Trans. Nonferrous Met. Soc. China 23(2013) 1966-1970

Effect of intermetallic compounds on heat resistance of hot roll bonded titanium alloy-stainless steel transition joint

Dong-sheng ZHAO1, Jiu-chun YAN2, Yu-jun LIU1

1. State Key Laboratory of Structural Analysis for Industrial Equipment, School of Naval Architecture, Dalian University of Technology, Dalian 116024, China;

2. State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology, Harbin 150001, China

Received 20 June 2012; accepted 17 September 2012

Abstract: The effect of intermetallic compounds on the heat resistance of transition joint was investigated. The experiment of post-weld heat treatment for the hot roll bonded titanium alloy-stainless steel joint using nickels interlayer was carried out, and the interface microstructure evolution due to heat treatment was presented. There was not found significant interdiffusion at stainless steel/nickel interface, when the specimens were heat treated in the temperature range of 600-800 °C for 10 and 30 min, while micro-cracks occurred at the stainless steel/nickel interface heat treated at 700 °C for 30 min. The thickness of intermetallic layers at nickel/titanium alloy interface increased at 600 °C, and micro-cracks occurred at 700 and 800 °C. The micro-cracks occurred between intermetallic layers or between intermetallic layer and nickel interlayer as well. The tensile strength of the transition joint decreased with the increase of heat treatment temperature or holding time.

Key words: intermetallics; titanium alloy; stainless steel; transition joint; heat resistance; heat treatment; hot roll bonding

1 Introduction

Nuclear, aerospace, and chemical industries strongly demand the joints of titanium/titanium alloy to stainless steel for different applications. It is difficult to obtain complete welding joint between titanium alloy and stainless steel by fusion welding such as arc welding [1,2]. The reason is the difference of the physical property, especially the coefficient of thermal expansion, which can lead to high welding stress, and a large number of intermetallic compounds formed in the fusion welding [3-5]. Making of titanium alloy/stainless steel transition joint by solid-phase bonding method can solve above problems, then arc welding is used to connect titanium/titanium side of transition joint and stainless steel/stainless steel side of transition joint. Thus, the welding of dissimilar materials can be converted to the welding of same materials. Transition joint of titanium alloy and stainless steel has wide applications in reprocessing units of nuclear industries and as accessories in oil rig of refineries [6-8].

The transition joint will be welded with titanium alloy and stainless steel, respectively. There is a requirement of heat resistance for the transition joint, but currently such researches are very little. The post-weld heat treatment experiment of explosively welded titanium-stainless steel composite shows that the post-weld heat treatment can lead to the formation of the intermetallics at the joint interface [9,10]. The thickness of the intermetallic layers increases with the increase of heat treatment temperature, even micro-cracks forms at the interface. The heat resistance of the transition joint is the main factor of selecting of welding method and process parameters to connect transition joint and base materials. So it is necessary to study the effect of post-weld heat treatment on the microstructure and properties of titanium/stainless steel transition joint.

Joining of titanium and stainless steel has to face the problem of intermetallic compounds [11-13], and the research on the post-weld heat treatment of the transition joint can observe the effect of intermetallic compounds on the heat resistance of the joint.

The hot roll bonding is performed in vacuum condition, and the bonding time is very short [14]. The volume fraction of intermetallics will be controlled effectively, because there is no enough time for interdiffusion of the elements. Using nickel as an interlayer, the generation of Fe-Ti and Fe-Cr-Ti intrmetallics can be avoided [15], and the maximum tensile strength of 440.1 MPa was obtained at the bonding temperature of 760 °C, the reduction of 20% and the rolling speed of 38 mm/s.

In the present work, the effect of heat treatment on the interface microstructure evolutions of the hot roll bonded titanium/stainless steel joint is investigated, and the effect of intermetallic compounds on the heat resistance of the transition joint is examined.

2 Experimental

The specimens used in the experiment were cut from the hot roll bonded titanium alloy-stainless steel bimetal plate, and the cutting location is shown in Fig. 1. The cross-section dimension of the specimen was 10 mm×3 mm, and the length was about 30 mm which was the same as the thickness of the hot roll bonded bimetal plate. The initial dimensions of Ti-6Al-4V alloy and 0Cr18Ni10Ti stainless steel were 100 mm×70 mm×19 mm and 120 mm×70 mm×19 mm, respectively, and the initial dimension of the pure nickel foil was 110 mm×80 mm×0.4 mm. The hot roll processing parameters were as follows: bonding temperature of 760 °C, reduction of 20%, and rolling speed of 38 mm/s. The details are shown in Ref. [15].

Fig. 1 Image of cutting location on hot roll bonded bimetal plate

After hot roll bonding, the joint was cut into several specimens which were heated treated in the vacuum furnace in the temperature range of 600-800 °C for 10 min and 30 min, respectively. Then the specimens were furnace cooled to room temperature.

The tensile strength of the joints was measured using electronic testing machine (Instron 5569). The dimensions of sheet tensile specimens are 10 mm×3 mm and length of 30 mm. The nickel interlayer was at the centre of the gauge length. Tensile strength of the joints was evaluated using a tensile testing machine with a crosshead speed of 1 mm/min at room temperature. Three samples were tested at each process parameter to check the reproductivity of results.

The microstructure of interface was observed by scanning electron microscope (SEM, HITACHIS-4700), and the chemical composition of the intermetallic layers at bonded interface was detected by energy dispersive X-ray analysis (EDAX).

3 Results and discussion

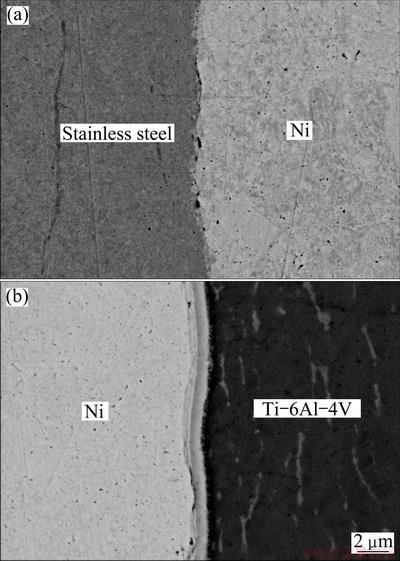

Figure 2 shows the SEM electron back-scattered diffraction (EBSD) image of the hot roll bonded stainless steel/titanium alloy interface. There is no obvious diffusion layer at the stainless steel/Ni interface, while there are two intermetallic layers at the Ni/Ti alloy interface with the possible phases TiNi3+Ni and TiNi3+TiNi [15].

Fig. 2 SEM-EBSD images of stainless steel/Ni interface (a) and Ni/Ti alloy interface (b)

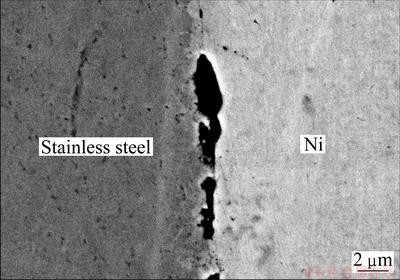

There is no obvious diffusion layer formed at the stainless steel/Ni interface after heat treatment at 600-800 °C. When the specimens are heat treated at 600 °C for 10 and 30 min, there is a good connection interface with a small amount of micro-voids. Figure 3 shows SEM-EBSD image of the stainless steel/Ni interface heat treated at 700 °C for 30 min, and micro-cracks form at the stainless steel/Ni interface. Due to the difference of the coefficient of thermal expansion between stainless steel and Ni, thermal stress is generated during the post-weld heat treatment. And the thermal stress increases with the heat treatment temperature increasing. So micro-cracks form on the location where micro-voids or weak bonding exist at the stainless steel/Ni interface.

Fig. 3 SEM-EBSD image of stainless steel/Ni interface after heat treatment at 700 °C for 30 min

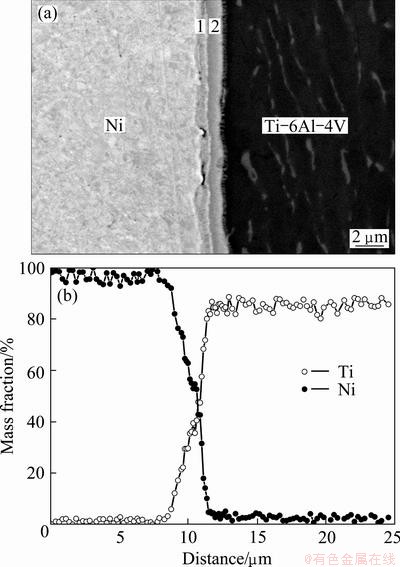

Figure 4 shows the SEM-EBSD image and element distribution profile of the Ni/Ti-6Al-4V interface heat treated at 600 °C for 30 min. It indicates that interdiffusion occurs at the interface and the total thickness of intermetallic layers increases after the heat treatment. The thickness increases from 0.9-1.2 μm to 0.8-1.8 μm (holding time of 10 min) and 1.1-2.1 μm (holding time of 30 min), respectively. Some locations at the interface do not have significant diffusion, which can be explained by the existence of micro-voids before heat treatment.

Fig. 4 SEM-EBSD image (a) and element distribution profile (b) of Ni/titanium alloy interface heat treated at 600 °C for 30 min

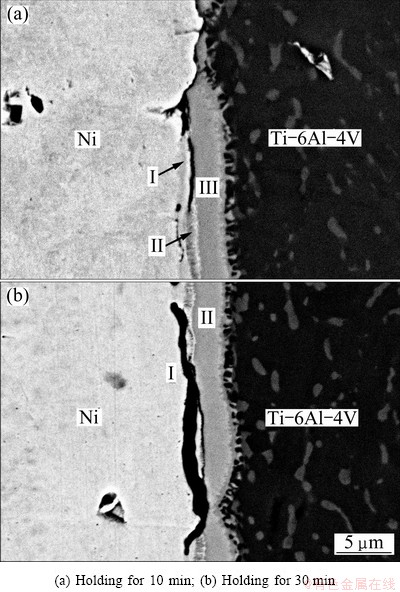

Figures 5 and 6 show SEM-EBSD images of the Ni/Ti-6Al-4V interface heat treated at temperature of 700 °C and 800 °C, respectively. They show that, when the heat treatment temperature is up to 700 and 800 °C, cracks appear at the Ni/Ti-6Al-4V interface.

Fig. 5 SEM-EBSD images of Ni/Ti-6Al-4V interface after heat treatment at 700 °C

Fig. 6 SEM-EBSD images of Ni/Ti-6Al-4V interface after heat treatment at 800 °C

The cracks mainly occur between intermetallic layers when the specimen is heat treated at 700 °C for 10 min, but the cracks occur between nickel interlayer and intermetallic layer when the holding time is up to 30 min. When the specimen is heat treated at 800 °C for 10 min, the cracks occur between intermetallic layers and between intermetallic layer and nickel layer. Through the observation of the thickness of intermetallic layers after heat treatment, it shows that the diffusion distance of Ni in the titanium alloy is farther than that of Ti in the Ni interlayer. According to the location of the cracks after heat treatment, it’s concluded that the existence of intermetallic compounds is the main reason for cracking. This possible reason can be that the intermetallic compounds are hard and brittle. Because of the difference of the coefficient of thermal expansion, high stress is generated at the interface when bonded joint is heated, which leads to stress concentration and cracking in the locations between intermetallic layers and the locations between intermetallic layers and Ni interlayer. By comparing the following figures (Fig. 2(b), Fig. 5, and Fig. 6), it is found that the thickness of the intermetallic layers increases after heat treatment. This shows that the cracking do not occur in the beginning stages of heat treatment process. In the heat treatment process, elements interdiffusion occur so the thickness of intermetallic layers increases, and the composition and phases of intermetallic layers change accordingly.

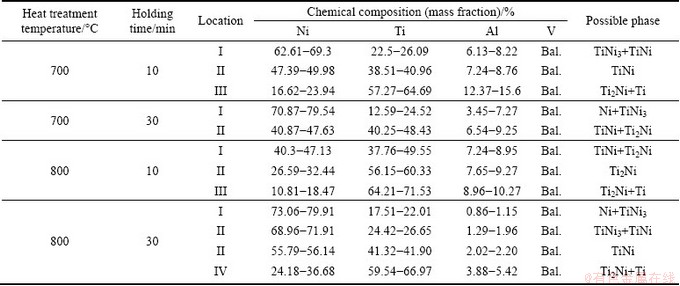

The chemical composition and possible phase for the cracking locations are shown in Table 1, determined by EDAX and Ni-Ti binary phase diagram.

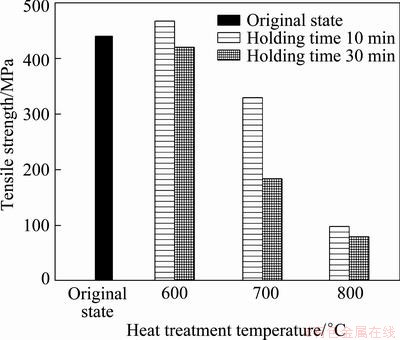

Figure 7 shows the room-temperature tensile strengths of the transition joint before and after heat treatment. The tensile specimens of transition joints fracture at the interface between Ni and Ti alloy, when they are heated at the temperature of 600-800 °C for 10 min and 30 min. When the specimen is heat treated at temperature is 600 °C for 10 min, the tensile strength of transition joint achieves about 467.45 MPa, which has an increase of 27.35 MPa compared to that before heat treatment. It can be explained by the element interdiffusion during the heat treatment process which removes some micro-void at the interface. When the holding time is 30 min, the tensile strength reduces as a result of the volume fraction of intermetallic compounds increasing. In the case of heat treatment at temperature of 700 °C and 800 °C, the room-temperature tensile strength after heat treatment reduces when the heat treatment temperature or the holding time increases. This is because of the increase of volume fraction of intermetallic compounds after heat treatment, and even thermal stress leads to cracking of some area of the bonded interface. The lowest tensile strength 79.26 MPa is obtained when the specimen is heat treated at 800 °C for 30 min.

Fig. 7 Room-temperature tensile strength of transition joint before and after heat treatment

Table 1 Chemical composition and possible phase for cracking locations at interface of nickel and titanium alloy

4 Conclusions

1) When the specimens are heat treated in the temperature range of 600-800 °C for 10 and 30 min, no significant interdiffusion occurs at stainless steel/Ni interface. Micro-cracks occur at the stainless steel/nickel interface when the specimen is heat treated at temperature is 700 °C for 30 min.

2) When the temperature is 600 °C, interdiffusion occurs at the Ni/Ti-6Al-4V interface and the total thickness of intermetallic layers increases slightly. The thickness of intermetallic layers increases from 0.9-1.2 μm to 0.8-1.8 μm (holding time of 10 min) and 1.1-2.1 μm (holding time of 30 min), respectively.

3) Cracks occur at Ni/Ti-6Al-4V interface when the heat treatment temperature is 700 °C and 800 °C. The cracks occur between intermetallic layers and between intermetallic layer and nickel interlayer.

References

[1] KUNDU S, CHATTERJEE S. Interface microstructure and strength properties of diffusion bonded joints of Titanium-Al interlayer- 18Cr-8Ni stainless steel [J]. Materials Science and Engineering A, 2010, 527: 2714-2719.

[2] GHOSH M, CHATTERJEE S. Diffusion bonded transition joints of titanium to stainless steel with improved properties [J]. Materials Science and Engineering A, 2003, 358(1-2): 152-158.

[3] WANG J Z, YAN X B, WANG W Q. Titanium cladding steel plates with interlayer by explosion and rolling bonding [J]. Rare Metal Materials and Engineering, 2010, 39(2): 309-313. (in Chinese)

[4] LEE J G, LEE J K, HONG S M, LEE M K, RHEE C K. Microstructure and bonding strength of titanium to stainless steel joints brazed using a Zr-Ti-Ni-Cu-Be amorphous filler alloy [J]. Journal of Materials Science, 2010, 45(24): 6837-6840.

[5] WANG M, GUO H Z. Techniques and mechanism of superplastic diffusion bonding between titanium alloy and stainless steel [J]. Rare Metal Materials and Engineering, 2010, 39(11): 1964-1969. (in Chinese)

[6] LEE M K, LEE J G, CHOI Y H. Interlayer engineering for dissimilar bonding of titanium to stainless steel [J]. Materials Letters, 2010, 64: 1105-1108.

[7] GHOSH M, LAIK A, BHANUMURTHY K, KALE G B, KRISHNAN J. Evolution of interface microstructure and strength properties in titanium-stainless steel diffusion bonded transition joints [J]. Materials Science and Technology, 2004, 20(12): 1578-1584.

[8] LEE J G, HONG S J, LEE M K, RHEE C K. High strength bonding of titanium to stainless steel using an Ag interlayer [J]. Journal of Nuclear Materials, 2009, 395: 145-149.

[9] AKBARI MOUSAVI SAA, SARTANGI P F. Effect of post-weld heat treatment on the interface microstructure of explosively welded titanium-stainless steel composite [J]. Materials Science and Engineering A, 2008, 494: 329-336.

[10] WEI Y H, DONG Z B, LIU B, MA R, ZHAN X H, LU Y F, GUO P. Stress distributions of welding joints in titanium-steel composite pressure vessel under working conditions [J]. Science and Technology of Welding and Joining, 2011, 16(8): 709-716.

[11] KUNDU S, CHATTERJEE S. Effects of temperature on interface microstructure and strength properties of titanium-niobium stainless steel diffusion bonded joints [J]. Materials Science and Technology, 2011, 27: 1177-1182.

[12] ORHAN N, KHAN TI. Diffusion bonding of microduplex stainless steel to Ti-Al-4V [J]. Scripta Mater, 2001, 45: 441-446.

[13] GHOSH M, BHANUMURTHY K, KALE G B, KRISHNAN J, CHATTERJEE S. Diffusion bonding of titanium to 304 stainless steel [J]. Journal of Nuclear Materials, 2003, 322(2-3): 235-241.

[14] ZHAO D S, YAN J C, WANG C W, WANG Y, YANG S Q. Interfacial structure and mechanical properties of hot roll bonded joints between titanium alloy and stainless steel using copper interlayer [J]. Science and Technology of Welding and Joining, 2008, 13: 765-768.

[15] YAN J C, ZHAO D S, WANG C W, YANG S Q. Vacuum hot roll bonding of titanium alloy and stainless steel using nickel interlayer [J]. Materials Science and Technology, 2009, 25: 914-918.

金属间化合物对钛合金与不锈钢的热轧焊过渡接头耐热性的影响

赵东升1,闫久春2,刘玉君1

1. 大连理工大学 工业装备结构分析国家重点实验室 船舶工程学院,大连 116024;

2. 哈尔滨工业大学 先进焊接与连接国家重点实验室,哈尔滨 150001

摘 要:研究金属间化合物对过渡接头耐热性的影响,采用镍中间层的钛与不锈钢热轧焊接头的焊后热处理方法,研究焊后热处理引起的连接界面微观组织演变。结果表明:当热处理温度为600~800 °C,热处理时间为10 min和30 min时,在不锈钢与镍的连接界面处没有发生明显的互扩散。但是,当热处理温度为700 °C热处理时间为30 min时,在不锈钢与镍的连接界面出现微裂纹。热处理温度为600 °C时,镍与钛合金的连接界面的金属间化合物层的厚度增大,而热处理温度为700和800 °C时,界面出现微裂纹。微裂纹产生在金属间化合物层之间或者是金属间化合物层与镍层之间。过渡接头的拉伸强度随着热处理温度的升高或时间的延长而降低。

关键词:金属间化合物;钛合金;不锈钢;过渡接头;耐热性;热处理;热轧焊

(Edited by Chao WANG)

Foundation item: Project (AWPT-M07) supported by the State Key Laboratory of Advanced Welding and Joining, Harbin Institute of Technology

Corresponding author: Jiu-chun YAN; Tel: +86-451-86418695; E-mail: jcyan@hit.edu.cn

DOI: 10.1016/S1003-6326(13)62684-9