Main influencing factors and coal fly ash characteristics of gasoues fuel reburning process

来源期刊:中南大学学报(英文版)2009年第1期

论文作者:苏胜 向军 孙路石 胡松

文章页码:160 - 160

Key words:coal fly ash; unburned carbon; nitrogen oxides; coal combustion; reburning; down-fired furnace

Abstract: The unburned carbon concentration in fly ash and the influence of main factors on the reduction of nitrogen oxides during gaseous fuel reburning process were experimentally studied in a 36 kW down-fired furnace when five typical coals with different qualities were served as the primary fuel. It is found that the higher nitrogen oxide reduction efficiency can be obtained by reburning process when the coal used as the primary fuel contains more volatile matter. But under the optimizational operating conditions, both above 50% nitrogen oxide reduction and low carbon loss can be achieved by reburning process even though the primary fuel is the low-volatile coal. The experimental results show that the reasonable residence time in reburn zone is 0.6-0.9 s, the appropriate gaseous reburn fuel percentage is 10%-15% and the optimal average excess air coefficient in reburn zone is 0.8-0.9. These results extend the ranges of the key parameter values for reburning process with respect to that the low-volatile coals are used as the primary fuel.

基金信息:the National Natural Science Foundation of China

J. Cent. South Univ. Technol. (2009) 16: 0160-0165

DOI: 10.1007/s11771-009-0027-1![]()

SU Sheng(苏 胜), XIANG Jun(向 军), SUN Lu-shi(孙路石), HU Song(胡 松)

(State Key Laboratory of Coal Combustion, Huazhong University of Science and Technology,Wuhan 430074, China)

Abstract: The unburned carbon concentration in fly ash and the influence of main factors on the reduction of nitrogen oxides during gaseous fuel reburning process were experimentally studied in a 36 kW down-fired furnace when five typical coals with different qualities were served as the primary fuel. It is found that the higher nitrogen oxide reduction efficiency can be obtained by reburning process when the coal used as the primary fuel contains more volatile matter. But under the optimizational operating conditions, both above 50% nitrogen oxide reduction and low carbon loss can be achieved by reburning process even though the primary fuel is the low-volatile coal. The experimental results show that the reasonable residence time in reburn zone is 0.6-0.9 s, the appropriate gaseous reburn fuel percentage is 10%-15% and the optimal average excess air coefficient in reburn zone is 0.8-0.9. These results extend the ranges of the key parameter values for reburning process with respect to that the low-volatile coals are used as the primary fuel.

Key words: coal fly ash; unburned carbon; nitrogen oxides; coal combustion; reburning; down-fired furnace

1 Introduction

Nitrogen oxides (NOx) and sulfur dioxide (SO2) emitted from pulverized coal-fired boilers are significant contributors to atmospheric pollution and globe warming [1-2]. Among the most recent developments for reducing NOx emissions [3-4], reburning technology is considered to be one of the most promising and cost-effective NOx reduction strategies for coal combustion systems, and capable of providing above 50% NOx reduction [5-6]. The conventional reburning process divides the combustion domain of boiler into three stages, namely primary zone, reburn zone and burnout zone. In the primary zone, the pulverized coal is burnt under fuel-lean conditions with low excess air and a certain quantity of NOx is formed. In the reburn zone, a reburn fuel is injected immediately into the downstream of the primary zone to establish a localized fuel-rich environment. Under conditions of oxygen unavailable, the reburn fuel decomposes rapidly into hydrocarbon radicals that subsequently react with NOx to convert NOx into N2. In the burnout zone, burnout air is finally injected to complete combustion. The usual gaseous reburn fuels are hydrocarbons, such as methane and natural gas [7-8].

In the past several years, reburning technology has been largely studied. It is accepted that the NOx reduction efficiency by the reburning depends on suitable operating conditions in reburn zone [9]. Different studies on laboratory measurements [10], kinetic mechanisms [11] and numerical simulation [12] for reburning process were carried out to investigate the influence of amount of reburn fuel on the NOx reduction. However, most experimental studies and applications show that the reburning technology needs to use the high-volatile coal as the primary fuel [5, 13-14]. Because of the prevalence of faulty coal in power plant in China [15], further studies and optimization for the reburning processes that use the low-volatile coal as the primary fuel are required. Moreover, the fuel is difficult to burn out in the reburning process because of the oxygen-lean condition in reburn zone. Thus, the further evaluation on the burnout characteristic of the low-volatile coal in the reburning process is also required for the satisfactory application of the reburning technology [16]. In this work, the main influencing factors and coal fly ash characteristics of gasoues fuel reburning process were investigated.

2 Experimental

2.1 Experimental system and measurement

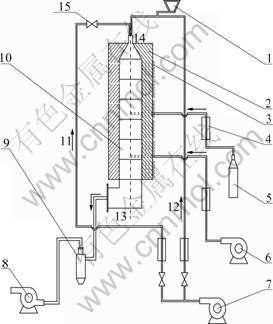

Fig.1 shows the schematic diagram of the experimental system that consisted of down-fired furnace, fuel supply, and blower. The down-fired furnace was made up of seven sections and heated by electric heater of silicon-carbon rod. The total power of the down-fired furnace was 36 kW. The temperature in the furnace was measured by Pt-Rh thermocouple and reached up to 1 500 K. The ceramic reaction tube of the furnace had a total length of 3.5 m and an internal diameter of 0.175 m. The coal feeder provided the pulverized coal with a feeding rate of 1.8 kg/h. The burner was an axial swirl one and located at the top of the furnace. The pulverized coal and the primary air were mixed with the secondary air and burnt downward. Some test holes were positioned vertically along the furnace wall to measure the temperature and species concentrations in the furnace. During the reburning experiments, the gaseous reburn fuel and burnout air were introduced in the furnace through these test holes. The residence time in reburn zone (tR) was varied by altering the location of the reburn fuel and burnout air inlet. The gaseous reburn fuel was stored in a high-pressure tank and injected horizontally in the furnace from a 12 mm diameter tube with a refractory nozzle. The flow rate of the gaseous reburn fuel was measured by a flowmeter. The burnout air was supplied by a centrifugal blower and injected into the furnace without preheating.

Fig.1 Schematic diagram of experimental system: 1—Pulverized coal feeder; 2—Thermal insulation material; 3—Test hole; 4—Flowmeter; 5—Gaseous reburn fuel tank; 6— Burnout air blower; 7—Centrifugal blower; 8—Induced fan; 9—Cyclone separator; 10—Ceramic reaction tube; 11— Secondary pipe; 12—Primary air pipe; 13—Horizontal flue; 14—Burner; 15—Valve

During the experiments, the flow rate of the primary air was 5 m3/h. The flow rate of the secondary air was varied between 4 and 7 m3/h for adjusting the excess air level in the furnace. The overall reburn zone stoichiometry was set by controlling the flow rate of the reburn fuel and volumetric rate of the primary zone. Burnout air was injected at the end of the reburn zone to bring the final excess air level to the same with base case. The average excess air coefficient for different zones (αP(R)) in the furnace is defined as

![]() (1)

(1)

where subscripts P and R stand for the primary zone and reburn zone, respectively; mt is the total mass of air in the furnace; and mr is the mass of theoretically required air.

A water-cooled sampling probe was used to extract gaseous combustion products in the furnace. A continuous monitoring flue gas analyzer was used for the on-line analysis of the NO concentration (chemiluminescence) and the O2 concentration (paramagnetism). The precision of the analyzer was stated as 1×10-6 for NO and 0.1% for O2. The analyzer was calibrated before and after each test run. The coal fly ash was collected from the cyclone separator during experiments. The unburned carbon mass fraction in fly ash was determined from the measured mass loss due to heating in the electric muffle furnace. To evaluate the influence of reburning process on burnout characteristics of the coal, the relative variance rate of the unburned carbon concentration in the fly ash is defined as

![]() (2)

(2)

where x1 and x2 are the unburned carbon mass fractions in fly ash for base case and reburning case, respectively.

2.2 Experimental fuels

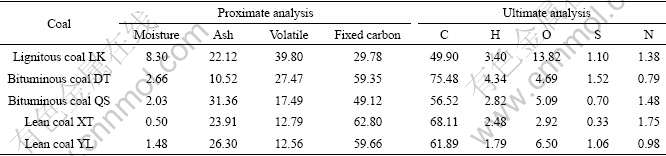

Five typical Chinese coals including two low-volatile lean coals were served as the primary fuel. The results of the proximate and ultimate analyses of the coals are given in Table 1. Prior to any analysis or experiments, the five coals were ground and dried. The fraction in the size range of 50-150 μm was selected by pneumatic sieving. After this treatment, the particle size of the five coals is similar, and should not be responsible for any difference observed during the experiments.

Table 1 Characteristics of coal (as received) (mass fraction, %)

The gaseous reburn fuel is methane (99.999%). During the reburning experiments, the amount of reburn fuel injected into the furnace was varied according to ratio of the reburn fuel thermal energy to the total thermal energy input in the furnace. The reburn fuel percentage (β) is defined as

![]() (3)

(3)

where Q1 and Q2 represent the total thermal energy input in the furnace and the thermal energy from the reburn fuel, respectively.

The values of β are respectively 5%, 10%, 15%, and 20% during the reburning experiments for investigating the influence of the amount of reburn fuel on NO reduction efficiency.

3 Results and discussion

3.1 Influence of coal quality

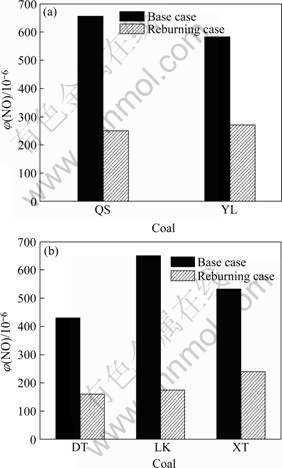

Fig.2 shows the NO emission of the base case and reburning case by using different coals as the primary fuel. For the base case, the NO emission concentration is relative to the contents of volatile and nitrogen in the coal. For the reburning case, the NO emission can be reduced when different kinds of coal are served as the primary fuel. However, the NO reduction efficiency varies with the coal quality. As shown in Fig.2(a), the NO reduction efficiency using the bituminous coal QS as the primary fuel is higher than that using the lean coal YL as the primary fuel. As shown in Fig.2(b), the NO exhaust emission is reduced from 532×10-6 of the base case to 240×10-6 of the reburning case when the lean coal XT is served as the primary fuel and a 55% NO reduction efficiency can be achieved. For the bituminous coal DT, the NO reduction efficiency is about 63% and the NO emission drops to 160×10-6 of the reburning case from 430×10-6 of the base case. For the lignitous coal LK, the NO emission of the reburning case is 174×10-6, which is higher than that (160×10-6) using the bituminous coal DT as the primary fuel. But the largest 73% NO reduction efficiency can be obtained by comparing with 650×10-6 NO emission of the base case.

Fig.2 Relationship between NO emission (volume fraction, φ(O2)=3%) and coal quality: (a) tR≈0.9 s, β≈15%, αR≈0.9; (b) tR≈0.6 s, β≈20%, αR≈0.9

The results shown in Fig.2 reveal that the coal severed as the primary fuel contains more volatile matter, and that the larger NO reduction efficiency can be obtained by gaseous fuel reburning. The explanation of this phenomenon is that the more coal-N will evolve with the volatile and less NO will be produced from char-N when the coal contains more volatile matter. Therefore, a higher NO concentration will be produced in the primary zone because of the higher volatile-N content, and much less NO will form in the burnout zone. As a result of the higher initial NO concentration formed in the primary zone, the reduction of NO to N2 in the reburn zone will be enhanced. So the larger NO reduction efficiency can be achieved by the gaseous fuel reburning process when the coal contains the higher volatile content.

3.2 Influence of residence time in reburn zone

Fig.3 shows the NO emission as a function of the residence time in reburn zone, where tR=0 represents the base case, in which the reburn fuel is not injected into the furnace. For the reburning case, the residence time in reburn zone is varied by altering the injection position of reburn fuel (as shown in Fig.3(a)) and burnout air (as shown in Fig.3(b)), respectively.

Fig.3 Relationship between NO emission (φ(O2)=3%) and residence time in reburn zone: (a) β≈15%, αR≈0.9; (b) β≈20%, αR≈0.9

As shown in Fig.3, the NO emission decreases with the increase of the residence time in reburn zone. Compared with the bituminous coal, the longer residence time in reburn zone is needed by the lean coal to obtain the same NO reduction efficiency. As shown in Fig.3(a), the NO exhaust emission slightly increases when the residence time in the reburn zone exceeds 1.5 s. This phenomenon can be explained as follows: increasing the residence time in the reburn zone results in the injection position of reburn fuel being close to the burner outlet when the location of the burnout air inlet is not altered during the experiments. The residence time in the primary zone is not enough for the oxygen in the primary zone to fully react with the coal. As a consequence, excessive residual air will flow into the reburn zone and react with the reburn fuel. This may restrain the NO reburning reduction reactions and results in the increase of NO emission. Therefore, the increasing trend of NO exhaust emission may be reversed with the increase of the residence time, after a certain limit of the residence time in the reburn zone is exceeded.

As shown in Fig.3, increasing the residence time from 0 to 0.6 s results in an obvious NO reduction, but a further increase of the residence time from 0.9 to 1.7 s does not show an obviously larger NO reduction (only 5% increase). According to the experimental results, above 50% NO reduction can be achieved for different coals when the residence time in the reburn zone is 0.6- 0.9 s. The NO emission dose not show an obviously further decrease when the residence time in the reburn zone exceeds 0.9 s. This result extends the range of the values for residence time in the reburn zone with respect to the reburning process that the low-volatile coals are served as the primary fuel [6].

3.3 Influence of amount of reburn fuel

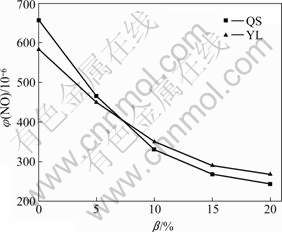

Fig.4 shows the relationship between the NO emission and the reburn fuel percentage (β), where β=0 represents the base case without reburning.

Fig.4 Relationship between NO emission (φ(O2)=3%) and reburn fuel percentage (β) at tR=0.7 s

As shown in Fig.4, the NO emission decreases with the increase of the amount of the gaseous reburn fuel. For the bituminous coal QS, above 50% NO reduction can be obtained when β achieves 10%. However, β should reach 15% to obtain above 50% NO reduction when the low-volatile lean coal YL is served as the primary fuel. For both coals, only less than 4% further NO reduction can be obtained when β increases from 15% to 20%.

Fig.4 reveals that the NO emission obviously decreases with the increase of the amount of reburn fuel at first. Only slightly further NO reduction can be achieved when the reburn fuel percentage exceeds a certain limit. For the low-volatile coal, more gaseous reburn fuel should be injected into the furnace during the reburning process to achieve the same NO reduction level of that using the high-volatile coal as the primary fuel. Under the present experimental conditions, the reasonable gaseous reburn fuel percentage is 10%-15%, which is sufficient for the reburning process to get above 50% NO reduction when different kinds of coals are served as the primary fuel. A further increase of the gaseous reburn fuel percentage does not show the obviously larger NO reduction.

3.4 Influence of excess air coefficient

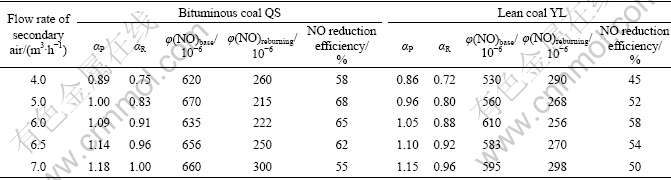

Table 2 shows the NO exhaust emission with different excess air coefficient. During the experiments, the excess air coefficient was varied by altering the amount of the secondary air and supplying the amount of coal and reburn fuel invariably.

Table 2 NO emission of coals with different excess air coefficients at flow rate of primary air of 5 m3/h

For base case, the largest NO emission (670×10-6 for QS and 610×10-6 for YL) is achieved when αP is close to 1 and the lowest NO emission (620×10-6 for QS and 530×10-6 for YL) is achieved when αP reaches the minimum, as listed in Table 2. For reburning case, the lowest NO emission (215×10-6 for QS and 256×10-6 for YL) cannot be obtained when αP reaches the minimum. It can be gained under the conditions that αP is close to 1 and αR is 0.8-0.9. The explanation of this phenomenon is that the highest NO concentration can be gained when the amount of air in primary zone is stoichiometric air addition (αP=1). The higher NO concentration enhances the NO reduction reaction and results in a lower NO exhaust emission. This result implies that the NO reduction efficiency can be improved by increasing the initial NO concentration for NO reburning reduction reaction. In the practical reburing process, it is not usually to improve the NO reduction efficiency by increasing the initial NO concentration. But it is realizable and favorable to get a lower NO emission for reburning process by injecting the reburn fuel into the region where the NO concentration is the highest.

The data in Table 2 also show that the NO reduction efficiency increases initially and then decreases with the increase of the excess air coefficient in reburn zone. This indicates that there is an optimal excess air coefficient for the reburn zone to obtain the largest NO reduction efficiency. According to the experimental results, the optimal excess air coefficient in the reburn zone is 0.8-0.9. Under those experimental conditions, above 50% NO reduction for different kinds of coals can be achieved.

3.5 Unburned carbon in fly ash

For the reburning process, the coal is difficult to burn out thoroughly because of the oxygen-lean condition in reburn zone, especially when the low-volatile coal is served as the primary fuel. The high unburned carbon concentration in fly ash will decrease the combustion efficiency of the reburning process. The objective of reburning process optimization is not only to achieve the high NOx reduction efficiency, but also to obtain the low carbon loss and burnout of fuel. Fig.5 shows the relationship between the relative variance rate of the unburned carbon concentration in fly ash and the residence time in the reburn zone when the low-volatile lean coal YL is served as the primary fuel.

Fig.5 Relationship between λ and residence time in reburn zone under changing location of reburn fuel inlet

As shown in Fig.5, λ increases with the increase of the residence time in the reburn zone at different reburn fuel heat inputs. This indicates that the unburned carbon concentration in fly ash for the reburning case is higher than that for the base case, and the carbon loss of the reburning case increases with the increase of residence time in the reburn zone. During the reburning experiments, the residence time in the reburn zone is varied by altering the location of the reburn fuel inlet and keeping the injection position of burnout air unchanged. The increase of the residence time in the reburn zone will decrease the residence time of the coal in oxygen-rich primary zone, which increases the unburned carbon in the reacting particles and is unfavourable for the burnout of the coal. Additionally, the burnout characteristic of the coal will further deteriorate with the increase of the residence time of the coal in fuel-rich reburn zone. So the burnout rate of the coal decreases with the increase of the residence time in the reburn zone when the location of burnout air inlet is not changed.

Fig.5 also shows that λ reaches 25%-30% when tR=1.8 s. The carbon loss caused by reburning process obviously increases under that condition. This is not economical for the reburning process even though the long residence time in the reburn zone could enhance the NO reduction reactions. However, λ is lower than 10% when the residence time in the reburn zone achieves 0.6-0.9 s. The unburned carbon concentration in the fly ash for the reburning case does not remarkably increase compared with that for base case. But above 50% NO reduction is obtained under that condition (as shown in Fig.3(a)). This indicates that high NO reduction efficiency with low carbon loss can be obtained when the optimal variables are adopted in the reburning process even though the low-volatile coal is served as the primary fuel.

4 Conclusions

(1) In order to obtain a wider and more detailed knowledge of the influence of the main factors on the gaseous reburning process, detailed experimental studies are performed in a 36 kW down-fired furnace when five typical coals including two low-volatile lean coals are served as the primary fuel, and the burnout characteristics of coal are also evaluated during the experiments. The results show that above 50% NO reduction efficiency with low carbon loss can be obtained by the gaseous reburning process when the residence time in the reburn zone is 0.6-0.9 s, the gaseous reburn fuel percentage is 10%-15%, and the average excess air coefficient in reburn zone is 0.8-0.9, even though the primary fuel is the low-volatile coal.

(2) It is found that the higher nitrogen oxides reduction efficiency can be obtained by reburning process when the coal used as the primary fuel contains more volatile matter. When the low-volatile coal is used as the primary fuel, more gaseous reburn fuel and longer residence time in the reburn zone are needed to achieve the same NO reduction level of that using high-volatile coal as the primary fuel.

(3) The range of the key parameter values in this work provides a basis for the reburning applications, especially when the low-volatile coal is served as the primary fuel.

References

[1] GLARBORG P, JENSEN A D, JOHNSSON J E. Fuel nitrogen conversion in solid fuel fired systems [J]. Progress in Energy and Combustion Science, 2003, 29(2): 89-113.

[2] HE De-wen, PENG Chang-hong, WANG Yun-yan. Main influence factors on desulfurization of coal by sulfolobas [J]. Journal of Central South University of Technology, 2003, 10(2): 113-116.

[3] HILL S C, SMOOT L D. Modeling of nitrogen oxides formation and destruction in combustion systems [J]. Progress in Energy and Combustion Science, 2000, 26(4/6): 417-458.

[4] YANG Wei-hong, JIANG Shao-jiang, HSIAO Tse-chiang, YANG Li-xing. Numerical simulation of high temperature air combustion flames properties [J]. Journal of Central South University of Technology, 2000, 7(3): 156-158.

[5] SMOOT L D, HILL S C, XU H. NOx control through reburning [J]. Progress in Energy and Combustion Science, 1998, 24(5): 385-408.

[6] ZHANG Zhong-xiao, YAO Xiang-dong, WU Xiao-jiang, WEI Hua-yan, TAO Xiao-hua, ZHU Ji-mu. Experimental study on low NOx emission using gas reburning [J]. Proceeding of the CSEE, 2005, 25(9): 99-102. (in Chinese)

[7] BILBAO R, MILLERA A, ALZUETA M U, PRADA L. Evaluation of the use of different hydrocarbon fuels for gas reburning [J]. Fuel, 1997, 76(14/15): 1401-1407.

[8] FANG Bing, LUO Yong-hao, LU Fang, FENG Yan-lei. The characteristics and selection of reburned fuels involved in the reburning technology of a coal-fired boiler [J]. Journal of Engineering for Thermal Energy and Power, 2004, 19(5): 443-446. (in Chinese)

[9] BILBAO R, ALZUETA M U, MILLERA A. Experimental study of the influence of the operating variables on natural gas reburning efficiency [J]. Ind Eng Chem Res, 1995, 34(12): 4531-4539.

[10] LI Sen, XU Tong-mo, ZHOU Qu-lan, TAN Hou-zhang, HUI Shi-en, HU Hong-li. Optimization of coal reburning in a an MW tangentially fired furnace [J]. Fuel, 2007, 86(7/8): 1169-1175.

[11] SHEN Bo-xiong, YAO Qiang, XU Xu-chang. Kinetic model for natural gas reburning [J]. Fuel Processing Technology, 2004, 85(11): 1301-1315.

[12] DIMITRIOU D J, KANDAMBY N, LOCKWOOD F C. A mathematical modeling technique for gaseous and solid fuel reburning in pulverized coal combustors [J]. Fuel, 2003, 82(15/17): 2107-2114.

[13] HAMPARTSOUMIAN E, FOLAYAN O O, NIMMO W, GIBBS B M. Optimisation of NOx reduction in advanced coal reburning systems and the effect of coal type [J]. Fuel, 2003, 82(4): 373-384.

[14] QIU Zhong-zhu, PAN Wei-guo, REN Jian-xing, LI Peng, SUN Jian-rong, WANG Wen-huan. Experimental study on reburning with natural gas for reducing NOx emission [J]. Journal of Power Engineering, 2007, 27(1): 126-129. (in Chinese)

[15] HE Xue-zhi, WANG Chun-chang. Study on adaptability of low NOx burners to various coal quality [J]. Thermal Power Generation,2003, 8: 12-15. (in Chinese)

[16] MCCAHEY S, MCMULLAN J T, WILLIAMS B C. Techno- economic analysis of NOx reduction technologies in p.f. boilers [J]. Fuel, 1999, 78(14): 1771-1778.

Foundation item: Projects(50806025; 50721005) supported by the National Natural Science Foundation of China

Received date: 2008-07-16; Accepted date: 2008-10-08

Corresponding author: SUN Lu-shi; Associate professor, PhD; Tel: +86-27-87542417-8318; E-mail: sunlushi@mail.hust.edu.cn

(Edited by CHEN Wei-ping)