文章编号:1004-0609(2010)S1-s0248-05

热挤压γ-TiAl基合金的组织演变

刘仁慈,刘 冬,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:研究γ-TiAl基合金在温度低于α相转变温度(tα-10)时挤压过程中的组织演变。结果表明:在初始变形阶段,片层发生扭折,随着应变量和应变速率的增大,扭折处发生动态再结晶,形成细小的晶粒;而残余片层随着应变量的增大,其垂直流线方向横断面的尺寸逐渐减小,体积分数也逐渐减少,但其沿流线方向尺寸没有明显减小,残余片层界面方向随着受力状态的变化而变化,其法向平行于主应力方向;经过挤压加工的试样,其边缘片层接近完全破碎,而中心残余片层尺寸较大;挤压坯料与模具的摩擦作用与热传导严重影响了全片层晶粒的破碎细化,温度场以及变形的不均匀是造成材料不同部位微观组织差异的重要因素。

关键词:γ-TiAl基合金;热挤压;组织演变;残余片层

中图分类号:TF 804.3 文献标志码:A

Microstructure evolution of hot extruded γ-TiAl based alloy

LIU Ren-ci, LIU Dong, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The microstructure evolution of γ-TiAl alloy extruded at temperature below α phase transition temperature (tα-10) was investigated. The results show that the lamellar structure kinks at initial deformation stage with increasing strain and strain rate, the region undergoes dynamic recrystallization and forms fine crystal zone and shear localization zone. The size perpendicular to flow line and volume fraction of remnant lamellar are reduced at higher strain, but the size along flow line is not reduced. The direction of remnant lamellar boundary is changed with changing stress state. The phase boundary between Ti3Al and γ-TiAl parallels to flow line. The lamellar of sample at the edge fabricated by extrusion has almost completely broken down, but the remnant lamellar size is large at the central region, especially at the longitudinal section. Friction and heat transfer between the perform and die have great influence on the refinement of full lamellar grain. The heterogeneity of temperature and strain are responsible to the difference of microstructure.

Key words: γ-TiAl based alloy; hot extrusion; microstructure evolution; remnant lamellar structure

γ-TiAl基合金具有较低的密度、良好的高温强度、高温抗氧化性以及阻燃性等特点,有望在航空发动机部分部件中取代密度较大的Ni基高温合金,从而提高发动机的推重比,但其较差的室温塑性与可加工性能制约了其进一步应用[1]。具有细小晶粒尺寸的的全片层γ-TiAl基合金具有良好的综合力学性能。添加B元素和热加工是细化晶粒的常用手段,但B元素的添加易导致片层间距增大,不利于改善材料的力学性能[2]。包套热挤压、包套锻造与等温锻造是γ-TiAl基合金开坯与热加工的常用工艺。在包套热挤压过程中,挤压坯料处在强烈的三向压应力作用下,这种受力状态更有利于材料的塑性变形,所以热挤压常用于脆性材料的开坯与热成型[3]。目前,包套热挤压已经成功应 用于γ-TiAl基合金的开坯与二次成型[1-2]。研究者对γ-TiAl基合金的热挤压组织特征已有所研究[4-9],但对γ-TiAl基合金在热挤压过程中微观组织的演变以及大量残余片层的形成并没有详细的论述。因此,本文作者研究了基本填充阶段末期坯料各材料流动与变性行为,对比各区域的显微组织,揭示了全片层γ-TiAl基合金热挤压过程中组织细化与残余片层的形成规律,以期为后续的γ-TiAl基合金热挤压变形组织与工艺优化提供理论与实验基础。

1 实验

实验所用铸态合金名义成分为Ti-46.5A1-2Cr- 2Nb-0.15B(摩尔分数,%),经过一次水冷铜坩埚自耗电弧熔炼和一次真空感应熔炼得到d 70 mm×500 mm铸锭,然后采用热等静压(1 260 ℃, 130 MPa, 3 h)消除缩松。而后将经过热等静压处理的铸锭加工成d 68 mm×80 mm的坯料。具体包套挤压工艺如文献[10]所述。挤压温度为1 330 ℃(tα-10 ℃),挤压比为7:l。压头下压70 mm后停止,取出挤压坯料,砂冷至室温,去除包套。采用电火花线切割从热等静压铸锭和热挤压件切取研究所需试样,研究坯料各部位的微观组织。试样经研磨、抛光,再经Kroll’s试剂腐蚀后,观察其低倍流线,采用MEF4型金相显微镜观察其显微组织。

2 结果与讨论

2.1 基本挤压阶段坯料形状及其形成

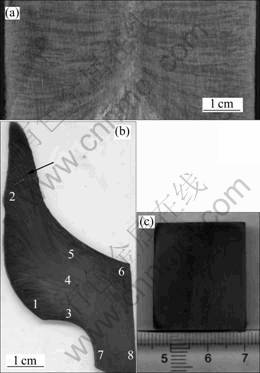

图1(a)所示为热等静压后铸锭底部铸态组织的宏观组织形貌。由图1(a)可看出,沿铸锭径向存在取向明显,晶粒粗大的柱状晶,铸锭中心有微量等轴晶粒。这与γ-TiAl基合金通过模壁热传导散热,晶粒沿着铸锭径向缓慢生长有关。

图1(b)所示为接近终了挤压阶段时坯料的宏观组织形貌。测量其直径约为74 mm,接近模孔与接近挤压筒边缘的底部坯料呈圆弧状,而两者之间部分与模孔大致呈90?夹角,坯料高度对称于模孔圆心呈杯状。对比挤压坯料与原始坯料尺寸可发现,挤压后坯料的直径增大6 mm,而靠近挤压模的坯料锥形部分也向外扩展直到与模子锥面相接触,这与填充挤压阶段坯料向间隙流动、发生端面侧翻与镦粗有关。而坯料沿径向的高度差以及基本填充阶段坯料不同部位的流速差异都与温度场分布有关。模孔对坯料中心部位的阻力小、边缘坯料受到模具摩擦作用(见图1(b)中箭头所指)以及坯料与模具的热传导等因素综合作用使得中心部位流速大,边缘流速慢,从而形成中心缩尾,得到如图1所示的杯状[3, 11-12]。但从图1也可看出,在模孔周围区域,杯面与最低点的高度差相差不大,这说明坯料中心区域温度差别不大;而γ-TiAl基合金的包套热挤压是一个快速过程,坯料与挤压模具之间的热传导对坯料整体温度下降的影响较小,所以挤压模具与坯料之间的摩擦作用是导致中心缩尾形成的主要因素。为提高热挤压坯料的利用率,有必要降低挤压坯料与挤压筒之间的摩擦作用。

图1(c)所示为挤压制备棒材的宏观组织形貌。由图1(c)可看出,距离棒材轴心3~4 mm之间的区域有粗大、连续的黑色长条,而边缘处几乎没有。

2.2 铸态及基本挤压阶段坯料微观组织

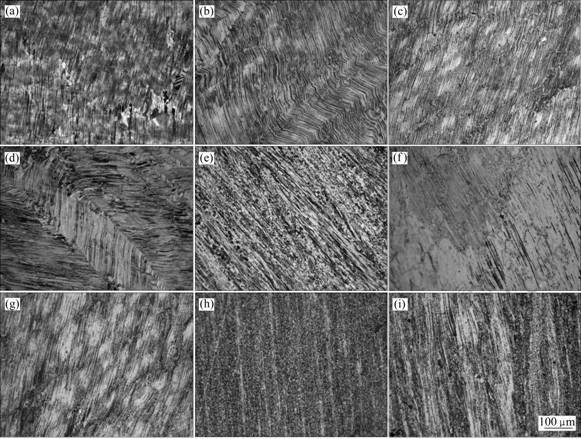

图2(a)所示为铸态合金热等静压后纵向微观组织。由图2(a)可见,铸态合金为全片层组织,晶粒尺寸约为500 μm,在晶界处有少量γ相等轴晶粒。片层界面稍微偏离铸锭轴向,这与铸锭凝固过程中α晶粒沿径向散热方向生长有关。

图2(b)~(i)对应图1(b)所示位置1~8的微观组织。其中图2(b)所示为边缘变形死区的微观组织,片层局部位置发生扭折,其片层界面与原始片层界面夹角接近50?,但并没有形成明显的剪切带,晶粒未发生明显破碎,片层界面的总体方向与铸态对比并没有明显变化。这是由于该位置坯料受到模具沿圆弧面法向的压应力,晶粒片层发生扭折,扭转直到片层界面垂直于受力方向。同时变形死区没有合金的流动,所以扭折带未能连续变形,形成剪切变形带和细小晶粒。图2(c)所示为边缘微变形区2的微观组织,片层界面与原始片层界面没有形成明显的夹角,晶粒也没有发生明显的破碎,但局部位置已经形成一定量的剪切破碎带,该位置的片层受到一个平行于片层界面的压应力。当压应力达到一定临界值时,片层中尺寸较大的γ片层率先发生胀形破碎,对临近的片层形成沿界面法向的压应力,从而诱发临近片层破碎,形成一定取向的剪切带。但坯料与模具的摩擦作用与热传导导致该区域的变形不够充分。图2(d)所示为底部坯料与模具接触区3的微观组织。由图2(d)可知,片层界面大部分与坯料轴向垂直,局部位置界面平行于坯料轴向,没有明显的晶粒破碎带。这是由于坯料在挤压填充阶段发生镦粗变形,片层扭折旋转直到界面垂直于挤压杆施加的压应力,但由于受到模具的摩擦作用后续基本挤压阶段持续,使得该部位没有发生径向流动,未能形成明显的剪切带。根据TiAl多孪晶合成晶体(PST)屈服强度与承载方向的关系,在片层界面与受力方向呈90?夹角时,片层的屈服强度最大,伸长率最小[13],所以该部位在持续的压应力下作用下,片层取向最终垂直于挤压杆,这与SEMIATIN等[14]和IMAYEV等[15]对γ-TiAl基合金的锻造组织研究结果项符合。图2(e)所示为坯料中心变形区4的微观组织。由图2(e)可知,片层破碎明显,已破碎片层的体积分数超过50%,残余片层垂直流线方向的横断面尺寸明显减小,而沿流线方向的尺寸未明显变化,残余片层界面方向与原始坯料片层界面的夹角约为40?。该区域位于挤压变形区,受到平行坯料轴向的压应力,沿坯料底部边缘圆弧法向的压应力和沿顶部杯面法向的压应力,晶粒在流动过程中发生扭转,晶界与先剪切带部位的片层持续破碎。当片层界面与该区域主应力方向垂直时,即片层界面与平行于挤压流线时,晶粒暂时停止扭转。图2(f)所示为坯料与压头接触区5的微观组织。由图2(f)可知,晶粒组织特征与原始坯料晶粒特征几乎一致,这与该部位位于坯料顶端,与垫片存在摩擦作用与热传导作用有关。这与图1(b)中该部位没有明显流线相吻合。图2(g)所示为坯料杯状最低点下方区域6的微观组织。由图2(g)可知,片层界面方向,晶粒尺寸没有发生明显变化,但有明显的、与挤压方向呈一定角度的剪切变形带,且其所占的体积分数也较大,这可能是由于在挤压后期该位置坯料径向流速增大以满足体积不变条件造成的[3]。图2(h)和 (i)所示分别为挤压棒同一横断面边缘7与中心8的纵向微观组织,图2(h)中片层接近完全破碎,形成细小的α+γ两相,残余片层的体积分数不到5%,残余片层平行于模孔轴向,其横向尺寸不到10 μm,而纵向尺寸接近300~400 μm;图2(i)中的残余片层超过60%,残余片层内部也有少许片层破碎,残余片层方向也平行于模孔轴向,其横向尺寸在70 μm左右,而纵向尺寸大于400 μm;其明显的组织差异对应挤压过程中横断面的剪切变形量差异[3]。同时,3.1节所述变形过程中的合金流动速度不均匀以及温度变化对这种组织差异也有一定影响。

图1 γ-TiAl的宏观组织

Fig.1 Macrostructures of γ-TiAl based alloy along vertical axes: (a) Ingot; (b) Extrusion bar numbers corresponding to regions underwent different deform process; (c) Extrusion incompletely

图2 γ-TiAl基合金的微观组织

Fig.2 Microstructures of γ-TiAl based alloy (perform axis is vertical): (a) Ingot; (b)-(i) Microstructures of zones corresponding to positions 1-8 pointed out in Fig.1(b), respectively

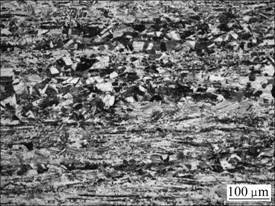

图3所示为图1(c)中黑色连续长条部位的微观组织。由图3可知,主要由细小的双态组织以及呈带状分布的粗大γ相晶粒组成,γ相晶粒尺寸在40 μm左右。这种带状组织主要是γ-TiAl基合金铸锭中存在的Al成分偏析造成的。结合图2(a)中晶界存在少量的等轴γ相晶粒,这些最后凝固的区域,Al含量较高,在热变形条件下,Al含量高的γ相更容易发生动态再结晶,晶粒生长也更加充分,于是形成了粗大的γ相晶粒带。

结合图1、2和3可发现,γ-TiAl基合金在α相转变温度(tα)以下的热挤压变形主要以晶粒片层的扭折以及全片层晶粒的扭转变形为主。在此过程中,坯料的受力状况以及片层晶粒的扭折,扭转等因素的综合作用,同时坯料全片层组织其本身所具有的力学特点,导致晶粒在连续的合金流动中,其残余片层界面平行于流线方向。坯料与模具接触处的全片层晶粒都未发生明显变形,说明挤压坯料与挤压桶之间的摩擦作用以及热传导导致温度的下降严重影响了边缘坯料的热挤压成型,降低了材料的利用率。合金挤压变形中,沿坯料径向的剪切作用随着具体位置与模孔轴线之间距离的增大而增大,从而导致坯料边缘部分发生较大的剪切变形,片层得到较充分的破碎,而中心部分剪切变形量不够,残余片层的体积分数与尺寸较大。凝固过程形成的成分偏析是导致挤压棒中心部位形成粗大带状组织的根本原因,保证挤压坯料的成分均匀有利于提高γ-TiAl基合金挤压棒材的力学性能。

图3 γ-TiAl基合金挤压棒中心带状组织

Fig.3 Banded structure in central zone of extruded γ-TiAl based alloy

3 结论

1) 在模孔位置,模具与坯料的摩擦作用与坯料各部位温度不均是导致热挤压过程中γ-TiAl基合金各部位流速不均匀,坯料中心快速流动,形成中心缩尾的主要因素。

2) 坯料与模具接触部位未发生明显变形。挤压坯料与模具之间的摩擦作用与热传导对γ-TiAl基合金热加工晶粒破碎影响较大,需改善隔热层的隔热性能和润滑性能以提高坯料的利用率以及晶粒破碎程度。

3) 低于α相转变温度热挤压可有效细化γ-TiAl,得到横向晶粒细化明显的变形双态组织;其组织在横向截面各部位具有明显的不均匀性,距实际应用还需进一步的热加工及热处理。

4) 残余片层为长条状,其界面平行于挤压方向,沿挤压方向,破碎不完全。

REFERENCES

[1] APPEL F, BROSSMANN U, CHRISTOPH U, EGGERT S, JANSCHEK P, LORENZ U, MULLAUER J, OEHRING M, PAUL J D H. Recent progress in the development of gamma titanium aluminide alloys[J]. Advanced Engineering Materials, 2000, 2(11): 699-720.

[2] CHRISTOPH L, PETERS M. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 79-80.

CHRISTOPH L, PETERS M. Titanium and titanium alloy[M]. CHEN Zhen-hua, transl. Beijing: Chemical Industry Press, 2005: 79-80.

[3] 谢建新, 刘静安. 金属挤压理论与技术[M]. 北京: 冶金工业出版社, 2002: 43

XIE Jian-xin, LIU Jing-an. Principle and technology of metal extrusion[M]. Beijing: Metallurgical Industry Press, 2002: 43.

[4] SEETHARAMAN V, MALAS J C, LOMBARD C M. Hot extrusion of a Ti-Al-Nb-Mn alloy[C]//High-Temperature Ordered Intermetallic Alloys IV Symposium, 1991: 889-894.

[5] SEMIATIN S L, SEETHARAMAN V, GOETZ, ROBERT L, JAIN V K. Controlled dwell extrusion of difficult-to-work alloys. US005361477A[P]. 1994-11-08.

[6] GOETZ R L, JAIN V K, LOMBARD C M. Effect of core insulation on the quality of the extrudate in canned extrusions of [gamma]-titanium aluminide[J]. Journal of Materials Processing Technology, 1992. 35(1): 37-60.

[7] ZHANG W J, LORENZ U, APPEL F. Recovery, recrystallization and phase transformations during thermomechanical processing and treatment of TiAl-based alloys[J]. Acta Materialia, 2000, 48(11): 2803-2813.

[8] PETER D, PFETZING J, WAGNER M F X, SOMSEN C, PESICKA J, SKROTZKI B, EGGELER G. Quantitative characterisation and microstructurel anisotropy of a hot-extruded TiAl alloy[J]. Praktische Metallographie, 2008, 45(5): 210-224.

[9] 刘 冬. γ-TiAl热挤压成型工艺、组织控制及性能研究[S]. 沈阳: 中国科学院金属研究所, 2007: 57.

LIU Dong. Study of hot extrusion,microstructure control and property of γ-TiAl[S]. Shenyang: Institute of Metal Research, 2007, 2007: 57.

[10] 刘 冬, 柏春光, 崔玉友, 杨 锐. γ-TiAl显微组织与性能[J]. 稀有金属材料与工程, 2005, 34(增刊3): 47-49.

LIU Dong, BAI Chun-guang, CUI Yu-you, YANG Rui. Microstructure and property of extruded gamma TiAl[J]. Rare Metal Materials and Enginging, 2005, 34(Supple 3): 47-49.

[11] 吴诗惇. 挤压理论[M]. 北京: 国防工业出版社, 1994: 77.

WU Shi-dun. Extrusion principle[M]. Beijing: National Defense Industry Press, 1994: 77.

[12] 司家勇, 韩鹏彪, 张 继. Ti-46.5Al-2.5V-1.0Cr-0.3Ni合金热变形行为[J]. 稀有金属材料与工程, 2008, 37(增刊3): 193-197.

SI Jia-yong., HAN Peng-biao, ZHANG Ji, Thermal deformation behavior of Ti-46.5Al-2.5V-1.0Cr-0.3Ni Alloy[J]. Rare Metal Materials And Enginging, 2008, 37(Supple 3): 193-197.

[13] 张永刚, 韩雅芳, 陈国良, 郭建亭, 万晓景, 冯 涤. 金属间化合物结构材料[M]. 北京: 国防工业出版社, 2003: 736-738.

ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang, GUO Jian-ting, WAN Xiao-jing, FENG Di. Intermetallics structure materials[M]. Beijing: National Defence Industry Press, 2003: 736-738.

[14] SEMIATIN S L, SEETHARAMAN V, JAIN V K. Microstructure development during conventional and isothermal hot forging of a near γ-titanium aluminide[J]. Metallurgical and Materials Transactions A, 1994, 25(12): 2753-2768.

[15] IMAYEV R M, SALISHCHEV G A, IMAYEV V M, SHAGIEV M R, KUZNETSOV A V, APPEL F, OEHRING M, SENKOV O N, FROES F H. Hot deformation of gamma TiAl alloys: Fundamentals and application[J]. Gamma Titanium Aluminides, 1999(2): 565-572.

(编辑 龙怀中)

通信作者:刘仁慈,博士研究生;电话:024-83978842;E-mail: rcliu@imr.ac.cn