Effect of extrusion ratio on coating extrusion of Pb-GF composite wire by numerical simulation and experimental investigation

WANG Xin(王 欣), SUN Hong-fei(孙宏飞), FANG Wen-bin(房文斌)

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 10 June 2009; accepted 15 August 2009

Abstract: The extrusion ratio is one of the key parameters for manufacturing the lead-glass fiber (Pb-GF) composite wire by coating extrusion. The effect of extrusion ratio on coating extrusion of Pb-GF composite wire was studied by finite element numerical simulation with the use of the DEFOEM simulation software. The simulation result shows that the higher the extrusion ratio, the higher the effective stress that the glass fiber bears during extrusion. It is also observed that the extrusion force increases with the increase of the extrusion ratio. The extrusion experiment of Pb-GF composite wire reveals that extrusion ratio is changed by changing the quantity of glass fiber and composite diameter. The rule that increasing the extrusion ratio enhances the coating speed limit suggests that the load on the glass fiber increases with increasing extrusion ratio. Both the simulation and the extrusion experiments show that the extrusion force increases with increasing extrusion ratio.

Key words: numerical simulation; Pb-GF composite wire; coating extrusion; extrusion ratio

1 Introduction

With the environmental and oil cost pressures, the electric vehicles(EVs) and the hybrid vehicles(HEVs) become more and more important[1-2]. Many kinds of advanced lead-acid batteries have been designed for EVs and HEVs[3-5]. The composite of lead-clad fiber glass (Pb-GF composite wire) is a kind of new material for the grid of new advanced lead-acid battery[6]. The Pb-GF composite wire is also very useful in different fields, such as absorbing ionizing, electromagnetic radiation and sound insulation.

The coating extrusion as an important method for forming Pb-GF composite wire has been studied by many scholars in different fields and in different countries. But most study has been concentrated on the technology and engineering[7-8], and few researches have been related to the theory of Pb-GF coating extrusion. Although there are many researchers working on the theory of coating a kind of plastic material with other plastic material, such as aluminum-clad copper wire[9-10], little has been reported on the theory of coating a kind of brittle material with plastic material. The Pb-GF composite wire is a typical kind of metallic matrix composite reinforced by brittle fiber[11-12]. Therefore, it is very important to investigate both theoretically and experimentally the forming process of Pb-GF composite wire by coating extrusion. In recent years, our group has been got some results in this field [12-15] and found that extrusion ratio is a very important parameter for extrusion coating technology of Pb-GF.

Nowadays, the simulation software has become highly developed. It is possible to simulate the coating extrusion process of Pb-GF composite wire. DEFORM is the most important software commonly used for bulk deformation simulation. Coating extrusion of Pb-GF is a typical kind of bulk deformation. In the present work, the Pb-GF composite wire coating extrusion process has been simulated by using DEFORM. Due to the fact that extrusion ratio is one of the most important technical parameters for the Pb-GF coating extrusion process, both simulation and experimental studies have been focused on the effect of extrusion ratio.

2 Simulation

2.1 Model of numerical simulation

The geometry, constraint condition, and load for Pb-GF coating extrusion are axisymmetric. Therefore, the axisymmetric model as shown in Fig.1 was used for the numerical simulation of the Pb-GF coating extrusion process.

Fig.1 Simulation model for Pb-GF coating extrusion

2.2 Materials property

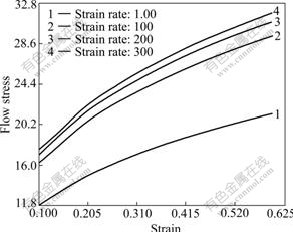

The property of material is an important parameter to numerical simulation. In the present investigation, the glass fiber used was the EC8-24*1*3S-600 consisting of 600 fine single glass fibers. In simulation, the glass fiber was considered to be a brittle, non-deformable, rigid material. Therefore, no deformation will occur to the glass fiber yarn so long as the stress transferred to it does not exceed its tensile strength. For Pb, on the other hand, the strain hardening model was used. The following expression for the flow stress of Pb was used in the present simulation. Based on Eq.(1), the flow stress of Pb under different strain and strain rate is shown in Fig.2.

(1)

(1)

Fig.2 Flow stress vs strain curves of Pb under different strain rates

2.3 Effect of extrusion ratio on coating extrusion

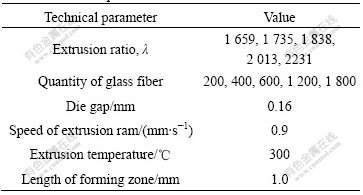

Table 1 lists the parameters used in numerical simulation. For more detailed study of the extrusion ratio effect on the coating extrusion process, some important parameters, such as the die gap, the extrusion ram speed, and the length of forming zone, are confirmed, as shown in Table 1.

Table 1 Technical parameters selected for extrusion simulation

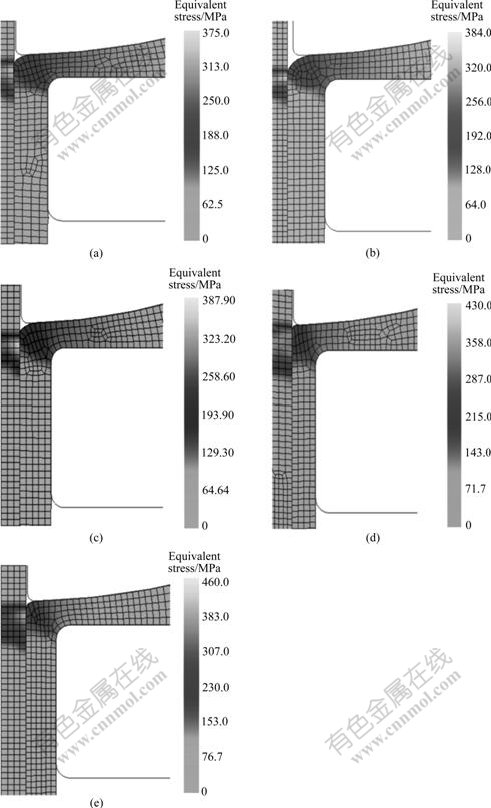

The simulation results were introduced for different extrusion ratios in Fig.3. Based on the simulation results, the following conclusions can be drawn.

Firstly, the higher the extrusion ratio, the higher the effective stress that the fiber glass has suffered during extrusion. When the extrusion ratio was enhanced from 1 659 to 2 231, the effective stress increased from 375 MPa to 460 MPa. When the effective stress is higher than the tension strength of the glass fiber (480-510 MPa), the coating extrusion will not succeed because of the rupture of the glass fiber, so the simulation result shows that the extrusion ratio must be lower than 2 231.

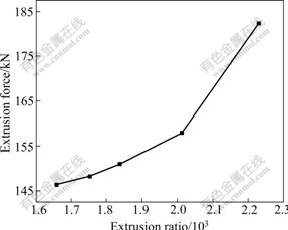

Secondly, with the increase of the extrusion ratio, the extrusion force increases. The relationship between the extrusion force and the extrusion ratio obtained by numerical simulation is shown in Fig.4. The reason that the extrusion force increases with increasing ratio is that the extent deformation increases when the extrusion ratio is enhanced.

3 Experiment

The coating extrusion experiments were performed in the same conditions as in Ref.[12]. The apparatus was WE600-B material test press. Extrusion mode of forward extrusion was used. The coating material was 1# pure lead. The glass fiber yarns used were EC8-24-1-3S- (200-1800) and EC9-24-1-3S-(200-1800), respectively.

4 Results and discussion

4.1 Effect of quantity of glass fiber on extrusion ratio and extrusion speed

Fig.3 Equivalent stress under different extrusion ratios for forward extrusion of Pb-GF composite wire: (a) λ=1 659; (b) λ=1 735; (c) λ=1 838; (d) λ=2 013; (e) λ=2 231

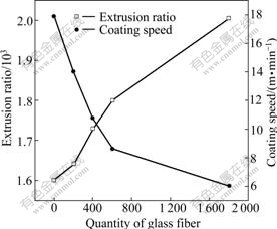

In extrusion experiments, the change of extrusion ratio is determined by quantity of glass fiber and composite wire diameter. When other parameters of extrusion are unchanged, the quantity of glass fiber and composite become the most important factors for extrusion ratio. Fig.5 shows the relationship among the extrusion ratio, quantity of glass fiber and the coating speed. From Fig.5, it is clear that the higher the quantity of glass fiber, the higher the extrusion ratio and the lower the limited coating speed. This means that the effective stress acting on the fiber glass increases with the increase of the extrusion ratio and quantity of fiber glass, because the higher limited coating speed means the lower force undertaken by fiber glass for the same overall extrusion force. This is in good accordance with the simulation result. Other parameters in the experiment are: extrusion force of 170 kN, extrusion temperature of 317 ℃, composite wire diameter of 0.75 mm and die gap of 0.18 mm.

Fig.4 Relationship between extrusion ratio and extrusion force for simulation

Fig.5 Relationship among extrusion ratio, coating speed and quantity of glass fiber in forward extrusion

4.2 Effect of composite wire diameter on extrusion ratio and extrusion speed

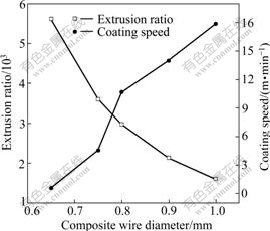

When quantity of glass fiber is unchanged, the change of composite wire diameter can cause the change of extrusion ratio. Fig.6 shows the relationship among the extrusion ratio, composite wire diameter and coating speed. From Fig.6, it is clear that the higher the composite wire diameter, the lower the extrusion ratio and the higher the limited coating speed. This means that the effective stress acting on the glass fiber increases with the increase of the extrusion ratio caused by change of composite wire diameter, because the higher limited coating speed means the lower force undertaken by fiber glass for the same overall extrusion force. This is also in good accordance with the simulation result. Other parameters in the experiment are: extrusion force of 170 kN, extrusion temperature of 317 ℃, quantity of glass fiber of 600 and die gap of 0.18 mm.

Fig.6 Relationship among extrusion ratio, coating speed and composite wire diameter in forward extrusion

5 Conclusions

1) Numerical simulation on the effect of extrusion ratio on coating extrusion forming of Pb-GF composite wire was performed by using DEFORM. The effective stress distribution was well predicted. It is revealed that the higher the extrusion ratio, the higher the stress that transfers to the glass fiber during extrusion. The relationship between the extrusion force and the extrusion ratio was also made clear by simulation.

2) The experimental investigation of Pb-GF coating extrusion shows that both the quantity of glass fiber and composite wire diameter are important parameters for change of extrusion ratio. The results show that the larger the quantity of glass fiber (0-1 800), and the higher the extrusion ratio (1 580-2 100), the lower the permitted coating speed (18-2.5 m/min), which means that the force acting on the glass fiber becomes high when the extrusion ratio and quantity of glass fiber are enhanced. This is in good accordance with the simulation result. The experiment results also show that when quantity of glass fiber is unchanged, the larger the composite wire diameter (0.65-1.0 mm) and the lower the extrusion ratio (5 600-1 400), the higher the permitted coating speed (2.5-18 m/min), which also means that the force acting on the glass fiber becomes high.

References

[1] MOSELEY P T, BONNET B, COOPER A, KELLAWAY M J. Lead-acid battery chemistry adapted for hybrid electric vehicle duty [J]. Journal of Power Sources, 2007, 174(1): 49-53.

[2] MOSELEY P T. ABLABC 2000—The way ahead [J]. Journal of Power Sources, 2001, 95: 218-223.

[3] KARDEN E, PLOUMEN S. Energy storage devices for future hybrid electric vehicles [J]. Journal of Power Sources, 2007, 168(1): 2-11.

[4] LAM L T, LOUEY R. Development of ultra-battery for hybrid-electric vehicle applications [J]. Journal of Power Sources, 2006, 158(2): 1140-1148.

[5] STIENECKER A W, STUART T, ASHTIANI C. An ultracapacitor circuit for reducing sulfation in lead acid batteries for mild hybrid electric vehicles [J]. Journal of Power Sources, 2006, 156(2): 755-762.

[6] BLANYER R J, MATHEWS C L. Method and apparatus for coating a core material with metal: US4658623 [P]. 1987.

[7] SIDDIQUI A M, HAROON T, KHAN H. Wire coating extrusion in a pressure-type die in flow of a third grade fluid via homotopy perturbation method [J]. International Journal of Nonlinear Sciences and Numerical, 2009, 10(2): 247-257.

[8] HAWKES D J, MORGEN R E. Conform extrusion current methods and capabilities [J]. Wire Industry, 1991, 6: 87-89.

[9] SOLLOGOUB C, FELDER E, DERNAY Y, AGASSANT J F, DEPARIS P, MIKLER N. Thermomechanical analysis and modeling of the extrusion coating process [J]. Polymer Engineering and Science, 2008, 48(8): 1634-1648.

[10] CHRISTOGLOU C, ANGELOPOULOS G N. Deposition of CrAl coating on Ni by means of a Pb and FBCVD process [J]. Journal of Physique IV, 2001, 11: 1125-1130.

[11] ALSHINA L A, KUDYAKOV V Y, ZYRYANOV V G. A lead-film electrode on an aluminium substrate to serve as a lead-acid battery plate [J]. Journal of power Sources, 1999, 78(2): 84-87.

[12] KURISAWA I, SHIOMI M, OHSUMI, SIWATA M, TSUBOTA M. Development of positive electrodes with an SnO2 coating by applying a sputtering technique for lead-acid batteries [J]. Journal of Power Sources, 2001, 95(2): 125-129.

[13] SUN Hong-fei, FANG Wen-bin, WANG Er-de. Fabrication of composite wire of lead coated on glass fiber by extrusion. [J] Trans Nonferrous Met Soc China, 2003, 13(3): 609-612.

[14] SUN Hong-fei, FANG Wen-bin, WANG Er-de. Extrusion process of lead-clad glass fiber composite [J]. Trans Nonferrous Met Soc China, 2003, 13(S1): 179-182.

[15] SUN Hong-fei, FANG Wen-bin, WANG Er-de. Effect of temperature on coating extrusion of Pb-GF composite wire by numerical simulation [J]. Trans Nonferrous Met Soc China, 2005, 14 (S2): 213-216.

(Edited by YANG Bing)

Corresponding author: SUN Hong-fei; Tel: +86-451-86418713; E-mail: sunhf@hit.edu.cn