Trans. Nonferrous Met. Soc. China 22(2012) 72-77

Fabrication of wavy γ-TiAl based sheet with foil metallurgy

LIU Jiang-ping, SU Yan-qing, LUO Liang-shun, CHEN Hui, XU Yan-jin, GUO Jing-jie, FU Heng-zhi

School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 15001, China

Received 23 September 2010; accepted 5 January 2011

Abstract: A 0.7 mm-thick wavy γ-TiAl sheet with fully lamellar microstructure was fabricated by hot pressing Ti/Al alternate foils with heat treatment of 640 °C, 15 h+850 °C, 35 h+1350 °C, 2 h. The intermetallic compounds formed during heat treatments were identified by scanning electron microscopy (SEM) and X-ray diffraction (XRD). TiAl3 was the only observed phase at the Ti/Al interface when Al foils were not consumed. After being annealed at 850 °C for 35 h, the microstructure was composed of α-Ti, α2-Ti3Al, γ-TiAl and TiAl2. A fully lamellar microstructure formed after annealing at 1350 °C. Most of the angles between the lamellar interface and the sheet plane are below 30°. Using thinner starting foils is favorable to produce sheets with fine microstructure.

Key words: solid state reaction; phase transformation; titanium aluminides; foil metallurgy

1 Introduction

γ-TiAl based materials with fully lamellar microstructure have great potential in aerospace and automotive applications, due to their high specific strength and excellent high temperature properties [1-3]. The lamellar microstructure shows a significant anisotropy in mechanical properties according to the previous studies on polysynthetically twinned (PST) crystals. When the loading axis is parallel to the lamellar boundaries, the materials exhibit an optimal combination of yield strength and ductility [4]. PST crystals with their boundaries parallel or perpendicular to the stress axis show higher yield stress and longer creep life than those with their lamellar boundaries oriented at an intermediate angle to the stress axis [5]. For real fully lamellar polycrystalline γ-TiAl alloy, the high volume fraction of the lamellar colonies inclined at low angles contributes to higher yield strength than the random distribution of lamellar orientation [6, 7]. PST crystals with notch plane perpendicular to lamellar boundaries show a better toughness than that of notch plane parallel to lamellar boundaries [8]. As a result, γ-TiAl sheet materials with lamellar boundaries parallel to the sheet plane are expected to show a good combination of strength, ductility and toughness. Because of the poor ductility of γ-TiAl alloy, there are no relative simple approaches for producing TiAl-based sheet, especially those with complicated shape, such as honeycomb, corrugation and gator-hide structure[9]. Elemental foils have been used to fabricate intermetallics sheets due to their relatively better ductility.

In the present study, a wavy TiAl sheet with a particular microstructure mentioned above was fabricated by hot pressing the alternate Ti/Al foils, which was a low-cost method. Before the fabrication of the wavy sheet, a flat sheet was produced to investigate the inner mechanism.

2 Experimental

Elemental titanium foils (99.6%, molar fraction, 0.030 mm in thickness) and elemental aluminum foils (99.6%, molar fraction, 0.023 mm in thickness) were employed. The Ti and Al foils were etched in 10% HF and 15% NaOH solution, respectively, water washed, alcohol cleaned and dried. Alternating layers of titanium and aluminum foils were stacked with outer layers of titanium foils. The nominal composition was Ti-46% Al. Two procedures were applied in the present work. In the first procedure, stacked foils were hot pressed at 610 °C for 3 h, cut into size of 6 mm×6 mm and assembled in a stainless steel sample holder which was sealed in a quartz tube filled with argon, followed by three heating stages: 640 °C, 12 h; 850 °C, 35 h and 1350 °C, 2 h. In the second procedure, to produce wavy TiAl sheet, stacked foils were hot pressed in vacuum better than those stacked under 10-2 Pa and 15 MPa. The basic process consisted of successive three heating stages: 650 °C, 15 h; 850 °C, 35 h and 1350 °C, 2 h.

The intermetallic compounds formed during heat treatments were identified by scanning electron microscopy (SEM) and X-ray diffraction (XRD). The distribution of lamellar orientation was estimated based on different parts of specimens by metallographic method.

3 Results and discussion

3.1 Hot pressing below Al melting point

Figure 1(a) shows the cross-sectional microstructure of specimen subjected to heat treatment of 610 °C, 3 h in the first procedure. As seen in Fig. 1(a), the interfaces between the bonded Ti and Al foils are fairly straight, indicating a good bonding between Ti and Al foils. At higher magnification, thin reaction layers with an average thickness of 0.5 μm can be observed (Fig. 1(b)), and further heat treatment results show that before Al foils are consumed, there is only one compound layer between Ti and Al foils, which is consistent with the work by YANG et al [10]. XRD analysis (as shown in Fig. 2) shows that this reaction layer is TiAl3. There are several compounds in Ti-Al system, such as TiAl3, TiAl2 TiAl and Ti3Al. The preferential growth of TiAl3 is the result of interface thermodynamics and growth kinetics. The slight mismatch between the closed planes of Ti, Al and TiAl3 also favors the first formation of TiAl3. TARDY and TU [11] has pointed out that epitaxial relationship of  and

and  exist between the Ti and TiAl3 layers. Figure 3(a) shows the microstructure of the cross section after the heat treatment of 610 °C, 3 h + 640 °C, 12 h. As seen in Fig. 3(a), Al is consumed and replaced by TiAl3, and there are many pores exist in TiAl3 layer, especially in the center zone where a fissure is formed due to the high concentration of voids caused by Kirkendall effect [12]. When Al diffuses into Ti foils, TiAl3 is formed at the interface and voids are formed in Al foils. When the TiAl3 layer grows towards Al foils, the voids move with the migration of the interface between Al and TiAl3. Hence, the voids exist in the form of rows at the mid-plane sites of the starting Al foils. Al foils are substituted by TiAl3 layers when they are consumed. Thus, rows of voids exist in the mid-plane of TiAl3 layers. When the sample is cooled from high temperature, a fissure may be formed by cracking along the rows of voids as TiAl3 are extremely brittle. It should be pointed out here that if subjected to a proper pressure, these pores would disappear.

exist between the Ti and TiAl3 layers. Figure 3(a) shows the microstructure of the cross section after the heat treatment of 610 °C, 3 h + 640 °C, 12 h. As seen in Fig. 3(a), Al is consumed and replaced by TiAl3, and there are many pores exist in TiAl3 layer, especially in the center zone where a fissure is formed due to the high concentration of voids caused by Kirkendall effect [12]. When Al diffuses into Ti foils, TiAl3 is formed at the interface and voids are formed in Al foils. When the TiAl3 layer grows towards Al foils, the voids move with the migration of the interface between Al and TiAl3. Hence, the voids exist in the form of rows at the mid-plane sites of the starting Al foils. Al foils are substituted by TiAl3 layers when they are consumed. Thus, rows of voids exist in the mid-plane of TiAl3 layers. When the sample is cooled from high temperature, a fissure may be formed by cracking along the rows of voids as TiAl3 are extremely brittle. It should be pointed out here that if subjected to a proper pressure, these pores would disappear.

Fig. 1 SEM images of cross section of sample after heat treatment of 610 °C, 3 h (a) and TiAl3 with average thickness of 0.5 μm appeared at Ti/Al interface (b)

Fig. 2 XRD pattern of cross sections of samples after heat treatment of 610 °C, 3 h

3.2 Hot pressing at high temperatures

EDS analysis shows that the microstructure of the cross section after the heat treatment of 610 °C, 3 h +640 °C, 12 h + 850 °C, 35 h is composed of α-Ti, α2-Ti3Al, γ and TiAl2 layers. This indicates that after all the Al foils have transformed to TiAl3, α2, γ and TiAl2 form between Ti and TiAl3. Further experimental results show that α2-Ti3Al, γ and TiAl2 layers widen, and α-Ti and TiAl3 layers become thinner with the increase of annealing time. When TiAl3 is exhausted, α2-Ti3Al and γ grow at the expense of TiAl2 and α-Ti. XRD patterns shown in Fig. 4 reveal the corresponding microstructure evolution. After heat treatment of 850 °C, 5 h, the microstructure is composed of TiAl3, TiAl2, TiAl, Ti3Al and α-Ti. Judging from the XRD patterns shown in Fig. 4, when subjected to the heat treatment of 850 °C for 20 h, the microstructure consists of TiAl2, TiAl and Ti3Al. Compared with the EDS results, the pattern of α-Ti is absent, which may be caused by the slight quantity of α-Ti. After heat treatment for sufficient time, the microstructure is composed of α2 and γ [13]. Figure 3(b) shows the cross section microstructure after the heat treatment of 610 °C, 3 h + 640 °C, 12 h + 850 °C, 35 h + 1350 °C, 2 h. It is seen that the lamellar microstructure develops in the whole area of the specimen, i.e., the fully lamellar microstructure develops. The XRD patterns (Fig. 4) show the matrix is composed of α2-Ti3Al and γ. The distance between two adjacent rows of pores is the total thickness of single Ti foil and single Al foil. The sizes of most colonies in the sheet thickness direction are nearly the same, equal to the total thickness of one Ti foil and one Al foil, indicating that thinner starting Ti and Al foils are good to yield fine microstructures. Compared with the microstructure shown in Fig. 1(b), the number of pores in the fully microstructure shown in Fig. 3(b) is less. This is the result of the larger force loaded on the specimen when heat treated at higher temperature.

Fig. 3 SEM images of cross section of sample after different heat treatments: (a) 610 °C, 3 h + 640 °C, 12 h; (b) 610 °C, 3 h + 640 °C, 12 h + 850 °C, 35 h + 1300 °C, 2 h

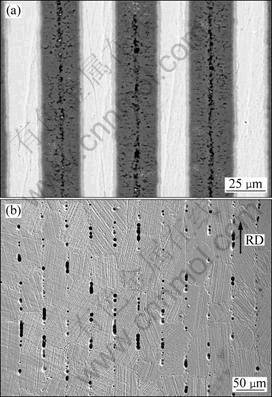

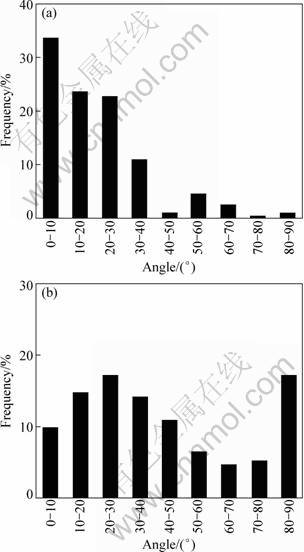

As seen in Fig. 3(b), only one kind of alignment exists in one lamellar colony. The alignments of most colonies are nearly parallel to RD. The distribution of lamellar interfaces is shown in Fig. 5(a). 80% of the angles between the lamellar interface and the rolling direction are smaller than 30°. On the contrary, the frequency around 40°-90° is quite low. As a result, most of the lamellaes are parallel to the sheet plane.

Fig. 4 XRD patterns of samples after different heat treatments: (a) 640 °C, 12 h + 850 °C, 35 h + 1350 °C, 2 h; (b) 640 °C, 12 h + 850 °C, 20 h; (c) 640 °C, 12 h + 850 °C, 5 h

3.3 Formation of oriented lamellar microstructure

When Ti-(35-48)%Al (molar fraction) alloy is cooled from the α single phase region to the (α2 + γ) two-phase region,  lamellar planes are parallel to the

lamellar planes are parallel to the planes [14]. So if the rolled α-Ti foils and sheets can be held in the α-Ti single phase region at high temperature (>1200 °C) by enriching Al, a final fully lamellar microstructure where the lamellaes are parallel to the sheet surface is obtained by cooling to the (α2 + γ) two phase region. In Ti-Al alloy, when α phase forms from β phase, the

planes [14]. So if the rolled α-Ti foils and sheets can be held in the α-Ti single phase region at high temperature (>1200 °C) by enriching Al, a final fully lamellar microstructure where the lamellaes are parallel to the sheet surface is obtained by cooling to the (α2 + γ) two phase region. In Ti-Al alloy, when α phase forms from β phase, the may lie in any six possible

may lie in any six possible planes according to the orientation relationship of

planes according to the orientation relationship of  and

and  [15]. That is, if the transformation of α→β→α takes place, α-Ti foils subjected to such a phase transformation have a weaker

[15]. That is, if the transformation of α→β→α takes place, α-Ti foils subjected to such a phase transformation have a weaker texture than the starting ones. As a result, the transformation of α→β should be avoided. In present work, enriching Al is performed at 850 °C, which is a relatively high temperature below the transformation temperature of α→β. Figure 6 shows a (002) pole figure of the starting titanium. The pole densities are projected onto the surface of the foils and the mean pole density is used as a unit. The area of the high pole density is situated at about 30° to 40° from the center of the figure in the transverse direction. The maximum pole density is about 8.

texture than the starting ones. As a result, the transformation of α→β should be avoided. In present work, enriching Al is performed at 850 °C, which is a relatively high temperature below the transformation temperature of α→β. Figure 6 shows a (002) pole figure of the starting titanium. The pole densities are projected onto the surface of the foils and the mean pole density is used as a unit. The area of the high pole density is situated at about 30° to 40° from the center of the figure in the transverse direction. The maximum pole density is about 8.

Fig. 5 Distribution of angles between rolling direction and lamellar interfaces after different heat treatments: (a) 640 °C, 12 h + 850 °C, 35 h + 1300 °C, 2 h; (b) 640 °C, 12 h + 1000 °C, 10 h + 1350 °C, 2 h

Fig. 6 (002) pole figure of starting titanium foil

As discussed above, when heat treated above 850 °C, not all Ti atoms in the starting Ti foils exist in the form of α-Ti, and some of them transform into γ-TiAl and Ti3Al. Fortunately, these transformations do not weaken the  texture obviously. When the starting Al foils transform into TiAl3, the diffusion couple becomes Ti/TiAl3. Although it is failed to determine the first formation phase in Ti/TiAl3 diffusion couple, previous studies have shown that γ-TiAl forms first at the Ti/TiAl3 interface [16]. Because the misfit between the close packed plane

texture obviously. When the starting Al foils transform into TiAl3, the diffusion couple becomes Ti/TiAl3. Although it is failed to determine the first formation phase in Ti/TiAl3 diffusion couple, previous studies have shown that γ-TiAl forms first at the Ti/TiAl3 interface [16]. Because the misfit between the close packed plane  and

and  is only about 1%, if γ-TiAl precipitates from TiAl3, it should obey the orientation relationship of

is only about 1%, if γ-TiAl precipitates from TiAl3, it should obey the orientation relationship of  This relationship needs experimental evidence, but the rationality of this deduction can be proved in the transformation of γ→α. γ phase transforms into α phase according to the orientation relationship of

This relationship needs experimental evidence, but the rationality of this deduction can be proved in the transformation of γ→α. γ phase transforms into α phase according to the orientation relationship of and

and [17]. The misfit between the close packed plane

[17]. The misfit between the close packed plane  and

and  is also only about 1%. Ref. [11] pointed out that the formation of TiAl3 in Ti/Al diffusion couple obeys the relationship of

is also only about 1%. Ref. [11] pointed out that the formation of TiAl3 in Ti/Al diffusion couple obeys the relationship of  As a result, γ phase layer inherits the

As a result, γ phase layer inherits the  texture of the starting Ti foils. When the specimen is annealed at 850 °C, the α phase becomes unstable if the Al concentration in α-Ti exceeds the equilibrium concentration, and orders into α2 phase with the same basal plane [18]. Obviously, α2 phase layer holds the

texture of the starting Ti foils. When the specimen is annealed at 850 °C, the α phase becomes unstable if the Al concentration in α-Ti exceeds the equilibrium concentration, and orders into α2 phase with the same basal plane [18]. Obviously, α2 phase layer holds the  texture of the starting Ti foils. When heat treated at 1350 °C, α2 and γ transform into α-Ti according to the relationship mentioned above, and the

texture of the starting Ti foils. When heat treated at 1350 °C, α2 and γ transform into α-Ti according to the relationship mentioned above, and the  texture still exists at 1350 °C. A fully lamellar microstructure with a proper alignment of lamellae can be obtained when the sheet is cooled from 1350 °C. To reveal the importance of keeping α-Ti during the heat treatment, another experiment was performed. Alternate Ti/Al foils were hot pressed by the procedure of 640 °C, 12 h + 1000 °C, 10 h + 1350 °C, 2 h. A fully lamellar microstructure develops. The distribution of the angles between rolling direction and the lamellar interfaces is shown in Fig. 5(b). As seen in Fig. 5(b), the distribution is more random compared with Fig. 5(a). This is the result of the transformation of α→β at 1000 °C, which weakens the

texture still exists at 1350 °C. A fully lamellar microstructure with a proper alignment of lamellae can be obtained when the sheet is cooled from 1350 °C. To reveal the importance of keeping α-Ti during the heat treatment, another experiment was performed. Alternate Ti/Al foils were hot pressed by the procedure of 640 °C, 12 h + 1000 °C, 10 h + 1350 °C, 2 h. A fully lamellar microstructure develops. The distribution of the angles between rolling direction and the lamellar interfaces is shown in Fig. 5(b). As seen in Fig. 5(b), the distribution is more random compared with Fig. 5(a). This is the result of the transformation of α→β at 1000 °C, which weakens the  texture.

texture.

Because Ti and Al foils have good ductility, TiAl sheet with complex shape can be fabricated by this method in the second procedure. Ti and Al foils with wavy shape are preformed, assembled alternately and hot pressed. Figure 7(a) shows a wavy sheet during a thickness of 0.7 mm fabricated with the second procedure. Figure 7(b) shows the fully lamellar microstructure of the cross section of the sheet edge, there are few pores in the matrix. As can be seen in Fig. 7(b), the colony size is larger than that in Fig. 3(b), and this should be the result of the merger of adjacent colony with the same orientation.

Fig. 7 Photo of wavy γ-TiAl sheet (a) and SEM image of cross section of wavy sheet edge (b)

4 Conclusions

1) A 0.7 mm-thick wavy γ-TiAl sheet with fully lamellar microstructure can be fabricated by hot pressing alternate Ti/Al foils. Most of the angles between the lamellar interface and the rolling direction are below 30°.

2) The thinner starting Ti and Al foils are good for yielding fine microstructures. This may contribute to the fabrication of complicated shaped γ-TiAl alloy based sheet with a particular lamellae orientation.

References

[1] WU X H, HU D, LORETTO M H. Alloy and process development of TiAl [J]. Journal of Materials Science, 2004, 39(12): 3935-3940.

[2] WANG Xiu-feng, MA Mo, LIU Xue-bin, WU Xue-qing, TAN Chao-gui, SHI Rong-kai, LIN Jian-guo. Diffusion bonding of γ-TiAl alloy to Ti-6Al-4V alloy under hot pressure [J]. Transactions of Nonferrous Metals Society of China, 2006, 16(5): 1059-1063.

[3] ZHANG De-ming, CHEN Gui-qing, HAN Jie-cai, ZHANG Xing-hong, YAO Zhen-zhong. Macro-microscopic morphology and phase analysis of TiAl-based alloys sheet fabricated by EB-PVD method [J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 777-782.

[4] YAMAGUCHI M, JOHNSON D R, LEE H N, INUI H. Directional solidification of TiAl-base alloys [J]. Intermetallics, 2000, 8: 511-517.

[5] KIM H Y, WEGMANN G, MARUYAMA K. Effect of stress axis orientation on the creep deformation behavior of Ti-48Al polysynthetically twinned (PST) crystals [J]. Materials Science and Engineering A, 2002, 329-331: 795-801.

[6] SUZUKI T, FUKUYAMA T, TADA M. Anisotropy in strength of a TiAl base polycrystal with unidirectionally oriented lamellae [J]. Materials Transactions JIM, 2000, 41(10): 1287-1292.

[7] CAO G X, FU L F, LIN J G, ZHANG Y G, CHEN C Q. The relationships of microstructure and properties of a fully lamellar TiAl alloy [J]. Intermetallics, 2000, 8(5-6): 647-653.

[8] YOKOSHIMA S, YAMAGUCHI M. Fracture behavior and toughness of PST crystals of TiAl [J]. Acta Materialia, 1996, 44(3): 873-883.

[9] DAS G, KESTLER H, CLEMENS H, BARTOLOTTA P A. Sheet gamma TiAl: Status and opportunities [J]. JOM, 2004, 56(11): 42-45.

[10] YANG D K, HODGSON P, WEN C. The kinetics of two-stage formation of TiAl3 in multilayered Ti/Al foils prepared by accumulative roll bonding [J]. Intermetallics, 2009, 17(9): 727-732.

[11] TARDY J, TU K N. Solute effect of Cu on interdiffusion in Al3Ti compound films [J]. Physical Review B, 1985, 32(4): 2070-2081.

[12] HE Y H, JIANG Y, XU N N, Z J, HUANG B Y, LIU C T, LIAW P K. Fabrication of Ti–Al micro/nanometer-sized porous alloys through the Kirkendall effect [J]. Advanced Materials, 2007, 19(16): 2102-2106.

[13] OH J, LEE W C, PYO S G, PARK W, LEE S, KIM N J. Microstructural analysis of multilayered titanium aluminide sheets fabricated by hot rolling and heat treatment [J]. Metallurgical and Materials Transactions A, 2002, 33(12): 3649-3659.

[14] FUKUTOMI H, UENO M, NAKAMURA M, SUZUKI T, KIKUCHI S. Production of TiAl sheet with oriented lamellar microstructure by diffusional reaction of aluminum and textured titanium foils [J]. Materials Transactions JIM, 1999, 40(7): 654-658.

[15] McCULLOUGH C, VALENCIA J J, LEVI C G, MEHRABIAN R. Phase equilibria and solidification in Ti-Al alloys [J]. Acta Metallurgica, 1989, 37(5): 1321-1336.

[16] XU L, CUI Y Y, HAO Y L, YANG R. Growth of intermetallic layer in multi-laminated Ti/Al diffusion couples [J]. Materials Science and Engineering A, 2006, 435-436(5): 638-647.

[17] CAO G H, SHEN G J, LIU Z G, SKROTZKI W. Transmission electron microscopic investigation of the γ→α phase transformation in a Ti-45Al-5Nb alloy [J]. Scripta Materialia, 2004, 51(5): 417-421.

[18] DJANARTHANY S, VIALA J C, BOUIX J. An overview of monolithic titanium aluminides based on Ti3Al and TiAl [J]. Materials Chemistry and Physics, 2001, 72(3): 301-319.

箔冶金法制备γ-TiAl基波纹板

刘江平, 苏彦庆,骆良顺,陈 晖,徐严谨,郭景杰,傅恒志

哈尔滨工业大学 材料科学与工程学院,哈尔滨 150001

摘 要:用热压逐层叠置的Ti/Al箔的方法制备具有全片层结构的γ-TiAl波纹板。热处理工艺为640 °C,15 h + 850 °C,35 h + 1350 °C,2 h。用扫描电镜(SEM)和X射线衍射(XRD)分析热处理过程中产生的金属间化合物相。在Al箔完全消耗之前,Ti/Al界面仅有TiAl3相生成。在850 °C热压35 h后,基体由α-Ti, α2-Ti3Al, γ-TiAl 和TiAl2相组成。冷却得到全片层结构,大部分片层与板面的夹角小于30°。采用较薄的原料箔可以获得相对细小的微观组织。

关键词:固态反应;相变;钛铝;箔冶金

(Edited by FANG Jing-hua)

Foundation item: Project (50771041) supported by the National Natural Science Foundation of China; Project (05-0350) supported by the New Century Excellent Talents in University, China

Corresponding author: SU Yan-qing; Tel: +86-451-86417395; Fax: +86-451-86415776; E-mail: suyq@hit.edu.cn

DOI: 10.1016/S1003-6326(11)61142-4