高织构热解炭基炭/炭复合材料的制备与力学性能

来源期刊:中国有色金属学报(英文版)2013年第7期

论文作者:李 伟 李贺军 王 杰 张守阳 杨 茜 魏建锋

文章页码:2129 - 2134

关键词:C/C复合材料;高织构;化学气相沉积;石墨化度;力学性能

Key words:carbon/carbon composites; high texture; chemical vapor infiltration; graphitization degree; mechanical properties

摘 要:以天然气为炭源气体,采用等温化学气相沉积工艺对孔隙率为89.5%的短切炭纤维毡进行致密化。经过150 h的沉积,所制备的炭/炭 (C/C) 复合材料的密度达到1.89 g/cm3。利用PLM、XRD、SEM以及三点弯曲测试对所制备的C/C复合材料的纤维结构和力学性能进行研究。结果表明:沉积的热解炭基体为高织构热解炭;经过高温石墨化处理后,大幅度地提高了材料的晶粒尺寸与石墨化度,降低了材料的强度和模量,并提高了其韧性。这些力学性能的变化与石墨化处理后材料内部显微结构的变化相关。

Abstract: Short carbon fiber felts with an initial porosity of 89.5% were deposited by isobaric, isothermal chemical vapor infiltration using natural gas as carbon source. The bulk density of the deposited carbon/carbon (C/C) composites was 1.89 g/cm3 after depositing for 150 h. The microstructure and mechanical properties of the C/C composites were studied by polarized light microscopy, X-ray diffraction, scanning electron microscopy and three-point bending test. The results reveal that high textured pyrolytic carbon is deposited as the matrix of the composites, whose crystalline thickness and graphitization degree highly increase after heat treatment. A distinct decrease of the flexural strength and modulus accompanied by the increase of the toughness of the C/C composites is found to be correlated with the structural changes in the composites during the heat treatment process.

Trans. Nonferrous Met. Soc. China 23(2013) 2129-2134

Wei LI, He-jun LI, Jie WANG, Shou-yang ZHANG, Xi YANG, Jian-feng WEI

C/C Composites Research Center, State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China

Received 30 January 2013; accepted 6 May 2013

Abstract: Short carbon fiber felts with an initial porosity of 89.5% were deposited by isobaric, isothermal chemical vapor infiltration using natural gas as carbon source. The bulk density of the deposited carbon/carbon (C/C) composites was 1.89 g/cm3 after depositing for 150 h. The microstructure and mechanical properties of the C/C composites were studied by polarized light microscopy, X-ray diffraction, scanning electron microscopy and three-point bending test. The results reveal that high textured pyrolytic carbon is deposited as the matrix of the composites, whose crystalline thickness and graphitization degree highly increase after heat treatment. A distinct decrease of the flexural strength and modulus accompanied by the increase of the toughness of the C/C composites is found to be correlated with the structural changes in the composites during the heat treatment process.

Key words: carbon/carbon composites; high texture; chemical vapor infiltration; graphitization degree; mechanical properties

1 Introduction

Carbon/carbon (C/C) composites composed of carbon fibers and pyrolytic carbon matrix have attracted particular attention in aeronautic, astronautic and biomedical fields because of their series unique properties [1-3]. Isobaric, isothermal chemical vapor infiltration (ICVI) is the most widely used technique to prepare the composites [4]. The microstructures of the deposited pyrolytic carbons can be varied from a nearly amorphous to a highly textured graphitic state by adjusting the deposition parameters including the composition and pressure of the precursor gases, temperature and residence time [5]. Polarized light microscopy (PLM) is frequently used in industry and basic research for a rapid texture characterization of pyrolytic carbon [6]. Under PLM, the textures of pyrolytic carbons were determined according to their optical activity and the extinction angle (Ae). The corresponding pyrolytic carbon textures with progressive values of Ae are defined as isotropic (Ae=0°), low texture (0°≤Ae<12°), medium texture (12°≤Ae<18°), and high texture (HT, Ae≥18°) [7]. Generally, HT pyrolytic carbon is desired in C/C composites, because it has relatively high density, strength, toughness and thermal conductivity. Besides the matrix texture, carbon fiber preform and porosity of the composites also play important roles in the mechanical properties that are essential for structural component applications. Nowadays, more concerns are focused on continuous fiber reinforced C/C composites [8-11] than the short carbon fiber felt reinforced C/C composites, because the continuous fibers allow the C/C composites to possess better mechanical, friction and ablation properties. However, the low density short carbon fiber felt has a relatively low price which can effectively reduce the cost of C/C composites. In addition, the short carbon fiber felts reinforced C/C composites usually have a higher electrical resistance, making them more suitable for using as heating elements in furnace than two dimensional C/C composites [12]. Therefore, preparation and understanding the mechanical properties of short carbon fiber felts reinforced C/C composites are necessary to assess their potentially operational performance and expand the commercial applications of the composites.

In the present work, short carbon fiber felts reinforced C/C composites with a high density were prepared by ICVI. The distribution of densities and open porosities of the composites along the precursor gas diffusion direction were measured. The texture and microstructure of the composites were analyzed by PLM and X-ray diffraction (XRD). The mechanical properties of the materials were determined by three-point bending tests and the fractural behavior was analyzed by scanning electron microscopy (SEM).

2 Experimental

2.1 Preparation materials

The preforms with dimensions of d80 mm×14 mm for depositing C/C composites were short carbon fiber felts (Yixing Tianniao Co., Ltd., China) with an initial relative porosity of 89.5%. Polyacrylonitrile-based carbon fibers forming the felts had a typical density of 1.76 g/cm3, an average diameter of 7 μm, and were randomly orientated in the felts. The preforms were deposited by means of ICVI in the temperature range of 900-1200 °C, at a reduced pressure of 0.1-20 kPa. During the process, the preforms were fixed in a self-designed configuration (Fig. 1(a)) and natural gas with methane content higher than 95% (volume fraction) was used as carbon source. After deposition, a part of the composites were heat treated at 2500 °C for 2 h under argon atmosphere.

Fig. 1 Schematic of ICVI configuration (a) and cutting samples for measuring density and open porosity distribution (b)

2.2 Characterization of C/C composites

2.2.1 Density and porosity distribution

Small bulk samples were cut from the composites according to Fig. 1(b). The density and open porosity of the samples were determined by a water penetration technique [13].

2.2.2 Mechanical property

Three-point bending test was carried out to determine the mechanical properties of the composites. For this purpose rectangular bars with dimensions of 55 mm×10 mm×4 mm were cut from the composites. Five rectangular bars were tested for each group of the samples, namely, one group was the deposited samples and the other is the heat treated samples. Tests were carried out on a MTS CMT5304-30 kN universal test machine. During the test, a span of 40 mm was set, giving a span to thickness ratio of 10. All the tests were conducted under a controlled cross head speed mode at a constant speed of 0.5 mm/min. The load and deflection were recorded as a function of time. The stress (σ) and the strain (ε) were calculated according to Eqs. (1) and (2) [14]:

(1)

(1)

(2)

(2)

where F is the load, L is the span, b is the sample width, d is the sample thickness, and s is the displacement or deflection.

2.2.3 Microstructure

The phase of the composites was analyzed by X-ray diffraction (XRD) using a Philips X’ pert MPD X-ray diffractometer with Cu Kα radiation (45 kV, 40 mA). The interlayer spacing (d002) was calculated by Bragg equation, and the microcrystalline height (Lc) was calculated by Scherrer equation. The value of the graphitization degree (g) of the composites was calculated by Maire and Mering equation.

The textures of the pyrolytic carbon in the composites were observed under a Leica DMLP microscope. The morphology of the fractured surface of the sample after three-point bending test was observed using a ZEISS SUPRA 55 scanning electron microscope (SEM).

3 Results and discussion

Figure 2 shows the bulk density of the C/C composites as a function of the deposition time. It is found that the deposition rate has a slight increase with prolonging deposition time within the first 50 h, because in this regime the deposition surface in the composites gradually increases, which offers more active sites for depositing pyrolytic carbon. After deposition for 50 h, the density of the composites reaches 1.07 g/cm3. Some small pores in the composites begin to vanish, and some active sites disappear accompanied by the vanishing of the pores. Therefore, the deposition rate starts to decrease. A rapid decrease of the deposition rate happens after depositing for 100 h, because most of the original porosity in the composites has been filled. Finally, after depositing for 150 h, the density of the composites was measured to be as high as 1.89 g/cm3.

Fig. 2 Curve of bulk density of deposited composites as function of deposition time

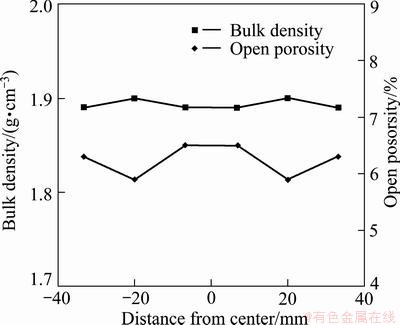

In order to determine the bulk density and open porosity distribution of the composites, small bulks were cut from a half of one composite according to Fig. 1(b) because of their symmetrical nature, and the tested results are shown in Fig. 3. It can be seen that the density and open porosity distribute uniformly along the gas diffusion direction. The carbon source, i.e. natural gas, plays an important role in the uniform deposition of the composites. The main composition of the natural gas is methane which has higher diffusion coefficient, decomposition active energy (~440 kJ/mol) [15] and lower deposition rate than any other gaseous hydrocarbons. The high density of the deposited composites, uniform distribution of the density and porosity combining with the relatively short deposition time indicate that the process is suitable for depositing short carbon fiber felts.

Fig. 3 Bulk density and open porosity distribution within C/C composites

Figure 4 shows the PLM images of the composites after depositing for 150 h. It is found that the fibers randomly orientate in the carbon matrix. Small pores within the felt are totally filled with pyrolytic carbon, but a few relatively large pores are only densified partially, leaving some residual pores. The magnified optical micrograph clearly represents the appearance of the carbon fibers and pyrolytic carbon. Carbon fibers are not sensitive to light, while the pyrolytic carbon has high optical activity and exhibits numerous rough and irregular extinction crosses that are the typical characteristics of the HT pyrolytic carbon. The Ae of the pyroytic carbon is determined to be 22° which is located in the range of HT pyrolytic carbon [7].

Fig. 4 PLM images of C/C composites

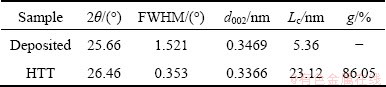

Figure 5 shows the XRD patterns of the deposited and heat treated C/C composites. It is observed that the intensive peak of the deposited sample locates in the range of 25°-27°, which correlates to the (002) peak of graphite. The leftward shift of the peak position and the broad full width at half-maximum intensity (FWHM) of the (002) peak indicate that a lot of defects exist in the sample. After heat treatment, the (002) peak position shifts rightwards, and the peak becomes sharp and narrow. The structural parameters calculated according to the diffraction data obtained from Fig. 5 are listed in Table 1. The Lc of the deposited sample is 5.36 nm, while the FWHM of the (002) peak of the sample after high temperature heat treated (HTT) sample decreases by 76.8%, and accordingly its Lc increases by 3.3 times. The calculated g value of the HTT sample reaches 86.05%, showing consistent with other work that the HT pyrolytic carbon is easy to be graphitized [10].

Fig. 5 XRD patterns of deposited (a) and HTT (b) C/C composites

Table 1 XRD structural parameters of C/C composites

Figure 6(a) shows the typical stress—strain curves for the deposited and HTT samples. The curves show a linear zone followed by a clearly nonlinear part before fracture of the samples, but the nonlinear zone of the HTT sample is larger than that of the deposited sample. During the fracture procedure, the stress of the deposited sample shows an abrupt decrease as a function of the strain, while that of the HTT sample slowly decreases with increasing the strain. These phenomena imply that the HTT sample exhibits a more nonbrittle fracture behavior than the deposited sample. The average flexural stress and modulus of the samples are shown in Fig. 6(b). Deposited sample has obvious higher flexural stress and modulus than HTT sample, whilst the scatter in flexural strength of deposited samples is higher than that in HTT sample. After heat treatment, the flexural strength of sample (67.3 MPa) is 36.1% lower than that of the deposited sample (105.4 MPa), whilst its modulus (11.4 GPa) decreases by 24.5% compared with deposited sample (15.1 GPa). At first sight, the flexural strength seems to be low, but taking into account the low content of the carbon fibers in the felt, these values are reasonable. In comparison with other documents [14,16], the flexural strength is comparable with (or higher than) that of the C/C composites using short carbon fiber felt as preform.

Fig. 6 Stress—strain curves (a) and mechanical properties (b) of C/C composites

Figure 7 shows the SEM micrographs of the fracture surfaces of the C/C composites after bending tests. The fracture surface of the deposited sample demonstrates rugged morphology. Only several fibers are pulled out after the fracture, and other fibers are embedded in the pyrolytic carbon matrix. This indicates that the adhesion between fibers and matrix is strong. As the generated cracks arrive at the fiber-pyrolytic carbon matrix interface region in the sample, they will directly penetrate the matrix and fibers without deflection at the interface. The fracture surface of HTT sample shows a more rough appearance. A lot of fibers are pulled out after the failure of the sample, which demonstrates that the fiber-pyrolytic carbon matrix interface has been weakened after heat treatment. The weakened interface can make the cracks deviate from their original propagating direction, which can improve the toughness of the sample. The high resolution SEM image of the fracture surface of the deposited HT pyrolytic carbon is shown in Fig. 7(c). The fracture of the fiber and the pyrolytic carbon matrix occur approximately in the same fracture plane and there is also no obvious debonding between the fiber and matrix. The pyrolytic carbon shows a dense and lamellar microstructure. When the matrix bears loading, cracks can deflect within the lamellae or sublayers. The energy dissipation resulted from the multiple crack deflection contributes to nonbrittle fracture behavior of the deposited samples. The Lc of the pyrolytic carbon grows thick during the heat treatment process, and the bonding strength among the sublayers becomes weak. As a consequence the number of the sublayers increases, and the cracks are more easily deflected among these sublayers [17]. Therefore, a very intensive fragmentation takes place within the HTT HT pyrolytic carbon, leading to a more rough fracture surface.

The obvious decrease of the flexural strength and increase of the toughness of the C/C composites after heat treatment could be explained with the structural evolution of the composites. After heat treatment, the density of defects in the HT pyrolytic carbon distinctly decreases, which could be inferred from the high graphitization degree of the composites, and the graphene layers become better rearranged, forming a higher density of sublayers. During the bending test, the sublayers can easily slide on each other, resulting in a decrease of the flexural strength [18]. However, on the other side this slide within the HT pyrolytic carbon combing with the interfacial sliding between fibers and matrix can effectively dissipate the energy and thus lead to the enhancement of the toughness.

Fig. 7 SEM images of fracture surface of deposited (a, c) and HTT (b, d) C/C composites

4 Conclusions

1) Short carbon fiber felts reinforced C/C composites with a density of 1.89 g/cm3 were prepared after densification for 150 h by ICVI. The distribution of density and open porosity is uniform along the gas diffusion direction. The matrix of the C/C composites was measured to be HT pyroytic carbon.

2) After heat treatment at 2500 °C, the crystalline thickness of the C/C composites increases by ~3.3 times, and the graphitization degree is 86.05%.

3) The flexural strength and modulus of the deposited C/C composites are 105.4 and 15.1 GPa, respectively, which are decreased by 36.1% and 24.5% after heat treatment, while the tough fracture behavior is obviously enhanced.

4) After heat treatment, the bonding strength of the fiber-matrix interface is weakened and the number of the sublayers in the matrix increases, which result in easier sliding not only among the sublayers but also at fiber-matrix interface. The sliding decreases the mechanical properties and makes the fracture behavior of the HTT composites tougher.

References

[1] SAVAGE G. Carbon/carbon composites [M]. London: Chapman & Hall, 1993: 351-367.

[2] FITZER E, Manocha L M. Carbon reinforcements and carbon/carbon composites [M]. Berlin: Springer, 1998: 310-335.

[3] Zhang Lei-lei, Li He-jun, Zhang Shou-yang, Lu Jin-hua, Zhang Yu-lei, Zhao Xue-ni, GU Cai-ge, ZENG Xie-rong. Characterisation of wear particles from biomedical carbon/carbon composites with different preforms in hip joint simulator [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2562-2568.

[4] Delhaes P. Chemical vapor deposition and infiltration processes of carbon materials [J]. Carbon, 2002, 40(5): 641-657.

[5] ZHANG W G, HU Z J,  K J. Chemical vapor infiltration of carbon fiber felt: Optimization of densification and carbon microstructure [J]. Carbon, 2002, 40(14): 2529-2545.

K J. Chemical vapor infiltration of carbon fiber felt: Optimization of densification and carbon microstructure [J]. Carbon, 2002, 40(14): 2529-2545.

[6] REZNIK B, GERTHSEN D, BORTCHAGOVSKY E. An improved method for angular-resolved characterization of the optical anisotropy of pyrolytic carbon [J]. Journal of Microscopy, 2006, 224(3): 322-327.

[7] REZNIK B,  K J. On the terminology for pyrolytic carbon [J]. Carbon, 2002, 40(4): 621-624.

K J. On the terminology for pyrolytic carbon [J]. Carbon, 2002, 40(4): 621-624.

[8] YIN J, XIONG X, ZHANG H b, HUANG B y. Microstructure and ablation performances of dual-matrix carbon/carbon composites [J]. Carbon, 2006, 44(9): 1690-1694.

[9] XU G z, LI H j, BAI R c, WEI J, ZHAI Y q. Influence of the matrix texture on the fracture behavior of 2D carbon/carbon composites [J]. Materials Science and Engineering A, 2008, 478(1-2): 319-323.

[10] Xiong X, Huang B Y, Li J H, Xu H J. Friction behaviors of carbon/carbon composites with different pyrolytic carbon textures [J]. Carbon, 2006, 44(3): 463-467.

[11] Zhang Ming-yu, Su Zhe-an, Li Jian-li, Huang Qi-zhong. Bending properties and fracture mechanism of C/C composites with high density preform [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1795-1800.

[12] THOMAS C R. Essentials of carbon-carbon composites [M]. Cambridge: Royal Society of Chemistry, 1993: 1-36.

[13] ASTM C830. Standard test methods for apparent porosity, liquid absorption, apparent specific gravity, and bulk density of refractory shapes by vacuum pressure [S].

[14] GUELLALI M, OBERACKER R, HOFFMANN M J. Influence of the matrix microstructure on the mechanical properties of CVI-infiltrated carbon fiber felts [J]. Carbon, 2005, 43(9): 1954-1960.

[15]  M, HU Z,

M, HU Z,  K J. Chemistry and kinetics of chemical vapor deposition of pyrocarbon: VI. Influence of temperature using methane as a carbon source [J]. Carbon, 1999, 37(12): 2021-2030.

K J. Chemistry and kinetics of chemical vapor deposition of pyrocarbon: VI. Influence of temperature using methane as a carbon source [J]. Carbon, 1999, 37(12): 2021-2030.

[16] REZNIK B, GUELLALI M, GERTHSEN D, OBERACKER R, HOFFMANN M J. Microstructure and mechanical properties of carbon–carbon composites with multilayered pyrocarbon matrix [J]. Materials Letters, 2002, 52(1-2): 14-19.

[17] LI Wei, LI He-jun, ZHANG Shou-yang, WEI Jian-feng, WANG Jie, LI Zhao-qian. Effect of high temperature treatment on the microstructure and mechanical properties of binary layer textured 2D C/C composites [J]. New Carbon Materials, 2011, 26(5): 328-334. (in Chinese)

[18] GUELLALI M, OBERACKER R, HOFFMANN M. Influence of heat treatment on microstructure and mechanical properties of CVI-CFC composites with medium and highly textured pyrocarbon matrices [J]. Composites Science and Technology, 2008, 68(5): 1115-1121.

李 伟,李贺军,王 杰,张守阳,杨 茜,魏建锋

西北工业大学 凝固技术国家重点实验室,C/C复合材料工程技术研究中心,西安 710072

摘 要:以天然气为炭源气体,采用等温化学气相沉积工艺对孔隙率为89.5%的短切炭纤维毡进行致密化。经过150 h的沉积,所制备的炭/炭 (C/C) 复合材料的密度达到1.89 g/cm3。利用PLM、XRD、SEM以及三点弯曲测试对所制备的C/C复合材料的纤维结构和力学性能进行研究。结果表明:沉积的热解炭基体为高织构热解炭;经过高温石墨化处理后,大幅度地提高了材料的晶粒尺寸与石墨化度,降低了材料的强度和模量,并提高了其韧性。这些力学性能的变化与石墨化处理后材料内部显微结构的变化相关。

关键词:C/C复合材料;高织构;化学气相沉积;石墨化度;力学性能

(Edited by Xiang-qun LI)

Foundation item: Projects (51221001, 50972121) supported by the National Natural Science Foundation of china; Project (B08040) supported by the Introducing Talents of Discipline to Universities, China; Project (11-BZ-2012) supported by the Research Fund of the State key laboratory of solidification Processing (NWPU), China

Corresponding author: He-jun LI; Tel: +86-29-88495764; E-mail: lihejun@nwpu.edu.cn

DOI: 10.1016/S1003-6326(13)62707-7