴

北京航空航天大学材料科学与工程学院

沈阳飞机设计研究所

摘 要:

超高强合金因其优越的力学性能广泛应用于承力构件如起落架等, 40CrNi2Si2MoVA超高强度合金是继30CrMnSiNi2A之后研究出的新超高强度合金, 其强度高于30CrMnSiNi2A, 但是其在实际服役环境中的服役性能特别是应力腐蚀性能是否优于30CrMnSiNi2A, 是决定其成功取代30CrMnSiNi2A应用的关键。采用双悬臂应力腐蚀实验研究了30CrMnSiNi2A及40CrNi2Si2MoVA两种超高强度合金在质量分数为3.5%的NaCl溶液中的应力腐蚀开裂行为 (SCC) 。通过光学显微镜和扫描电镜 (SEM) 对两种超高强度合金的形貌以及断口显微组织进行了分析。实验结果表明, 30CrMnSiNi2A比40CrNi2Si2MoVA更早失效, 其耐应力腐蚀性能较差。两种材料在NaCl溶液中容易出现裂纹并迅速扩展, 裂纹横向扩展, 并出现明显的分叉行为, 不同取向试样对材料应力腐蚀开裂行为的影响较小。断口分析结果表明两种超高强度合金在应力和腐蚀介质的共同作用下发生失效, 裂纹扩展前期主要为解理穿晶断口, 裂纹扩展中后期为沿晶形貌。

关键词:

超高强度合金;应力腐蚀开裂;双悬臂;分叉;

中图分类号: TG172.9

作者简介:刘建华 (1957-) , 男, 湖南人, 博士, 教授;研究方向:材料腐蚀与防护 E-mail:liujh@buaa.edu.cn;

收稿日期:2012-12-31

基金:国家自然科学基金 (51171011);北京航空航天大学博士创新基金资助项目;

Stress Corrosion Cracking Behavior of Two Kinds of Ultra-High Strength Alloys

Liu Jianhua Wen Chen Yu Mei Zhao Kuo Chen Yazheng Xu Guangxing

School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics

Shenyang Aircraft Design and Research Institute

Abstract:

Ultra-high strength alloys were widely used in structural parts such as landing gears due to their excellent mechanical properties. 40CrNi2Si2MoVA was a kind of ultra-high strength alloy with higher yield strength after developed the ultra-high strength alloy30CrMnSiNi2A. However, whether the actual service performance, especially its stress corrosion property, superior to 30CrMnSiNi2A would be a crucial reason that 40CrNi2Si2MoVA alloy could displace 30CrMnSiNi2A in application. The behavior of stress corrosion cracking ( SCC) of two kinds of ultra-high strength alloy, 30CrMnSiNi2A and 40CrNi2Si2MoVA, in 3. 5% NaCl solution was investigated by double cantilever beam methods. The microstructure and fracture surface of the two ultra-high strength alloys were characterized by optical microscopy ( OM) and scanning electron microscopy ( SEM) . The results showed that cracks of 30CrMnSiNi2A propagated to failure more quickly than that of 40CrNi2Si2MoVA, which illustrated that 30CrMnSiNi2A was more sensitive to SCC than40CrNi2Si2MoVA. The cracks extended towards landscape orientation fast and branched off. The orientations had little influence on the SCC behavior of the specimens. The fracture morphology of two ultrahigh strength alloys showed that the failure mode had the characteristic of trans-granular, cleavage fracture initially and inter-granular fracture at middle-final process by effects of stress and corrosive solution.

Keyword:

ultra high strength alloy; stress corrosion cracking; double cantilever beam; branch;

Received: 2012-12-31

30Cr Mn Si Ni2A为超高强度合金, 含合金元素量少, 经济性好, 强度高, 屈服比低, 但其韧性相对较低, 抗应力腐蚀和抗氢脆性能低。40Cr Ni2Si2Mo VA作为30Cr Mn Si Ni2A的替代合金, 其强度高于30Cr Mn Si Ni2A, 其他力学性能相当, 综合性能更好[1], 常用在飞机起落架以及压力容器等承力部件上[2,3,4,5]。作为主承力构件, 超高强合金主要失效形式为应力腐蚀和氢脆[6,7], 是影响该合金安全使用的重要因素, 易引起突发灾难性事故, 造成巨大经济损失并危及人员安全。因此, 研究超高强合金应力腐蚀对超高强合金的应用具有十分重要的意义。

关于超高强合金在时效处理及应力腐蚀开裂方面的研究一直是科学研究的热点。肖亚洲等[8]研究了外极化对40Cr Ni2Si2Mo VA腐蚀断裂特性的影响, 阴、阳极极化都增加了40Cr Ni2Si2Mo VA腐蚀断裂敏感性, 40Cr Ni2Si2Mo VA腐蚀断裂机制为裂尖阳极溶解与氢脆共同作用;Eliaz等[9]总结了超高强合金应力腐蚀失效的主要特性, 并指出断口分析是评价材料失效最有效的方式;刘道新等[10]利用慢应变速率拉伸试验研究300M超高强度合金应力腐蚀开裂行为, 结果表明在3.5%Na Cl溶液和蒸馏水中均对SCC敏感, 温度、拉伸速率、阴/阳极极化、除氧及降低溶液p H均会提高合金的敏感性;刘道新等[11]研究了带镀层300M合金超高强度合金应力腐蚀行为及机制, 电镀Cr, CdTi层均使300M合金的SCC敏感性增加;Graca等[12]发现, 某超高强合金压力容器失效主要是因为氢脆导致的应力腐蚀开裂造成的。本实验室的前期工作中, 对30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA合金的模拟海水环境下的腐蚀性能[13]以及恒载荷拉伸应力腐蚀性能[14]进行了研究, 得到了典型超高强合金的耐海水腐蚀特性及腐蚀产物组成。

本文采用自加载双悬臂 (DCB) 试样对30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA 3.5%溶液下的应力腐蚀开裂及裂纹扩展行为进行了研究, 并采用光学显微镜和扫描电子显微镜 (SEM) 对断口形貌进行了表征。

1 实验

1.1 材料

实验所用材料为30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA, 化学成分如表1所示。

1.2 实验过程

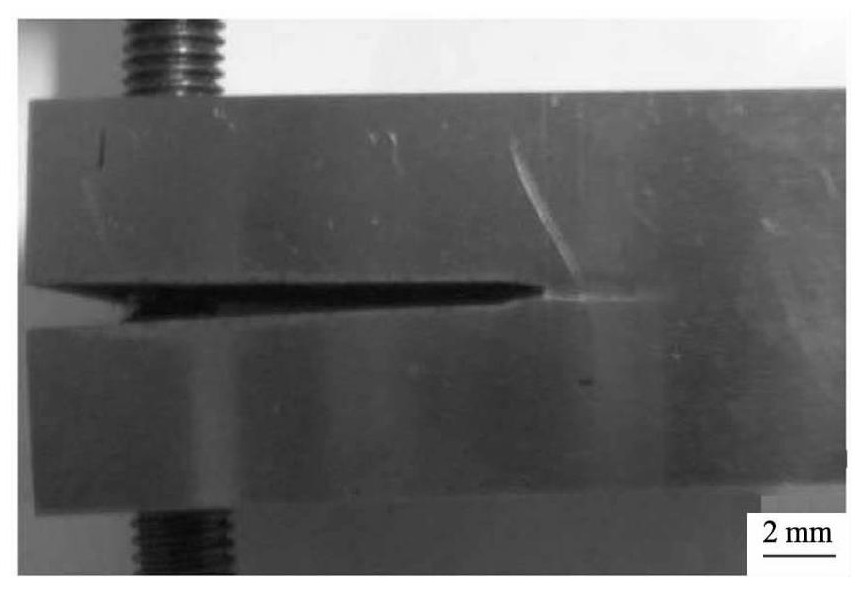

30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA两种材料均选取了L-T, T-L两个方向的试样进行测试。试样试验过程如下:沿试样中心线采用Instron疲劳试验机 (Instron英国) 对试样进行预制疲劳裂纹至2 mm, 加上载荷后, 将试样浸泡于3.5%Na Cl溶液中, 每隔24 h对裂纹形貌及裂纹扩展长度进行观察, 至试样断裂后, 线切割获取试样断口, 进行形貌表征。试样加载后如图1所示。

1.3 裂纹形貌及断口表征

每隔一定时间取出试样, 采用数码相机 (Canon, 日本) 及体式显微镜 (XTZ-E, 中国) 对试样表面裂纹扩展形貌进行观察, 待裂纹扩展速率低于1×10-9m·s-1时, 打开断口, 采用扫描电子显微镜 (Cambridge 3400, 英国) 对断口形貌进行表征。

表1 30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA化学成分 (%, 质量分数) Table 1Nominal composition of 30Cr Mn Si Ni2A and40Cr Ni2Si2Mo VA alloys (%, mass fraction) 下载原图

表1 30Cr Mn Si Ni2A和40Cr Ni2Si2Mo VA化学成分 (%, 质量分数) Table 1Nominal composition of 30Cr Mn Si Ni2A and40Cr Ni2Si2Mo VA alloys (%, mass fraction)

图1 DCB试样加载后形貌示意图Fig.1 DCB specimen after loading

2 结果与讨论

2.1 裂纹扩展形貌分析

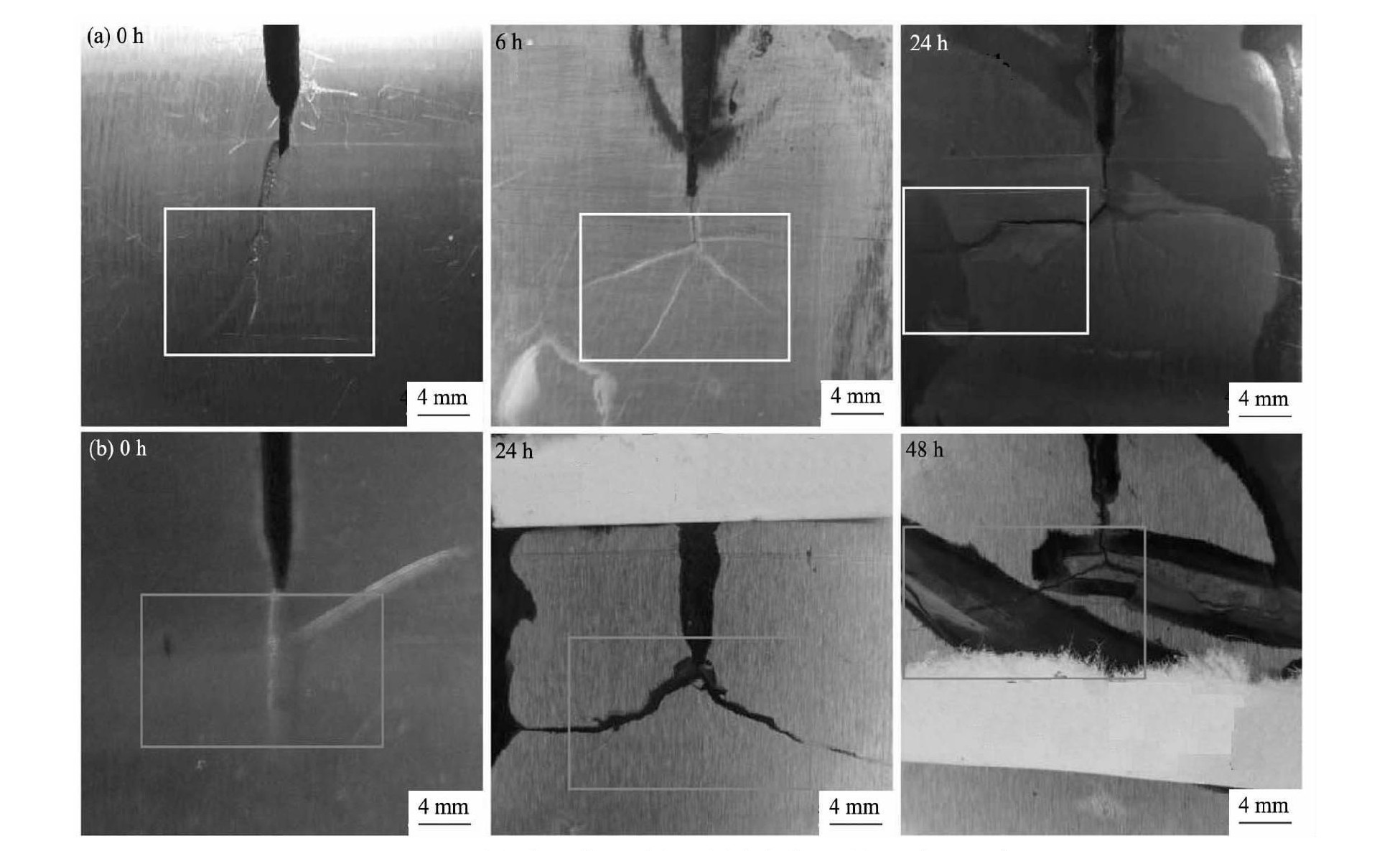

图2为30Cr Mn Si Ni2A (图2 (a) ) 和40Cr Ni2Si2Mo VA (图2 (b) ) 试样不同时间裂纹扩展形貌。从图2 (a) 可以看出, 30Cr Mn Si Ni2A试样出现明显的多支分叉, 6 h已经发展成为4个分支, 并在24 h内其中一个分支横向扩展失效, 其他分支扩展相对缓慢。而从图2 (b) 可以看出, 40Cr Ni2Si2Mo VA在放入溶液中扩展24 h后出现两个较明显的分叉, 扩展也十分迅速, 在48 h内两条裂纹都扩展一段距离, 试样已基本失效。从断裂时间可以看出, 40Cr Ni2Si2Mo VA具有更好的耐应力腐蚀性能。这主要是因为40Cr Ni2Si2Mo VA中Mo和V的存在, Mo促进了晶粒细化[14,15], 提高了韧性及耐腐蚀性能[16,17], V提高了残余奥氏体的含量, 改善了40Cr Ni2Si2Mo VA的耐应力腐蚀性能[18,19]。

2.2 试样取向对材料应力腐蚀开裂形貌的影响

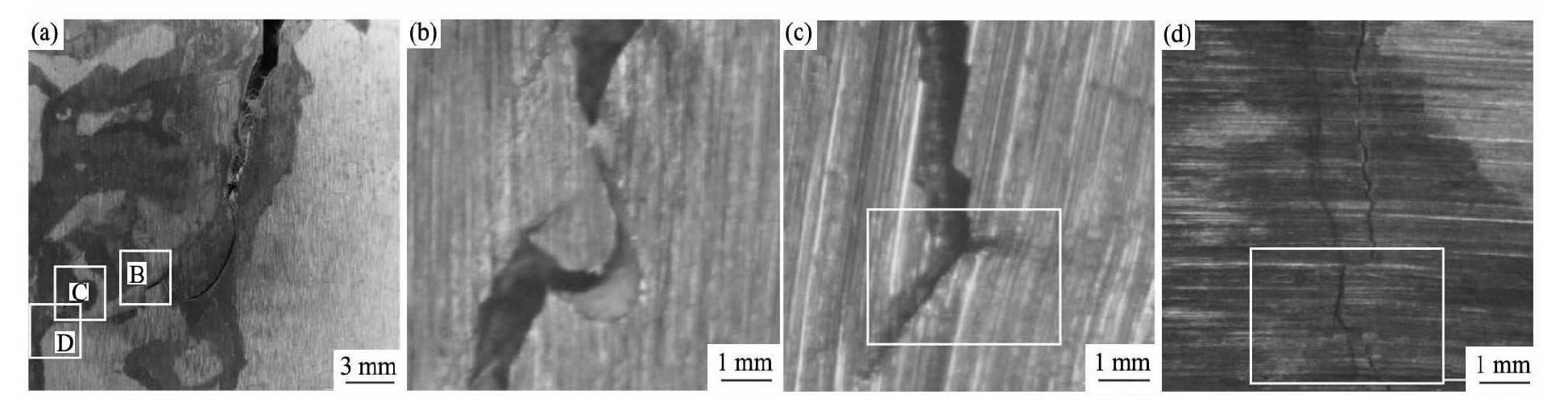

图3为30Cr Mn Si Ni2A (图3 (a, b) ) 和40Cr Ni2Si2Mo VA (图3 (c, d) ) 试样扩展失效后表面形貌。从图3可以看出, 30Cr Mn Si Ni2A裂纹扩展迅速, 裂纹曲折发展, 6 h后出现了4个分支, 而主裂纹往一个横向扩展, 至24 h已经扩展到试样边缘失效。40Cr Ni2Si2Mo VA试样均出现了裂纹分叉和横向扩展, 且横向裂纹长度基本一致。试验发现, L-T及T-L方向均出现裂纹分叉, 取向对两种超高强合金的裂纹扩展形貌影响较小。

2.3 光学显微镜分析

图4为30Cr Mn Si Ni2A试样断口表面腐蚀产物后的微观形貌。图4 (b) , (c) , (d) 分别为裂纹扩展前期, 中期及后期裂纹尖端形貌。从图4可以看出, 裂纹微观上为非直线扩展, 裂纹扩展前期受机械作用明显, 而中期在应力及腐蚀作用下, 出现分叉 (图4 (c) ) 。如图4 (d) 所示, 至裂纹扩展后期, 裂纹尖端存在明显的间断裂纹。

2.4 扫描电镜形貌分析

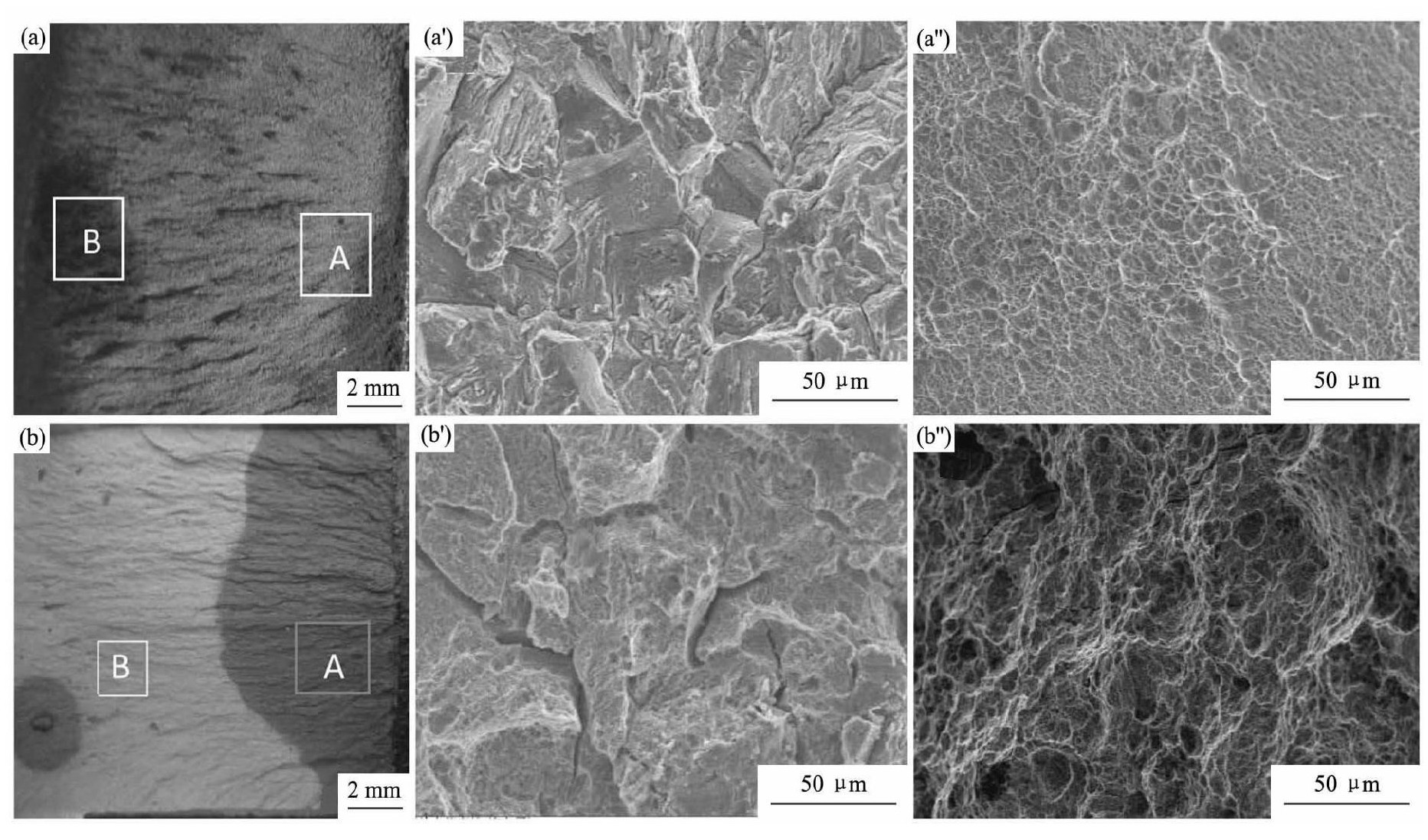

清除断口腐蚀产物后, 采用扫描电镜对断口进行观察。图5为30Cr Mn Si Ni2A (图5 (a) ) 和40Cr Ni2Si2Mo VA (图5 (b) ) 试样断口去除表面腐蚀产物后的微观形貌。从图5可以看出, 尽管形貌存在明显的差异, 但是两种超高强度合金的断口形式趋于一致, 均为前期的解理和穿晶断裂及后期的沿晶断裂。这主要是因为裂纹前期应力较大, 试样出现穿晶脆性断裂形貌, 而中后期应力和腐蚀共同作用下出现沿晶扩展形貌[10,11,12]。

图2 两种超高强合金裂纹不同应力腐蚀时间后表面形貌Fig.2 Crack paths after different testing time in SCC of two ultra-high strength alloys

(a) 30Cr Mn Si Ni2A alloy; (b) 40Cr Ni2Si2Mo V alloy

图3 两种超高强合金不同取向裂纹扩展表面形貌Fig.3Crack paths for different orientations of two ultra-high strength alloys

(a) 30Cr Mn Si Ni2A alloy L-T; (b) 30Cr Mn Si Ni2A alloy T-L; (c) 40Cr Ni2Si2Mo VA alloy, L-T; (d) 40Cr Ni2Si2Mo VA alloy, T-L

图4 裂纹扩展不同位置微观形貌 ( (b) , (c) , (d) 分别为 (a) 中区域B, C, D的放大图) Fig.4 Surface morphologies after different testing time of two ultra-high strength alloys ( (b) , (c) , (d) being magnifications of re-gion B, C, D in (a) , respectively)

图5 两种超高强合金断口SEM形貌Fig.5 SEM images in SCC of two ultra-high strength alloys

(a) 30Cr Mn Si Ni2A alloy; (b) 40Cr Ni2Si2Mo VA alloy, (a') , (a″) , (b') (b″) being magnifications of corresponding region A, Bin (a) and (b) , respectively

3 结论

1.40Cr Ni2Si2Mo VA比30Cr Mn Si Ni2A断裂失效时间更长, 具有更好的耐应力腐蚀性能。

2.40Cr Ni2Si2Mo VA和30Cr Mn Si Ni2A在Na Cl溶液中均出现裂纹横向扩展, 并分叉, 不同取向试样对材料应力腐蚀开裂行为的影响较小。

3.40Cr Ni2Si2Mo VA和30Cr Mn Si Ni2A在应力和腐蚀介质的共同作用下均发生失效, 裂纹扩展前期断口为解理和穿晶形貌, 而裂纹扩展中后期为沿晶形貌。

参考文献

[1] Jiang J J, Lin Z Y, Feng M L, Meng X Q, Cai X J, Liu F.Experimental study on temperature influence to fracture toughness of Cr5 cold roll steel[J].Forging&Stamping Technology, 2012, 37 (4) :135. (姜晶晶, 林卓英, 冯淼林, 孟祥琦, 蔡晓静, 刘飞.温度对Cr5冷轧辊钢断裂韧度影响的试验研究[J].锻压技术, 2012, 37 (4) :135.)

[2] Liu M T, Liu J H, Zhong P.Review of stress corrosion properties of ultra-high strength steels[J].Technology Review, 2010, 28 (9) :112. (柳木桐, 刘建华, 钟平.超高强度钢耐腐蚀性能研究进展[J].科技导报, 2010, 28 (9) :112.)

[3] Yu M, Qi J Y, Liu J H, Li S M.Corrosion behavior of23Co14Ni12Cr3 steel in simulated seawater environment[A].The 7th Cross-Strait Seminar of Materials Corrosion and Protection[C].2010.6. (于美, 祁晋豫, 刘建华, 李松梅.23Co14Ni12Cr3钢在模拟海洋环境中的腐蚀行为研究[A].第七届海峡两岸材料腐蚀与防护研讨会[C].2010.6.)

[4] Liu K P, Jiang R P, Dun X L, Xu J Q, Wang W, Liu H S.Influence of multiple modifier containing rare earths and low melting-point alloy on microstructure and mechanical properties of ultra-high carbon steel[J].Chinese Journal of Rare Metals, 2011, 35 (1) :47. (刘坤鹏, 姜荣票, 敦小龙, 徐建秋, 王伟, 刘华山.稀土-低熔点合金复合变质处理对超高碳钢微观组织及力学性能的影响[J].稀有金属, 2011, 35 (1) :47.)

[5] Li H, Sun J L, Zhou S Q, Zhang P C.Element diffusion of Be/HR-1 stainless steel near diffusion bonding interface[J].Chinese Journal of Rare Metals, 2012, 36 (3) :329. (李辉, 孙纪兰, 周上祺, 张鹏程.Be/HR-1不锈钢扩散连接界面附近的元素扩展[J].稀有金属.2012, 36 (3) :329.)

[6] Aranfin M A, Szpunar J A.A new understanding of intergranular stress corrosion cracking resistance of pipeline steel through grain boundary character and crystallographic texture studies[J].Corrosion Science, 2009, 51 (1) :119.

[7] Lu B T, Song F, Gao M, Elboujdaini M.Crack growth model for pipelines exposed to concentrated carbonate-bicarbonate solution with high pH[J].Corrosion Science, 2010, 52 (1) :4064.

[8] Xiao Y Z, Jin S.The effect of applied potential on corrosion cracking of 40CrNi2Si2MoVA steel[J].Acta Aeronautica Et Astronautica Sinica 1993, 14 (9) :503. (肖亚洲, 金石.加外极化对40CrNi2Si2MoVA钢腐蚀断裂特性的影响[J].航空学报, 1993, 14 (9) :503.)

[9] Eliaz N, Shachar A, Tal B, Eliezer D.Characteristics of hydrogen embrittlement, stress corrosion cracking and tempered martensite embrittlement in high-strength steels[J].Engineering Failure Analysis, 2002, 9 (2) :167.

[10] Liu D X, Jin S, He J W.Stress corrosion cracking of ultra-high strength steel 300 M[J].Special Steel, 1997, 18 (6) :20. (刘道新, 金石, 何家文.300 M超高强度钢的应力腐蚀开裂[J].特殊钢, 1997, 18 (6) :20.)

[11] Liu D X, Jin S, He J W, Huang S J.The stress corrosion cracking behavior and mechanism of coated ultrahigh strength steel 300 M[J].Journal of Xi'an Jiaotong University, 1998, (6) :51. (刘道新, 金石, 何家文, 黄淑菊.带镀层300 M超高强度钢的应力腐蚀行为与机理研究[J].西安交通大学学报, 1998, (6) :51.)

[12] Graca M L A, Hoo C Y, Sillva O M, Lourenco N J.Failure analysis of a 300 M steel pressure vessel[J].Engineering Failure Analysis, 2009, 16 (1) :182.

[13] Yu M, Qi J Y, Liu J H, Li S M, Sun Y J.Corrosion behaviors of ultra-high strength steel 40CrNi2Si2MoVA in submerged zone of simulated seawater[J].Corrosion&Protection, 2011, 32 (10) :779. (于美, 祁晋豫, 刘建华, 李松梅, 孙玉静.40CrNi2Si2MoVA超高强钢在模拟海水全浸区的腐蚀行为研究[J].腐蚀与防护, 2011, 32 (10) :779.)

[14] Liu J H, Tian S, Li S M, Yu M.Stress corrosion crack of new ultrahigh strength steel[J].Acta Aeronautica Et Astronautica Sinica, 2011, 32 (6) :1164. (刘建华, 田帅, 李松梅, 于美.新型超高强钢应力腐蚀开裂行为研究[J].航空学报, 2011, 32 (6) :1164.)

[15] Zhen F, Liu J, Jia J, Cheng J H, Xu J Q, Guo B.Influence of Mo and B contents on microstructure and mechanical properties of HSLA steels[J].Journal of Wuhan University of Science and Technology, 2010, 33 (1) :53. (镇凡, 刘静, 贾娟, 程吉浩, 徐进桥, 郭斌.Mo, B对低合金高强钢组织和性能的影响[J].武汉科技大学学报, 2010, 33 (1) :53.)

[16] Luo Y Z.Technical progress in development of high strength stainless steel resistant to seawater corrosion[J].Development and Application of Materials, 1998, 13 (1) :1. (罗永赞.高强耐海水腐蚀不锈钢研制技术进展[J].材料开发与应用, 1998, 13 (1) :1.)

[17] Li H P.Seawater corrosion enduring stainless steels[J].China Molybdenum Industry, 2003, 5 (1) :32. (李惠萍.耐海水腐蚀的不锈钢[J].中国钼业, 2003, 5 (1) :32.)

[18] Tang J H.Technology and Property Investigations of400~500 MPa Atmosphere Corrosion Enduring Steel[D].Kunming:Kunming University Science and Technology, 2007.13. (唐建伟.400~500 MPa耐大气腐蚀钢工艺及性能研究[D].昆明:昆明理工大学, 2007.13.)

[19] Shi W.Study on the Microstructure and Properties of Low Carbon Low Silicon TRIP Steel Containing Vanadium[D].Shanghai:Shanghai University, 2006.1. (史文.含钒低碳低硅相变诱发塑性钢的组织和性能的研究[D].上海:上海大学, 2006.1.)