文章编号:1004-0609(2013)06-1530-06

单级退火对BTi-6431S合金组织和力学性能的影响

张文婧1, 宋晓云1, 惠松骁1, 叶文君1, 王永玲1, 王小翔2, 王韦琪2

(1. 北京有色金属研究总院 有色金属材料制备与加工国家重点实验室,北京 100088;

2. 宝钛集团有限公司,宝鸡 721014)

摘 要:采用光学显微镜、电子探针和拉伸实验研究单重退火处理对BTi-6431S合金显微组织和力学性能的影响。结果表明:随退火温度的升高,合金中的初生α相粗化,趋于等轴状,体积分数逐渐降低;β相和次生α相的体积分数增加。随退火温度的升高,合金的室温强度先升高后降低,高温强度则逐渐升高;但是室温和高温塑性均不断下降。经过980 ℃退火处理后,BTi-6431S合金获得良好的高温强度和室温塑性匹配,此时合金650 ℃的抗拉强度达到600 MPa以上,室温伸长率超过8%。

关键词:高温钛合金;BTi-6431S合金;单重退火;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

Effect of single annealing on microstructure and mechanical properties of BTi-6431S titanium alloy

ZHANG Wen-jing1, SONG Xiao-yun1, HUI Song-xiao1, YE Wen-jun1, WANG Yong-ling1, WANG Xiao-xiang2, WANG Wei-qi2

(1. State Key Laboratory of Nonferrous Metals and Processes, General Research Institute for Nonferrous Metals, Beijing 100088, China;

2. Baoti Group Co., Ltd., Baoji 721014, China)

Abstract: The effects of single annealing on the microstructure and mechanical properties of BTi-6431S titanium alloy were studied by OM, EPMA and tensile test. The results show that, with increasing annealing temperature, the primary α phase becomes coarse, then changes into equiaxed shape, and its volume fraction decreases gradually, while the volume fractions of β phase and secondary α phase increase. With elevating the annealing temperature, the room temperature strength increases at first and then decreases, while the high temperature strength increases gradually, but the room-temperature and high-temperature ductility decreases. After annealing at 980 ℃, BTi-6431S alloy acquires good strength at high-temperature and plasticity at room-temperature. The ultimate tensile strength at 650 ℃ can reach more than 600 MPa, and the room-temperature elongation is more than 8%.

Key words: high temperature titanium alloy; BTi-6431S alloy; single annealing; microstructure; mechanical properties

高温钛合金具有较高的比强度、良好的热强性和优异的耐蚀性,广泛地应用在航空航天领域[1]。目前,国内外得到应用的高温钛合金的最高使用温度为600 ℃,典型代表为英国的IMI834[2]、美国的Ti-1100[3]、俄罗斯的BT36[4]以及中国的Ti60[5]和Ti600[6]。由于使用温度的升高会大大降低高温钛合金的蠕变抗力和高温抗氧化性能,因此,发展600 ℃以上的高温钛合金成了困难。

随着航天工业的快速发展,新型高性能飞行器的研制工作受到了人们的高度重视,这要求壳体材料在650~700 ℃下具有良好的瞬时强度和持久的蠕变性能。为了保证材料在严格工作环境下具有可靠的综合性能,宝钛集团联合北京有色金属研究总院在BT25y的基础上,同时加入一定量的Nb和W两种高熔点β稳定元素,并将Mo元素的含量调整到3%左右,研究出一种新型α+β型钛合金BTi-6431S,其名义成分为Ti-6.5Al-3Sn-3Zr-3Mo-3Nb-1W-0.2Si。该合金具有良好的室温强度、加工塑性和焊接性能,并且在高温下显示出更高的瞬时强度以及大载荷持久和蠕变的良好匹配[7-8],可用于650~700 ℃下短时应用的航空航天结构件。热处理是一种改善钛合金力学性能的有效方法。目前,关于热处理对BTi-6431S合金组织和性能影响的研究工作甚少,因此,本文作者对BTi-6431S合金进行单重退火处理,研究其对合金显微组织和力学性能的影响,为该合金热处理制度的制定奠定基础。

1 实验

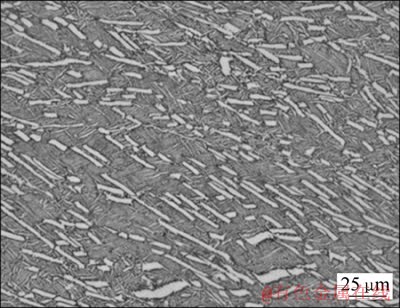

实验用BTi-6431S合金薄板由宝钛集团有限公司提供,为了得到大尺寸的3 mm厚的薄板,保证合金的加工工艺性能,适当降低了合金中β稳定元素含量。经两相区温度退火处理后合金的原始组织如图1所示。由图1可知,合金由块状和板条状的初生α相和片层状的β转变组织(βt)组成。采用淬火金相法测得该合金的相变点为990~1 000 ℃。根据相变点制定热处理制度如表1所列。

图1 经两相区轧制后的原始组织

Fig. 1 Optical original microstructure rolled in (α+β) phase field

将热处理后的合金线切割成标距为50 mm的标准拉伸试样,在AG-250 KNIS Ms型万能拉伸实验机上进行室温拉伸,拉伸速度为3 mm/min;并在Instron-5582型高温拉伸试验机上进行高温拉伸,拉伸速度为4 mm/min;利用Axiovert 200 MAT型Zeiss光学显微镜观察分析热处理前后的显微组织;采用JEOL JXA-8100型电子探针测定了合金中元素含量。

表1 BTi-6431S合金的热处理工艺

Table 1 Heat treatment of BTi-6431S alloy

2 结果与分析

2.1 热处理对合金显微组织的影响

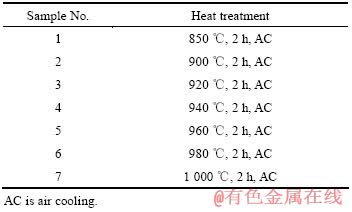

图2所示为BTi-6431S合金单重退火后的金相组织。样品经850 ℃退火后,初生α相含量(体积分数)高达76%,呈板条状,提高退火温度,初生α相逐渐趋于等轴化。由图2可知,随着退火温度的升高,初生α相的体积分数有所变化,经850~940 ℃退火后,初生α相体积分数约为70%,变化不明显,但在960~ 1 000 ℃下退火时,初生α相体积分数大幅减少,由940 ℃时的70%下降到980 ℃时的43%,经1 000 ℃退火后,在晶界处已观察不到初生α相。说明退火温度越接近相变点,该合金的初生α相体积分数对温度越敏感。而对于次生α相,在850~940 ℃下退火,转变得到的β相体积分数少,空冷过程中转变的次生α相少且细小;而当退火温度升高到960和980 ℃时,原子的扩散系数增加,初生α相向β相转变的数量增多,使得β相中的Al含量升高,在随后空冷过程中,退火温度高的β相中Al通过短程扩散生成次生α相,次生α相优先在α/β界面上析出,通过界面迁移长大[9]。

采用电子探针对热处理后的试样中各相进行成分分析,如表2所列。试样中初生α相中的Al含量均高于βt的,而Nb、Mo、W的含量都明显低于βt的。随退火温度的升高,βt中Al含量升高,而Nb、Mo和W的含量降低。说明在退火过程中,原来固溶在α相中的Al通过扩散进入β相中,温度越高则元素扩散系数越大,初生α转变为β相的速率增加,得到更多的β相;同时β相中β稳定元素含量的减少降低了β相的稳定性,有利于空冷过程中β相向次生α相转变,使得次生α相体积分数增加,这与图2观察到的结果相一致。

图2 不同条件下热处理后合金金相组织

Fig. 2 Optical micrographs of samples after annealing under different conditions

表2 不同热处理状态下各相元素的质量分数

Table 2 Mass fractions of elements in each phase after different heat treatments

2.2 热处理对合金室温性能的影响

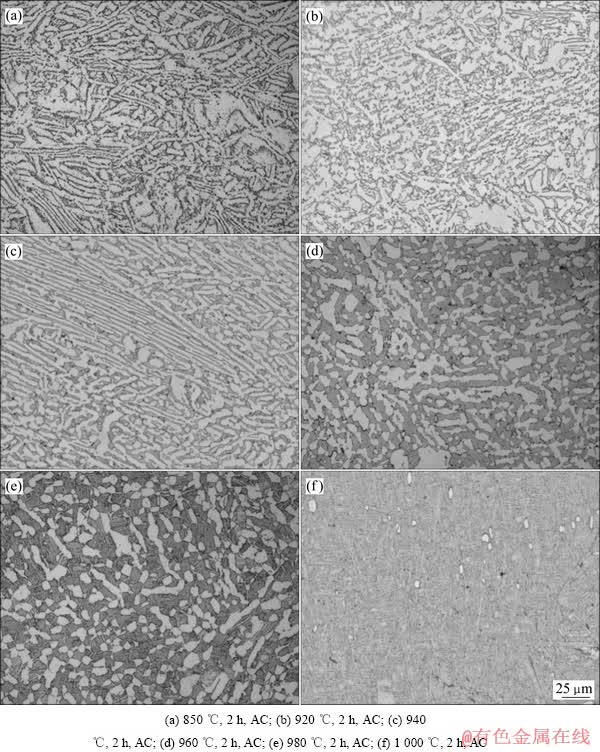

图3所示为BTi-6431S合金经850~1 000 ℃退火后室温拉伸性能随退火温度的变化曲线。由图3可知,合金具有优异的室温性能,经650 ℃和980 ℃退火后,抗拉强度(σb)大于1 000 MPa,屈服强度(σ0.2)大于900 MPa,伸长率(δ)在10%左右。

图3 单重退火温度与合金室温拉伸性能的关系

Fig. 3 Relationships among annealing temperature and tensile properties of alloys at room temperature

由图2可知,合金在850~960 ℃退火时,初生α相向β相发生转变,随着退火温度的升高,β相体积分数增加,使得α相与β相之间的相界面数目增加,有利于提高材料的界面强度;并且次生α相体积分数增加,细小的次生α相起到了弥散强化的作用。但当温度升高到980 ℃后,晶粒尺寸发生长大,减少了相界面的面积,合金强度降低。

室温塑性随退火温度的升高而降低,伸长率由850 ℃退火后的12%降低到1 000 ℃退火后的3%,这主要由两个方面引起的。首先,双态组织的拉伸变形是在初生α相的个别晶粒中以滑移开始的,随着变形程度的增加,滑移占据越来越多的α晶粒,并向周围的βt扩展。退火温度越低,初生α相体积分数越多,降低了初生α相间的平均自由程,减小滑移带间距,位错分布均匀,减小了应力集中,对塑性有利[10]。其次,次生α相的影响。当退火温度超过960 ℃时,片状次生α相的体积分数增加。由于βt中的变形先从β相开始,逐渐向次生α相进行。而α/β界面具有一定的伯格斯位向关系,即 ,

,

,只有当位错沿着

,只有当位错沿着 滑移系方向进行时,变形才会顺利地从β相向次生α相进行[11],这使得片状组织与初生α相相比塑性变形困难,所以退火温度越高,βt体积分数越高,塑性越低。且

滑移系方向进行时,变形才会顺利地从β相向次生α相进行[11],这使得片状组织与初生α相相比塑性变形困难,所以退火温度越高,βt体积分数越高,塑性越低。且 [12]认为减小片层α相的尺寸有利于提高材料伸长率,所以,退火温度较低时,BTi-6431S中次生α相比较细小,塑性好。

[12]认为减小片层α相的尺寸有利于提高材料伸长率,所以,退火温度较低时,BTi-6431S中次生α相比较细小,塑性好。

2.3 热处理对合金高温性能的影响

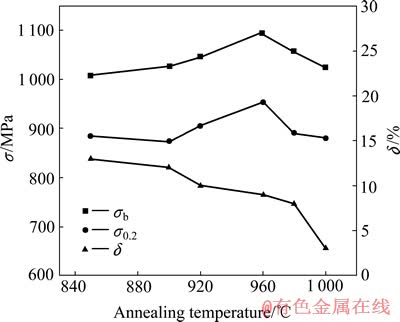

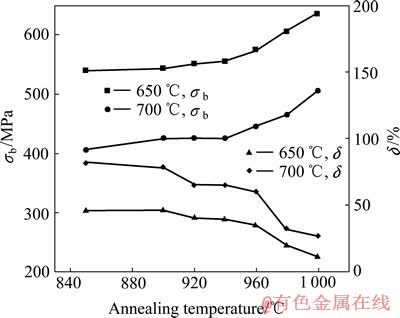

图4所示为BTi-6431S合金的650和700 ℃拉伸性能与退火温度的关系曲线。该合金经简单的退火处理后,650 ℃下的σb可达到600 MPa以上,与Ti-1100和BT36在600 ℃下的σb相当(Ti-1100的σb约为630 MPa,BT36的σb约为640 MPa)[13]。随退火温度的升高,抗拉强度升高,塑性降低。虽然经1 000 ℃退火后合金高温强度最高,但此时合金为魏氏组织,室温塑性很差,无法满足加工性能的要求,所以退火温度选择在相变点以下。

图4 单重退火温度与合金高温拉伸性能的关系

Fig. 4 Relationships among annealing temperature and tensile properties of alloys at 650 and 700 ℃

合金的高温强度的变化与图2中βt含量的变化趋势一致,即随退火温度的升高二者都增大。850~940 ℃退火时,由于退火温度较低,βt和次生α相体积分数较少,强度上升缓慢;而在较高温度(960~1 000 ℃)下退火时,初生α相向β相转变速度加快,βt的尺寸增大,含量不断增加,次生α相体积分数增加,高温强度明显上升。可知,片层状βt有利于提高BTi-6431S合金在650和700 ℃时的强度。电子探针结果表明,随退火温度的升高,初生α相中的Al元素含量增加,提高初生α相固溶强化的作用,使合金的高温强度上升。

与室温拉伸不同的是,BTi-6431S合金在650和700 ℃拉伸过程中,强化机制发生了变化。室温下,界面数量的增加可以有效提高合金的强度,但在高温下其强化作用被削弱。这是因为一方面随变形温度的升高,界面对变形的阻力大为减弱[14];另一方面,对BTi-6431S合金而言,β相稳定元素(Nb、Mo、W)的加入强化了β相的同时,增加了β相的体积分数,使α/β相界面增加,而α/β相界面在α/β、α/α、β/β这3种相界面的强度中是最低的(相界变形抗力大小α/β<<α/α≈β/β),即α/β相界易发生滑移[15-18],此时α/β相界面数目的增加会降低合金高温强度。

退火温度升高时,初生α相和βt的尺寸增大,粗大组织不利于合金塑性变形,导致BTi-6431S合金的高温塑性随退火温度的升高而降低。

在本研究所选用的相变点以下热处理制度中,合金经980 ℃退火后,在片层状的βt基体上分布着约40%的初生α相,其室温抗拉强度为1 060 MPa,屈服强度为900 MPa,伸长率大于8%,并且在650和700 ℃下的抗拉强度最高,塑性均大于20%,具有良好的室温塑性和高温强度匹配,可确定BTi-6431S合金的最佳退火温度为980 ℃。

3 结论

1) BTi-6431S合金经两相区退火后,随着退火温度的升高,初生α相向β相转变速度增大,β相中的次生α相尺寸和体积分数增加。

2) 随着退火温度的升高,由于初生α相与β相之间的相界面数目的变化和次生α相的生成与长大,使得BTi-6431S合金的室温强度先升高后降低,塑性逐渐降低。

3) 随着退火温度的升高,βt和次生α相的体积分数增加,初生α相固溶强化效果的增强,使得BTi-6431S合金在650和700 ℃下的强度升高,塑性下降;其在650 ℃下的抗拉强度与Ti-1100和BT36在600 ℃下的相当。

REFERENCE

[1] 刘 莹, 曲周德, 王本贤. 钛合金TC4的研究开发与应用[J]. 兵器材料科学与工程, 2005, 28(5): 48-50.

LIU Ying, QU Zhou-de, WANG Ben-xian. Research development and application of Ti6A14V alloy[J]. Ordnance Material Science and Engineering, 2005, 28(5): 48-50.

[2] WANJARA P, JAHAZI M, MONAJATI H, YUE S, IMMARIGEON J P. Hot working behavior of near-α alloy IMI834[J]. Materials Science and Engineering A, 2005, 396: 50-60.

[3] MADSEN A, GHONEM H. Effects of aging on the tensile and fatigue behavior of the near-α Ti-1100 at room temperature and 593 ℃[J]. Materials Science and Engineering A, 1994, 177: 63-73.

[4] 郝孟一, 蔡建明, 杜 娟. 热处理对BT36高温钛合金组织及性能的影响[J]. 航空材料学报, 2003, 23(2): 14-17.

HAO Meng-yi, CAI Jian-ming, DU Juan. The effect of heat treatment on microstructure and properties of BT36 high temperature alloy[J]. Journal of Aeronautical Material, 2003, 23(2): 14-17.

[5] JIA Wei-jun, ZENG Wei-dong, ZHOU Yi-gang, LIU Jian-rong, WANG Qing-jiang. High-temperature deformation behavior of Ti60 titanium alloy[J]. Materials Science and Engineering A, 2011, 528: 4068-4074.

[6] NIU Yong, LI Miao-quan. Effect of 0.16 wt% hydrogen addition on high temperature deformation behavior of the Ti600 titanium alloy [J]. Materials Science and Engineering A, 2009, 513/514: 228-232.

[7] 王小翔, 王韦琪, 马红海. 700 ℃时高温高强BTi-6431S合金的组织与力学性能[J]. 中国有色金属学报, 2010, 20(S1): s792-s795.

WANG Xiao-xiang, WANG Wei-qi, MA Hong-hai. Microstructure and mechanical properties of high temperature and high strength BTi-6431S alloy at 700 ℃[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s792-s795.

[8] 杨 伟, 王 俭, 王红武, 董振建, 王小翔, 王韦琪. 热加工工艺对BTi-6431S钛合金厚板与组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s104-s106.

YANG Wei, WANG Jian, WANG Hong-wu, DONG Zhen-jian, WANG Xiao-xiang, WANG Wei-qi. Effect of hot working process on microstructure and properties of BTi-6431S titanium alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s104-s106.

[9] 王志辉, 夏长清, 彭小敏, 陈志宏, 李学雄. 热处理工艺对Ti62421s高温钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2010, 20(12): 2298-2306.

WANG Zhi-hui, XIA Chang-qing, PENG Xiao-min, CHEN Zhi-hong, LI Xue-xiong. Effect of heat treatment on microstructure and mechanical properties of Ti62421s high temperature titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2298-2306.

[10] 段 锐, 蔡建明, 李臻熙. 初生α相含量对近α钛合金TG6拉伸性能和热稳定性的影响[J]. 航空材料学报, 2007, 27(3): 17-21.

DUAN Rui, CAI Jian-ming, LI Zhen-xi. Effect of primary α phase volume fraction on tensile property and thermal stability of near-alpha TG6 titanium alloy[J]. Journal of Aeronautical Material, 2007, 27(3): 17-21.

[11] WANG Tao, GUO Hong-zhen, WANG Yan-wei, PENG Xiao-na, ZHAO Yan, YAO Ze-kun. The effect of microstructure on tensile properties, deformation mechanisms and fracture models of TG6 high temperature titanium alloy [J]. Material Science and Engineering A, 2011, 528: 2370-2379.

[12] LUTJERING G. Influence of processing on microstructure and mechanical properties of (α+β) titanium alloys[J]. Materials Science and Engineering A, 1998, 243: 32-45.

[13] 许国栋, 王凤娥. 高温钛合金的发展和应用[J]. 稀有金属, 2008, 32(6): 774-780.

XU Guo-dong, WANG Feng-e. Development and application on high-temperature Ti-based alloys[J]. Rare Metal, 2008, 32(6): 774-780.

[14] 胡赓祥, 蔡 珣, 戎咏华. 材料科学基础[M].北京: 上海交通大学出版社, 2000: 185.

HU Geng-xiang, CAI Xun, RONG Yong-hua. Fundamentals of material science[M]. Beijing: Shanghai Jiaotong University Press, 2000: 185.

[15] KIM J H, CHANG Y W, LEE C S. Quantitative analysis on boundary sliding and its accommodation mode during super plastic deformation of two-phase Ti-6Al-4V alloy[J]. Metallurgical and Material Transaction A, 1998, 29(1): 217-226.

[16] KIM J H, SEMIATIN S L, LEE C S. High-temperature deformation and grain-boundary characteristics of titanium alloys with an equiaxed microstructure[J]. Material Science and Engineering A, 2008, 485: 601-612.

[17] KIM J H, LEE Y T, PARK C G, LEE C S. Microstructural analysis on boundary sliding and its accommodation mode during super plastic deformation of Ti-6Al-4V alloy[J]. Material Science and Engineering A, 1999, 263: 272-280.

[18] 王 永, 卢 斌, 杨 锐. 钼钨含量和热处理对一种高温钛合金拉伸性能的影响[J]. 材料研究学报, 2010, 24(3): 283-288.

WANG Yong, LU Bin, YANG Rui. Effect of (Mo, W) content and heat treatment on the tensile properties of high-temperature titanium alloy[J]. Chinese Journal of Material Research, 2010, 24(3): 283-288.

(编辑 龙怀中)

基金项目:有研总院创新基金资助项目(23056)

收稿日期:2012-08-27;修订日期:2013-01-10

通信作者:宋晓云,工程师,博士;电话:010-82241162;E-mail: songxiaoyun82@126.com