Superplasticity of fine-grained AZ31 Mg alloy sheets

YIN De-liang(尹德良), ZHANG Kai-feng(张凯锋),WANG Guo-feng(王国峰), HAN Wen-bo(韩文波)

(School of Material Science and Engineering, Harbin Institute of Technology, Harbin 150001, China)

Abstract: Superplastic mechanical properties of fine-grained AZ31 Mg alloy sheets in the temperature range of 250-450℃ and strain rate range of 0.7×10-3-1.4×10-1s-1 were investigated by uniaxial tensile tests. The microstructure evolution during the superplastic deformation of AZ31 Mg alloy was examined by means of metallurgical microscope and transmission electronic microscope (TEM). It is shown that, fine-grained AZ31 Mg alloy starts to exhibit superplasticity at 300℃ and the maximum elongation of 362.5% is obtained at 400℃ and 0.7×10-3s-1. The predominate superplastic mechanism of AZ31 Mg alloy in the temperature range of 300-400℃ is grain boundary sliding (GBS). Twinning caused by pile-up of dislocations during the early stage of superplastic deformation is the hardening mechanism, and dynamic continuous recrystallization (DCRX) is the important softening mechanism and grain stability mechanism during the superplastic deformation of the alloy.

Key words: AZ31 Mg alloy; superplasticity; microstructure evolution; dynamic recrystallization CLC number: TB31

Document code: A

1 INTRODUCTION

Compared with heavier structural alloys such as aluminum alloys and steels, magnesium alloys have unique advantages in superplastic forming structural components with complex shapes due to their low density and high specific strength. Therefore, wide applications of superplastic magnesium alloys can be expected in such fields as automobiles, electronic appliances and aeronautic instruments. The raw material with equaxial fine grains (mean grain size less than 10μm ) is the usual requirement for superplastic forming of metals[1, 2]. To date, equal-channel angular pressing (ECAP)[3, 4] and hot rolling[5-7] have been used to obtain microstructure of equaxial fine grains for superplastic deformation, and superplasticity in several magnesium alloys and their composites have been achieved[8-11]. Howbeit, the superplasticity of Mg alloys still relies on the stability of grain size and shape during the superplastic deformation at elevated temperatures[1, 12].

Consequently, it is of great significance to investigate the microstructure evolution and dislocation activity of Mg alloys during their superplastic deformation so as to understand the inherent mechanism of superplastic deformation, obtain the optimum superplastic deformation conditions and then promote the practical application of the alloys. In the present study, hot rolling process was employed to obtain fine-grained AZ31 alloy sheets. Uniaxial tensile tests were conducted to investigate the superplasticity of AZ31 Mg alloy at various temperatures and strain rates, and metallurgical microscope and transmission electronic microscope (TEM) were used to observe and analyze microstructure evolution and dislocation activity of the alloy under various deformation conditions.

2 EXPERIMENTAL

2.1 Preparation of fine-grained sheets

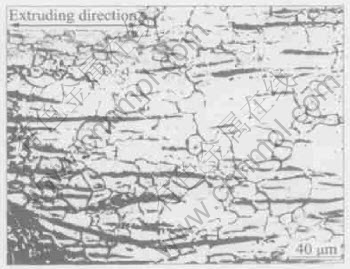

The material used in this study was a commercial extruded AZ31 Mg alloy sheet with a thickness of 1.2mm, its chemical composition and microstructure are shown in Table 1 and Fig.1 respectively. It is noticed that the extruded AZ31 sheets have a non-uniform microstructure with many small grains along the boundary of large grains. The average grain size of 15μm is relatively large for superplastic deformation. To refine the as-received sheets, hot rolling process was adopted. The Mg alloy sheets were heated to 320℃ followed by four passes.

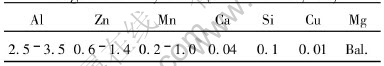

Table 1 Chemical composition of AZ31 magnesium alloy sheet (mass fraction, %)

Fig.1 Microstructure of as-received extruded AZ31 alloy sheet

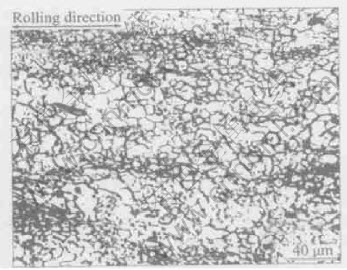

With the thinning of the sheets, the reduction was decreased progressively. After each pass, the sheet was reheated to 320℃ for the next rolling pass in order to avoid cracks of sheet due to heat dissipation. After the treatment, AZ31 Mg alloy sheets with fine-grained microstructure(mean grain size being 4.5μm) were obtained, as shown in Fig.2.

Fig.2 Microstructure of hot-rolled AZ31 alloy sheet

2.2 Experimental procedure

Uniaxial tensile samples were machined directly from the hot-rolled sheets. The gauge length and width were 12 mm and 5 mm, respectively. Uniaxial tensile tests were conducted on a SHIMADZU AG-200kN testing machine equipped with an air-heating furnace, the tensile axe is parallel to the rolling direction of the sample. The temperature range and stain rate range for the test were 250-450℃ and 0.7×10-3-1.4×10-1s-1 respectively. To preserve the microstructures at the specified strain or at fracture, samples were immediately unloaded and quenched in water. Specimens for optical microscopy were sectioned, cold mounted, polished and then etched in 3% malic acid+2% nitric acid and distilled water solution. Metallurgical structure was observed by Neophot-32 microscope and the mean grain size was determined using linear intercept method[13].The interior morphology of grains in deformed specimens were observed by a PHILIPS EM400T transmission electronic microscope (TEM) with an accelerating voltage of 200kV.

3 RESULTS AND DISCUSSION

3.1 Superplastic mechanical properties

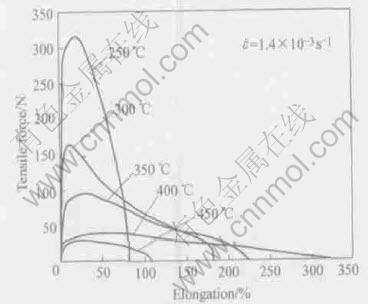

The uniaxial tensile curves obtained at a strain rate (ε[DD(-*2]·[DD)]) of 1.4×10-3s-1 and a temperature range of 250-450℃ are shown in Fig.3. It is demonstrated that the elongation of AZ31 Mg alloy increases progressively with increasing temperatures below 400℃. With the deformation temperature increasing from 250℃ to 300℃, the elongation increases from 80.8% to 182.1%, whereas the flow stress decreases significantly. This shows that AZ31 Mg alloy starts to exhibit superplasticity from 300℃. At 400℃, the maximum elongation of 327.5% is achieved. When temperature is continuously increased to 450℃, the elongation of AZ31 Mg alloy decreases drastically to 108.3% due to oxidation. This non-monotonic change of elongation with temperatures indicates that the optimum temperature for the superplastic deformation of AZ31 Mg alloy is 400℃. It should be noticed that, at 300℃, the flow stress decreases slowly after quickly reaching a peak value, showing obvious characteristic of softening. With the increase of temperature, the softening extent decreases gradually after peak stress, while the hardening extent increases significantly before peak stress. This shows the strain rate hardening and resistance to necking of AZ31 Mg alloy are obviously enhanced by increasing temperature.

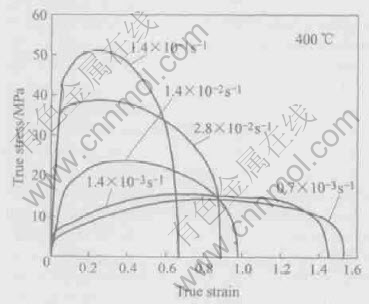

The true stress—strain curves at 400℃ and a strain rate range of 0.7×10-3-1.4×10-1s-1 are

Fig.3 Tensile curves of AZ31 alloy at various temperatures

shown in Fig.4. It is seen that, in a relatively high strain rate range of 2.8×10-2-1.4×10-1s-1, the flow stress reaches a peak value, then decreases quickly followed by fracture after an elongation less than 100%, without exhibiting well-defined quasi-steady stage of superplastic deformation. With the decrease of strain rate from 2.8×10-2s-1, the flow stress decreases obviously, while the elongation increases significantly. When the strain rate is decreased to 1.4×10-3s-1, the flow curve exhibits obvious steady state. Continuously lowering the strain rate to 0.7×10-3s-1, the elongation increases from 327.5% to 362.5%, indicating that low strain rate is favorable for improving the superplasticity of AZ31 Mg alloy.

Fig.4 Stress—strain curves of AZ31 alloy at various strain rates

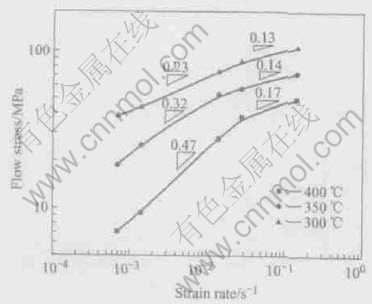

Fig.5 shows the double logarithm relations between flow stress and strain rate at a true strain of 0.2 and the superplastic temperature of 300-400℃. It is shown that there exists a sigmoidal relationship between stress and strain rate, especialy at high temperature, indicating three well-

Fig.5 Flow stress vs strain rates at various temperatures

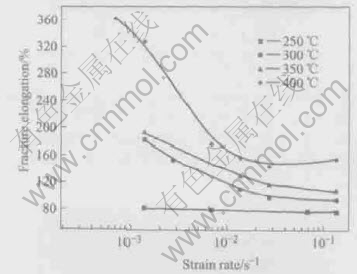

known deformation regions[1, 12] of superplastic alloys, and the suitable strain rate range for superplastic deformation of AZ31 alloy is 1.4×10-3s-1-1.4×10-2s-1. Fig.6 shows the relationship between fracture elongation and strain rate at various temperatures. It is found that, at relatively low temperatures(250℃, for example), the fracture elongation δ almost doesnt change with strain rate, showing weak strain rate sensitivity. In contrast, δ decreases significantly with increasing strain rate at higher temperatures(≥300℃), showing strong strain rate sensitivity.

Fig.6 Elongation vs strain rate at various temperatures

3.2 Microstructure evolution

Fig.7 shows the microstructures of fractured specimens at a strain rate of 1.4×10-3s-1 and a temperature of 300-400℃ (the tensile direction is vertical). It is seen that the mean grain size is slightly increased after considerable superplastic deformation. The grains are slightly elongated along the tensile direction, but the grain shapes basically remains equaxial, indicating the dominate superplastic deformation mechanism of AZ31 Mg alloy at temperature of 300-400℃ is grain boundary sliding (GBS)[14]. The slight elongation of grains along the tensile direction implies occurrence of intragranular slip during the superplastic deformation of AZ31 Mg alloy[15].

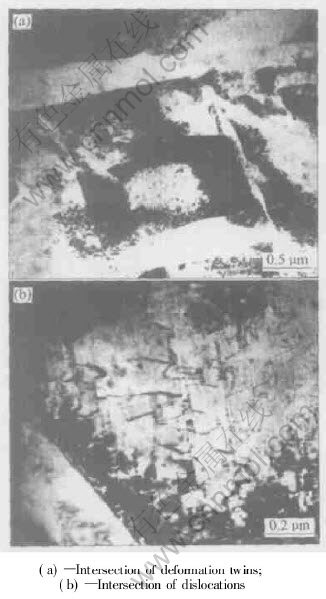

To understand the superplastic deformation behavior of AZ31 Mg alloy more clearly, transmission electronic microscope (TEM) was used to observe grain interior. Fig.8 shows the TEM morphology of a specimen elongated to 48.3% at 400℃ and 1.4×10-3s-1. It is found that, at the early stage of superplastic deformation, there are large amount of intersecting twins inside grains. The dislocation density in the vicinity of twin boundaries is high (Fig.8(a)), while the dislocation density inside twins is very low (Fig.8(b)). This indicates that, in the early stage of superplastic de-

Fig.7 Microstructures of fractured specimens at various temperatures

formation, dislocations are seriously blocked due to different orientation of grains and the impeding effect of triple junction grain boundaries, thus resulting in large amount of intersecting twins and consequently obvious hardening of the alloy. It needs to be mentioned that twinning deformation makes grains rotate to favorable orientation, hence promoting subsequent deformation more uniform.

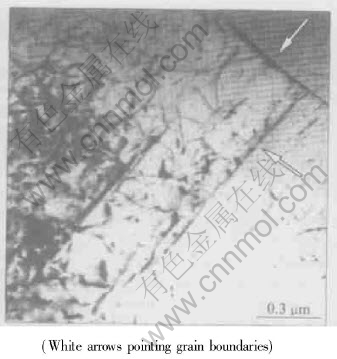

The TEM morphology of a specimen elongated to 116.7% at a temperature of 400℃ and a strain rate of 1.4×10-3s-1 is shown in Fig.9. It is seen that obvious dynamic recrystallization occurs. The dynamic recrystallization starting from the middle stage and large amount of twins produced in the early stage demonstrate that the ener gy accumulated by twinning at the early stage is the prerequisite for dynamic recrystallization of AZ31 Mg alloy. This is because that extended dislocations are wide due to low stack fault energy of Mg alloy[16], as a result, dislocations can be neither free from dislocation nets nor offset each other by cross-slip and climbing, thus producing high density of dislocations near twin boundaries and grain boundaries. When the deformation energy accumulated is sufficient enough, dynamic recrystallization occurs. Fig.9(a) shows the coexistence of recrystallized large grain A and small grain B, indicating dynamic recrystallization proceeds continuously. Curved grain boundaries (Fig.9(a)) and crumpled bands (Fig.9(b)) near grain boundaries prove occurrence of grain boundary sliding among grains[17] once again.

Fig.8 TEM images of grain interior at elongation of 48.3%

Usually, dynamic recrystallization is classified into dynamic continuous recrystallization (DCRX) and dynamic discontinuous recrystallization (DDRX)[7]. During continuous recrystallization, dislocations will remain in the recrystallized grains whereas discontinuous recrystallization removes dislocations through the sweeping action of high angle boundaries[18]. In the present study, there still remain large amount of dislocations in recrystallized grain interior (Fig.10), indicating the occurrence of DCRX during the superplastic deformation of AZ31 alloy. It is implied that dislocation cells in grains transform to subgrains and low angle

Fig.9 TEM images of grains at elongation of 116.7%

Fig.10 TEM image of specimen deformed to 116.7% at 400℃ and 1.4×10-3s-1

boundaries convert to high angle boundaries continuously. Fine grains produced in DCRX ensure the stability of grain shape and size, thus lowering the flow stress during the deformation. Therefore, it is concluded that DCRX is the mechanism of softening and grain stability to ensure the superplasticity of AZ31 Mg alloy, however this process starts not in the early stage of deformation but in the middle stage after considerable strain hardening due to twinning.

4 CONCLUSIONS

1) Hot rolling process was adopted to refine as-received extruded AZ31 Mg alloy sheets and fine-grained AZ31 Mg alloy sheets with a mean grain size of 4.5μm were obtained for superplastic deformation.

2) Fine-grained AZ31 Mg alloy starts to exhibit superplasticity from 300℃ and the strain rate sensitivity is significantly enhanced with increasing temperature and decreasing strain rate. The maximum elongation of 362.5% was obtained at a temperature of 400℃ and a strain rate of 0.7×10-3s-1.

3) It is indicated by metallurgical observation that, the grains of AZ31 alloy remain equaxial after superplastic deformation, indicating the dominate mechanism in superplastic deformation of AZ31 alloy is GBS. The slight elongation of grains implies intragranular dislocation slip during superplastic deformation.

4) The TEM observation shows that a large amount of twins are produced in the early stage of superplastic deformation and the twinning deformation is the prerequisite for DRX. It is demonstrated by high density of dislocations that DCRX occurs during the superplastic deformation of AZ31 alloy.

5) DCRX is the mechanism of softening and grain stability for superplastic deformation of AZ31 Mg alloy. The curved grain boundaries and crumpled bands at grain boundaries after deformation prove the occurrence of GBS during superplastic deformation of AZ31 Mg alloy.

REFERENCES

[1]Nieh T G, Wadsworth J, Sherby O D. Superplasticity in Metals and Ceramics[M]. Cambridge: Cambridge University Press, 1997.

[2]Sherby O D, Wadsworth J. Superplasticity—Recent advances and future directions[J]. J Prog Mater Sci, 1989, 33: 169-221.

[3]Watanabe H, Mukai T, Higashi K. Superplasticity in a ZK60 magnesium alloy at low temperatures[J]. Scripta Mater, 1999, 40: 477-484.

[4]Mabuchi M, Iwasaki H, Yanase K, et al. Low temperature superplasticity in an AZ91 magnesium alloy processed by ECAE[J]. Scripta Mater, 1997, 36: 681-686.

[5]Somekawa H, Watanabe H, Mukai T, et al. Low temperature diffusion bonding in a superplastic AZ31 magnesium alloy[J]. Scripta Mater, 2003, 48: 1249-1254.

[6]Kim W J, Chung S W, Chung C S. Superplasticity in thin magnesium alloy sheets and deformation mechanism maps for magnesium alloys at elevated temperatures[J]. Acta Mater, 2001, 49: 3337-3345.

[7]Mohri T, Mabuchi M, Nakamura M. Microstructural evolution and superplasticity of rolled Mg-9Al-1Zn[J]. Materials Science and Engineering, 2000, A290: 139-144.

[8]Watanabe H, Mukai T, Kohzu M, et al. Effect of temperature and grain size on the dominant diffusion process for superplastic flow in an AZ61 magnesium alloy[J]. Acta Mater, 1999, 47: 3753-3758.

[9]Mabuchi M, Ameyama K, Iwasaki H, et al. Low temperature superplasticity of AZ91 magnesium alloy with non-equilibrium grain boundaries[J]. Acta Mater, 1999, 47: 2047-2057.

[10]Uoya A, Shibata T, Higashi K, et al. Superplastic deformation characteristics and constitution equation in rapidly solidified Mg-Al-Ga alloy[J]. J Mater Res, 1996, 11: 2731-2738.

[11]Mohri T, Mabuchi M, Saito N, et al. Microstructure and mechanical properties of a Mg-4Y-3RE alloy processed by thermo-mechanical treatment[J]. Materials Science and Engineering, 1998, A257: 287-294.

[12]Kaibyshev O A. Superplasticity of Alloys, Intermetallides, and Ceramics[M]. Berlin: Springer, 1992. 316.

[13]American Society of Testing and Materials. Annual Book of ASTM Standards, Section 3: 03.01, E112-96[S]. Philadelphia, PA, 1998. 229.

[14]CHEN P Q. Structural Superplasticity[M]. Harbin: Harbin Institute of Technology Press, 1988. 51-53. (in Chinese)

[15]LIN Z R. Principles and Applications of Superplastic Forming of Metals[M]. Beijing: Aviation Industry Press, 1990, 11: 8-9. (in Chinese)

[16]Avedesian M M, Baker H. ASM Speicalty Handbook-Magnesium and Magnesium Alloys[M]. ASM International, 1999.

[17]Kayibeshev. Plasticity and Superplasticity of Metals[M]. Beijing: China Machine Press, 1982. 194. (in Chinese)

[18]TAN J C, TAN M J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet[J]. Materials Science and Engineering, 2003, A339: 124-132.

(Edited by YUAN Sai-qian)

Received date: 2004-04-20; Accepted date: 2004-07-15

Correspondence: YIN De-liang, PhD; Tel: +86-451-86413681; E-mail: d_l_yin2000@hit.edu.cn