Trans. Nonferrous Met. Soc. China 24(2014) 401-405

In situ formation of RE2S3 and RE2O2S phases on sinter skin of Cr–mischmetal co-doped WC-Co alloy

Li Zhang1, Yu-ping FENG1, Shu Chen2, Hou-ping Wu1

1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. Changsha Mining and Metallurgy Research Institute Co., Ltd., Changsha 410012, China

Received 11 January 2013; accepted 1 July 2013

Abstract: The as-sintered sinter skin of WC-11Co-0.71Cr3C2-0.06RE cemented carbide with WC+β microstructure was analyzed by scanning electron microscope, energy dispersive X-ray spectroscope and X-ray diffractometer. RE represents La-, Ce-, Pr- and Nd-containing mischmetal, and β is cobalt-based binder phase. It was discovered that La, Ce, Pr and Nd migrated directionally from the alloy to the sinter skin to combine with the impurity elements S and O from the sintering atmosphere during the sintering process. As a result, main dispersed phase RE2S3 and minor RE2O2S were formed in situ on the sinter skin. The mechanisms for the stimulation of the migration activity and the directional migration of RE atoms were discussed in terms of the thermodynamics stability of Cr3C2, solubility characteristic of Cr in Co and the polarization or ionization of RE atoms.

Key words: RE2S3; RE2O2S; cemented carbide; sintering; rare earth directional migration; atom polarization

1 Introduction

The in situ formation of a layer-structured RE2O2S phase (RE=La-, Ce-, Pr- and Nd-containing mischmetal) with lubricating function on the cutting faces of mischmetal doped WC-Co inserts was reported [1,2]. To realize this self lubricating function of rare earth doped cemented carbide tools by in situ stimulation in service, the prerequisite is that the rare earth must stay stably in the alloy during the sintering process. It is known that there is a huge difference in the atomic radius between La/Ce/Pr/Nd and W, La/Ce/Pr/Nd and Co, i.e., 32.8%-37.2% and 45.6%-50.4%. Therefore, it is an amazing phenomenon to observe the directional migration of La/Ce/Pr/Nd in the RE doped WC-Co alloy. Investigation of the way of the migration is the foundation for the stability control of rare earth in WC-Co alloys during the sintering process.

It is demonstrated that the behavior of La was stable in La2O3 independently doped WC-Co alloy [3]. During the sintering process of the alloy with WC+β+η three-phase microstructure (cross section, the same in the following), La atoms close to the sinter skin could migrate to the sinter skin; nevertheless, massive or long-range migration of La atoms and enrichment of La on the sinter skin have not been observed, where β is a cobalt-based binder phase and η is a carbon-deficient phase with a composition of Co3W3C. Nevertheless, we observed the massive directional migration of La in La2O3 and Cr3C2 co-doped WC-Co alloy with WC+β+η three-phase microstructure and the in situ formation of La2O2S and LaCoO3 phases on the sinter skin [4].

For La-, Ce-, Pr- and Nd-containing mischmetal (RE) independently doped WC-Co alloy, where RE was added in the form of RE-Co pre-alloyed powder, the situation was little complicated. For bulk alloy (in normal size) with WC+β+η three-phase microstructure, La and Ce got separated and Ce predominantly migrated towards the sinter skin during the sintering process [5,6]. Nevertheless, the behavior of RE in WC-Co alloy with WC+β two-phase microstructure followed a so called size effect. For WC-Co grainy alloy (less than 0.2 mm in diameter), La and Ce in the alloy migrated towards the sinter skin during the sintering process [7]; for WC-Co bulk alloy, both La and Ce stayed stably in the alloy during the sintering process [3].

In this work, we demonstrate that the directional migration ability of La, Ce, Pr and Nd can be activated by the addition of Cr3C2 in WC-Co bulk alloy with WC+β two-phase microstructure.

2 Experimental

Commercial powders of tungsten carbide (FSSS 7.0 μm), cobalt (FSSS 1.42 μm), chromium carbide (FSSS 1.45 μm) and RE-65%Co pre-alloyed powder (in mass fraction, the same in the following) were used to prepare the samples with a composition of WC-11%Co- 0.71%Cr3C2-0.06%RE (WC-11Co-0.71Cr3C2-0.06RE). The composition of mischmetal was La 29.91%, Ce 45.84%, Pr 5.65% and Nd 18.20%. Sintering of the samples was performed at 1430 °C for 60 min in a vacuum furnace. The final dimensions of the samples were approximately 5.25 mm in height, 6.5 mm in width and 20 mm in length. The polished cross-section etched with Murakami’s reagent was observed by optical microscope. It turned out that the alloy had a WC+β two-phase microstructure.

The sinter skin was analyzed by JEOL JSM-6490 LV scanning electron microscope (SEM) and the attached EDAX Genesis XM4 Neptune energy dispersive X-ray spectroscope (EDS). Phase identification was conducted on Rigaku Dmax /2550VB X-ray diffractometer. EDS and XRD (X-ray diffraction) examinations were performed on the same sample with a surface area of 6.5 mm×20 mm. MDI Jade 6.0 analysis software developed by Materials Data Inc. was used to analyze the XRD spectrum.

3 Results and discussion

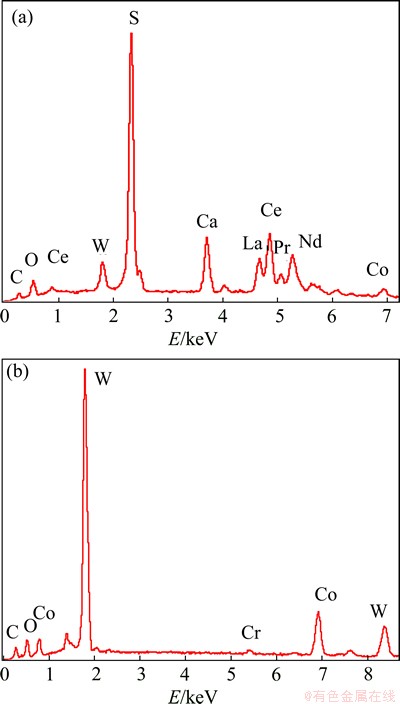

It was discovered that there is something quite different on the sinter skin of WC-11Co-0.71Cr3C2- 0.06RE alloy, as shown in Figs. 1 (a) and (b). It can be observed that there exists a dispersedly distributed new phase with bulgy shape on the sinter skin. EDS analysis results of the micro zones shown in Fig. 1 are given in Fig. 2 and Table 1.

Table 1 indicates that La, Ce, Pr, Nd and W, Co, C, as well as impurity elements S, Ca and O were detected in zones 1-3; nevertheless, both S and Ca were not detected in the WC+β matrix, i.e., zone 4 shown in Fig. 1. Therefore, it can be deduced that RE atoms have a strong ability to combine S and Ca atoms. It is notable that the average S content is as high as 23.96% in the RE enriched areas and the relative mass ratio of La, Ce, Pr and Nd is close to their original one in mischmetal. The oxygen contents in zones 1-4 are close to each other.

Fig. 1 SEM images of sinter skin of WC-11Co-0.71Cr3C2- 0.06RE alloy

Fig. 2 EDX spectra corresponding to zones 1 and 4 in Fig. 1

Table 1 EDX analysis results of zones shown in Fig. 1

It is relatively easy to understand the existence of O in the sintering atmosphere for the vacuum level is limited. As for the other impurity elements, e.g. S and Ca, there were two kinds of resources. One was originally from the graphite tray and carbon fiber in the sintering furnace, and the other was from the volatiles deposited on the graphite tray and carbon fiber during the sintering process of cemented carbides.

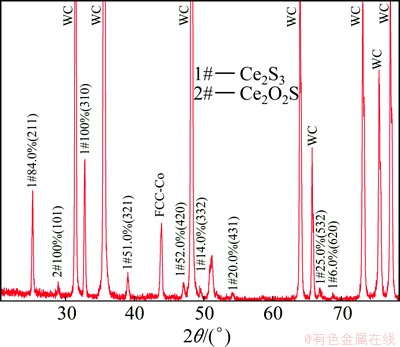

For the new phase identification, the as-sintered sinter skin with dimensions of 6.5 mm×20 mm was examined by X-ray diffractometer, as shown in Fig. 3. Figure 3 indicates a good consistency between the detected diffraction peaks and the standard diffraction peaks of Ce2S3, which means that the crystal structure of RE2S3 is a γ-Ce2S3 type and the substitution of Ce by La, Pr and Nd does not result in notable lattice distortion. Bigger Ce vacancy size than Ce cation in γ-Ce2S3 crystal is responsible for the small lattice distortion [8]. Only one diffraction peak, i.e. (101) main peak of RE2O2S with the same crystal structure of Ce2O2S, was detected, which indicates that the amount of RE2O2S is very small.

Fig. 3 XRD pattern of as-sintered sinter skin of WC-11Co- 0.71Cr3C2-0.06RE alloy

It can be summarized that together with hard phase WC and FCC-structured β phase, there are two new phases on the sinter skin, namely RE2S3 and RE2O2S. Considering the fact that the La, Ce, Pr and Nd enrichment phenomenon has not been observed in RE independently doped WC-Co bulk alloy with WC+β two-phase microstructure [3], it can be deduced that Cr plays a vital role in the directional migration. There are two kinds of hypothesis to decipher the Cr-induced migration activity stimulation mechanism, all related to the transiently existing free carbon atoms with high activity. Hypothesis one is based on the stability of high carbon type of chromium carbide. Due to the variability of valent states of chromium, there are different kinds of chromium carbides, i.e., CrC, Cr3C2, Cr2C, Cr7C3 and Cr23C6 with carbon mass fractions of 18.75%, 13.33%, 10.34%, 9.0% and 5.68%, respectively. It is well established that the valence electron structures of rare earth elements are unique. It can be deduced that under the coexistence condition of RE atoms with high activity and Cr3C2, the stability of Cr3C2 with relatively high carbon content can be deteriorated due to the interaction among the valence electrons from RE and chromium carbide [4]. Another hypothesis is based on the high solubility of Cr in Co. During the sintering process of WC-11Co-0.71Cr3C2-0.06RE alloy, due to the high solubility of Cr in Co, as high as 30%-33% at the temperature of 1400 °C [9,10] and larger than 95% of the Cr additive is dissolved in the Co-based binder phase at room temperature [11], free carbon atoms can be released as a result of the solution of Cr in Co. Owing to the large difference in electronegativity between RE elements and carbon, there are strong interactions between the valence electrons from RE atoms and transiently existing free carbon atoms. As a result, the energy of RE atoms in the alloy can be substantially raised and the polarization or ionization of RE atoms can be realized. Similarly, the carbon-donation conjecture of Cr3C2 in WC-Co alloy was reported by LEE et al [12].

From the phase diagrams of La–Co and Ce–Co, it is known that the liquid emergence temperature of RE–65%Co alloy is around 1200 °C. Therefore, the migration of RE atoms could be in the liquid state during the sintering process. As is known that the electronegative parameters of S and O are much bigger than those of La, Ce, Pr and Nd, there is a strong tendency for S and O to interact and combine with La, Ce, Pr and Nd. Therefore, owing to the existence of S and O in the sintering atmosphere although in minor amount, RE atoms existing with high activity stimulated by carbon atoms can be attracted to the sinter skin.

RE2O2S and RE2S3 are characterized with high melting point, e.g. La2O2S 2000-2200 °C [13], Ce2O2S (2000±200) °C [14], γ-La2S3 2080 °C [15,16], γ-Ce2S3 1870-2296 °C [17,18]. Therefore, with the formation of the compounds, RE atoms migrated from the alloy can be locked on the sinter skin of the alloy.

According to the skeleton theory of the liquid phase sintering of powder metallurgy products, at the liquid phase sintering stage, it is very difficult for the long- distance migration of liquid phase with good wetability to the solid phase in the alloy. It was reported that when the amount of RE in metallic state in cemented carbide reached 0.2% or above, a RE-containing dispersed phase was formed, and good interface combining strength of RE-containing dispersed phase with the WC hard phase and the binder phase was confirmed in WC-Co alloy [19,20]. Therefore, it can be deduced that there is a good wetability of liquid RE to the WC phase. Although the fast directional migration behavior of RE in cemented carbide still remains a mystery, under the situation of the polarization or ionization of RE atoms accompanied by the substantial decrease in atom radius, it is possible for RE atoms in polarization or ionization state to pass through the WC solid phase during their directional migration process. It is supposed that at the liquid phase sintering stage, the RE atoms normally migrate through the interfaces between the WC and the liquid Co binder phase; if the migration paths are blocked by the WC solid phase, RE atoms in polarized or ionized state can diffuse directly into the WC lattice and pass through the WC solid phase.

4 Conclusions

1) During the sintering process of metallic mischmetal and Cr3C2 co-doped WC-Co alloy with WC+β two-phase microstructure in the inner part of the alloy, La, Ce, Pr and Nd atoms in mischmetal migrated directionally from the alloy to the sinter skin, forming in situ RE-containing compounds, i.e. main RE2S3 and minor RE2O2S, with crystal structures of Ce2S3 and Ce2O2S type, respectively.

2) Cr3C2 with carbon-donation ability and the impurity elements S and O from the sintering atmosphere with much larger electronegative parameters than La, Ce, Pr and Nd are thought to be the reason behind the directional migration of RE atoms.

3) At the liquid phase sintering stage, RE atoms normally migrate through the interfaces between WC and liquid Co binder phase; if the migration paths are blocked by WC solid phase, RE atoms in polarized or ionized state can diffuse directly into the WC lattice and pass through the WC solid phase.

References

[1] WU Hou-ping, ZHANG Li, YU Xian-wang, CHEN Shu, XIONG Xiang-jun. In-situ formation of RE oxysulfide with self lubricating function during cutting process of cemented carbide tool [J]. The Chinese Journal of Nonferrous Metals, 2009, 19(4): 670-676. (in Chinese)

[2] WU Hou-ping, ZHANG Li, ZHAO Xiao-zhao, CHEN Shu, HUANG Bai-yun. EDX analysis of RE enriched phase on the working surface of mischmetal doped cemented carbide cutting insert [J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(2): 117-122. (in Chinese)

[3] ZHANG Li, SCHUBERT W D, HUANG Bai-yun. Surface observation of rare earth doped cemented carbide [J]. Journal of Central South University of Technology, 2003, 34(5): 467-471. (in Chinese)

[4] ZHANG Li, WU Hou-ping, CHEN Shu, WANG Zhen-bo. In situ formation of La containing dispersed phase on the sinter skin of La2O3 and Cr3C2 unitedly doped WC-Co cemented carbide [J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(6): 991-995.

[5] ZHANG Li, CHEN Shu, XIONG Xiang-jun, YU Xian-wang. Directional migration behavior of cerium during the sintering process of mischmetal doped cemented carbide [J]. Journal of Central South University of Technology, 2008, 15(1): 6-10.

[6] ZHANG Li, CHEN Shu, XIONG Xiang-jun, HUANG Bai-yun. Cerium enrichment on sinter skin of mischmetal doped WC–Co cemented carbide [J]. Journal of Central South University of Technology, 2005, 12(S1): 5-8.

[7] ZHANG Li, SCHUBERT W D, CHEN Shu, ZHANG Chuan-fu. Rare earth enrichment phenomenon during the sintering process of grainy hardmetal [J]. Materials Science and Engineering A, 2004, 384(1-2): 395-401.

[8] Windiks R, Wimmer E, Pourovskii L, Biermann S. Structure and optical properties of α- and γ-cerium sesquisulfide [J]. Journal of Alloys and Compounds, 2008, 459(1-2): 438-446.

[9] Hayashi K, Fuke Y, Suzuki H. Effect of addition carbides on the grain size of WC-Co alloy [J]. Journal of the Japan Society of Powder and Powder Metallurgy, 1972, 19(2): 67-71.

[10] ZHANG Li, WU Chong-hu, CHEN Shu. Micro-behaviors of the grain growth inhibitors in cemented carbides [J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(6): 667-673. (in Chinese)

[11] ZHANG Li, XIE Ming-wei, CHENG Xin, NAN Qing, WNAG Zhe, FENG Yu-ping. Micro characteristics of binder phases in WC-Co cemented carbides with Cr-V and Cr-V-RE additives [J]. International Journal of Refractory Metals and Hard Materials, 2013, 36(1): 211-219.

[12] Lee W B, Kwon B D, Jung S B. Effects of Cr3C2 on the microstructure and mechanical properties of the brazed joints between WC-Co and carbon steel [J]. International Journal of Refractory Metals and Hard Materials, 2006, 24(3): 215-221.

[13] Luo X X, Cao W H. Ethanol-assistant solution combustion method to prepare La2O2S: Yb, Pr nanometer phosphor [J]. Journal of Alloys and Compounds, 2008, 460(1-2): 529-534.

[14] Vahed A, KAY D A R. Thermodynamics of rare earths in steelmaking [J]. Metallurgical Transactions B, 1976, 7(3): 375-383.

[15] Madelung O,  O, Schulz M. La2S3: Crystal structure, physical properties [M]. Berlin: Springer–Verlag, 2000: 1-3.

O, Schulz M. La2S3: Crystal structure, physical properties [M]. Berlin: Springer–Verlag, 2000: 1-3.

[16] Andreev O V, Mitroshin O Y, Razumkova I A. Phase diagrams of the systems Sc2S3–RE2S3 for RE=La, Nd, or Gd [J]. Russian Journal of Inorganic Chemistry, 2007, 52(7): 1161-1164.

[17] Roméro S, Mosset A, Macaudière P, Trombe J C. Effect of some dopant elements on the low temperature formation of γ-Ce2S3 [J]. Journal of Alloys and Compounds, 2000, 302(1-2): 118-127.

[18] Hirai S, Shimakage K, Saitou Y, Nishimura T. Synthesis and sintering of cerium(III) sulfide powders [J]. Journal of the American Ceramic Society, 1998, 81(1): 145-151.

[19] WU Hou-ping, ZHANG Li, WANG Zhen-bo, CHEN Shu. Existing states of lanthanum and cerium in WC-Co hardmetal [J]. Journal of the Chinese Rare Earth Society, 2009, 27(5): 693-697. (in Chinese)

[20] ZHANG Li, CHEN Shu, XIE Ming-wei, NAN Qing, WU Hou-ping. Synergetic migration behavior of La and Ce and related microstructure character of Cr-V-RE co-doped WC-Co alloy [J]. Journal of Rare Earths, 2012, 30(5): 480-485.

Cr-RE共掺杂WC-Co合金烧结体表面RE2S3和RE2O2S相的原位形成

张 立 1,冯于平1,陈 述2,吴厚平1

1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 长沙矿冶研究院有限责任公司,长沙 410012

摘 要:采用扫描电镜、能谱仪以及X射线衍射仪对具有WC+β (β为钴基粘结相)两相结构的WC-11Co- 0.71Cr3C2-0.06RE (RE为含La、Ce、Pr、Nd 的混合稀土)硬质合金烧结体表面进行观察与分析。结果表明,在烧结过程中合金中的La、Ce、Pr、Nd通过定向迁移与烧结炉内气氛中的S、O等杂质元素结合,在合金烧结体表面形成RE2S3(主)和RE2O2S(少量)弥散相。从合金中Cr3C2的热力学稳定性、Cr在Co中的溶解度特性以及稀土原子激发等3个方面,对稀土迁移活性的激发机制和稀土原子的定向迁移机制进行分析与讨论。

关键词:RE2S3;RE2O2S;硬质合金;烧结;稀土定向迁移;原子极化

(Edited by Xiang-qun LI)

Foundation item: Project (51074189) supported by the National Natural Science Foundation of China; Project (2012ZX04003–021) supported by the National Science & Technology Special Foundation of China; Project (Y2012–010) supported by the Nonferrous Metals Research Foundation from Hunan Nonferrous Metals Holding Group Co., Ltd. –CSU, China

Corresponding author: Li ZHANG; Tel: +86-731-88876424; E-mail: zhangli@csu.edu.cn

DOI: 10.1016/S1003-6326(14)63075-2