DOI: 10.11817/j.issn.1672-7207.2018.12.009

深海扬矿泵不同导叶流道中粗颗粒运动试验研究

罗荣昌,余淑琦,符瑜,姚妮均,夏建新

(中央民族大学 生命与环境科学学院,北京,100081)

摘要:为提高管道水力输送安全性,设计导叶进口安放角和叶片数不同的模型泵,建立管道输送试验系统,采用粒径为3 mm的石英砂在输送颗粒体积分数为5%的条件下通过不同模型泵,分析导叶设计参数对颗粒过泵的影响。研究结果表明:导叶进口安放角为25°、叶片数为5的模型泵最优;颗粒在该模型泵中运动,在导叶进口区域,颗粒主要从导叶背面进入,而且颗粒冲击导叶背面的现象不明显;在出口部位,颗粒主要靠近流道中部流出导叶,这样减少了对导叶出口叶片的碰撞;颗粒在此泵中运动的时间较少,不集中在泵中1个部位发生碰撞,对泵的磨损较轻。

关键词:进口安放角;叶片数;运动轨迹;碰撞;过导叶时间

中图分类号:P751 文献标志码:A 文章编号:1672-7207(2018)12-2963-09

Experimental studies on characteristics of coarse particle motion in different guide vanes of lifting pump for deep-sea mining

LUO Rongchang, YU Shuqi, FU Yu, YAO Nijun, XIA Jianxin

(College of Life and Environment Science, Minzu University of China, Beijing 100081, China)

Abstract: In order to improve the safety of pipeline transportation, model pumps with different inlet angles and blade quantities were designed and the pipeline transportation system was built. The particles with volume fraction of 5% and diameter of 3 mm were transported to different model pumps. Based on the results, the influence of the design parameters of the guide blade on the particle passing the pump was analyzed. The results show that the pump is better when the inlet angle is 25° and when there are 5 blades. In this model pump, the particles enter the passageway from the back of the guide leaf, and it is not obvious that the particle impacts the back of guide vane. Particles flow out of the guide vane from the center of the passageway, potentially reducing the impact. The particles have less time to pass through this pump than other pumps, and particles do not all collide in one single place, which leads to less wear for the guide vane.

Key words: inlet angle; blade quantity; particles trajectory; collision; passing time

丰富的海底矿产资源是满足人类未来金属资源需求的有效保障[1-4]。近20年来,我国在海底矿产资源开发技术上取得了重大进展,但按照新拟定的海洋勘探采矿规章要求,海洋采矿必须将保护海洋环境作为前提。目前,水力管道提升系统被认为是目前比较环保可行的深海采矿提升工艺,在该系统中扬矿泵是其最关键的动力设备,其性能对于整个系统安全运行具有重要作用。我国已经开发出扬矿试验泵,但在实验中屡次出现堵塞现象,泵磨损也很严重。出现这些问题是对粗颗粒在泵中的运动的研究不透彻、泵的设计参数选择不合理等导致的。国外研究表明[5]离心式泵型不适用于海洋采矿,应采用混流泵泵型。国内对于颗粒在离心式固-液两相流泵[6-8]中运动的研究较多,对于混流式固-液两相流泵[9]的研究相对较少。诸多学者研究发现深海扬矿泵的设计需满足抗高压、粗颗粒、无堵塞、高扬程、耐磨损、耐腐蚀、高效率、长寿命、高可靠性等特点[10-12],杨恒玲等[13]针对深海扬矿泵设计的需求,对比国外深海采矿模型,提出了高扬程粗颗粒多级输送电泵的设计方法。蔡超[14]设计制作了2种不同叶轮进口安放角的模型泵,通过试验分析了叶轮进口安放角对颗粒在导叶中运动的影响,得出最佳叶轮设计参数,并以此模型泵开展了不同粒径颗粒在不同流速下过导叶的相关实验研究[15]。在此研究基础上,罗荣昌等[16]从颗粒在导叶中的受力出发,建立受力方程和运动方程,从扬矿泵结构参数和输送参数2个方面研究颗粒在扬矿泵导叶中的运动情况。余淑琦等[17]运用离散相模型模拟颗粒流动轨迹,研究了颗粒粒径、导叶进口安放角、导叶数量对扬矿泵堵塞及磨损特性的影响,研究结果表明随着导叶进口安放角增大,平均碰撞次数和平均过导叶时间均随之增加,颗粒与压力面碰撞区域越靠近导叶进口处,对压力面进口造成的磨损越严重;随着导叶数量增加,过导叶时间有减小的趋势,颗粒与导叶压力面碰撞位置向导叶中部移动,对压力面的磨损程度较轻。陈奇[18]以Fluent软件为工具对颗粒在矿浆泵内的运动规律进行了数值模拟,研究转速、流量、颗粒粒径以及颗粒体积分数对矿浆泵内固-液两相流动规律的影响。以上研究多采用数值仿真的手段,大多研究叶轮设计参数对颗粒运动规律的影响。但是,深海采矿实际作业时,导叶处于静止状态,颗粒更容易在此处堆积堵塞流道,导叶的设计参数关系到颗粒过泵能力、回流能力以及性能,对颗粒在导叶中的运动规律至关重要。本文作者在已有研究的基础上,以我国中试扬矿泵为参考,对扬矿泵叶轮和导叶进行水力设计,并搭建管道水力输送试验系统,对颗粒在泵中的运动情况进行试验研究。通过改变扬矿泵导叶设计参数来研究颗粒在不同模型泵中的运动变化情况。

1 试验系统

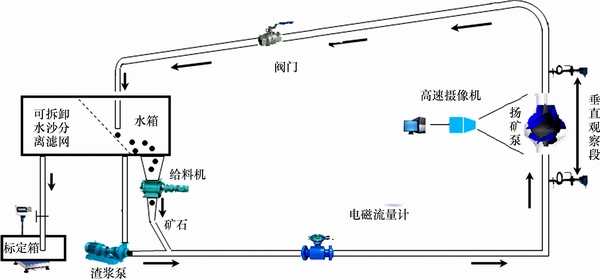

基于固-液两相流输送特性,以颗粒在管道中的运动特性为研究对象,设计建立管道输送试验系统。该系统由给料子系统、管道水力输送子系统、动力控制子系统以及测量子系统4部分组成,如图1所示。其中给料子系统由供水管道、水箱、叶轮式给料机等组成。管道水力输送子系统采用直径为50 mm的不锈钢管作为主输送管道,全长20 m,包括水平管段、垂直管段和倾斜管段。动力子系统包括扬矿泵、渣浆泵、电机、变频调速器等部件。扬矿泵安装在垂直管段,测量部分的管道采用透明有机玻璃制作,这样便于观察与记录,扬矿泵泵体采用黑色POM制作,与白色石英砂形成对比,泵轴采用35CrMo制作,连接泵体和电机。渣浆泵安装在水箱垂直管段与水平管段的连接处,渣浆泵作为备用动力设备,在大流速(>3 m/s)下收集物料时启动。扬矿泵和渣浆泵均采用变频调速器进行调速,确保满足试验所需的输送速度。测量子系统由压力传感器、电磁流量计、高速摄像机、标定箱以及数据采集系统等组成。

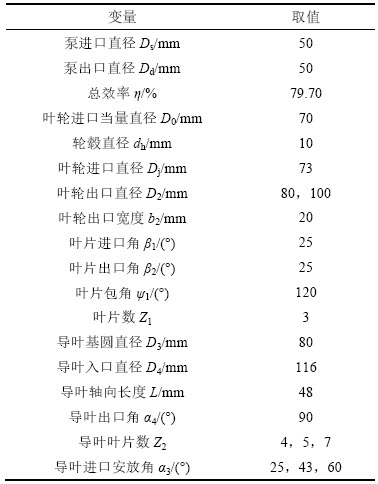

以我国中试扬矿泵参数为基础,根据试验室的条件,按照相关设计程序进行泵参数的计算[19]。设计时考虑:1) 对于海洋采矿的扬矿管线,由于扬矿浓度的改变会很敏感地改变扬矿管道的阻力,扬矿泵陡降的流量-扬程特性刚好适应扬矿实际工艺参数的变化,较少的叶片数能获得陡降的流量-扬程特性曲线,所以,确定叶轮叶片数Z=3。设计导叶叶片数时,为避免系统振动,导叶叶片数应大于叶轮叶片数,且互质,叶片数越多,单流道过流面积越小,粗大颗粒不易通过,容易引起堵塞,所以,将导叶叶片数设定为4,5和7。2) 按相关计算程序计算得到导叶进口安放角为25°,为研究进口安放角对颗粒过泵的影响,将角度设定为25°,43°和60°。扬矿泵主要设计参数如表1所示。

图1 试验系统示意图

Fig. 1 Schematic diagram of test system

表1 扬矿泵主要设计参数

Table 1 Main design parameters of lifting pump

2 试验方法

导叶叶片数决定了单流道过流面积,试验拟设计导叶进口安放角分别为25°,43°和60°,导叶叶片数分别为4,5和7的多个扬矿泵,自行设计扬矿泵,由安徽省天长市有机玻璃厂和北京造梦空间3D打印公司负责加工制作。试验参数如表2所示。

试验采用清水为液相介质,固相颗粒为石英砂,密度为2 650 kg/m3,平均粒径为3 mm。观察段外壁采用有机玻璃制作。试验前,从投料口添加清水充满系统,启动扬矿泵使清水在循环流动中实现满管流,在试验过程中,调节扬矿泵的变频电机调节流速,模拟颗粒在不同工况下的运动,使用高速摄像机拍摄不同工况下颗粒通过扬矿泵流道模型的运动图像和视频,拍摄频率为2 000~3 000帧/s。拍摄完成后,利用计算机绘出主要颗粒在导叶中的运动轨迹,采用统计学相关知识统计颗粒在导叶进出口颗粒分布情况、颗粒与导叶壁面的碰撞情况以及颗粒过导叶的时间。

表2 参数设计

Table 2 Design of parameters

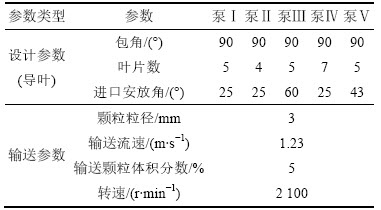

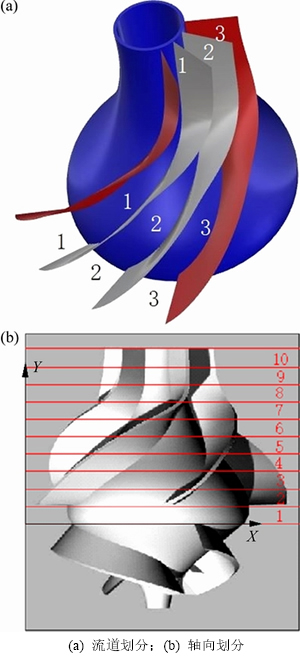

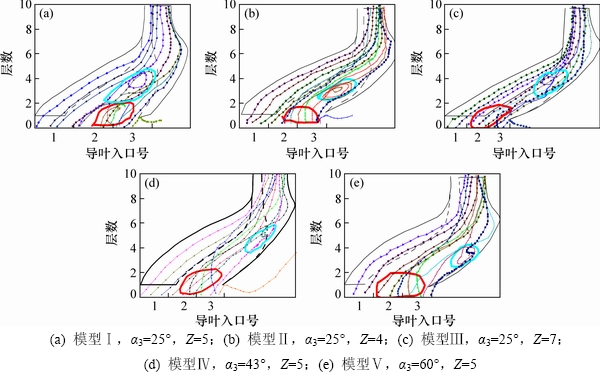

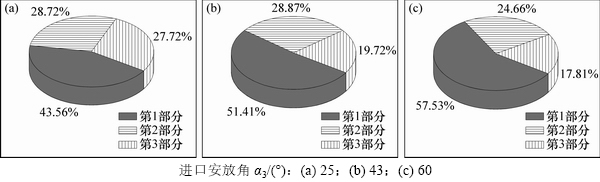

导叶形状特异,颗粒在其中运动复杂。通过实验发现,颗粒在导叶流道中分布不均匀,且在实际工程应用中为减少颗粒与导叶壁面的碰撞,希望颗粒主要从流道中部流出导叶,因此,将导叶流道划分为3个部分,如图2(a)所示:第1部分为导叶背面区域,第2部分为流道中部区域,第3部分为导叶工作面区域。从旋转叶轮出来的颗粒以一定角度进入导叶,颗粒会与导叶发生碰撞。实验发现,颗粒的碰撞以与导叶工作面的碰撞为主,碰撞会减小颗粒的动能,增大颗粒在导叶中的停留时间,同时会磨损导叶,所以,为了研究碰撞的位置,将导叶轴向长度L分为10层,导叶入口处记为第1层,最上端记为第10层。轴向划分如图2(b)所示。

图2 导叶区域划分

Fig. 2 Dividing of guide vane area

3 结果与分析

3.1 运动轨迹

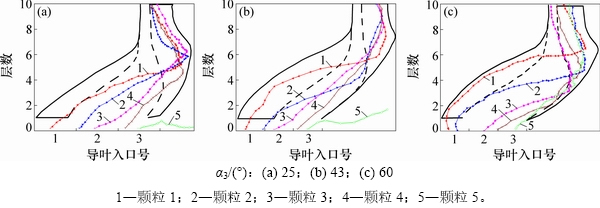

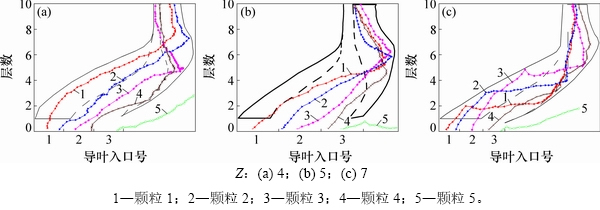

颗粒在不同模型泵中的运动轨迹如图3和图4所示。由于实验条件限制,绘制的轨迹为颗粒三维轨迹投影到高速相机平面上的投影。图中黑色实线代表导叶叶片外边界,虚线代表导叶叶片内边界,中间不同点线1~5为颗粒轨迹。

颗粒运动的基本规律为通过旋转叶轮出来的颗粒以一定角度进入导叶,向导叶工作面运动,颗粒的旋转速度逐步被转换为轴向速度,最后沿着泵出口段流出。

颗粒在导叶内主要受水流绕流阻力、重力和离心力的影响,碰撞前运动趋势与水流运动趋势基本一致,先向工作面运动;碰撞后,颗粒的运动方向改变,偏向背面,运动方向与水流方向相反,由于颗粒质量大,惯性大,所以,碰撞后的轨迹总有向工作面运动的趋势,颗粒在背面的碰撞不明显。由图3(b)和(c)可见:颗粒在入口的运动轨迹有先冲击导叶背面的趋势,然后向导叶工作面运动。由图4(c)可见:对于7叶片的导叶,流道过流面积最小,部分颗粒从叶轮出来,先碰撞导叶的背面然后向工作面运动,发生第2和第3次碰撞,这些现象在其他模型泵中不明显。

为分析上述现象出现的原因,本文研究了导叶中清水的运动情况。根据曹斌等[20]研究结果,采用粒径为0.1 mm的颗粒代表清水,用高速摄像机拍摄其过导叶的运动过程表示清水在泵中的运动情况。结果如图5所示。

从图5可以看出,在导叶入口处有漩涡出现,在涡流处,水体运动混乱,不成明显规律,在非涡流区,水体的运动基本与流道形状一致;随着进口安放角的增大,进口涡流区的面积有所增大,这可能是导致颗粒在43°和60°导叶中有先冲击导叶背面现象的原因。在导叶中部靠近工作面的位置会出现回流区。在叶片数为7时,颗粒从导叶背面入口进入,在涡流的影响下,向导叶背面运动。由于过流面积小,水体还未将颗粒的运动方向导向工作面,颗粒先撞击了背面,而其他模型泵流道过流面积较大,在颗粒与背面碰撞前,水体就可将颗粒的运动方向导向了工作面。

图3 颗粒在进口安放角不同的模型泵中的运动轨迹(d=3 mm,vf=1.23 m/s)

Fig. 3 Trajectory of particle in model pump with different inlet angles (d=3 mm, vf=1.23 m/s)

图4 颗粒在叶片数不同的模型泵中的运动轨迹(d=3 mm,vf =1.23 m/s)

Fig. 4 Trajectory of particle in model pump with different blade numbers (d=3 mm, vf =1.23 m/s)

图5 不同模型泵中水体迹线(vf=1.23 m/s)

Fig. 5 Trajectory of water in model pump (vf=1.23 m/s)

3.2 进出口颗粒分布情况

统计相同时间内,导叶入口各个区域的颗粒数量以及总数,每个区域的概率Fin由下列式子计算得出:

(1)

(1)

式中: 为入口第i区的平均颗粒数;

为入口第i区的平均颗粒数; 为入口平均颗粒总数。

为入口平均颗粒总数。

统计相同时间内,导叶出口3个部分的颗粒数量以及总数。每个部分的概率Fout由下式计算得出:

(2)

(2)

式中: 为出口第i部分的平均颗粒数;

为出口第i部分的平均颗粒数; 为出口平均颗粒总数。

为出口平均颗粒总数。

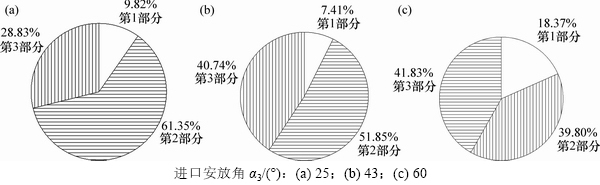

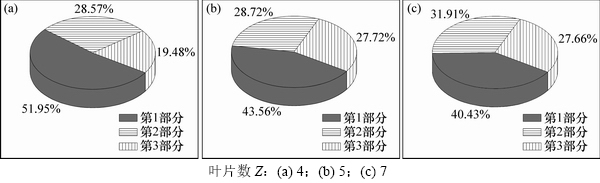

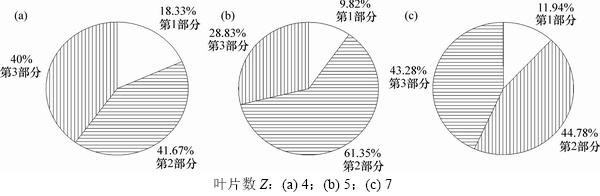

颗粒在不同模型泵进出口的分布情况如图6~9 所示。

从拍摄的视频和图像看出,从叶轮出来的颗粒只有部分直接进入导叶流道,有一部分颗粒从叶轮出口处以较小角度进入导叶,这些颗粒不能顺畅流入导叶流道,而是从一个区域流到附近区域或是从一个流道流入另一个流道。从图6和图8可以看出:随着进口安放角的增大,第1部分的碰撞概率增大,说明颗粒从导叶背面区域进入的情况更明显;而随着叶片数的增多,颗粒从导叶背面进入的概率有所减小。从图7和图9可以看出:在60°和43°模型泵中,颗粒主要从流道中部和导叶工作面出去,在25°模型泵中,颗粒主要从流道中部出去,从导叶背面出去的较少。在4叶片和7叶片的模型泵中,颗粒主要从流道中部和导叶工作面出去,在5叶片模型泵中,颗粒主要是从流道中部出去,从导叶背面出去的较少。

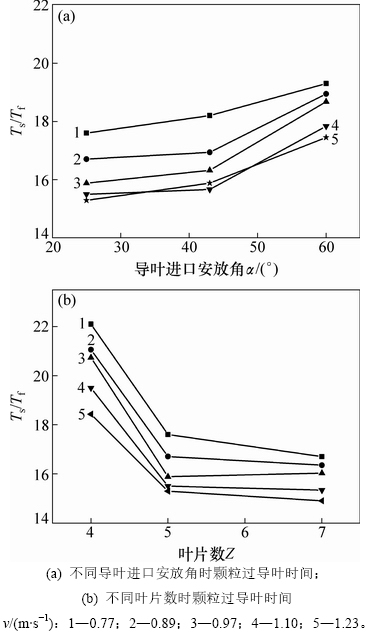

3.3 过导叶时间

以颗粒从导叶入口开始计时,到颗粒流出导叶出口停止,统计诸多颗粒通过导叶的时间,以平均值为颗粒通过导叶的时间(Ts),以粒径0.1 mm颗粒代表清水,其通过导叶的时间记为Tf,以Ts/Tf为纵坐标作图,结果如图10所示。

在进口安放角为25°~60°范围内,颗粒通过导叶的时间随着进口安放角增大而增大,随着叶片数的增多而减少。叶片数减小,单个流道的过流面积就增大,清水流速和颗粒速度都减小,颗粒在导叶中运行时间会延长,而且导叶的导流效果降低。叶片数增加,单个流道的面积就会减小,会增加颗粒堵泵的概率。

图6 进口安放角不同的模型泵入口颗粒分布情况(d=3 mm,vf=1.23 m/s)

Fig. 6 Distribution of particles in inlet of model pump with different inlet angles (d=3 mm, vf=1.23 m/s)

图7 进口安放角不同的模型泵出口颗粒分布情况(d=3 mm,vf=1.23 m/s)

Fig. 7 Distribution of particles in outlet of model pump with different angles of entrance (d=3 mm, vf=1.23 m/s)

图8 叶片数不同的模型泵入口颗粒分布情况(d=3 mm,vf=1.23 m/s)

Fig. 8 Distribution of particles in inlet of model pump with different blade numbers (d=3 mm, vf=1.23 m/s)

图9 叶片数不同的模型泵出口颗粒分布情况(d=3 mm,vf=1.23 m/s)

Fig. 9 Distribution of particles in outlet of model pump with different blade number (d=3 mm, vf=1.23 m/s)

图10 颗粒过导叶时间

Fig. 10 Time of particles passing through guide leaves

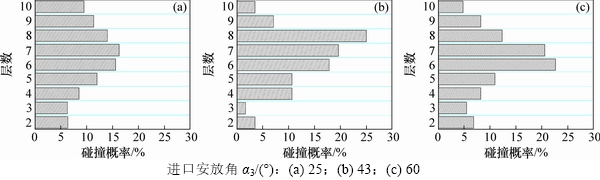

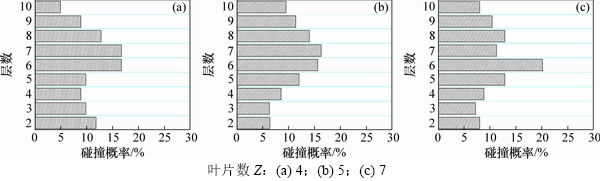

3.4 碰撞位置

将导叶轴向划分为10层,计算每一层颗粒的碰撞频率。因第1层为导叶入口与导叶叶片之间的区域,此区域无壁面,故不讨论该区域颗粒的碰撞情况。

第2~10层的碰撞概率为第i层碰撞的颗粒数与总碰撞颗粒数的比值,记为Pci:

(3)

(3)

式中:nci为第i 层碰撞的颗粒数。

在进口安放角为43°模型泵中,颗粒在第8层碰撞较明显;在进口安放角为60°模型泵中,第6层碰撞较明显;在进口安放角为25°模型泵中,颗粒在每层的碰撞概率比较均匀;颗粒在每层的碰撞频率随着进口安放角的变化不呈规律变化。对于叶片数为4的模型泵,颗粒主要在第2、第3层和中部第6、第7层发生碰撞;对于叶片数为7的模型泵,在第6层的碰撞较多,其他位置碰撞情况相差不大;流道过流面积居中的模型泵Ⅰ,碰撞情况呈正态分布,主要在第6和第7层碰撞。碰撞会对壁面造成磨损,越靠近导叶入口,颗粒碰撞时动能越大,对泵的损害越严重。实际工作时希望颗粒不与泵发生碰撞,但由于颗粒质量大于水体,对水的跟随性较差,在流道中会与壁面发生碰撞,因此,希望碰撞次数越少、越靠近导叶出口越好,而且碰撞不能集中于某一部位,如果颗粒集中撞击某位置,长时间碰撞会击穿该部位,减少机械的寿命。

统计颗粒在导叶中的运动轨迹、进出口分布情况和碰撞情况发现:颗粒进入导叶的位置越靠近导叶背面,其在导叶工作面碰撞的位置越靠近中后部(第6,7和8层),且主要从流道中部和工作面流出导叶;从流道中部和靠近工作面进入的颗粒主要与导叶工作面入口(第2,3和4层)碰撞,在第3和第4层碰撞的颗粒有沿着导叶工作面滚动的现象,发生多次碰撞后向导叶背面运动,主要从导叶背面流出。

图11 颗粒在进口安放角不同的模型泵中的碰撞概率

Fig. 11 Probability of collision on model pump with different inlet angles

图12 颗粒在叶片数不同的模型泵中的碰撞概率

Fig. 12 Probability of collision on model pump with different blade numbers

4 结论

1) 导叶进口安放角为25°、叶片数为5的模型泵最优。当颗粒在此模型泵中运动时,在导叶进口部分,颗粒冲击导叶背面的现象不明显,而是直接向导叶的工作面运动;颗粒在进口分布比较均匀,主要靠近流道中部流出导叶,减少了对导叶出口叶片的碰撞;颗粒在此泵中运动的时间较少,不集中在泵中某部位发生碰撞,对泵的磨损较轻。

2) 在设计制作扬矿泵时,对导叶第2,6和7层进行加厚处理可以延长泵的寿命。

参考文献:

[1] 董冰洁. 我国海洋多金属矿产资源研究现状及战略性开发前景[J]. 世界有色金属, 2016(12): 168-169.

DONG Bingjie. Research status and strategic development prospect of marine polymetallic mineral resources in China[J]. World Nonferrous Metal, 2016(12): 168-169.

[2] SHARMA R. Deep-sea mining economic, technical, technological and environmental considerations for sustainable development[J]. Marine Technology Society Journal, 2011, 45(5): 28-41.

[3] 肖业祥, 杨凌波, 曹蕾, 等. 海洋矿产资源分布及深海扬矿研究进展[J]. 排灌机械工程学报, 2014, 32(4): 319-326.

XIAO Yexiang, YANG Lingbo, CAO Lei, et al. Distribution of marine mineral resource and advances of deep-sea lifting pump technology[J]. Journal of Drainage and Irrigation Machinery Engineering, 2014, 32(4): 319-326.

[4] VALSANGKAR A B. Deep-sea polymetallic nodule mining challenges ahead for technologists and environmentalists[J]. Marine Georesource and Geotechnology, 2003, 21(2): 81-91.

[5] DOVER V, LEE C. Tighten regulations on deep-sea mining[J]. Nature, 2011, 470(7332): 31-33.

[6] YOON C H, PARK Y C, LEE D K, et al. Flow analysis of solid-liquid mixture in a lifting pump[C]//Sixth ISOPE Ocean Mining Society of Offshore and Polar Engineers. Changsha, China, 2005: 101-105.

[7] 汪家琼, 叶群, 闫科委, 等. 颗粒直径对渣浆泵冲蚀磨损性能的影响[J]. 排灌机械工程学报, 2014, 32(10): 840-844.

WANG Jiaqiong, YE Qun, YAN Kewei, et al. Effect of particle diameter on erosion wear performance of slurry pump[J]. Journal of Drainage and Irrigation Machinery Engineering, 2014, 32(10): 840-844.

[8] 王洋, 徐小敏, 张翔. 离心泵内低浓度固体颗粒运动的数值模拟[J]. 流体机械, 2009, 37(2): 24-28.

WANG Yang, XU Xiaomin, ZHANG Xiang. Numerical simulation for the motion of dilute solid particles in centrifugal pump[J]. Fluid Machinery, 2009, 37(2): 24-28.

[9] 徐海良, 曾义聪, 陈奇, 等. 深海采矿矿浆泵内颗粒流动规律的数值模拟[J]. 中南大学学报(自然科学版), 2017, 48(1): 84-90.

XU Hailiang, ZENG Yicong, CHEN Qi, et al. Numerical simulation of particle flow trajectory in slurry pump for deep-sea mining[J]. Journal of Central South University (Science and Technology), 2017, 48(1): 84-90.

[10] 唐达生, 阳宁. 深海粗颗粒矿石垂直管道水力提升技术[J]. 矿冶工程, 2013, 33(5): 1-8.

TANG Dasheng, YANG Ning. Hydraulic lifting technique with vertical pipe for deep-sea coarse mineral particles[J]. Mining and Metallurgical Engineering, 2013, 33(5): 1-8.

[11] 唐达生, 阳宁, 龚德文, 等. 深海采矿锰结核泵的试验研究[J]. 海洋工程, 2015, 33(4): 101-107.

TANG Dasheng, YANG Ning, GONG Dewen, et al. Experimental study of manganese nodules pump in deep-sea mining[J]. The Ocean Engineering, 2015, 33(4): 101-107.

[12] 徐海良, 曾义聪, 陈奇, 等. 颗粒粒径对深海采矿提升泵工作性能影响分析[J]. 海洋湖沼通报, 2016(5): 50-59.

XU Hailiang, ZENG Yicong, CHEN Qi, et al. Analysis on influence of particle diameter on lift pump work performance for deep-sea mining[J]. Transactions of Oceanology an Limnology, 2016(5): 50-59.

[13] 杨恒玲, 刘少军, 邹伟生. 深海采矿高扬程粗颗粒多级输送电泵研究[J]. 中南大学学报(自然科学版), 2018, 49(5): 1110-1117.

YANG Hengling, LIU Shaojun, ZOU Weisheng. Research on multistage lifting motor pump of high lift and coarse particles in deep sea mining[J]. Journal of Central South University(Science and Technology), 2018, 49(5): 1110-1117.

[14] 蔡超. 深海采矿扬矿泵参数设计及模拟研究[D]. 北京: 中央民族大学生命与环境科学学院, 2015: 14-37.

CAI Chao. Parameter design and simulation research for deep sea lift pump[D]. Beijing: Minzu University of China. College of Life and Environmental Sciences, 2015: 14-37.

[15] 蔡超, 邱灏, 曹斌, 等. 深海采矿扬矿泵导叶区域粗颗粒通过特性试验研究[J]. 海洋工程, 2016, 34(2): 64-70.

CAI Chao, QIU Hao, CAO Bin, et al. Experimental studies on passing characteristics of coarse particles in lifting pump of deep-sea mining system[J]. The Ocean Engineering, 2016, 34(2): 64-70.

[16] 罗荣昌, 余淑琦, 夏建新, 等. 深海扬矿泵导叶结构中粗颗粒运动特性研究[J]. 海洋工程, 2017, 35(4): 117-125.

LUO Rongchang, YU Shuqi, XIA Jianxin, et al. Motion characteristics of coarse particle in guide vanes of lifting pump for deep-sea-mining[J]. The Ocean Engineering, 2017, 35(4): 117-125.

[17] 余淑琦, 罗荣昌, 曹斌, 等. 深海采矿扬矿泵内固体颗粒运动特性数值模拟[J]. 矿冶工程, 2018, 38(1): 35-40.

YU Shuqi, LUO Rongchang, CAO Bin, XIA Jianxin. Numerical simulation of particle motion trajectory in lifting pump for deep-sea mining[J]. Mining and Metallurgical Engineering, 2018, 38(1): 35-40.

[18] 陈奇. 深海采矿矿浆泵内固液两相流数值模拟及性能预测研究[D]. 长沙: 中南大学机电工程学院, 2014: 10-51.

CHEN Qi. Numerical simulation on solid-liquid two-phase flow and performance prediction of slurry pump for deep-sea mining[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2014: 10-51.

[19] 关醒凡. 现代泵理论与设计[M]. 北京: 中国宇航出版社, 2011.

GUAN Xingfan. Morden pumps theory and design[M]. Beijing: China Astronautic Publishing House, 2011.

[20] 曹斌, 邹燚, 夏建新. 不同粒度颗粒在非恒定管流中跟随性试验[J]. 水科学进展, 2017, 28(3): 356-363.

CAO Bin, ZOU Yi, XIA Jianxin. Experimental study on the behavior of coarse particles in two phases flow during water hammer[J]. Advances in Water Science, 2017, 28(3): 356-363.

(编辑 赵俊)

收稿日期:2018-01-29;修回日期:2018-05-08

基金项目(Foundation item):国家自然科学基金资助项目(51339008,51209238,51434002);一流大学与一流学科建设过渡性经费专项资金资助项目(2017)(Projects(51339008, 51209238, 51434002) supported by the National Natural Science Foundation of China; Project(2017) supported by the Special Fund of Building First-class Universities and Disciplines Construction Transitional Funds)

通信作者:夏建新,博士,教授,从事深海资源开发研究;E-mail: jxxia@vip.sina.com