J. Cent. South Univ. Technol. (2010) 17: 163-168

DOI: 10.1007/s11771-010-0026-2

Combination effect of seasonal freezing and artificial freezing on frost heave of silty clay

YU Lin-lin(于琳琳)1, XU Xue-yan(徐学燕)1, MA Chen(马琛)2

1. School of Civil Engineering, Harbin Institute of Technology, Harbin 150090, China;

2. College of Science, China Agricultural University, Beijing 100193, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract: To investigate the frost-heave properties of silty clay under the combination action of seasonal freezing and artificial freezing, and verify the feasibility of combined freezing, eight combined freezing experiments were performed on silty clay with water content (mass fraction) of 23.5% and 28.0%, through developed frost-heave test apparatus, in closed or open system. Two sorts of freezing temperature models, namely, constant and sine models, were applied to artificial freezing. The experimental results indicate that the frost-heave degree in seasonal freezing stage accounts for over 90% of the total in open system and it is up to 95% in closed system; the change of artificial sine-freezing temperature has no influence on the frost-heave degree in closed system, however, slight influence in open system. It is found that the variation of temperature gradient of sine-freezing specimen lags behind that of sine-freezing temperature with half phase; sine-freezing temperature model can reduce frost-heave degree of soil. Brand new technology is proposed for the application of artificial ground freezing and new study field of artificial freezing is created.

Key words: seasonal freezing; artificial freezing; combined freezing; sine-freezing; freezing-temperature models; frost-heave degree

1 Introduction

Seasonal freezing is the freezing of thaw soil with an annual average temperature above 0 ℃. Seasonally frozen layer is the soil layer undergoing seasonal freezing. In China, the seasonally frozen ground region is about 53% of the total land surface and the depth of seasonal freezing layer alters from several centimeters to several meters in North Area [1-4].

As a special construction technique, artificial ground freezing has notable advantages, by which soil can be frozen to form a coherent, closed waterproof curtain. So far, it has been applied in more and more geotechnical projects and civil constructions worldwide due to its high strength, good applicability, integrity for support and almost pollution-free [5-9]. In order to safely and effectively use artificial ground freezing, lots of researches have been carried out on artificial freezing and frost heave. YU et al [10] studied Poisson ratio for frozen soil and proposed the relationship between Poisson ratio and frost heave; AKAGAWA [11] and BIE et al [12] suggested that the variation of freezing temperature could control stationary frost heave of soil caused by artificial freezing; MATSUOKA et al [13] studied influencing factors of differential frost heave through field measurements and a laboratory experiment; HAN and GOODINGS [14] put forward a model of frost-heave prediction of soil, but only for clay soils; LACKNER et al [15] systematically researched viscoelastic behavior of fully saturated soil with artificial ground freezing; and HU et al [16] founded models of temperature field of artificial frozen soil based on freezing point. Currently, researchers only study artificial freezing or simply investigate seasonal freezing at home and aboard. However, the combination effect of artificial freezing and seasonal freezing has not been researched. Generally, construction with artificial ground freezing needs a great deal of power, especially cold energy, so the project cost will greatly increase. However, if it is used in the seasonally frozen ground regions, the cost will be cut down vastly, for the existence of frozen layer in cold season, whereas the relevant research has not been reported at home and abroad. It would be believed that the construction method will become a kind of new technology for geotechnical engineering and civil constructions worldwide. Therefore, the characteristics and laws of frost heave were creatively investigated, which is caused by the combined action of seasonal freezing and artificial freezing with the experiments on undisturbed silty clay. The results may provide some technical and theoretical references for the application of artificial ground freezing in the seasonally frozen ground regions; furthermore, the research field of artificial freezing and seasonal freezing will be widened and deepened.

2 Experimental

2.1 Materials

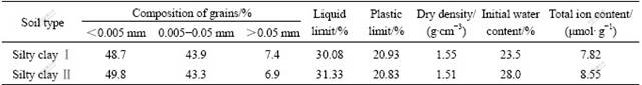

The experiments were carried out on silty clayⅠand silty clay Ⅱ from Harbin, in Northeast China. The physical properties of soil are listed in Table 1.

Table 1 Basic physical properties of silty clay

2.2 Preparation of specimens and experimental apparatus

Eight cylindrical specimens nominally with 100 mm in diameter and 120 mm in height were prepared by in-situ excavating, four of silty clayⅠand the others of silty clay Ⅱ.

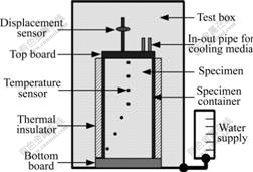

In terms of experimental requirements, a frost-heave test apparatus was developed, as shown in Fig.1. The following apparatuses were also applied in this work: advanced Type-ST5405 freeze-thaw-cycle device (±0.1 ℃) with three cooling parts, i.e., top board, bottom board and test box; DT615 data taking system; displacement sensor with a precision of ±0.001 mm to measure frost-heave degree; type-T thermocouples (±0.01 ℃); and water-supplying device. All the experimental data were collected continually by computer.

Fig.1 Sketch of experimental apparatus

2.3 Testing procedure

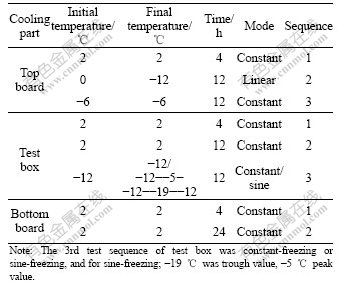

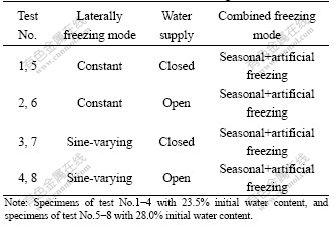

The test schedule is given in Table 2. Initial water contents for No.1-4 and No.5-8 are 23.5% and 28.0%, respectively. After being taken from pit, undisturbed silty clay block was cut into cylindrical specimen, and then put into the test cell made of synthetic glass. Teflon liners were used to prevent side friction between specimen and the test cell.

Table 2 Test procedures of controlling temperatures

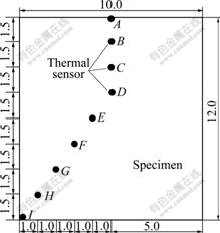

After that, type-T thermocouples were employed as thermal sensors distributed in specimen to determine temperature. From the top (12.0 cm) to 7.5 cm along height of specimen, thermal sensors were inset centrally every 1.5 cm to monitor the temperature field of seasonal freezing. From 7.5 cm to the bottom (0 cm), thermal sensors were placed every 1.0 cm along radial direction and every 1.5 cm along height to monitor that of artificial freezing, as shown in Fig.2.

Fig.2 Distribution of thermal sensors in specimen (Unit: cm)

To simulate seasonal freezing, after being kept for 4 h in a testing environment with a constant temperature of 1 ℃, specimen was placed into the frost-heave test apparatus to start seasonal freezing from the top downward with a linearly dropping temperature from 0 to -12 ℃ in 12 h. At the same time, the temperature of test box was 2 ℃ to form a seasonal frozen layer with 4.5 cm-thick in the upper of specimen. Then, the temperature of the top board was set to be -6 ℃ for 12 h to preserve the existence of the frozen layer. Following the above progress, for simulating the artificial freezing and the development of freezing front from the vertical surface to the center of specimen, temperature of the test box was set to be -12 ℃ for 12 h for constant freezing model, or it began to change as a sine with peak value of -5 ℃ (first arrival), valley point of -19 ℃ for a period of 12 h. Through the whole process, the temperature of bottom board was kept at 2 ℃. The test procedures of controlling temperatures of the three cooling parts are particularly listed in Table 2. The 3rd test sequence of test box was constant-freezing or sine-freezing. The testing conditions of specimens with or without water-supply are illustrated in Table 3.

Table 3 Test schedule for combined freezing

3 Results and discussion

3.1 Temperature fields of specimens in combined freezing process

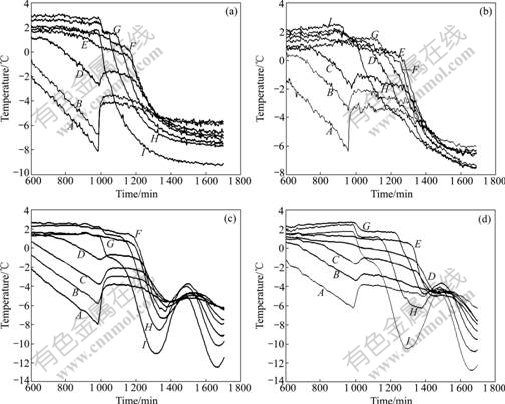

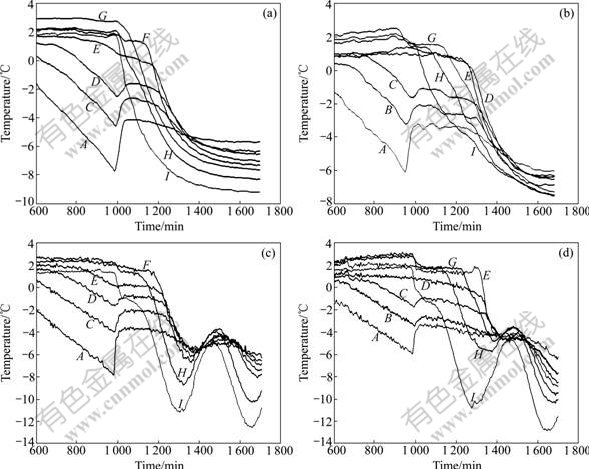

The relationships between temperature and time are shown in Figs.3 and 4. The numbers of temperature curves are the same as those of thermal sensors shown in Fig.2. From Figs.3 and 4, it can be seen that in the seasonal freezing process (600-960 min), the temperatures at the upper part of specimens (at A- 12.0 cm, B-10.5 cm, C-9.0 cm and D-7.5 cm) fell slowly, but under the same conditions, temperatures of specimens with water-supply are higher than those without water-supply. For instance, the lowest temperature of curve A is -8.1 ℃ in Fig.4(c), and it is -6.7 ℃ in Fig.4(d). After the seasonal freezing is conducted, the artificial freezing begins at 960 min. In the stage of 960-1 020 min the temperatures at the upper part of specimens increase fleetly, and then start to nonlinearly decrease with constant change or sine fluctuation of artificial freezing temperature. For the determined-points on A-vertical surface, at H-1 cm, G- 2 cm, F-3 cm, E-4 cm and D-5 cm along radius, their temperatures drop fleetly in 960-1 680 min, and nearly reach a stable value with artificial freezing mode of constant temperature, seen in Figs.3(c)-(d) and Figs.4(c)-(d), separately. However, in Figs.3(c)-(d) and Figs.4(c)-(d), separately, the temperatures fluctuate with sine law and the time lagged behind the sine change of the artificial freezing temperature.

Fig.3 Temperature curves of tests on specimens with 23.5% initial water content: (a) Test 1; (b) Test 2; (c) Test 3; (d) Test 4

Fig.4 Temperature curves of tests on specimens with 28.0% initial water content: (a) Test 5; (b) Test 6; (c) Test 7; (d) Test 8

As a result, all the temperature curves demonstrate that the influence of top board on the temperature field of specimen wears off from the top board downward along height, and under the same experimental conditions the tendencies of the curves are almost coherent for all the experiments with initial water contents of 23.5% and 28.0%.

Considering the whole relationship between temperature field and time, three eighths of specimens were frozen in the test stage of seasonal freezing (240-960 min), while seasonally frozen soil layer developed, so the specimen would be completely frozen as long as the remnant five eighths of specimens were frozen by artificial freezing. Therefore, a great mass of energy, especially electricity power, could be saved and construction time of artificial ground freezing could be shortened largely in the actively freezing stage and frozen-soil-preserved stage.

As shown in Figs.3(c)-(d) and Figs.4(c)-(d), separately, 960-1 680 min, it can be obtained that the variation of the temperature gradient of sine-freezing specimen lagged behind that of sine-freezing temperature by half phase position, i.e., when temperature of test points (thermal sensors) reached valley value (-19 ℃), the temperature gradient between two test points nearly arrived at its peak value, vice versa. Evidently, the influence of artificial freezing temperature on the temperature fields of specimens gradually lessened from vertical surface to the center of specimen because vertical surface was closer to the cold part than the center of specimen, and it took some time for cold energy to be transferred to the inside of specimen.

3.2 Frost heave under combined freezing

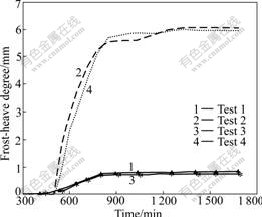

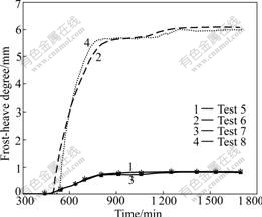

Figs.5 and 6 display the frost-heave characteristics caused by combined freezing. Firstly, for all the freezing experiments, frost heave occurred at about 300 min. In the seasonal freezing stage (300-960 min), the frost- heave degree mainly developed and accounted for 98% of the total frost-heave degree in closed system (seen from curves of 1 and 3 in Fig.5, curves of 1 and 3 in Fig.6, respectively), and over 90% in open system (seen from curves of 2 and 4 in Fig.5, curves of 2 and 4 in Fig.6, respectively), because most water migrated to the seasonally frozen zone and became segregating ice, leading to frost heave in the seasonal freezing stage. However, in the artificial freezing stage, there was less water supply, and not only the frozen soil that formed in the seasonally frozen zone had high strength, but also the bonding force was rather strong between grains and ice, so the development of the frost heave caused by artificial freezing was hindered. At the same time, the artificial freezing from the vertical surface of specimen toward the center made the cross section of water-supply smaller and smaller. Thus, for all experiments the frost-heave degree caused by artificial freezing was only 0.05 mm (in closed system)-0.52 mm (in opened system).

Fig.5 Frost-heave curves by combined freezing with 23.5% initial water content

Fig.6 Frost-heave curves by combined freezing with 28.0% initial water content

Secondly, according to the data of temperature and frost heave in open and closed systems, it can be concluded that the part, from the top board (12 cm) downward to 9 cm of specimen, was the mainly developing zone of frost heave. The segregating ice on specimen’s top grew well with fibroid and slight ice layers, some of which had an obvious thickness of more than 1 mm, as well as lots of ice grains. Because at the top board the slow falling process of cooling temperature (0--12℃ for 12 h) provided enough time for water migration to the seasonally frozen zone to form abundant segregating ice.

Thirdly, under the same experimental conditions, it is evident that the frost-heave degree caused by seasonal and artificial constant-temperature freezing had difference with that resulting from seasonal and artificial sine-varying-temperature freezing in open system; however, they were almost equal in closed system. Thirdly, it is apparently found that the frost-heave degree of specimen with 28.0% initial water content was higher than that with 23.5% initial water content under the same experimental conditions.

Finally, in 960-1 680 min, with the sine change of freezing temperature the frost-heave degree had slightly change in open system, but it did not change in closed system.

Based on the analyses mentioned above, the most significant conclusion that can be drawn is that if artificial ground freezing is applied in seasonally frozen area, which can not only save energy by using natural cold power, greatly decrease project cost and sharply shorten time limit for a project, but also greatly reduce the frost-heave degree caused by artificial ground freezing due to the existence of seasonally frozen layer, and the harmful influence of construction on surrounding buildings and structures.

4 Conclusions

(1) The frost-heave degree is mainly developed in the seasonal freezing stage for combined freezing, and it accounts for over 90% of the total frost-heave degree in the open system, 95% in closed system. Combined freezing has an active restraining effect on frost heave of soil.

(2) In the artificial freezing stage of combined freezing, sine-freezing temperature mode is creatively applied and the whole temperature field of specimen varies along with the sine changing of sine-freezing temperature. The experimental phenomenon that the variation of temperature gradient of sine-freezing specimen lags behind that of sine-freezing temperature by half phrase position is first discovered. The frost-heave degree of sine-temperature frozen specimen is smaller than that of constant-temperature frozen specimen; furthermore, artificial sine-freezing temperature mode has slight influence on frost-heave degree of specimen in open system, but has no influence on that in closed system.

(3) The feasibility of combined freezing is verified by the experimental results at home and abroad. It can be concluded that the frost-heave harm to buildings will be greatly reduced; plenty of electricity power will be saved and the freezing construction time will be sharply shortened if artificial ground freezing is applied in seasonally freezing area. It can be suggested that sine-freezing mode can decrease the frost-heave degree and make the frost heave caused by artificial freezing under well controlled. Combined freezing could be proposed as a new kind of constructing technology for artificial ground freezing, especially in the seasonally frozen ground regions; furthermore, a new research field of artificial freezing and seasonal freezing may have been exploited.

Acknowledgements

The authors would like to express especial their thanks to Professor LAI Yuan-ming for revising the paper and valuable advice.

References

[1] SIMONSEN E, JANOO V C, ISACSSON U. Resilient properties of unbound road materials during seasonal frost conditions [J]. Journal of Cold Regions Engineering, 2002, 16(1): 28-50.

[2] ZHANG Ming-yi, LAI Yuan-ming, LIU Zhi-qiang, GAO Zhi-hua. Nonlinear analysis for the cooling effect of Qinghai—Tibetan railway embankment with different structures in permafrost regions [J]. Cold Regions Science and Technology, 2005, 42(3): 237-249.

[3] LAI Yuan-ming, WANG Qiu-sheng, NIU Fu-jiu. Three-dimensional nonlinear analysis for temperature characteristic of ventilated embankment in permafrost regions [J]. Cold Regions Science and Technology, 2004, 38(2/3): 165-184.

[4] ZHOU You-wu, GUO Dong-xin, QIU Guo-qing. Geocryology in China [M]. Beijing: Science Press, 2000: 63-65. (in Chinese)

[5] YU Zhan-kui, HUANG Hong-wei, WANG Ru-lu, XU Ling, LI Wen-ting. Application of the artificially ground freezing method [J]. Journal of Glaciology and Geocryology, 2005, 27(4): 550-556. (in Chinese)

[6] CHENG Hua, YAO Zhi-shu, ZHANG Jing-shuang, RONG Chuan-xin. A model test study on the effect of freeze heaving and thaw subsidence for tunnel construction with artificial horizontal ground freezing [J]. China Civil Engineering Journal, 2007, 40(10): 80-85. (in Chinese)

[7] ALEXANDROV V N, FILONOVU A, MASLAK V A. Zone nitrogen freezing of technological boreholes in the Saint Petersburg metro (underground railway) [C]// TAUSCHER P, COLOMBO A. Proceedings of the AITES-ITA 2001 World Tunnel Congress. Milan, 2001: 13-20.

[8] HEIDKAMP H, KATZ C, HOFSTETTER C. Enlargement of the marienplatz metro station—A complex tunnel project beneath Munich City Hall [J]. The Structural Engineer, 2006, 84(3): 41-44.

[9] ANDERSLAND O, LADANYI B. Frozen ground engineering [M]. 2nd ed. New Jersey: John Wiley & Sons Inc, 2004: 1-5.

[10] YU Zhan-kui, ZHU Yuan-ling, HE Ping, ZHANG Jia-yi. Experimental study of Poisson ratio for frozen soil [C]// KELLER F, GARDAZ J M. Proceedings of the 7th International Conference on Permafrost. Yellowknife, 1998: 1185-1186.

[11] AKAGAWA S. A method for controlling stationary frost heaving [C]// THIMUS J F, BRAUN B. Proceedings of the 9th International Symposium on Ground Freezing and Frost Action in Soils. Louvain-la-Neuve, Belgium: A A Balkema Publishers, 2000: 63-68.

[12] BIE Xiao-yong, LIANG Heng-chang, HU Jing-li. Commentary on frost heave of artificially frozen soil and its control [J]. Journal of Lianyungang College of Chemical Technology, 2002, 15(1): 47-49. (in Chinese)

[13] MATSUOKA N, ABE M, IJIRI M. Differential frost heave and sorted patterned ground: Field measurements and a laboratory experiment [J]. Geomorphology, 2003, 52(1/2): 73-85.

[14] HAN S J, GOODINGS D J. Practical model of frost heave in clay [J]. Journal of Geotechnical and Geoenvironmental Engineering, 2006, 132(1): 92-101.

[15] LACKNER R, PICHLER C, KLOIBER A. Artificial ground freezing of fully saturated soil: Viscoelastic behavior [J]. Engineering Mechanics, 2008, 134(1): 1-11.

[16] HU Xiang-dong, HUANG Feng, BAI Nan. Models of artificial frozen temperature field considering soil freezing point [J]. Journal of China University of Mining & Technology, 2008, 37(4): 551-552. (in Chinese)

Foundation item: Project(40571032) supported by the National Natural Science Foundation of China; Project(2006G011-B-3) supported by Science Studies and Development Plan Foundation of Railway Ministry

Received date: 2009-02-12; Accepted date: 2009-06-19

Corresponding author: YU Lin-lin, PhD; Tel: +86-451-81778160; E-mail: lubote_2008@163.com

(Edited by YANG You-ping)