文章编号:1004-0609(2008)08-1453-05

纳米SiO2对铜基摩擦材料摩擦学性能的影响

杜建华,刘贵民,谢凤宽,李 超,韩文政

(装甲兵工程学院 装备再制造工程系,北京 100072)

摘 要:采用粉末冶金法制备添加0.75%的纳米SiO2(n-SiO2)和0.75%Cu包覆纳米SiO2(Cu/n-SiO2)复合粉体的新型铜基摩擦材料。采用惯性台架实验机,研究比较两种材料与未添加纳米SiO2的材料的摩擦学性能。结果表明:在铜基摩擦材料中添加微量n-SiO2可改善材料的耐磨性和耐热性;添加Cu/n-SiO2的铜基摩擦材料,耐热性提高32%,耐磨性提高2.02倍;添加n-SiO2的摩擦材料,耐热性提高7%,耐磨性提高18%;经铜包覆处理后的n-SiO2对材料性能的影响优于未处理的n-SiO2。

关键词:铜基摩擦材料;纳米SiO2;摩擦,磨损;粉末冶金

中图分类号:TB 125 文献标识码:A

Effect of nano-SiO2 on tribological properties of Cu-based friction materials

DU Jian-hua, LIU Gui-min, XIE Feng-kuan, LI Chao, HAN Wen-zheng

(Department of Arming Remanufacture Engineering, Academy of Armored Force Engineering, Beijing 100072, China)

Abstract: Two types of Cu-based friction materials with 0.75% nano-SiO2 and 0.75% Cu-coated nano-SiO2 (Cu/nano- SiO2) were obtained by powder metallurgy processes, respectively. The tribological properties of the two types of friction materials were investigated by using inertia friction tester and compared with that of the friction materials without nano-SiO2. The results show that a small quantity of nano-SiO2 can improve the heat resistance and the wear resistance of the friction materials, the heat resistance and the wear resistance of the friction materials with 0.75% Cu/nano-SiO2 are respectively improved by 32% and 2.02 times. While for the friction materials with 0.75% nano-SiO2, the heat resistance and the wear resistance are improved by 7% and 18%, respectively. Cu-coated nano-SiO2 exists a more obvious effect on the tribological properties than nano-SiO2.

Key words: Cu-based friction material; nano-SiO2; friction; wear; powder metallurgy

铜基摩擦材料是以铜及铜合金为基体,添加摩擦剂和润滑剂,采用粉末冶金法制备的多元复合材料。因其具有良好的导热性、耐磨性,摩擦因数高等优点而应用于重载车辆、高速列车、坦克传动系统的离合器和制动器中。目前随着这些设备向高速、重载方向的发展,以及离合器、制动器结构设计的紧凑性要求,对铜基摩擦材料的耐磨性和耐热性提出了更高要求,特别是高温制动稳定性。因此研究开发具有优异性能的新型铜基摩擦材料十分重要和迫切。为提高铜基摩擦材料的耐热性和耐磨性,主要途径有:添加Sn、Zn、Al等合金元素来强化提高基体的耐磨性和耐热强 度[1?2];通过改变材料的摩擦剂与润滑剂,调节材料的成分,如添加Fe和石墨等耐高温、耐磨材料来提高摩擦材料的整体性能等[3–7]。

目前铜基纳米复合材料的研究成果表明[8–11]:纳米Al2O3、纳米ZrO2等纳米级氧化物作为弥散增强相所制备的弥散强化铜基复合材料,在保持铜本身高导热性能的同时还大幅度提高了强度及抗高温软化特性,具有其它强化方法无法比拟的优点。因此,将纳米材料应用于铜基摩擦材料,为改善摩擦材料的摩擦学性能提供了新途径。本文作者采用粉末冶金法,分别制备了添加0.75%的纳米SiO2(n-SiO2)和Cu包覆纳米SiO2(Cu/n-SiO2)复合粉体的新型铜基湿式摩擦材料。通过湿式摩擦材料的台架实验,研究添加n-SiO2的铜基摩擦材料在湿式工况下的摩擦学性能。

1 实验

1.1 实验原料及制备方法

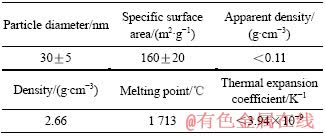

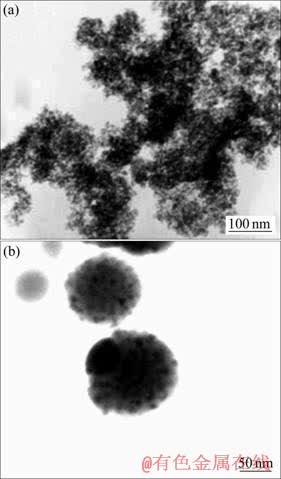

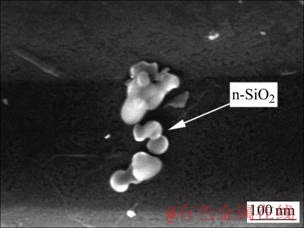

实验所用原材料有电解铜粉(纯度99.8%,平均粒度约74 ?m)、雾化锡粉(纯度98%,平均粒度约43 ?m)、雾化锌粉(纯度98%,平均粒度约43 ?m)、鳞片状天然石墨、微米级SiO2和n-SiO2。纳米SiO2为舟山明日纳米有限公司生产,其物理性能见表1。Cu/n-SiO2复合粉体采用歧化反应法,通过非均相沉积,在n-SiO2表面沉积包覆一层Cu,从而实现Cu对n-SiO2的表面包覆改性[13]。n-SiO2用Cu包覆处理前、后的TEM像见图1,可见未包覆处理的n-SiO2存在团聚现象;类球形的Cu/n-SiO2复合颗粒粒径约200 nm,颗粒内含有均匀分散的n-SiO2。

表1 纳米SiO2的物理性能[12]

Table 1 Physical parameters of nano-SiO2[12]

图1 包覆前、后n-SiO2的TEM像

Fig.1 TEM images of n-SiO2: (a) Original n-SiO2; (b) Cu/n-SiO2 composite particles

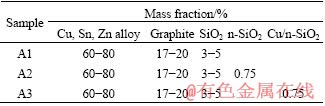

实验中试样的编号和材料配比见表2。材料的制备采用先冷压成形再加压烧结的工艺。按表2配比称取粉末,置于小型V型混料机中混合2~4 h,然后在钢模中将粉末压制成密度为4.5 g/cm3的坯块;将压坯在钟罩炉中于1.0~4.0 MPa压力下烧结,烧结温度为850~950 ℃,平均升温速率为5 ℃/min,在烧结过程中采用还原性保护气氛。

表2 材料的配比

Table 2 Composition of friction materials

1.2 性能测定

按照GB10421—1989和GB—5164分别测试3种材料的密度和孔隙率。按照JB/T7909—1999测定试样在润滑条件下的摩擦因数、磨损率和耐热系数。实验设备采用杭州粉末冶金研究所的“HF?85WT型”湿式摩擦材料摩擦性能实验机。摩擦副组成:摩擦片外径230 mm,内径190 mm,槽形为螺旋槽加径向槽;对偶片为65Mn钢,表面粗糙度Ra1.6,硬度HRC38~ 45。实验条件如下:平均功率密度115 W/cm2,接合频率3 次/min,接合时间(1±0.1) s,转动惯量2.76 kg?m2,润滑油为8号液力传动油,给油量8 mL/(cm2?min),进口处油温(80±5) ℃。采用扫描电子显微镜(SEM)观察材料的横断面形貌。

2 结果与分析

2.1 摩擦材料的物理性能

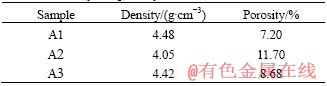

经测定,3种摩擦材料的表观密度、孔隙度见表3。可以看出,加入未经包覆处理的n-SiO2(A2),将降低摩擦材料的密度并增大孔隙度;而Cu/n-SiO2对摩擦材料的密度影响较小,但孔隙度略有增大(A3)。n-SiO2影响材料的烧结致密化。由于n-SiO2与铜基体之间为陶瓷颗粒与金属直接接触,而采用Cu/n-SiO2复合粉体后,铜-铜界面替代了铜-陶瓷颗粒界面,改善了n-SiO2与铜基合金的结合状态,因此改善了材料的成形性,并减小n-SiO2对烧结过程的影响[14]。

表3 摩擦材料的密度和孔隙度

Table 3 Density and porosity of friction materials

2.2 摩擦材料的摩擦性能

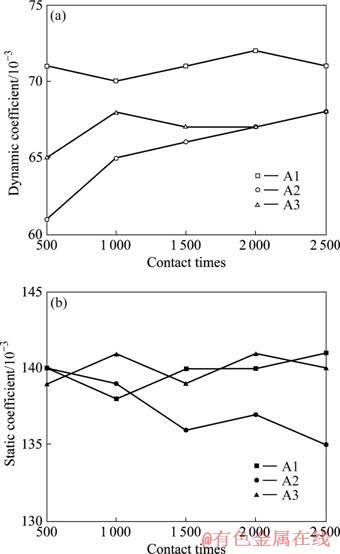

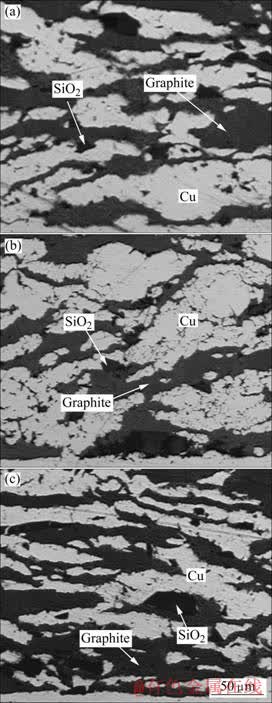

3种材料在转动惯量2.76 kg?m2,转速1 418 r/min条件下,动、静摩擦因数与接合次数的关系见图2。在图2(a)中,添加n-SiO2的A2和A3材料的动摩擦因数在整个接合过程中都低于A1的动摩擦因数;随接合次数增加,A3的动摩擦因数变化较平稳,A2的动摩擦因数逐渐增加。在图2(b)中,随接合次数增加,A3的静摩擦因数比较稳定,A2的静摩擦因数逐渐降低。因此加入n-SiO2,降低了摩擦材料的动摩擦因数。添加Cu/n-SiO2的A3的摩擦因数比添加n-SiO2的A2的摩擦因数稳定。

图2 动、静摩擦因数的变化

Fig.2 Variations of friction coefficient: (a) Dynamic friction coefficient; (b) Static friction coefficient

2.3 摩擦材料的磨损性能

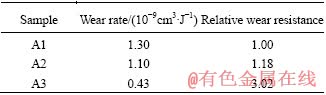

3种摩擦材料的磨损率是在1 418 r/min时接合2 500次后测量换算而得。若以未添加n-SiO2的A1的耐磨性作为1,可计算出A2和A3材料相对于A1材料的相对耐磨性。3种摩擦材料的磨损率和相对耐磨性见表4。添加n-SiO2的A2材料比A1材料的耐磨性提高了18%;添加Cu/n-SiO2的A3材料的耐磨性比A1提高了2.02倍。因此,在铜基湿式摩擦材料中添加n-SiO2,能提高材料的耐磨性。而且n-SiO2与铜基体之间结合状态对材料耐磨性的影响显著。

表4 摩擦材料的磨损率与相对耐磨性

Table 4 Wear rate and relative wear resistance of friction materials

2.4 摩擦材料的耐热性能

耐热系数又称能量负荷许用值,是在规定的实验条件下,摩擦副失效前,摩擦副的能量密度与最大功率密度的乘积[15],它反映了摩擦材料的耐热性能。经测试,3种材料的耐热系数和相对耐热性见表5。添加0.75%的n-SiO2,使摩擦材料的耐热性能提高7%;添加0.75%的Cu/n-SiO2,使摩擦材料的耐热性能提高32%。由此可知,n-SiO2颗粒可有效地提高铜基摩擦材料的耐热系数,而且提高的幅度与n-SiO2的分散性和与铜基合金的结合强度有关:分散性和结合强度愈好,提高的幅度也会愈大。

表5 摩擦材料的耐热系数与相对耐热性

Table 5 Coefficient of heat resistance and relative heat resistance of friction materials

3 讨论

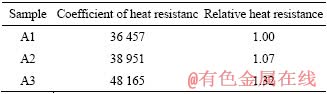

由上述实验结果可知,n-SiO2加入到铜基摩擦材料中,可改善材料的耐磨性和耐热性,材料的动摩擦因数略微降低。通过分析3种材料的显微组织(见图3) 可以看出,3种材料中基体Cu颗粒之间连接较好,无明显差异;但A1和A2显微组织中,铜颗粒较粗大;A3组织中铜颗粒则细长而致密。由于3种材料是在相同的工艺条件下制备,因此材料中添加Cu/n-SiO2复合颗粒后,烧结过程中Cu颗粒中晶粒的再结晶生长受到抑制。因组织结构决定材料的性能,由此判断A3材料耐磨性和耐热性的改善部分源于n-SiO2对材料显微组织的影响。

图3 摩擦材料的显微组织

Fig.3 Microstructures of friction materials: (a) Sample A1; (b) Sample A2; (c) Sample A3

图4所示为A3材料横断面的SEM像。在颗粒界面处发现部分“游离分布的n-SiO2颗粒”。与弥散分布于基体中的n-SiO2不同,游离态的硬质纳米颗粒在摩擦过程中可分布于摩擦副之间,起到“滚珠效应”,降低摩擦因数和磨损率[16]。

图4 A3材料横断面的SEM像

Fig.4 SEM image of transect of sample A3

另一方面,根据Orowan理论,在相同质量分数的情况下,由于纳米颗粒增强相更为弥散,可以更加有效地强化金属基体[17]。当n-SiO2颗粒均匀地分布于铜基摩擦材料的基体中,可有效地阻碍位错运动和晶界滑移,提高基体的强度和耐热性,从而提高摩擦材料的耐磨性和耐热性。

对于添加n-SiO2的A2和A3材料,A3材料的摩擦学性能明显优于A2。说明经包覆处理后的n-SiO2对材料性能的影响优于未经处理的n-SiO2。由于纳米颗粒具有高的表面活性,极易发生团聚。而发生团聚后纳米颗粒会降低或失去纳米相的增强作用。此外,纳米颗粒的增强作用除了取决于自身的性能外还取决于纳米颗粒与基体之间界面的结合状态[18]。因此,当直接添加n-SiO2时,由于n-SiO2的团聚以及与基体之间结合强度较差,导致A2材料的耐磨性和耐热性提高不显著。而A3材料中所使用的Cu/n-SiO2复合粉体是通过歧化反应,在n-SiO2颗粒表面沉积包覆一层Cu制备而成[13],其目的是防止n-SiO2之间的团聚,以提高n-SiO2在铜基体中的分散性。包覆处理后的n-SiO2保证了n-SiO2以纳米尺度分散于铜基体中,同时由于铜-铜界面替代了铜-陶瓷颗粒界面,提高了基体与n-SiO2的结合强度。因而较好的改善了摩擦材料的性能。

REFERENCES

[1] 鲁乃光. 烧结金属摩擦材料现状与发展动态[J]. 粉末冶金技术, 2002, 20(5): 294-298.

LU Nai-guang. The present state and tendency of sintered friction materials in the world[J]. Powder Metallurgy Technology, 2002, 20(5): 294-298.

[2] LU Y F. A combinatorial approach for automotive friction materials: Effects of ingredients on friction performance[J]. Composites Science and Technology, 2006, 66: 591-598.

[3] 姚萍屏, 李世鹏, 熊 翔. Fe和SiO2对铜基摩擦材料摩擦学行为的对比研究[J]. 湖南有色金属, 2003, 19(3): 31-35.

YAO Ping-ping, LI Shi-peng, XIONG Xiang. Comparison on the friction and wear behavior of Fe and SiO2 in Cu-based friction materials[J]. Hunan Nonferrous Mentals, 2003, 19(3): 31-35.

[4] 李世鹏, 熊 翔, 姚萍屏, 乔卫东. 石墨、SiO2在铜基摩擦材料基体中的摩擦学行为研究[J]. 非金属矿, 2003(6): 51-55.

LI Shi-peng, XIONG Xiang, YAO Ping-ping, QIAO Wei-dong. Study on friction and wear behaviors of graphite and SiO2 in matrix of Cu-based friction material[J]. Non-Metallic Mines, 2003(6): 51-55.

[5] 吴 芳, 高 游, 张金生, 樊 毅, 刘伯威. SiO2和SiC对Cu-Fe基烧结摩擦材料性能的影响[J]. 中国有色金属学报, 2001, 11(1): 110-113.

WU Fang, GAO You, ZHANG Jin-sheng, FAN Yi, LIU Bai-wei. Effect of SiO2 and SiC on properties of Cu-Fe matrix sinterer friction materials[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 110-113.

[6] KATO H, TAKAMA M, IWAI Y, WASHIDA K, SASAKI Y. Wear and mechanical properties of sintered copper-tin composites containing graphite or molybdenum disulfide[J]. Wear, 2003, 255: 573-578.

[7] DING H D, HAN W Z, FU S L, DU J H, YU Y H. Design and manufacture of intelligent Cu-based wet friction materials[J]. Trans Nonferrous Met Soc China, 2004, 14(5): 864-869.

[8] 龚荣洲, 沈 翔, 张 磊, 张 凌. 金属基纳米复合材料的 研究现状和展望[J]. 中国有色金属学报, 2003, 13(5): 1311-1320.

GONG Rong-zhou, SHEN Xiang, ZHANG Lei, ZHANG Ling. Status and expectation of research on metal matrix nanocomposites[J]. The Chinese Journal of Nonferrous Metals, 2003,13(5): 1311-1320.

[9] LIDIA A, DAVIDE B, GREGORIO B, ALBERTO G, SILVIA G, CINZIA M, EUGENIO T. Recent trends on nanocomosites based on Cu, Ag and Au clusters: A closer look[J]. Coordination Chemistry Reviews, 2006, 250: 1294-1314.

[10] TJONG S C, LAU K C. Abrasive wear behavior of TiB2 particle-reinforced copper matrix composites[J]. Mater Sci Eng A, 2000, 282: 183-186.

[11] 刘远廷, 凌国平, 郦 剑. 纳米Al2O3化学镀铜复合粉末的烧结致密化[J]. 中国有色金属学报, 2004, 24(3): 471-477.

LIU Yuan-ting, LING Guo-ping, LI Jian. Sintering densification of Cu/Al2O3p nano-composite powders by electroless copper plating[J]. The Chinese Journal of Nonferrous Metals, 2004, 24(3): 471-477.

[12] 时新钢, 冯 柳, 王 英, 陈志伟. 纳米颗粒增强铜基复合材料的最新研究动态及发展[J]. 冶金信息导刊, 2007(1): 26-29.

SHI Xin-gang, FENG Liu, WANG Ying, CHEN Zhi-wei. Latest research and development trends of copper-based composites materials reinforced by nano-particles[J]. Metallurgical Information Review, 2007(1): 26-29.

[13] 王少卿, 李 超, 杜建华, 韩文政. 非均匀形核法制备Cu包覆纳米SiO2复合粉体[J]. 装甲兵工程学院学报, 2006, 20(2): 91-94.

WANG Shao-qing, LI Chao, DU Jian-hua, HAN Wen-zheng. Preparation of Cu coated nano SiO2 composite particles with heterogeneous nucleation method[J]. Journal of Academy of Armorde Force Engineering, 2006, 20(2): 91-94.

[14] 刘伯威, 张金生, 樊 毅, 吴 芳, 高 游. 非金属颗粒镀铜及对烧结摩擦材料强度的影响[J]. 材料保护, 2001, 34(2): 23-24.

LIU Bo-wei, ZHANG Jin-sheng, FAN Yi, WU Fang, GAO You. Electroless copper plating non-metallic particles and its effects on strength of sintered friction materials[J]. Materials Protection, 34(2): 23-24.

[15] JB/T7909—1999, 湿式烧结金属摩擦材料摩擦性能试验台试验方法[S].

JB/T7909?1999, The friction behavior testing methods of the wet sintered metal friction materials[S].

[16] 岳美娥, 周惠娣. 纳米微粒在摩擦学中的应用研究[J]. 润滑与密封, 2003(2): 85-87.

YUE Mei-e, ZHOU Hui-di. Application of nanopartical in tribology[J]. Lubrication Engineering, 2003(2): 85-87.

[17] TIAN B H, LIU P, SONG K, LI Y, LIU Y, REN F Z, SU J H. Microstructure and properties at elevated temperature of a nano-Al2O3 particles dispersion-strengthened copper base composites[J]. Mater Sci Eng, 2006, 435: 705-710.

[18] MOUSTAFA S F, Ei-badry S A, SANAD A M, KIEBACK B. Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders[J]. Wear, 253: 699-710.

基金项目:武器装备预研基金资助项目(51457070103JB3503)

收稿日期:2007-10-23;修订日期:2008-01-20

通讯作者:杜建华,讲师,博士研究生;电话:010-81439766;E-mail: djh619@sina.com

(编辑 陈爱华)