DOI:10.19476/j.ysxb.1004.0609.2019.02.20

钛合金弯管动态流量控制法挤压成形的模拟与实验研究

石 磊1, 2,文九巴1,姚 怀1,贺俊光1,吴武伟2,廖桂华2

(1. 河南科技大学 材料科学与工程学院,洛阳 71023;

2. 洛阳理工学院 材料科学与工程学院,洛阳 71023)

摘 要:通过有限元分析和实验研究动态流量控制法挤压钛合金弯管件。实验验证弯管的尺寸精度和挤压载荷。分析调控量对弯曲曲率的影响、速度场和温度场。结果表明:挤压载荷的峰值误差为14.51%,挤出的管材弯曲曲率误差为3.47%;在模具结构中,调控通道Ⅱ截面面积不变时,弯管曲率半径随调控通道Ⅰ有效截面面积的增大而增大;在定径带处的合金呈非均匀流动,弯管件内外弧面存在流速差是挤出弯曲件的原因;合金的流速在通过定径带时发生分流补偿,由调控通道Ⅱ进入定径带的合金流速反超辅助通道内的流速,在焊合腔内边缘处存在金属流动死区。在定径带区域温升明显,最大温升为134 ℃。

关键词:弯管;挤压;动态流量调控;钛合金

文章编号:1004-0609(2019)-02-0380-08 中图分类号:TG376.9 文献标志码:A

金属弯曲管件是航空和航天领域大量应用的一类重要关键零件。尤其是对航空发动机而言,弯管件被喻为发动机的“血管”。钛合金由于其优良的综合力学性能被大量应用于航空和航天领域,尤其是钛合金弯管件的应用显得尤为重要。目前国内外普遍采用二次加工的成形方法加工弯管件,应用最多的有两种方法,一种是推弯[1],另一种是绕弯[2]。虽然二次加工工艺具有实用性和可行性,但是传统的二次加工工艺具有严重缺点和局限性。例如在绕弯成形过程中,截面畸变是管弯曲成形过程中的主要缺陷[3]。管外侧受拉、内侧受压而容易引起管坯截面畸变甚至开裂的现象,一旦发生,轻则报废工件,重则损坏模具。同时管壁的变薄及失稳,影响工件的强度、刚度和疲劳寿命[4-5]。二次加工工艺导致的工件外侧减薄、内侧增厚是无法避免的现象[6],其尺寸精度差,形状不易控制,且易失稳等一直是难以解决的问题[7]。起皱[8-9]和回弹[2, 10-15]也是常出现的缺陷。

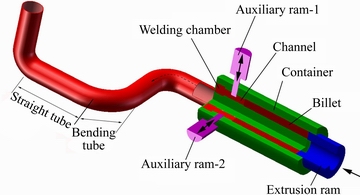

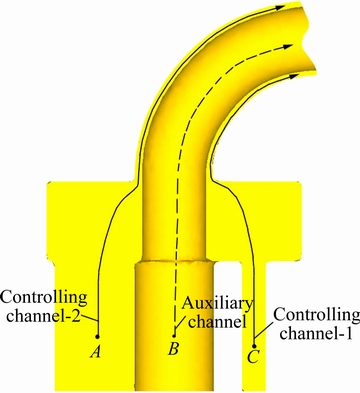

热挤压是先进的金属材料压力加工方法之一,挤压加工生产所得到的结构件的微观组织和力学性能良好[16-17]。分流挤压可获得高性能薄壁管材[18],且通过正确的模具结构设计和调整工艺参数以调整焊合腔的压力可使得焊缝实现冶金结合[19];先前的研究利用挤出管材易发生因流量不均产生的弯曲缺陷提出的动态流量控制法(Dynamic flow control extrusion, DFCE)挤出镁合金弯管件[20],如图1所示,有效避免了二次加工弯管件产生的缺陷。目前,针对钛合金弯管件挤压成形尺寸调控和质量控制尚属空白。

图1 DFCE挤出示意图(3/4挤压模具)

Fig. 1 Sketch of DFCE (3/4 part of die)

利用有限元分析和实验研究相结合的方法,通过建立动态流量控制法挤压成形TC1钛合金弯管件的有限元模型,并针对其工件尺寸形状和挤压过程的参数的准确性进行实验验证;利用有限元模型研究模具结构和工艺参数对工件尺寸等宏观变形参数的影响规律,基于有限元分析,获得高精度的弯管件的成形理论。

1 DFCE的有限元模型及实验验证

1.1 DFCE系统及其有限元模型的简化说明

DFCE弯管件的挤压,是通过动态调整分流挤压模具中各分流通道内的金属流量,以控制挤出过程中在焊合区域的径向金属供给量,实现挤出的管件具有可控曲率和可控弯曲部位的既定弯曲,最终获得满足要求的3D弯管的成形制造工艺。在该成形过程中,有一个主挤压杆和多个辅助调控挤压杆,各调控杆与主挤压杆互相垂直,通过主挤压位移控制弯曲部位、通过辅助调控挤压杆控制弯曲曲率和弯曲方向,并通过反复精确协同调控各挤压杆的位移,可使弯曲件在挤出过程中具有可控的体积转移,结合合理的温度控制、速度控制和挤压比的控制,可获得弯管件。综上所述,为了提高有限元模型的计算效率和精度,在不影响金属变形条件的前提下做以下假设[21]。

1) 调控过程控制的是分流通道的截面积,因此在有限元建模时可在几何模型中将动态通道截面积分别设计为不同的固定通道截面积,以此研究调控量对弯曲曲率的影响规律。

2) 在四孔分流DFCE简化后的结构中,有一个分流孔通道有效截面面积较小,因此,几何结构具有一个对称面,因此有限元模型以对称面取二分之一模型进行模拟计算。

3) 略去模具中的销钉、螺栓、螺母等零部件。

1.2 有限元模型的建立

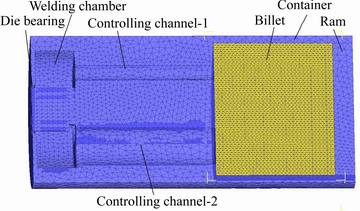

本文的研究对象是直径45 mm厚度为4 mm的弯管,模具结构采用四孔分流,圆形分流通道半径为20 mm,4个通道中的两个分别为调控通道Ⅰ和调控通道Ⅱ,如图2所示。理论上,两个通道的横截面积差越大,则挤出的弯管件越弯。本研究为调控通道Ⅱ的截面保持不变,仅改变调控通道Ⅰ的横截面积的情况。该调控当量换算成圆形分流通道的半径分别为0 mm,5 mm,10 mm,15 mm。采用SolidWorks软件绘制模具结构和坯料的三维几何结构图形,然后转换为STL文件格式,在DEFORM-3D软件中建立有限元模型;建模时,模具及挤压杆等工具材料视为刚体,坯料视为塑性材料。通过Gleeble-1500型试验机研究了TC1合金在温度区间为650~850 ℃、压缩应变速率区间为0.01~20 s-1的应力应变关系作为材料本构模型。摩擦模型选为剪切摩擦模型,求解器选用Newton-Raphson迭代法,步长不超过最小网格的1/3;再经过传热边界条件处理、网格优化等关键技术处理,建立了如图2所示的有限元模型。

图2 DFCE弯管件的有限元模型

Fig. 2 FEM model of DFCE bending tube

1.3 有限元模型的验证

在模拟和试验中的挤压坯料直径均为92 mm的棒材,根据前述所加工的管材规格,确定其挤压比为12.9;原始坯料温度为750 ℃,挤压速度为4 mm/s,模拟时按照有润滑情况摩擦因数为0.3,实际挤压实验时在焊合腔周边及定径带处刷水剂石墨润滑,为了避免各股金属流在有润滑情况下无法焊合或者焊合不良的问题,在分流孔及盛锭筒内不刷石墨水。

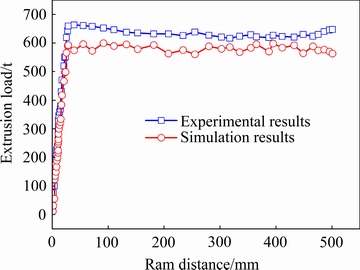

试验中,采用800 t卧式挤压机作为实验设备,在挤出过程中,测量并记录了挤压载荷和挤压杆位移的关系,测量并记录了挤出弯曲管件部位的弯曲半径,并将以上数据进行对比,验证有限元模型的可靠性。图3所示为挤压载荷随行程变化的曲线。可知,挤压力的峰值误差较大,为14.51%;实验的挤压力峰值较高,可能与润滑的情况有关;而挤出的管材形状吻合性较好,在调控量一致的情况下,挤出弯曲区域的半径误差为3.47%。表明了本文所建立的有限元模型高度可靠。

图4所示为实验照片和模拟挤出弯管件的结果,模拟挤出的弯管件的弯曲半径为110 mm,经过实测,实验挤出的弯管件弯曲半径为111 mm,在相同的模具结构和尺寸情况下,实验和模拟挤出弯管件的弯曲半径吻合良好;实际挤出弯管件的管径为45 mm,模拟挤出的管径为44~46 mm,存在尺寸误差,可能是由于网格误差的原因。弯曲半径和弯管管径的对比证明该有限元模型是可靠的。

图3 DFCE的有限元仿真和实验中的挤压载荷对比

Fig. 3 Comparison of extrusion load during DFCE from FE simulation and experiment

图4 弯管件形状、尺寸

Fig. 4 Shape and size of bending tube

2 DFCE的有限元仿真结果分析

2.1 调控量对曲率半径的影响规律

图5所示为两种调控量对应的弯管件的弯曲曲率半径,其中图5(a)所示为调控通道Ⅰ全部封闭所得到的弯管件,其弯曲曲率半径为97.5 mm,此时的调控量最大;当减少调控量,保留通道的有效横截面积为314 mm2,得到了如图5(b)所示的弯管件,其弯曲曲率半径为110 mm。

基于不同调控量的有限元分析,得到了如表1所列的分流通道有效截面面积与弯曲曲率半径的关系规律。随着被调控通道Ⅰ的截面面积增大,弯曲曲率半径随之增大,且在被调控的分流通道截面面积与其余通道相同时,挤出弯件为直管,其曲率半径为无穷大。

图5 两种调控量的弯管件的曲率半径

Fig. 5 Radius of curvature of different controlling level

表1 调控通道Ⅰ截面面积与曲率半径之间的规律

Table 1 Relationship of cross sectional area of controlling channel and radius of curvature

2.2 DFCE挤压过程坯料速度场的演变规律

有限元仿真挤压杆速度4 mm/s时,坯料进入模具至挤出弯管件的速度场和矢量如图6所示。坯料在分流孔内、焊合腔、定径带和挤出后区域的速度存在较大差异,根据体积不变原理,这是由各阶段的型腔截面积和挤压速度决定的,通过理论分析了各阶段的型腔截面积与坯料截面积的比值,各阶段的平均流动速度为:

(1)

(1)

式中:vi为坯料在第i个截面上的平均流速;S为坯料的横截面积;v为挤压杆速度;Si为坯料在第i个截面上的横截面积。

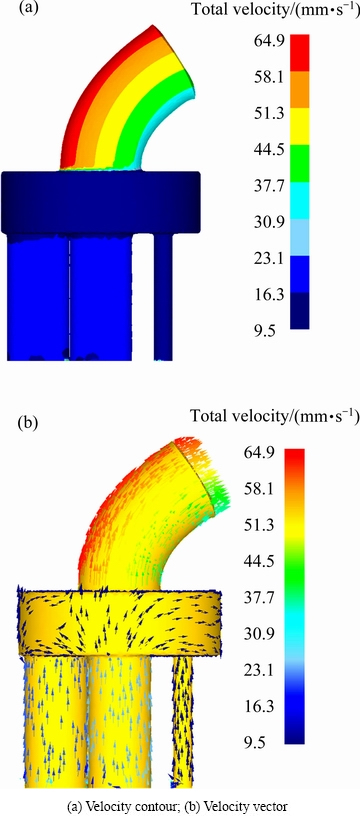

图6 DFCE挤压成形过程坯料在对外表面上的速度场分布

Fig. 6 Velocity field distribution on surface during DFCE forming

根据式(1),坯料与挤出弯管横截面积之比值确定的挤压比为12.9,在挤出的弯管截面上,沿圆周方向选取48个网格节点,挤出速度的平均值为51.0 mm/s,与理论计算值51.6 mm/s较接近,有限元分析成形过程的速度场与该理论分析结果吻合。但是,由于摩擦的作用,在第i个横截面上的各通道的流速是不均匀的。例如,被调控通道Ⅰ较细,坯料与模具的接触摩擦面积与通道体积比较大,因此合金在调控通道Ⅰ内的流速较慢,摩擦的作用增大了调控的效果。合金进入焊合腔后四股合金同时流向定径带,部分合金流向焊合腔的边缘区域,形成了慢速区,甚至流速接近0的流动死区。图6所示为变形体体表面的流速场,可以看出,焊合腔的流动速度较低。合金在焊合腔内焊合后进入定径带,由于不均匀的合金供给,使得在定径带处的合金流速呈现了较大的不均匀性,靠近调控通道Ⅰ的区域流速较慢,远离调控通道Ⅰ的区域流速较快。

图7所示为弯管件在挤出定径带后各网格节点的流动速度。在靠近外弧面的环形区域,弯管件的速度为60.6~64.0 mm/s,在靠近内弧面的环形区域,速度为34.4~38.8 mm/s,因此,在定径带环形区域内,合金呈非均匀流动状态。由外弧面至内弧面,各网格节点的流动速度均匀的线性减慢,是获得圆弧弯曲管件的原因。其特征为各节点的线速度与该节点到弯曲管件圆心的距离成线性正比例关系。在弯管件的径向截面上,通过SPSS软件回归分析了确定了节点速度与曲率半径的比值为其成形的角速度,拟合结果显示相关性大于99.4%。

图7 挤出弯管件的速度场分布云图

Fig. 7 Contours of velocity of extrusion bending tube

分析不同弯曲半径弯管件的网格节点的流动速度证实内外弧面的速度差决定了其弯曲半径。外圆弧边缘处的节点与内圆弧边缘处速度差和圆弧弯曲半径之间的关系如表2所列。随着弯曲半径的增大,速度差呈减小趋势,在调控量为0时,即4个分流孔的有效流通截面积一致时,挤出直管,管材两侧的速度差为0。

表2 内外圆弧边缘区域节点的速度差与圆弧弯曲半径之间的关系

Table 2 Relationship among velocity difference of extrados and intrados and radius of curvature

图8 焊合腔内对称面上的速度场分布

Fig. 8 Velocity field distribution on symmetry plane in region of welding

图8所示为焊合腔和定径带附近区域对称面上的流速场云图和矢量图。在焊合腔内,随着调控通道Ⅱ的快速供给和调控通道Ⅰ的慢速供给,流速场呈现出明显的不对称性。调控通道Ⅱ和两辅助通道内的三股合金在焊合腔内焊合后,以越来越快的速度流向定径带,并且在定径带附近达到最大,从上至下呈现明显的速度梯度。调控通道Ⅰ内的合金速度较慢,导致了焊合腔内合金供给的不均匀性,且在靠近定径带附近合金的流速增大速度较慢,最终形成了定径带两侧的合金呈现差速流动。根据图8(a)和图8(b)的调控通道Ⅰ内的流速场,在通道内心部的流速高于边缘流速,且在进入焊合腔后流动方向改变,流向定径带。

2.3 流经不同通道的金属流动速度演变的规律

挤压速度是决定挤压工艺条件和坯料流动均匀性的重要参数,为了研究挤压速度对通过不同通道合金速度的影响,如图9所示,分流模具内有3种通道,分别是调控通道Ⅰ、调控通道Ⅱ和两个辅助通道。其中两个辅助通道的具有对称性,考查其中一个即可。分别取通道内中心区域的一个网格节点,如图9中点A、B和C,观察从不同类型的通道中通过的合金在通过不同区域(通道-焊合腔-定径带-挤出弯管)的流速演变规律。

图9 调控通道Ⅰ、辅助通道和调控通道Ⅱ位置示意图

Fig. 9 Schematic diagram of sampling point locations in controlling channel, auxiliary channel and opposite channel

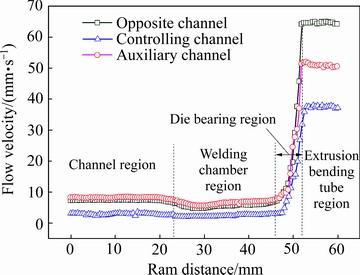

图10所示为挤压杆速度为4 mm/s时3个不同通道中心区域的合金流动速度演变规律。合金在经过通道时,由于调控通道I截面面积较小,摩擦的作用使得该通道内的合金流速最慢,约为3.15 mm/s,小于挤压杆速度;对比截面面积相同位置不同的辅助通道和调控通道Ⅱ内合金流动速度发现,调控通道Ⅱ的流速略慢于辅助通道,分别为7.20 mm/s和8.10 mm/s,产生这种现象的原因是通道两端的压力差不同,由于辅助通道的几何位置与调控通道Ⅰ相邻,而由调控通道Ⅰ流入焊合腔的合金较少,因此焊合腔内靠近调控通道Ⅰ一端的合金压力较小,导致了辅助通道两端的压差更大。合金进入焊合腔后,由于型腔的有效横截面积增大,导致了3种通道的流速下降,从3种通道流经的合金速度仍保持着:调控通道Ⅰ<调控通道Ⅱ<辅助通道;然而值得注意的是,在通过定径带时,以上网格节点对应的合金在径缩变形后,均发生较大幅度加速,速度的顺序也发生了变化,为:调控通道Ⅰ<辅助通道<调控通道Ⅱ,发生这种变化是由于由辅助通道进入焊合腔时,发生了方向的分流,一部分合金补偿了调控通道Ⅰ流量的不足,最终表现为上述速度顺序,从调控通道Ⅱ流入的合金速度实现了反超。通过定径带以后进入成形弯管区域,从3种通道流经的合金在该阶段的速度分别为:37.58 mm/s,50.65 mm/s和64.52 mm/s。

图10 不同通道内流动速度演变规律

Fig.10 Distribution of flow velocities in various channels

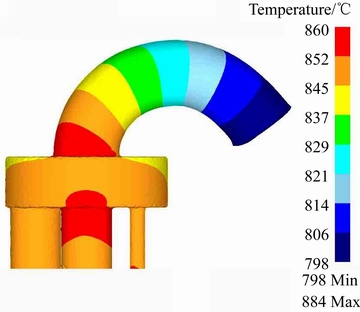

挤出弯管件的温度场分布如图11所示,坯料的初始温度为750 ℃,在坯料进入分流孔后,由于发生了径缩变形,产生了温升效应,分流孔内的合金温度约为845~852 ℃。在成形区域,温升更高,局部区域的温度达884 ℃,总温升达134 ℃。弯管件挤出定径带后,随着在空气中的辐射和传导散热,温度逐渐降低。分析各种弯曲半径的弯管件温度场分布,弯曲半径和温升相关性较小,随着弯曲半径的变化而温升无明显变化。

图11 挤出弯管件的温度场分布

Fig. 11 Contours of temperature distribution of extrusion bending tube

3 结论

1) DFCE可以有效加工钛合金弯管件,且通过动态流量调控可以精确控制弯管件的曲率半径,调控通道I的截面面积与弯管的曲率半径呈正比关系。

2) 在定径带处合金呈非均匀流动,弯管件内外弧面存在流速差是挤出弯曲件的原因,内外弧面上的流速差值的大小与曲率半径呈反比,在焊合腔内有金属流动死区。

3) 各通道内横截面上的流速是不均匀。各通道内心部的流速高于边缘流速;被调控的分流通道内的流速较慢,摩擦的作用增大了调控的效果;合金进入焊合腔后四股合金同时流向定径带,部分合金流向焊合腔的边缘区域,形成了慢速区;合金在焊合腔-定径带区域,呈现了较大的不均匀性,由于调控的作用,形成了差速流动。

4) 在通道内和焊合腔区域的合金流速大小顺序为:调控通道Ⅰ<调控通道Ⅱ<辅助通道,通过3种不同类型通道的合金流速在通过定径带时发生了分流补偿,由调控通道Ⅱ进入定径带的合金流速反超了辅助通道内的流速,最终顺序为:调控通道Ⅰ<辅助通道<调控通道Ⅱ。

5) DFCE导致的温升明显,分流孔处较原始坯料温升约100 ℃,在定径带区域温升最大,为134 ℃。

REFERENCES

[1] 郭训忠, 陶 杰, 唐巧生, 李华冠, 卞佳敏, 李 鸣. TA1-Al双金属复合管冷推弯模拟及试验[J]. 中国有色金属学报, 2012, 22(4): 1053-1062.

GUO Xun-zhong, TAO Jie, TANG Qiao-sheng, LI Hua-guan, BIAN Jia-min, LI Ming. Cold push-bending simulation and experiment on TA1-Al bimetallic clad tube[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1053-1062.

[2] XUE X, LIAO J, VINCZE G, GRACIO J J. Modelling of mandrel rotary draw bending for accurate twist springback prediction of an asymmetric thin-walled tube[J]. Journal of Materials Processing Technology, 2015, 216: 405-417.

[3] 刘泽宇, 滕步刚, 苑世剑. 内压对薄壁管充液压弯时的影响[J]. 塑性工程学报, 2009, 16(4): 35-38.

LIU Ze-yu, TENG Bu-gang, YUAN Shi-jian. Effect of internal pressure on thin-walled tubes bending with internal pressure[J]. Journal of Plasticity Engineering, 2009, 16(4): 35-38.

[4] YANG H,LI H,ZHANG Z Y, ZHAN M, LIU J, LI G J. Advances and trends on tube bending forming technologies[J]. Chinese Journal of Aeronautics, 2012, 25: 1-12.

[5] 杨 合, 孙志超, 林 艳, 李明奇. 管成形技术发展基础问题研究[J]. 塑性工程学报, 2001, 8: 83-85.

YANG He, SUN Zhi-chao, LIN Yan, LI Ming-qi. Advanced plastic processing technology and research progress on tube forming[J]. Journal of Plasticity Engineering, 2001, 8: 83-85.

[6] 张敬文, 鄂大辛, 李延民, 田 鑫. 弯曲速度对弯管壁厚变化的影响[J]. 精密成形工程, 2012, 4(1): 5-8.

ZHANG Jing-wen, E Da-xin, LI Yan-min, TIAN Xin. Effects of bending velocity on the changer of wall thickness in tube bending[J]. Journal of Netshape Forming Engineering, 2012, 4(1): 5-8.

[7] ZHAO G Y, LIU Y L, YANG H, LU C H. Cross-sectional distortion behaviors of thin-walled rectangular tube in rotary-draw bending process[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(3): 484-489.

[8] LI H, YANG H, ZHANG Z Y, WANG Z K. ‘Size effect’related bending formability of thin-walled aluminum alloy tube[J]. Chinese Journal of Aeronautics, 2013, 26(1): 230-241.

[9] TIAN S, LIU Y L, YANG H. Effects of geometrical parameters on wrinkling of thin-walled rectangular aluminum alloy wave-guide tubes in rotary-draw bending[J]. Chinese Journal of Aeronautics, 2013, 26(1): 242-248.

[10] LIAO J, XUE X, LEE M G, BARLAT F, GRACIO J. On twist springback prediction of asymmetric tube in rotary draw bending with different constitutive models[J]. International Journal of Mechanical Sciences, 2014, 89: 311-322.

[11] LIAO J, XUE X, BARLAT F, GRACIO J. Material modelling and springback analysis for multi-stage rotary draw bending of thin-walled tube using homogeneous anisotropic hardening model[J]. Procedia Engineering, 2014, 81: 1228-1233.

[12] TAO Z J, YANG H, LI H, ZHANG Z Y, CHEN Z M. Coupled thermo-mechanical FE simulation of unloading cooling springback in NC heating bending of large diameter thin-walled commercial pure titanium tube[J]. Procedia Engineering, 2014, 81: 2273-2279.

[13] ZHU Y X, LIU Y L, YANG H, LI H P. Improvement of the accuracy and the computational efficiency of the springback prediction model for the rotary-draw bending of rectangular H96 tube[J]. International Journal of Mechanical Sciences, 2013, 66: 224-232.

[14] E D X, LIU Y F. Springback and time-dependent springback of 1Cr18Ni9Ti stainless steel tubes under bending[J]. Materials and Design, 2010, 31: 1256-1261.

[15] YANG Y L, ZHAN L H, LI J. Constitutive modeling and springback simulation for 2524 aluminum alloy in creep age forming[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(9): 3048-3055.

[16] 胡渊蔚, 吉泽升, 徐宇鹏. 挤压比对Al-Cu-Mg-Ag-Er合金线材组织及性能影响[J]. 材料热处理学报, 2015, 36(2): 49-54.

HU Yuan-wei, JI Ze-sheng, XU Yu-peng. Effects of extrusion ratio on microstructure and properties of Al-Cu-Mg-Ag-Er alloy wire[J]. Transactions of Materials and Heat Treatment, 2015, 36(2): 49-54.

[17] WU Y P, ZHANG X M, DENG Y L, TANG C P, ZHONG Y Y. Effect of secondary extrusion on the microstructure and mechanical properties of a Mg–RE alloy[J]. Materials Science and Engineering A, 2014, 616: 148-154.

[18] TANG D, FANG W L, FAN X H, LI D Y, PENG Y H. Effect of die design in microchannel tube extrusion[J]. Procedia Engineering, 2014, 81:628-633.

[19] TANG D, ZHANG Q Q, LI D Y, PENG Y H. A physical simulation of longitudinal seam welding in micro channel tube extrusion[J]. Journal of Materials Processing Technology, 2014, 214: 2777-2783.

[20] 石 磊, 徐国辉, 任 畅, 金文中, 王玉江, 王利剑. 动态流量控制法挤出镁合金三维弯曲管件[J]. 材料科学与工艺, 2016, 24(6): 9-14.

SHI Lei, XU Guo-hui, REN Chang, JIN Wen-zhong, WANG Yu-jiang, WANG Li-jiang. Three dimensional magnesium alloy bent pipe produced by dynamic flow control extrusion[J]. Materials Science & Technology, 2016, 24(6): 8-13.

[21] WU C, YANG H, LI H W. Simulated and experimental investigation on discontinuous dynamic recrystallization of a near-α TA 15 titanium alloy during isothermal hot compression in β single-phase field[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(6): 1819-1829.

Numerical simulation and experimental study of titanium alloy bending tube extruded by dynamic flow control technique

SHI Lei1, 2, WEN Jiu-ba1, YAO Huai1, HE Jun-guang1, WU Wu-wei2, LIAO Gui-hua2

(1. School of Material Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. School of Material Science & Engineering, Luoyang Institute of Science and Technology, Luoyang 471023, China)

Abstract: The dynamic flow control extrusion (DFCE) of titanium alloy bending tubes was examined in the present study using both the finite element analysis and the experimental approach. The finite element analysis was first validated qualitatively and quantitatively by the experimental data obtained from the DFCE process. The effects of the area of channel cross section on the radius of curvature were studied by the finite element analysis. The fields of velocity and temperature of workpiece were studied. The results show that the relative errors of extrusion load and radius of curvature are 14.51% and 3.47%, respectively. The finite element analysis reveals that radius of curvature increases with the increase of cross-sectional area of controlling channel-Ⅰ. The different cross-sectional area of controlling channel-Ⅰand Ⅱ is found to be one major reason for the extrusion of bending tube. The velocity of workpiece is inhomogeneous in circumferential of bearing zone. The velocity of alloy flowing through die bearing from controlling channel-Ⅱ increases rapidly than that from auxiliary channel. The temperature rise is obviously and the maximum value is 134℃.

Key words: bending tube; extrusion; dynamic flow control extrusion; titanium alloy

Foundation item: Project(2016M602238) supported by Chinese Postdoctoral Science Foundation, China; Project (17A430025) supported by Key Scientific Research Foundation of Higher Education Institutions of Henan Province, China; Project(172102210403) supported by Key Science and Technology Program of Henan Province, China

Received date: 2017-11-28; Accepted date: 2018-04-10

Corresponding author: WEN Jiu-ba; Tel: +86-13838829072; E-mail: wenjiuba12@163.com

(编辑 王 超)

基金项目:中国博士后面上基金资助项目(2016M602238);河南省高等学校重点科研基金资助项目(17A430025);河南省科技攻关项目(172102210403)

收稿日期:2017-11-28;修订日期:2018-04-10

通信作者:文九巴,教授,博士;电话:13838829072;E-mail:wenjiuba12@163.com