应变速率对1050工业纯铝组织演变及热稳定性的影响

来源期刊:中国有色金属学报(英文版)2018年第1期

论文作者:杨扬 王君良 陈亚东 胡海波

文章页码:1 - 8

关键词:应变速率;热稳定性;连续再结晶;1050工业纯铝

Key words:strain rate; thermal stability; continuous recrystallization; 1050 commercial pure aluminum

摘 要:采用分离式Hopkinson压杆和Instron-3369力学试验机对1050工业纯铝进行动态和准静态单向压缩实验,随后变形试样在423~523 K(150~250 °C)保温1 h。透射电子显微镜(TEM)观察表明,动态/准静态单向加载后均获得了拉长片层状组织,并且应变速率越高,变形组织中位错密度越高。在423~523 K范围内,准静态加载试样结构更为稳定,晶粒没有显著长大。但是,经523 K (250 °C)、1 h退火后,动态加载试样变形组织已经被完全再结晶组织取代,平均晶粒尺寸急剧增大至4.7 μm。结果表明,准静态加载试样退火过程中的组织演变机制为传统的非连续再结晶机制,而动态加载试样退火组织演变行为为晶粒连续粗化过程,即连续再结晶。

Abstract: Effects of strain rate on the microstructure evolution and thermal stability of 1050 commercial pure aluminum processed by means of split Hopkinson pressure bar (SHPB) and Instron-3369 mechanical testing machine were investigated. Samples in the deformed state and after various annealing treatments at 423-523 K (150-250 °C) for 1 h were characterized by TEM and hardness test. The result reveals that the samples in the deformed state were mainly composed of elongated subgrains/cells with high density of dislocations. Microstructures of the quasi-static compressed aluminum were quite stable throughout the temperature range studied, and no significant grain growth was observed. However, for the dynamic impacted one, recrystallized grains with an average grain size of 4.7 μm were evolved after annealing at 523 K (250 °C) for 1 h. It is suggested that the annealing behavior of this dynamic deformed aluminum is a continuous process of grain coarsening, rather than the traditional discontinuous recrystallization for the quasi-static compressed aluminum.

Trans. Nonferrous Met. Soc. China 28(2018) 1-8

Yang YANG1,2,3, Jun-liang WANG1, Ya-dong CHEN1, Hai-bo HU2

1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Institute of Fluid Physics, China Academy of Engineering Physics, Mianyang 621900, China;

3. Key Laboratory of Ministry of Education for Nonferrous Metal Materials Science and Engineering, Central South University, Changsha 410083, China

Received 31 October 2016; accepted 21 June 2017

Abstract: Effects of strain rate on the microstructure evolution and thermal stability of 1050 commercial pure aluminum processed by means of split Hopkinson pressure bar (SHPB) and Instron-3369 mechanical testing machine were investigated. Samples in the deformed state and after various annealing treatments at 423-523 K (150-250 °C) for 1 h were characterized by TEM and hardness test. The result reveals that the samples in the deformed state were mainly composed of elongated subgrains/cells with high density of dislocations. Microstructures of the quasi-static compressed aluminum were quite stable throughout the temperature range studied, and no significant grain growth was observed. However, for the dynamic impacted one, recrystallized grains with an average grain size of 4.7 μm were evolved after annealing at 523 K (250 °C) for 1 h. It is suggested that the annealing behavior of this dynamic deformed aluminum is a continuous process of grain coarsening, rather than the traditional discontinuous recrystallization for the quasi-static compressed aluminum.

Key words: strain rate; thermal stability; continuous recrystallization; 1050 commercial pure aluminum

1 Introduction

Various severe plastic deformation (SPD) techniques have been developed to prepare bulk ultrafine grain (UFG) metallic materials. This UFG metallic materials exhibit extremely high strength but limited ductility [1-4]. However, the resultant grain sizes obtained by SPD are usually in the submicron scale. Further reduction of grain sizes needs some special plastic deformation techniques, such as dynamic plastic deformation (DPD) [5] and plastic deformation at liquid nitrogen temperature [6].

For pure aluminum, a high stacking fault energy (SFE) metal, plastic deformation is accommodated by dislocation slip and the refined grain/cell size is mainly determined by dislocation density (Dc=kρ-1/2) [7]. Plastic strain, strain rate and deformation approach have pronounced effects on dislocation density through the competition between the dislocation generation and the annihilation. Plenty of researches were carried out about the effect of plastic strain and deformation approach on the microstructure evolution of deformed aluminum and aluminum alloys at low strain rates [8-10], but relatively few researches have been done on the microstructure evolution [11-13] of aluminum subjected to DPD.

UFG metallic materials produced by DPD contain a large amount of dislocations and nonequilibrium dislocation configurations, which will inevitably reduce thermal stability of materials [14-17]. That is to say, such microstructures can be easily changed by recovery and recrystallization during annealing. Microstructural coarsening will certainly weaken the strength and hardness of materials, which is bad for their engineering application. In addition, the differentiation of microstructural morphology depending on the deformation approach and processing parameters will affect the mechanism of microstructure evolution on subsequent annealing treatment in turn. For example, JAZAERI and HUMPHREYS [18] and OSCARSSON et al [19] found a transition from discontinuous to continuous recrystallization with increasing rolling reduction for some aluminum alloys during annealing. However, the research on the effects of strain rate on the thermal stability of the work is rare. Therefore, it is essential to clarify the coincident influences of annealing treatment on microstructures, along with reducing the instabilities.

In this work, 1050 commercial pure aluminum was subjected to plastic deformation with different strain rates. Samples in the deformed state were given a standard isochronal heat treatment for 1h in the temperature range of 423-523 K (150-250 °C). Effects of strain rate on microstructure evolution and thermal stability of 1050 commercial pure aluminum were investigated.

2 Experimental

1050 commercial pure aluminum (0.25%Si, 0.05% Mn, 0.05% Cu, 0.05% Mg, 0.05% Zn, 0.05% Ti, ≤0.4% Fe, the balance Al, in mass fraction) was annealed at 673 K (400 °C) for 3 h in a salt-bath furnace to diminish the effect of residual stress and obtain homogeneous coarse grains. Average grain size of these as-annealed samples is about 46 μm. Two cylindrical samples (d5 mm × 23 mm) were prepared for dynamic uni-directional impact and quasi-static uni-directional compression, respectively.

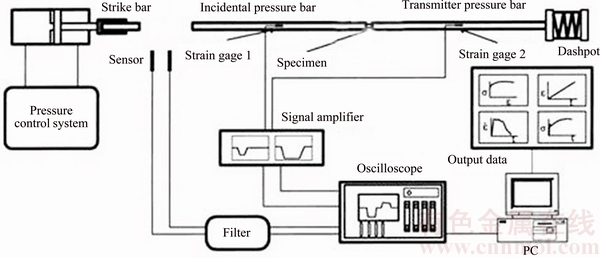

Dynamic impacted sample was deformed by split Hopkinson pressure bar (SHPB) with a strain rate up to 2.8×103 s-1. Figure 1 shows the schematic diagram of SHPB [5] and quasi-static compression was performed by an Instron-3369 mechanics testing machine with a strain rate of 1×10-3 s-1. The deformation strain obtained during each pass is defined as ε=ln(h0/hf), where h0 and hfare the initial and final height of sample in each pass. The total strain is the sum of strains during each pass. Cylindrical samples were subjected to uni-directional impact (by SHPB)/compression (by Instron). A reduction about 5 mm was achieved per pass until to the height of 3.8 mm, corresponding to an equivalent strain of 1.8. Petroleum jelly was applied on the surface between the test rig and the sample to reduce friction . Each sample was tested four times. The as-deformed samples were isochronally annealed from 423 K (150 °C) to 523 K (250 °C) for 1 h and then air-cooled to room temperature.

Samples in the deformed and annealed state were analyzed by using a Tecnai G2 20 ST transmission electron microscopy (TEM) operated in bright field mode at 200 kV. Thin foils for TEM observations were prepared by mechanical grinding to a thickness of 60-80 μm, and then electrochemical polishing at 253 K (-20 °C) with a Struers Tenupol-5 double jet electro- chemical machine in a 300 mL HNO3 + 700 mL CH3OH solution at a voltage of 20 V.

Microhardness measurements were carried out on a HV-10B Vickers hardness testing machine with a load of 3 kg and a loading time of 15 s. The hardness values were the average of 10 indents at least for each sample.

3 Results and analysis

3.1 Stress-strain response

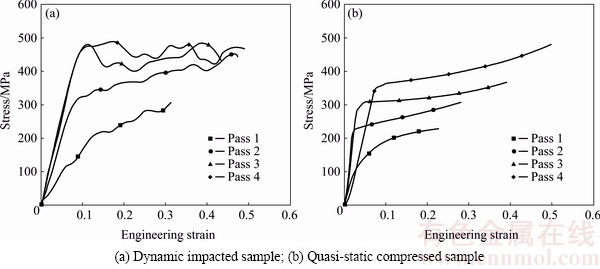

Stress-strain relationships are shown in Fig. 2, where (a) and (b) are the σ-ε curves of dynamic impacted sample and quasi-static compressed sample, respectively. As can be seen in Fig. 2, stress increases with strain in the initial stages of deformation, indicating apparent effects of work hardening. The flow stress of dynamic impacted sample keeps in a steady state after 3 passes, indicting a dynamic equilibrium between strain hardening and strain softening due to the formation of new subgrains/cells and the associated interactions between dislocations. However, Fig. 2(b) shows that the flow stress of quasi-static compressed sample increases with strain all the way. The limited strain hardening ability of DPD sample is mainly caused by the decrease of grain size, which leads to the lower activation volume for the dislocation motion. In addition, the oscillations of waves are caused by “dispersion” effect when waves spread in Hopkins bar [20]. A adiabatic temperature rise could be expected during DPD. It is generally acknowledged that 90% plastic deformation work is converted into heat. Thus, the adiabatic temperature rise could be estimated by Eq. (1):

(1)

(1)

where cV represents heat capacity, ρAl is the density for Al and  is the deformation work which is the area of σ-ε curve with the horizontal axis. It turns out that the △Tmax≈80 K could be ignored.

is the deformation work which is the area of σ-ε curve with the horizontal axis. It turns out that the △Tmax≈80 K could be ignored.

Fig. 1 Schematic diagram of split Hopkinson pressure bar (SHPB) [5]

Fig. 2 Engineering stress-strain cures of deformed samples

3.2 Microstructural characterizations of deformed sample

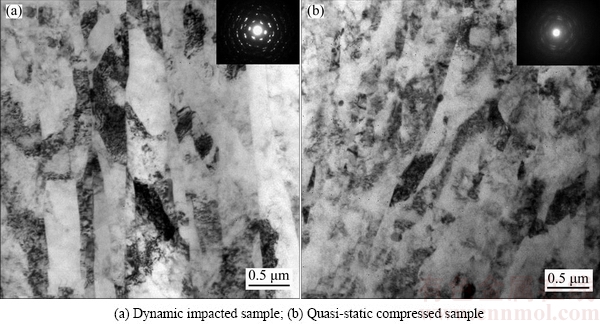

Figure 3 shows representative microstructures and the corresponding selected area electron diffraction patterns observed from the longitudinal section of the deformed samples. The majority of the microstructures was characterized by elongated subgrains and dislocation cells. The elongated ring-like diffraction patterns indicate that the initial coarse grains are refined significantly, and some special deformation textures have evolved. Most of the elongated subgrains in the dynamic impacted sample possess a regular shape with distinct and straight boundaries as well as a very high interior dislocation density (Fig. 3(a)), which is a result of shear localization in dynamic deformation of aluminum. However, for the quasi-static compressed sample, most of boundaries are blurred consisting of a high density of dislocation, and the grains are nearly free of dislocations interior (Fig. 3(b)). Hence, the dislocation nucleation mechanisms of the two samples are different depending on various strain rates.

It is well known that the dislocation nucleation mechanism in the process of quasi-static plastic deformation can be explained by the Frank-Read source model, while for deformation at extremely high strain rate, the homogeneous dislocation nucleation mechanism proposed by MEYERS [21] is applicable.

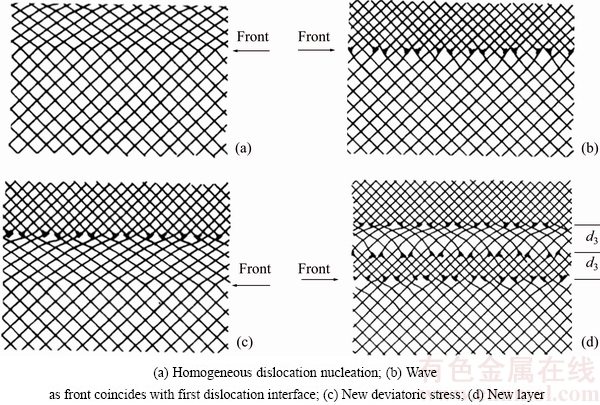

Figure 4 shows the progress of shock front according to homogeneous nucleation model. During DPD processed at high strain rate, stress propagates along the loading direction in the form of wave. As the shock wave penetrates into the material, high deviatoric stresses effectively distort the initially cubic lattice into a monoclinic lattice. When these stresses reach a certain threshold level, homogeneous dislocation nucleation can take place (Fig. 4(a)). Figure 4(b) shows the wave as the front coincides with the first dislocation interface. The density of dislocations at the interface depends on the difference in specific volume between the two lattices and can be calculated therefrom. In Fig. 4(c), the front has moved ahead of the interface and the deviatoric stresses build up again, other layers are formed in Fig. 4(d) [21]. Thus, samples subjected to DPD are characterized by uniformly distributed interior dislocation and a very high interior dislocation density.

Width and length of subgrains/cells were determined as the average length along a line perpendicular and parallel to the trace of lamellar boundaries. The average subgrain/cell sizes measured from at least 150 subgrains/cells are 293 nm and 694 nm for the dynamic impacted sample, and 400 nm and 600 nm for the quasi-static compressed samples, respectively. Obviously, with the increase of strain rate, finer subgrains/cells are formed.

The dominate deformation mechanism of aluminum is dislocation slip. Evolution of microstructure is performed by the generation, movement, rearrangement and annihilation of dislocations. Equation (2) gives the shear strain rate [22]:

(2)

(2)

where  is the shear strain rate, ρd is the average density of mobile dislocation per unit volume, υ is the dislocation velocity and b is the absolute value of the Burgers vector. During DPD, the extremely high strain rate is beneficial to the generation of dislocations, while the rearrangement and annihilation of dislocations are restricted and the average free path of mobile dislocation is limited, which results in a high density of dislocations and various dislocation configurations. So, the dynamic impacted microstructure is finer when compared with the quasi-static compressed one.

is the shear strain rate, ρd is the average density of mobile dislocation per unit volume, υ is the dislocation velocity and b is the absolute value of the Burgers vector. During DPD, the extremely high strain rate is beneficial to the generation of dislocations, while the rearrangement and annihilation of dislocations are restricted and the average free path of mobile dislocation is limited, which results in a high density of dislocations and various dislocation configurations. So, the dynamic impacted microstructure is finer when compared with the quasi-static compressed one.

Fig. 3 TEM micrographs and corresponding selected area electron diffraction patterns observed from longitudinal section of deformed samples

Fig. 4 Progress of shock front according to homogeneous nucleation model [21]

3.3 Microstructural characterizations and evolution mechanisms of annealed samples

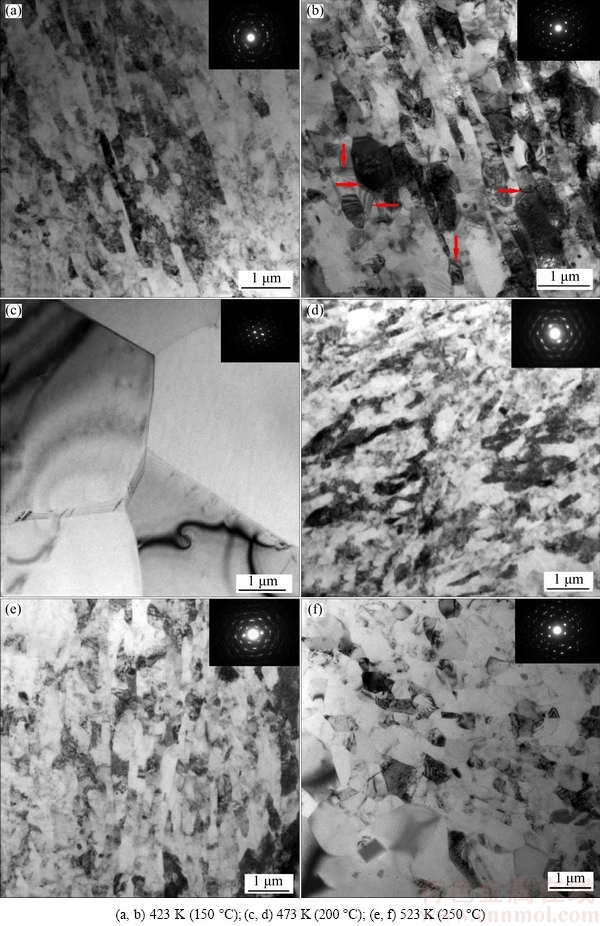

Isochronal annealing treatments for 1 h with increasing temperature lead to softening, microstructural coarsening and a change in the crystallographic morphology. A transition from continuous to discontinuous diffraction spots in the associated selected area electron diffraction patterns (see Fig. 5) confirms the progress of microstructural coarsening with the increasing annealing temperature. Figure 5 shows microstructures of the deformed samples after annealing at different temperatures for 1h. Microstructures of the samples annealed at 423 K (150 °C) are quite similar to those seen in the as-deformed state in Fig. 3, and no obvious microstructure change can be observed. After annealing at 473 K (200 °C) for 1h, the arrangement of dislocations results in formation of subgrains, but there is a significant difference in subgrain shape, subgrain size and dislocation distribution. Most of the subgrains of dynamic impacted sample are pancake-shaped and consist of large amounts of dislocations interior (Fig. 5(b)). However, the subgrains of quasi-static compressed sample are irregular and nearly free of dislocations interior (Fig. 5(e)). In addition, it is interesting to note that some subgrains in dynamic impacted sample are surrounded by the moire fringes (see Fig. 5(b)), which show a rather regular pattern and the dislocation density at the grain boundaries is not high. In the case of annealing at 523 K (250 °C) for 1 h, the microstructural features drastically change, a significant microstructural coarsening and equiaxed grains evolve (Figs. 5(c) and 5(f)). However, annealed microstructure of quasi-static compressed sample is heterogeneous, there are still some substructures (mainly dislocation cell blocks) exist, as shown in Fig. 5(f).

Fig. 5 Representative microstructures of deformed samples after annealing at different temperatures for 1 h

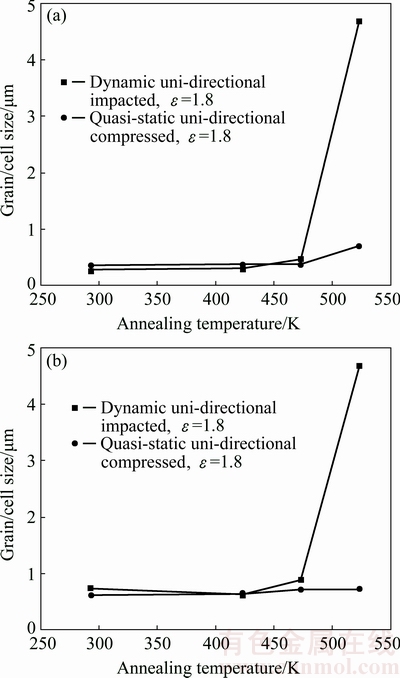

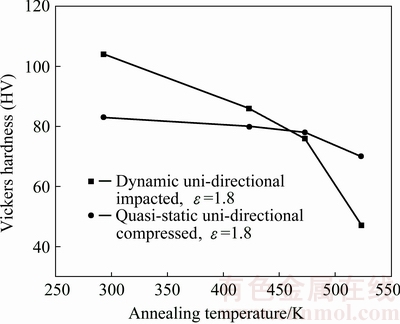

The average gain/cell sizes and hardness as a function of annealing temperature are illustrated in Figs. 6 and 7, respectively. Figure 6 shows that there is a radically structural coarsening for the dynamic impacted sample above 473 K (200 °C), being about 4.7 μm at 523 K (250 °C). Whereas only a slight grain growth for the quasi-static compressed samples is observed throughout the temperature range studied. With the increase of annealing temperature in the range below 473 K (200 °C), the hardness decreases gradually. However, a dramatic reduction occurs above 473 K (200 °C). It is noted that the rate of decrease in hardness of the dynamic impacted sample is considerably more rapid than that of the quasi-static compressed sample, as can be seen in Fig. 7. Thus, microstructural thermal stability of these dynamic impacted samples is relatively poor above 473 K (200 °C).

Fig. 6 Variations of transverse grain/cell size (a) and longitudinal grain/cell size (b) at different annealing temperatures for dynamic uni-directional impacted sample and quasi-static uni-directional compressed sample, respectively

Fig. 7 Vickers hardness of deformed samples as function of annealing temperature

Stored energy (Es) will increase as the dislocation density increases according to Eq. (3) [23] as follows:

Es=KρdGb2 (3)

where K is a constant, and G is the shear modulus. Higher density of dislocations produced in the process of dynamic impact means higher stored energy and more nonequilibrium dislocation configurations, which will inevitably provide more driving force for grain growth, and further cause significantly microstructural coarsening on subsequent annealing treatment.

Various structural features of the deformed samples contribute to the different microstructure evolution mechanisms during annealing. YU et al [2], JAZAERI and HUMPHREYS [18] and OSCARSSON et al [19] found that annealing treatment of cold rolled aluminum alloys could led to a possible change from conventional (discontinuous) recrystallization at low-to-medium strains to extended recovery or continuous recrystallization at very large strains. Our present investigation shows that increasing in strain rate could lead to a similar change. Annealing behavior of these quasi-static compressed samples is the traditional recovery and recrystallization, or discontinuous recrystallization (see Figs. 5(d-f)). However, the initial structure of dynamic impacted sample which consists of elongated grains was subdivided into pancake-shaped subgrains by the collapse of the lamellar microstructure at 473 K (200 °C), then a dramatic microstructural coarsening is observed at 523 K (250 °C), as shown in Figs. 5(b) and (c). This transformation consists with the mechanism of continuous recovery, which is thought to involve the collapse of elongate grains and subsequent coarsening of the lamellar grain structures [18]. In addition, the hardness after being treated at 523 K (250 °C) for 1 h (HV 47) is far from the hardness of a fully recrystallized Al 1050 (HV 20). Therefore, annealing behavior of this dynamic impacted aluminum is better considered as a continuous process of grain coarsening or continuous recovery.

4 Conclusions

1) Flow stress of dynamic impacted sample keeps in a stable range after three passes, indicting a dynamic equilibrium between generation and annihilation of strain-induced dislocation. However, the flow of quasi-static compressed sample increases with strain all the way, therefore, it is expected that the dynamic impacted sample displays better plasticity.

2) Microstructures of these uni-directional compressed samples are heterogeneous and most grains are elongated with a high density of dislocation. The homogeneous dislocation nucleation mechanism during DPD results in a higher density of dislocations and forming finer grains/cells.

3) Microstructures of these quasi-static compressed samples are quite stable at 523 K (250 °C) and no obvious grain growth is observed. However, the dynamic impacted sample is fully recrystallized with an average grain size of 4.7 μm after annealing at 523 K (250 °C) for 1 h. Obviously, microstructural thermal stability of this dynamic impacted pure aluminum gets worse due to higher density of dislocations (i.e. stored energy) and nonequilibrium dislocation configurations introduced by the homogeneous dislocation nucleation mechanism at high strain rate.

4) Annealing behavior of these dynamic impacted samples is better considered as a continuous process of grain coarsening or continuous recovery, rather the traditional recovery and recrystallization (or discontinuous recrystallization) for the quasi-static compressed samples.

References

[1] TSUJI N, ITO Y, SAITO Y, MINAMINO Y. Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing [J]. Scripta Materialia, 2002, 47: 893-899.

[2] YU C Y, SUN P Y, KAO P W, CHANG C P. Evolution of microstructure during annealing of a severely deformed aluminum [J]. Materials Science and Engineering A, 2004, 366: 310-317.

[3] MAY J, HOPPEL H W, GOKEN M. Strain rate sensitivity of ultrafine-grained aluminum processed by severe plastic deformation [J]. Scripta Materialia, 2005, 53: 189-194.

[4] HANSEN N, HUANG X, MOLLER M G, GODFREY A. Thermal stability of aluminum cold rolled to large strain [J]. Journal of Materials Science, 2008, 43: 6254-6259.

[5] YANG Yang, MA Fei, HU Hai-bo ,ZHANG Qing-ming, ZHANG Xiao-wei. Microstructure evolution of 2195 Al-Li alloy subjected to high-strain-rate deformation[J] .Materials Science and Engineering A, 2014, 606: 299-303.

[6] ZHAO W S, TAO N R, GUO J Y, LU Q H, LU K. High density nano-scale twins in Cu induced by dynamic plastic deformation [J]. Script Materialia, 2005, 53(6): 74-749.

[7] HOLT, DAVID L. Dislocation cell formation in metals [J]. Journal of Applied Physics, 1970, 41(8): 3197-3201.

[8] ORLOV D, TODAKA Y, UMEMOTO M, TSUJI N. Role of strain reversal in grain refinement by severe plastic deformation [J]. Materials Science and Engineering A,2009, 499: 427-433.

[9] RAO P N, SINGH D, JAYAGANTHAN R. Mechanical properties and microstructural evolution of Al 6061 alloy processed by multidirectional forging at liquid nitrogen temperature [J]. Materials and Design, 2014, 56: 97-104.

[10] HUANG F, TAO N R, LU K. Effects of strain rate and deformation temperature on microstructures and hardness in plastically deformed pure aluminum [J]. Journal of Materials Science and Technology, 2011, 27: 1-7.

[11] YANG Yang, CHEN Ya-dong, HU Hai-bo, TANG Tie-gang, LONG Ren-rong, ZHANG Qing-ming. Microstructural evolution and thermal stability of 1050 commercial pure aluminum processed by high-strain-rate deformation[J]. Journal of Materials Research, 2015, 30(22): 3502-3509

[12] YANG Yang, CHEN Ya-dong, MA Fei, HU Hai-bo, TANG Tie-gang, ZHANG Qing-ming, ZHANG Xiao-wei. Microstructure evolution of 1050 commercial purity aluminum processed by high-strain-rate deformation [J]. Journal of Materials Engineering and Performance, 2015, 24: 4307-4312.

[13] YANG Yang, ZHANG Hua, CHEN Ya-dong. Effects of dynamic multi-directional loading on the microstructural evolution and thermal stability of pure aluminum [J]. Journal of Materials Engineering and Performance, 2016, 25(9): 3924-3930.

[14] SABIROV I, MURAHKIN M Y, VALIEV R Z. Nanostructured aluminum alloys produced by severe plastic deformation: New horizons in development [J]. Materials Science and Engineering A, 2013, 56: 1-24.

[15] KOCH C C. Optimization of strength and ductility in nanocrystalline and ultrafine grained metals [J]. Scripta Materialia, 2003, 49: 657-662.

[16] SHANKER M R, CHANDRASEKAR S, KING A H, COMPTON W D. Microstructure and stability of nanocrystalline aluminum 6061 created by large strain machining [J]. Acta Materialia, 2005, 53: 4781-4793.

[17] KAPOOR R,KUMAR N, MISHRA R S, HUSKAMP C S, SAKARAN K K. Influence of fraction of high angle boundaries on the mechanical behavior of an ultrafine grained Al-Mg alloy [J]. Materials Science and Engineering A , 2010,527: 5246-5254.

[18] JAZAERI H, HUMPHREYS F J. The transition from discontinuous to continuous recrystallization in some aluminum alloys II—Annealing behavior [J]. Acta Materialia, 2004, 52: 3251-3262.

[19] OSCARSON A, HUTCHINSON B, EKSTROM H E. Transition from discontinuous to continuous recrystallization in strip-cast aluminum alloys [J]. Materials Science Forum, 1992, 113-115: 177-182.

[20] MEYERS M A, MISHR A, BENSON D J. Mechanical properties of nanocrystalline materials [J]. Progress in Materials Science, 2006, 51: 427-556.

[21] MEYERS M A. Dynamic behavior of materials [M]. New York: John Wiley & Sons, Inc, 1994.

[22] CAHN R W, HAASEN P. Physical metallurgy [M]. 4th ed. The Netherlands, North-Holland: Cambridge University Press,1996.

[23] GODFREY A, CAO W Q, HANSEN N, LIU Q. Stored energy, microstructure, and flow stress of deformed metals [J]. Metallurgical and Materials Transactions A, 2005, 36: 2371-2378.

杨 扬1,2,3,王君良1,陈亚东1,胡海波2

1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中国工程物理研究院 流体物理研究所,绵阳 621900;

3. 中南大学 有色金属科学与工程教育部重点实验室,长沙 410083

摘 要:采用分离式Hopkinson压杆和Instron-3369力学试验机对1050工业纯铝进行动态和准静态单向压缩实验,随后变形试样在423~523 K(150~250 °C)保温1 h。透射电子显微镜(TEM)观察表明,动态/准静态单向加载后均获得了拉长片层状组织,并且应变速率越高,变形组织中位错密度越高。在423~523 K范围内,准静态加载试样结构更为稳定,晶粒没有显著长大。但是,经523 K (250 °C)、1 h退火后,动态加载试样变形组织已经被完全再结晶组织取代,平均晶粒尺寸急剧增大至4.7 μm。结果表明,准静态加载试样退火过程中的组织演变机制为传统的非连续再结晶机制,而动态加载试样退火组织演变行为为晶粒连续粗化过程,即连续再结晶。

关键词:应变速率;热稳定性;连续再结晶;1050工业纯铝

(Edited by Xiang-qun LI)

Foundation item: Projects (51274245, 51574290, U1330126) supported by the National Natural Science Foundation of China; Project supported by the Opening Fund of State Key Laboratory of Nonlinear Mechanics, China

Corresponding author: Yang YANG; Tel: +86-15874219683; E-mail: yangyanggroup@163.com

DOI: 10.1016/S1003-6326(18)64632-1