Characterization of (100)-orientated diamond film grown by HFCVD method with a positive DC bias voltage

MA Ying(马 莹)1, WANG Lin-jun(王林军)1, LIU Jian-min(刘建敏)1, SU Qing-feng(苏青峰)1, XU Run(徐 闰)1, PENG Hong-yan(彭鸿雁)2, SHI Wei-min(史伟民)1, XIA Yi-ben(夏义本)1 1.School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China;

2.Physics Department, Mudanjiang Normal College, Mudanjiang 157012, China

Received 10 April 2006; accepted 25 April 2006

Abstract: The (100)-orientated diamond film was deposited by hot-filament chemical vapor deposition (HFCVD) technology with a positive DC bias voltage. The morphology, X-ray diffraction (XRD), RAMAN spectrum and dark current versus applied voltage characteristics analysis show that the positive dc bias can increase the nucleation density and (100)-orientated growth, making the growth of the high quality diamond film easier and cheaper than using other methods.

Key words: (100)-orientation; diamond film;, HFCVD; positive bias

1 Introduction

Diamond, a wide-band semiconductor material (5.5 eV), possesses a unique blend of excellent chemical and physical properties, such as high radiation hardness, transparency and heat conductivity, which makes it attractive as an optical and electronics material. Diamond films can be synthesized by various deposition techniques, for example, RF plasma chemical vapor deposition (CVD)[1], microwave plasma CVD (MPCVD)[2], electron-assisted CVD[3] and so on.

However, CVD diamond films are inherently polycrystalline, which influences the electrical properties of the devices. The (100)-orientated diamond film has lower surface roughness and better electrical performance than the other orientated films. The electronic devices based on this kind material can present better. In general, the (100)-orientated diamond film is deposited by negative or positive bias in the MPCVD system[4, 5]. Compared with MPCVD method, the hot-filament chemical vapor deposition (HFCVD) technique has many advantages including being much simpler and easier to adopt for large-deposition at a lower cost [6]. However, the growth of the (100)-oriented diamond film is almost not reported by HFCVD method using a positive bias nucleation. In this study, considering the cost and the convenience, we try to apply a positive DC bias voltage to the Si substrate to deposit (100)-orientated diamond film in the HFCVD system, which utilizes the electron bombardment assist nucleation. The film’s quality is evaluated by optical microscope, AFM, XRD, RAMAN spectroscopy and current versus applied voltage(I-V) characterization. This work motivates the further study on the growth mechanics of diamond, which plays a role on the application of this kind of material to some extent.

2 Experimental

The diamond film was deposited in HFCVD apparatus. The polished Si substrate was manually scratched by diamond powder (powder size of 0.1 mm) in order to promote the density of nucleation, using a mixture gas of hydrogen and acetone as the carbon source. The deposition process was divided into two steps. The first step was the nucleation process and the second was the growth process. During the deposition, the Si substrate was applied a positive bias voltage. The detail deposition parameters are listed in Table 1. For comparison, another diamond film was deposited using the same condition except no bias voltage during the nucleation process.

Table 1 Diamond deposition conditions during nucleation and growth process in HFCVD system

After deposition, the diamond film was treated by the solution of H2SO4 and 50%H2O2 to remove the non-diamond phase and promote the quality of the film. By thermal evaporation technology, the point Au contacts radius of 0.5 mm were fabricated on the surface of the diamond film and the continuous back Au contact on the back of Si substrate. In addition, the sample was annealed at 500 ℃ in the argon environment for better electronic character.

3 Results and discussion

The surface morphology of the diamond film deposited using positive bias nucleation is shown in Fig.1(a) and Fig.2. There are many square facets presented in both two pictures, which indicate that the diamond film is (100) orientation and the sizes of the diamond grains are about 3-4 mm. From the AFM testing, the average surface roughness is obtained (63.5 nm), which means that the diamond film has the smooth surface that administers to fabricate the device further.

Fig.1(b) shows the optical microscope image of the diamond film deposited without the bias nucleation. There are many irregular grains, which indicates that this diamond film is non-oriented. The comparison of Fig.1(a) and 1(b) demonstrates that the electron bombardment substrate by a positive dc bias voltage during the nucleation process promotes the (100)-orientation growth. And the growth rate can be enhanced by the position bias through the whole deposition[7].

The (100) orientation is also quantitatively measured by XRD, as shown in Fig.3. Diffraction peaks corresponding to the (111), (220), (311), (400) and (311) indexed ASTM values of bulk diamond are detected. The intensity ratio of I(100)/I(111) of the sample is calculated to be 0.316, which is much higher than the value of the natural diamond (0.07), indicating a very strong (100) orientation.

There are many researchers interested in the growth of (100)-oriented diamond film, and most of them use the negative bias to enhance the nucleation and complete the (100)-oriented growth. In this study, using positive DC bias can also obtain the (100)-oriented diamond film. The mechanics is difficult to understand. However,

Fig.1 Optical microscope image of diamond film deposited by HFCVD: (a) With positive bias nucleation; (b) Without bias nucleation

Fig.2 3D image of diamond film taken by AFM(scan size of 10 mm?10 mm)

Fig.3 XRD pattern of diamond film deposited by HFCVD using positive bias nucleation

positive bias has been proposed for growing diamond films with high nucleation density and high growth rate [7-9]. It has been suggested that the electron bombardment against substrate is enhanced when positive bias is applied. The electrons may change the surface energy distribution and may increase active sites and result in the formation of the carbon-silicon bond for nucleation of diamond. In addition, it has been reported that the bombardment may produce a thin layer of amorphous carbon or SiC, upon which diamond can nucleate [10]. Further the selective hydrogen etching results in diamond orientation on the substrates [11]. This means that the selective hydrogen etching may occur even if in the positive bias condition. And the small square nuclei may have been already formed in the nucleation stage. In the growth stage, these small square nuclei grow up to form the larger (100)-oriented crystalline grain. So the nucleation condition is very important to the growth of (100)-oriented diamond film, which should be studied further.

The typical RAMAN spectrum, given in Fig.4, shows a sharp diamond peak at 1 333.1 cm-1 with a full-width at half-maximum (FWHM) about 10.5 cm-1. A broad non-diamond carbon band at 1 400-1 650 cm-1 is observed without the graphite characteristic peak at

1 580 cm-1. The result of RAMAN spectrum indicates that the film has a good quality.

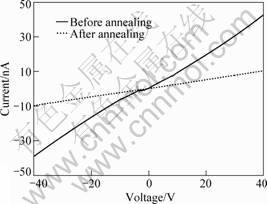

I-V characteristics curves of the (100)-oriented diamond film are shown in Fig.5. It is found that the dark current decreases obviously after an annealing treatment at 500 ℃ in the argon environment. The polycrystalline CVD diamond films have a higher concentration of impurities and/or defects forming the trap. The annealing process can make the shallow trap passive and enhance the resistivity up to 6.7×1010 W?cm. The linear I-V curves determine the fine ohmic contact and the high resistivity indicates a good quality of the (100)-oriented diamond film.

Fig.4 RAMAN spectrum of diamond film deposited by HFCVD using positive bias nucleation

Fig.5 Dark current versus applied voltage (I-V) curves of diamond film before and after annealing treatment

4 Conclusions

(100)-orientated diamond film is deposited on the manually scratched side of (100) Si substrate by a positive DC bias in hot-filament chemical vapor deposition (HFCVD) system. All the results of the testing, including optical microscopy technology, AFM, XRD, RAMAN spectroscopy analysis and dark I-V measurement, show the good orientation and quality of the diamond film. This indicates that positive bias can improve the nucleation and obtain high quality (100)-orientated diamond film with smooth surface. But the growth mechanics of (100)-orientated diamond film doposited by positive DC bias still can’t be interpreted definitely, which will be studied in the further work.

References

[1] WATANBE I, MATSUSHITA T, SASAHARA K. Low temperature synthesis of diamond films in thermoassisted rf plasma chemical vapor deposition[J]. Japanese Journal of Applied Physics, Part 1: Regular Papers & Short Notes, 1992, 31(5A): 1428-1431.

[2] TANG X, ZHAO B Y, HU K A. Using active carbon pellet as substrate for deposition diamond by MPCVD[J]. Materials Letters, 2005, 59(13): 1673-1677.

[3] ZUO D W, LI X F, XU F, WANG M. Smoothing of thick diamond film prepared by electron by electron-assisted CVD[J]. Key Engineering Materials, 2004, 258-259:507-511.

[4] XIA Y B, JU J H, DAI W Q, WANG L J. [100]-oriented textured growth of the diamond films and its infrared properties[J]. Journal of Synthetic Crystals, 2000, 29(3): 229-233.

[5] STOCKEL R, JANISCHOWSKY K, ROHMFELD S, RISTEIN J. Growth of diamond on silicon during the bias pretreatment chemical vapor deposition of polycrystalline diamond films[J]. Journal of Applied Physics, 1996, 79(2): 768-776.

[6] YANG X, SHEN H S, ZHANG Z M, HU X J. Large area and flat diamond film preparation[J]. Journal of Functional Materials and Devices, 2001, 7(3): 231-234.

[7] CUI J B, FANG R C. Evidence of the role of positive bias in diamond growth by hot filament chemical vapor deposition[J]. Applied Physics Letters, 1996, 69(23): 3507-3509.

[8] CHIANG M J, HON M H. Enhanced nucleation of diamond films assisted by positive dc bias[J]. Thin Solid Films, 2001, 389(1-2): 68-74.

[9] CUI J B, MA Y R, FANG R C. Species characterization for a direct-current-biased hot filament growth of diamond using spatial resolved optical emission spectroscopy[J]. Applied Physics Letters, 1996, 69(21): 3170-3172.

[10] YUGO S, KANAI T, KIMURA T, MUTO T. Generation of diamond nuclei by electric field in plasma chemical vapor deposition[J]. Applied Physics Letters, 1991, 58(10): 1036-1038.

[11] BATTAILE C C, SROLOVITZ D J, OLEINIK I I, PETTIFOR D G. Eteching effect during the chemical vapor deposition of (100) diamond[J]. Journal of Chemical Physics, 1999, 111(9): 4291-4299.

(Edited by YANG You-ping)

Foundation item: Project (60577040) supported by the National Natural Science Foundation of China; Project(0404) supported by Shanghai Foundation of Applied Materials Research and Development; Project(T0101) supported by Shanghai Leading Academic Disciplines

Corresponding author: WANG Lin-jun; Tel: +86-21-56333514; Fax: +86-21-56332694; E-mail: ljwang@staff.shu.edu.cn