DOI: 10.11817/j.ysxb.1004.0609.2020-39736

磷石膏充填体强度和浸出毒性的温变规律

陈秋松1, 2,张 琦1,齐冲冲1, 2,张钦礼1,冯 岩1,王道林1,陶云波1,路润夏1

(1. 中南大学 资源与安全工程学院,长沙 410083;

2. 中钢集团马鞍山矿山研究总院股份有限公司,马鞍山 243000)

摘 要:针对矿井不同时空下环境温度多变的实际问题,通过开展不同养护温度下的磷石膏充填体单轴抗压强度实验、浸出毒性实验和微观分析实验,考察环境温度对磷石膏胶结充填体的力学性能和浸出毒性的影响规律。结果表明:磷石膏充填体早期强度与养护温度呈指数关系,养护温度为10、20、30和40 ℃时,磷石膏充填体3 d的单轴抗压强度分别为0.055、0.096、0.186和0.527 MPa,而充填体后期(28 d)的单轴抗压强度与养护温度无显著关系;总磷的浸出量随养护温度先下降后略有上升,而氟化物的浸出量与养护温度成反比关系,在30 ℃时,总磷和氟化物的浸出量分别为0.05和8 mg/L;磷石膏充填体混合相的前期水化产物CH、AFt、C-S-H随温度升高而增加,而后期水化反应因未反应颗粒被胶凝产物包裹而受阻,可见温度通过调整水泥水化反应和磷石膏缓凝作用而影响充填体强度和浸出毒性规律,工程应用时需要根据现场环境进行配比参数调整。

关键词:磷石膏;胶结充填;养护温度;抗压强度

文章编号:1004-0609(2021)-04-1084-12 中图分类号:X754 文献标志码:A

引文格式:陈秋松, 张 琦, 齐冲冲, 等. 磷石膏充填体强度和浸出毒性的温变规律[J]. 中国有色金属学报, 2021, 31(4): 1084-1095. DOI: 10.11817/j.ysxb.1004.0609.2020-39736

CHEN Qiu-song, ZHANG Qi, QI Chong-chong, et al. Temperature-depending characteristics of strength and leaching toxicity of phosphogympsum-based cemented paste backfill[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 1084-1095. DOI: 10.11817/j.ysxb.1004.0609.2020-39736

磷石膏是在磷酸生产过程中产生的主要以二水合硫酸钙为主要成分的固体废物,同时还含有酸不溶物、未分解的磷矿及其他杂质,平均每产出1 t P2O5便会产生4~6 t的磷石膏[1-2]。据统计,2017年我国一般工业固体废物年产生量已经超过30亿t,其中磷石膏年产量为7500万t,综合利用率为38.67%[3-4]。磷石膏充填是指根据充填工艺要求,将磷石膏、胶结剂(一般为硅酸盐水泥)、添加剂等,按合适的配比在搅拌器中加水混合均匀,形成的泥浆通过重力输送或者泵送沿着充填管道输送至地下采场的技术,如图1所示。磷石膏充填技术为磷石膏固废规模化处置提供了一种经济、安全和相对环保的方法,同时推动矿山(尤其磷矿山)的无废害绿色开采[5-7]。

然而我国浅部矿产资源逐渐枯竭,深部开采成为矿产资源开发的发展方向[8-10]。由于地热梯度岩层温度明显提高,深部开采的岩温随着开采深度以(10~40) ℃/km的速率增加,如南非M-poneng金矿的开采深度已超过4000 m,井下气温达66 ℃[8]。此外,我国磷矿资源分布范围极广,西南地区储量最为丰富,但西北、东北和华北储量亦占10%左右。不同地区,不同季节温差条件较大,即使通过空气加热或冷媒降温等手段,井下温度在10 ℃至40 ℃之间波动也是正常工况。磷石膏充填体置于不同温度的井下环境中,由于温度的变化对其充填性能的影响规律尚不明确。

国内外对于磷石膏充填体性能的温变特性研究成果有限,而关于温度对水泥水化行为的影响研究较多。李响等[11]认为高温养护增强了粉煤灰的火山灰活性,提高了浆体早期水化程度;HAN等[12]发现随着固化温度的升高,C-S-H凝胶含量增加,充填体空间结构变得更致密和牢固,有利于早期强度的发展。ESCALANTE-GARCIA等[13]研究发现,温度升高可以加速水泥早期水化,促进水泥水化中间产物的形成。上述成果主要研究温度影响水泥基材料的水化行为,而磷石膏充填体主要原料成分二水磷石膏(CaSO4·2H2O)已被证实具有缓凝特性[14],对于水泥和磷石膏为混合固相的充填体温变性能研究尚属空白。磷石膏作为一种高污染固废用于矿山充填过程中,其中的可溶P、可溶F等污染离子以及重金属离子的污染风险已逐渐成为国内外学者研究的重点[15-16]。磷石膏水泥胶结充填,可以视为污染物的水泥固化稳化处置。那么,不同的环境温度影响磷石膏充填体强度特性,改变各类水化产物的稳定性,是否影响磷石膏充填体的污染物元素溶出行为也亟待研究。

因此,本研究以常见普通硅酸盐水泥为胶凝材料,以磷石膏充填体为研究对象开展配比试验,测定不同养护温度下的充填体单轴抗压强度和浸出毒性指标,考察磷石膏充填体强度和毒性释放的温变规律,并结合X射线衍射(XRD)和扫描电子显微镜(SEM)探究其机理,以期扩充磷石膏充填相关理论,助力磷石膏充填技术的推广应用。

1 实验

1.1 试验材料

1.1.1 磷石膏

本次研究所用磷石膏取自安徽省铜陵市的某个磷肥生产企业,为使样品具有代表性,从磷石膏排放口搜集新鲜的磷石膏样品,封装保存后运输至中南大学无废害开采实验室开展试验研究。使用前在温度为60 ℃的烘箱中进行烘干后,通过粉料打散机将结块磷石膏打散并混合均匀后,密封保存以待研究。

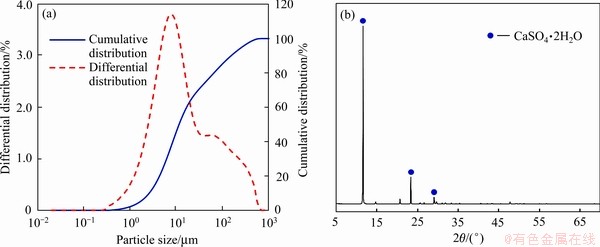

充填材料的物理化学性质对充填体性能有重要影响,因此在进一步开展试验前,采用激光衍射粒度分析仪(Mastersizer3000,马尔文,英国)测定其粒度组成,并使用X射线衍射仪(Advance D8,布鲁克,德国)确定磷石膏的矿物成分组成,结果如图2所示,表1所列为磷石膏主要化学成分表。磷石膏小于74 μm的颗粒占86.61%,小于19 μm的颗粒达62.31%,属于超细粒级充填材料,但是,经计算,磷石膏材料的不均匀系数(Cu)和曲率系数(Cc)分别为4.55和1.15,级配分布均匀连续(Cu<5,1<Cc<3)[17],粒径齐全。磷石膏中具有缓凝作用的CaSO4·2H2O含量高达98%以上,不利于充填体早期强度发展。

图1 磷石膏充填工艺流程图

Fig.1 Flow chart of phosphogypsum backfill process

图2 磷石膏粒度分析结果和XRD谱

Fig.2 Particle size distributions(a) and XRD patterns(b) of phosphogympsum

表1 磷石膏的主要化学成分

Table 1 Chemical composition of phosphogympsum

1.1.2 水泥

本次实验采用的水泥是基于中国通用硅酸盐水泥标准(GB 175—2007)生产的42.5R号硅酸盐水泥,水泥浆自胶结3 d抗压强度≥22 MPa,28 d抗压强度≥42.5 MPa。

1.1.3 化学试剂

实验采用的化学试剂主要包括盐酸、硝酸、氢氧化钠和冰醋酸溶液,纯度级为分析纯(AR)级,来自广州凯尔化工有限公司。

1.1.4 试验用水

在样品制备过程中,均采用去离子水标准溶液(购置于深圳华南高科水处理设备有限公司),以排除杂质对浸出毒性实验结果的影响。

1.2 实验方法

本研究的试验方法主要包括样品制备与养护、单轴抗压强度测试、浸出毒性实验、污染物指标检测和微观分析实验,试验过程及主要装置如图3所示。

1.2.1 样品制备与养护

参考取样磷石膏现场应用参数,将磷石膏、水泥、去离子水以灰砂比1:6(质量比),料浆质量浓度56%(塌落度≈23 cm)的比例混合,在电动搅拌器中混合5 min形成均质充填料浆后,灌注于d 50 mm×h 100 mm的塑料圆筒模具中。灌浆过程应尽可能多地将料浆倒入模具中,并用玻璃棒轻轻捣鼓,以避免固结收缩和内部空气泡的影响。

浆体灌注结束后,将样品连同模具一起置于4个恒温养护箱(HWS-70B,泰斯特,中国天津)中进行养护,养护温度分别为10、20、30和40 ℃,湿度为80%。定期观察样品固结情况,在样品初凝后(经观察,初凝时间约1.5 d),将样品表面刮平后脱模形成圆柱体试块,继续置于养护箱中养护。

1.2.2 单轴抗压强度测试

养护龄期为3、7、28 d时,使用微机控制压力试验机(WHY-200/10,华龙,中国上海)对充填体试块进行单轴抗压强度测试,加载速率为0.5 mm/min。每组样品测试三块,取其平均值作为充填体的单轴抗压强度。

图3 实验流程图

Fig. 3 Experimental flow chart

1.2.3 浸出毒性实验

根据以往研究,磷石膏充填体养护前期的浸出毒性量大,因此主要探讨3 d养护龄期毒害离子浸出毒性情况。为评估磷石膏充填体的环境特性,试块养护3 d后,将经抗压强度测试后的破碎试块采用固体废物浸出浸出毒性方法(醋酸缓冲溶液法,HJ/T 300—2007)测定充填体的极端浸出毒性[18]:将100 g破碎样品试块研磨至粒径<9.5 mm后,置于2 L聚乙烯(PE)广口瓶中与浸提剂按固液比1:20混合,盖紧瓶盖后固定于全自动翻转式振荡装置(YKC-12)上,调节转速为(30±2) r/min,于(23±2) ℃下振荡(18±2) h。静态放置2 h后采用真空过滤泵(GM-0.33A,津腾,中国上海)过滤,将0.6 μm滤纸过滤后的待测样品在4 ℃环境中保存。

1.2.4 微观分析实验

充填体样品的水化产物结构及微观形貌采用扫描电子显微镜(SEM) (JSM-IT500,捷欧路,日本)进行观测,试块水化产物的矿物成分通过X射线衍射仪(Advance D8,布鲁克,德国)进行分析。单轴抗压强度测试后,取破碎后样品的中间部分碎块浸入无水乙醇中,终止水化后,取一部分置于低温真空干燥机中干燥去除孔隙水,再进行SEM测试[19]。XRD测试前将样品转移至研钵中湿磨至无颗粒感,随后置于低温真空干燥机中干燥,将干燥后的样品过筛(筛的平均孔径为0.045 mm),未能过筛的样品继续研磨至所有样品过筛,装入密封袋密封保存并编号后,置于干燥皿中以备XRD测试使用[20]。

1.2.5 污染物指标检测

本研究检测指标是根据浸出毒性鉴别标准(GB 5085.3—2007)对对照组(预拌砂浆)的无机元素及其化合物的检测结果中检测限以上的元素进行选取,同时考虑到磷石膏中磷酸根离子含量较多,因此,选取以下六种毒害离子作为检测指标。本次检测在中南大学化学成分分析中心完成,其中pH的测定选用(GB/T 5750.4—2006)中规定的玻璃电极法,总磷和氟化物分别采用(GB/T 11893—1989)钼酸铵分光光度法和(GB/T 5085.3—2007)离子色谱法,六价铬的测定采用二苯碳酰二肼分光光度法(GB/T 15555.4—1995),总铬和总钡浓度均采用(GB/T 5085.3—2007)中的电感耦合等离子体原子发射光谱法进行检测,总砷的测定采用原子荧光法。

2 实验结果

2.1 磷石膏充填体强度对温度的敏感性

磷石膏充填体在不同温度下养护3 d、7 d和28 d龄期抗压强度如图4所示。由图4可知,磷石膏充填体的3 d和7 d抗压强度与养护温度之间呈正相关,即,养护温度的升高(本研究≤40 ℃),有利于促进磷石膏充填体前期强度的发展。当养护温度为10、20、30和40 ℃时,充填体3 d抗压强度分别为0.055、0.096、0.186和0.527 MPa;充填体7 d抗压强度分别为0.343、0.380、0.436和1.165 MPa。以养护温度(℃)为自变量,充填体3 d和7 d抗压强度为因变量,拟合方程如图4(b)和(c)所示,可见充填体抗压强度随温度升高表现出指数增长的趋势。

磷石膏充填体的28 d抗压强度对温度变化敏感性较低,随养护温度的升高略有下降趋势。当养护温度为10、20、30和40 ℃时,充填体28 d抗压强度为0.765、0.770、0.750和0.722 MPa。结合图4(d)曲线拟合结果,充填体28 d抗压强度随养护温度的升高线性下降,线性相关系数r为-0.8915,拟合优度 为0.7947,说明提高养护温度对于磷石膏充填体后期强度发展无促进作用,甚至有抑制后期强度的趋势。

为0.7947,说明提高养护温度对于磷石膏充填体后期强度发展无促进作用,甚至有抑制后期强度的趋势。

可见,提高养护温度会抑制后期强度的发展,甚至导致强度倒缩。而在低温下养护时,早期强度发展较慢,但有可能获得较高的最终强度,这与文献[21]的结果相一致。

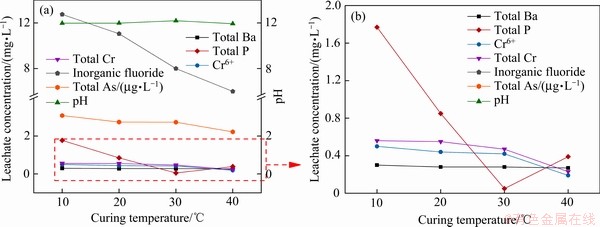

2.2 磷石膏充填体浸出毒性对温度的敏感性

为评估磷石膏充填体的环境危害,对3 d养护龄期磷石膏充填体进行浸出毒性实验,并将毒害离子浸出情况的检测结果与危险废物鉴别标准-浸出毒性鉴别(GB 5085.3—2007)和地下水质量标准(GB/T 14848—2007 Ⅲ级)进行比较,其中地下水Ⅲ级质量标准主要适用于集中式生活饮用水水源及工农业生活用水。其毒害离子浸出情况如图5和表2所示,由图5和表2可见。3 d养护龄期的磷石膏充填体试块pH值对养护温度的敏感性低,不同养护温度下的pH值维持在12左右。硅酸盐水泥水化产物为强碱性物质,水化过程中孔隙液呈碱性,pH值通常为10~12之间[22]。因此,当混合浆体中加入硅酸盐水泥开始水化反应后,短时间内中和磷石膏中残留的酸性成分,充填体酸碱度取决于水化产物混合相(本研究中pH为12左右),而与温度影响较小。

图4 不同养护温度下的抗压强度及3 d、7 d、28 d的抗压强度与养护温度关系拟合曲线图

Fig. 4 UCS values of samples curing at different curing temperatures(a) and fitting curves of relationship between UCS and curing temperature at 3 d(b), 7 d(c), and 28 d(d)

图5 3 d龄期不同养护温度下毒害离子浸出浓度

Fig. 5 Concentration of toxic ions of 3 d aged samples at different curing temperatures

表2 浸出毒性试验结果(3 d)

Table 2 Element concentration in toxicity characteristic leaching procedure (3 d)

不同养护温度下,相比于磷石膏原样,检测的磷石膏充填体浸出离子浓度均明显降低,均低于危险废物鉴别标准-浸出毒性鉴别(GB 5085.3—2007)中的危害成分浓度限值,表明磷石膏充填体有助于有毒有害离子的固化。

氟化物(除氟化钙)的浸出量与养护温度呈反比例关系,当养护温度为10、20、30和40 ℃时,氟化物的浸出浓度分别为12.75、11.05、8.00和6.00 mg/L;总磷的浸出量随养护温度先下降后出现回升,当养护温度30 ℃,磷的固化效果最佳,浸出浓度降低至0.05 mg/L,随着养护温度升高至40 ℃,其浸出量有所回升,达到0.39 mg/L。必须指出,在不同温度下养护3 d后六价铬和氟化物的浓度均高于地下水Ⅲ级质量标准(六价铬浓度<0.05 mg/L,氟化物浓度<1.0 mg/L GB/T 14848—2007(Ⅲ级))的允许范围,认为其在应用于充填时存在地下水污染隐患。

毒害离子Cr、As、Ba的浸出量随养护温度的升高而减少。其中,总As的浸出量与养护温度呈反比,随着养护温度的变化,总As的浸出量在0.0022~0.0031 mg/L之间浮动,均处于地下水Ⅲ级质量标准允许范围内(其中砷浓度<10 μg/L,GB/T 14848—2007),表明该批次磷石膏应用于地下充填对环境不存在砷污染的问题。

2.3 磷石膏充填体微观结构分析

2.3.1 SEM分析

磷石膏基充填体的水化产物主要包括水化硅酸钙(C-S-H)、氢氧化钙(CH)、钙矾石(AFt)等。除水化产物数量外,水化产物的形态分布同样影响了强度的发展,因此结合图6对水化产物的微观结构进行观察。

如图6(a1)、(b1)、(c1)所示,磷石膏充填体的水化产物数量与养护温度呈正相关。从图6(a1)中可以观察到10 ℃养护温度下的水化产物C-S-H和AFt较30 ℃和40 ℃少,但是扩散更为均匀。而结合图6(b2)、(c2),发现30 ℃和40 ℃养护温度下的试块的水化产物形态为针状、棒状钙矾石的相互搭接,颗粒状、纤维状C-S-H的交叉攀附,同时未水化的水泥被大量密集的胶凝层所包裹,导致中后期水化反应受阻。同时早期形成的水化产物晶体成长加速、扩散不均,进而沉析到水泥颗粒之间的空间,因此在凝胶分布稀疏的部位成为结构的弱点[14]。另外研究表明,高温养护会导致充填体内裂隙的形 成[23],40 ℃养护28 d的SEM图谱(见图6(c1))进一步证实了裂隙的存在,以上因素的作用使得后期强度下降。结合上述分析结果可知,提高养护温度,在为化学反应控制的水化反应早期促进了水化产物(如C-S-H和AFt)的生成,较高的水化量使得孔隙结构更加致密,这有利于早期强度的发展[24-25]。因此,40 ℃的3 d和7 d时抗压强度较高。但随着龄期的延长,水泥颗粒为密集胶凝层包裹,减缓甚至阻止水化反应的进一步发展,此时充填体的微观结构成为影响强度发展的决定性因素。说明磷石膏基充填体的后期强度是水化产物生成量和充填体微观结构二者综合作用的结果,这与前面系列实验结果吻合。

2.3.2 XRD分析

结合XRD谱对不同时期水化产物含量及种类进行分析,10 ℃和40 ℃养护下试块的XRD谱(见图7)。磷石膏充填体的物相组成主要为石膏( )、二氧化硅(SiO2)和少量氢氧化钙(CH)。如图7(a)所示,10 ℃养护下3 d和7 d的试块都只发现

)、二氧化硅(SiO2)和少量氢氧化钙(CH)。如图7(a)所示,10 ℃养护下3 d和7 d的试块都只发现 和少量SiO2的衍射峰,随着养护龄期的延长,结合XRD定量检测结果7 d和28 d样品中分别存在含量为1.94%和1.26%的CH。由图7(b)可知,40 ℃温度下养护7 d的试块中

和少量SiO2的衍射峰,随着养护龄期的延长,结合XRD定量检测结果7 d和28 d样品中分别存在含量为1.94%和1.26%的CH。由图7(b)可知,40 ℃温度下养护7 d的试块中 的衍射峰强度相比3d时明显增强,而随着养护龄期延长至28 d时,其衍射峰又随之减弱,说明后期

的衍射峰强度相比3d时明显增强,而随着养护龄期延长至28 d时,其衍射峰又随之减弱,说明后期 的消耗量逐渐增多。3 d、7 d和28 d龄期的样品CH的衍射峰均不明显,结合XRD定量结果显示随着龄期的延长CH的含量逐渐减少,分别为2.05%、1.71%和1.58%。

的消耗量逐渐增多。3 d、7 d和28 d龄期的样品CH的衍射峰均不明显,结合XRD定量结果显示随着龄期的延长CH的含量逐渐减少,分别为2.05%、1.71%和1.58%。

图6 28 d龄期10 ℃、30 ℃和40 ℃养护温度下试块的SEM像

Fig. 6 SEM images of 28 d aged samples at 10 ℃((a1), (a2)), 30 ℃((b1), (b2)), and 40 ℃((c1), (c2))

图7 10 ℃、40 ℃养护温度下试块的XRD谱

Fig. 7 XRD patterns of samples at 10 ℃(a) and 40 ℃(b) after curing for 3, 7 and 28 d

3 分析与讨论

3.1 养护温度对水化产物的影响

结合上述磷石膏充填体的XRD和SEM的检测结果,对不同养护温度及龄期下水化产物的形态和种类进行分析。

提高养护温度对磷石膏充填体水化反应的早期的促进作用主要表现在,高温下各种熟料矿物迅速水化,生成大量的水化产物,如C-S-H、CH、AFt等。同时高温下,铝酸三钙(C3A)生成的水化产物与石膏反应生成大量钙矾石,各种水化产物覆盖并封闭了水泥颗粒,此时可溶性离子的扩散速率下降,阻止了内部的未参与反应水泥颗粒的进一步水化,从而影响了后期强度的发展,而在低温下虽然水化速率较慢,但是水化产物的生长和扩散更为充分,结构内胶凝产物均匀分布,结合SEM像可以进一步证实这一观点。

结合XRD射线衍射图谱可知,10 ℃、40 ℃养护温度下不同龄期检测样品的水化产物中只有CH被测出。认为水化早期,温度升高促进水化反应的进行,因此,随着养护温度升高CH的生成量增 多[26]。在磷石膏充填体中CH的生成主要有以下几种途径,其可能发生反应如式(1)、(2)、(3)所示:

C3S+nH=C-S-H+(3-x)CH (1)

C2S+mH=C-S-H+(2-x)CH (2)

C3A +2C4AH13=

+2C4AH13= +2CH+20H (3)

+2CH+20H (3)

CH的消耗主要伴随着以下反应的发生,如式(4)和(5)所示:

C4AF+4CH+22H=2C4(A, F)H13 (4)

C4AF+2CH+ +50H=2C3(A, F)

+50H=2C3(A, F) (5)

(5)

在水化反应的第一阶段(0~30 min),C3S、C3A迅速水化生成大量的CH和AFt,在水化的第三阶段(1~90 d),C4AF开始水化生成C4(A, F)H13伴随着CH的消耗[27]。高养护温度下,在水泥熟料与水接触后第一阶段剧烈反应生成大量CH,但随着养护龄期的延长,水化反应步入稳定期,同时CH的消耗量大于CH的生成量,导致样品中CH的含量减少。

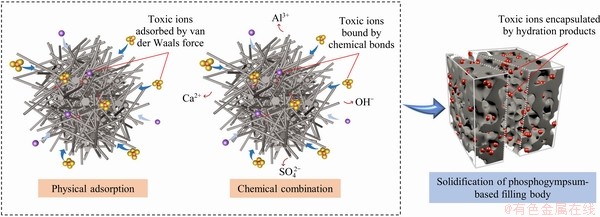

3.2 养护温度影响浸出毒性的原因探讨

胶凝产物对毒害离子固定作用主要包括两类,即物理吸附和化学结合,其中物理吸附是依靠分子之间的吸引力(即范德华力)实现,化学结合是通过与水化产物之间的化学键结合,且具有一定的稳定性和选择性[28],认为这一阶段毒害离子的固定与水化产物的数量有关。另外固化充填体通过固封作用阻止孔隙中的毒害离子通过扩散作用溶出,一般认为与充填体的密实度和孔结构有关[29],其示意图如图8所示。因此将影响毒害离子在充填体中的溶出行为的主要因素归为两大类,即水化产物的数量对毒害离子吸附量的影响,充填体内部孔结构对毒害离子溶出量的影响,下面就以上两个因素对毒害离子在不同养护温度下的溶出行为展开探讨。

图8 磷石膏充填体对毒害离子的固定示意图

Fig. 8 Schematic diagram of immobilization of toxic ions by phosphogypsum filling

磷石膏充填体对许多重金属离子(Cr、Cu、Pb等)的固定作用一方面是基于水化反应提供的高碱性环境生成难溶的氢氧化物沉淀,另一方面通过与水化产物C-S-H、AFt中的离子发生化学置换[30-32]。例如,由于AFt的“包容性”使得金属阳离子Cr3+、Ba2+可置换AFt的晶体结构中的Al3+、Ca2+,含氧酸根 、

、 和

和 可取代

可取代 ,并在其层间紧密结合[33],另外,C-S-H凝胶被证实对Cr3+具有较高的固化能力[28]。结合水化产物分析结果,养护温度升高对磷石膏充填体的水化反应具有促进作用,C-S-H、AFt、CH等对毒害离子具有物理和化学吸附包裹作用的水化产物生成量增多,有利于毒害离子在磷石膏充填体中的固定。

,并在其层间紧密结合[33],另外,C-S-H凝胶被证实对Cr3+具有较高的固化能力[28]。结合水化产物分析结果,养护温度升高对磷石膏充填体的水化反应具有促进作用,C-S-H、AFt、CH等对毒害离子具有物理和化学吸附包裹作用的水化产物生成量增多,有利于毒害离子在磷石膏充填体中的固定。

研究表明,磷石膏充填体对磷和氟的固定可以通过与 和F-生成Ca2(PO4)3、CaF2和Ca10(PO4)6F2(稳定pH为7~12[34])等难溶物[32, 35],同时,考虑到本次实验浸提剂的酸性环境(pH值2.64±0.05)对先前生成难溶物的影响,认为浸出过程中

和F-生成Ca2(PO4)3、CaF2和Ca10(PO4)6F2(稳定pH为7~12[34])等难溶物[32, 35],同时,考虑到本次实验浸提剂的酸性环境(pH值2.64±0.05)对先前生成难溶物的影响,认为浸出过程中 和F-主要以难溶物CaHPO4(25 ℃,稳定pH范围为2.0~6.0[34])、CaF2(其在稀醋酸中微量溶解[36])的形式固定在磷石膏基中。同时高养护温度下早期水化产物增多,微观结构更加致密有利于离子固定。不同的是一些水合磷酸盐会在高温下分解而释放出

和F-主要以难溶物CaHPO4(25 ℃,稳定pH范围为2.0~6.0[34])、CaF2(其在稀醋酸中微量溶解[36])的形式固定在磷石膏基中。同时高养护温度下早期水化产物增多,微观结构更加致密有利于离子固定。不同的是一些水合磷酸盐会在高温下分解而释放出 ,同时离子迁移和扩散速率随温度升高而增加[37],二者综合作用下在40 ℃时总磷的浸出量增多。

,同时离子迁移和扩散速率随温度升高而增加[37],二者综合作用下在40 ℃时总磷的浸出量增多。

3.3 研究不足

在磷石膏充填体强度的温变特性研究中,没有考虑在实际工程中极高温下应用的情况。许多胶凝产物的稳定性受极高温度的影响,例如AFt在温度大于53 ℃时开始失水、分解[38],对其是否对抗压强度和毒害离子浸出特性产生影响尚待考证。

在针对不同温度下磷石膏充填体的水化产物的研究中,即其对水化产物尤其是C-S-H、AFt的影响,尚缺乏在定量层次上展开进一步的研究。

在磷石膏充填体对毒害离子固定的分析中,毒害离子在不同水化产物中的富集特性有待深入探讨,或许通过SEM&EDS(扫描电子显微镜和X射线能量色散谱方法)的联合使用可以提供新的思路。

4 结论

1) 养护温度对磷石膏充填体的早期单轴抗压强度表现出较高的相关性,而后期强度与养护温度之间无显著关系,磷石膏充填体混合相的前期水化产物CH、AFt、C-S-H随温度升高而增加,而后期水化反应因胶凝产物包裹而受阻,同时,受水化产物扩散不均的影响,使得40 ℃养护下28 d强度发生倒缩。对于高温抑制磷石膏充填体后期强度的问题,或许可以运用冰渣代替部分水拌制充填体得以解决。

2) 在10~40 ℃的养护温度范围内,养护温度的升高有助于早期(3 d)各毒害离子的固定。在不同温度下固化磷石膏充填体各毒害离子浸出率的差异主要归因于水化产物的数量、充填体的孔结构的变化。针对氟离子存在的污染隐患问题,如通过添加外加剂的方式对其进一步辅助固化及稳化值得深入研究。

3) 温度通过调节水泥水化反应和磷石膏缓凝作用进而影响充填体强度,另外通过影响水化产物的生成及发展、充填体的孔结构等影响浸出毒性规律,因此,工程应用时需要根据现场环境对充填料浆进行配比参数调整,同时需要考虑环境温度对充填体环境特性的影响。

REFERENCES

[1] RASHAD A M. Phosphogypsum as a construction material[J]. Journal of Cleaner Production, 2017, 166(10): 732-743.

[2] MACIAS F, CANOVAS C R, CRUZ-HERNANDEZ P, et al. An anomalous metal-rich phosphogypsum: Characterization and classification according to international regulations[J]. Journal of Hazardous Materials, 2017, 331: 99-108.

[3] 中华人民共和国国家统计局. 中国统计年鉴[M]. 北京: 中国统计出版社, 2019: 243.

National Bureau of statistics of the People’s Republic of China. China Statistical Yearbook[M]. Beijing: China Statistics Press, 2019: 243.

[4] 叶学东. 2017年我国磷石膏利用现状、形势分析及措施[J]. 硫酸工业, 2018(8): 1-4.

YE Xue-dong. The using current situation, form analysis and measures of phosphogypsum utilization in China in 2017[J]. Sulphuric Acid Industry, 2018(8): 1-4.

[5] WANG X M, ZHAO B, ZHANG Q L. Cemented backfill technology based on phosphorous gypsum[J]. Journal of Central South University of Technology, 2009, 16(2): 285-291.

[6] CHEN Q S, ZHANG Q L, QI C C, et al. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact[J]. Journal of Cleaner Production, 2018, 186: 418-429.

[7] CHEN Q S, ZHANG Q L, FOURIE A, et al. Utilization of phosphogypsum and phosphate tailings for cemented paste backfill[J]. Journal of Environmental Management, 2017, 201: 19-27.

[8] 李夕兵, 刘 冰, 姚金蕊, 等. 全磷废料绿色充填理论与实践[J]. 中国有色金属学报, 2018, 28(9): 1845-1865.

LI Xi-bing, LIU Bing, YAO Jin-rui, et al. Theory and practice of green mine backfill with whole phosphate waste[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(9): 1845-1865.

[9] 李夕兵, 周 健, 王少锋, 等. 深部固体资源开采评述与探索[J]. 中国有色金属学报, 2017, 27(6): 1236-1262.

LI Xi-bing, ZHOU Jian, WANG Shao-feng, et al. Review and practice of deep mining for solid mineral resources[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(6): 1236-1262.

[10] RANJITH P G, ZHAO J, JU M H, et al. Opportunities and challenges in deep mining: A brief review[J]. Engineering, 2017, 3(4): 546-551.

[11] 李 响, 阎培渝. 高温养护对复合胶凝材料水化程度及微观形貌的影响[J]. 中南大学学报(自然科学版), 2010, 41(6): 2321-2326.

LI Xiang, YAN Pei-yu. Effect of high temperature curing on hydration degree and micro-morphology of complex binders[J]. Journal of Central South University(Science and Technology), 2010, 41(6): 2321-2326.

[12] HAN B, ZHANG S Y, SUN W. Impact of temperature on the strength development of the tailing-waste rock backfill of a gold mine[J]. Advances in Civil Engineering, 2019, 2019: 1-9.

[13] ESCALANTE-GARCIA J I, SHARP J H. Effect of temperature on the hydration of the main clinker phases in portland cements: Part Ⅱ, blended cements[J]. Cement and Concrete Research, 1998, 28(9): 1245-1257.

[14] 林宗寿. 胶凝材料学[M]. 武汉: 武汉理工大学出版社, 2014: 52-88.

LIN Zong-shou. Cementitious material science[M]. Wuhan: Wuhan University of Technology Press, 2014: 52-88.

[15] YIN T B, YANG R S, DU J, et al. Effects of acid and phosphate on arsenic solidification in a phosphogypsum-based cement backfill process[J]. RSC Advances, 2019, 48(9): 28095-28101.

[16] LI X B, DU J, GAO L, et al. Immobilization of phosphogypsum for cemented paste backfill and its environmental effect[J]. Journal of Cleaner Production, 2017, 156(10): 137-146.

[17] 李俊芳. 土力学[M]. 成都: 西南交通出版社, 2017: 5-6.

LI Jun-fang. Soil mechanics[M]. Chengdu: Southwest Jiaotong University Press, 2017: 5-6.

[18] 刘 锋, 孙思修, 王鲁昕, 等. 对用于危险废物鉴别的几种浸出方法比对研究[J]. 环境科学研究, 2005(S1): 23-26.

LIU Feng, SUN Si-xiu, WANG Lu, et al. A comparison study on the leaching test methods used in hazardous waste identification[J]. Research of Environmental Sciences, 2005(S1): 23-26.

[19] CHEN Q S, ZHANG Q L, FOURIE A, et al. Experimental investigation on the strength characteristics of cement paste backfill in a similar stope model and its mechanism[J]. Construction and Building Materials, 2017, 154: 34-43.

[20] 魏永起. 复合胶凝体系水化进程的定量表征与评价[M]. 上海: 同济大学出版社, 2016: 45.

WEI Yong-qi. Quantitative characterization and evaluation of hydration process of composite cementitious system[M]. Shanghai: Tongji University Press, 2016: 45.

[21] 刘贤萍, 王培铭. 不同养护温度下煤矸石/粉煤灰硅酸盐水泥的水化进程和强度发展[C]// 中国硅酸盐学会、中国建筑材料科学研究总院. 中国硅酸盐学会水泥分会首届学术年会论文集. 河南: 中国硅酸盐学会, 2009: 366-371.

LIU Xian-ping, WANG Pei-ming. Hydration process and strength development of portland cement blended with coal gangue or fly ash at various temperatures[C]// The Chinese Ceramic Society, China Building Materials Academy. Proceedings of the 1st Symposium of Chinese Ceramic Society. Henan: The Chinese Ceramic Society, 2009: 366-371

[22] 徐 路, 廖国胜, 廖宜顺. 不同温度下矿物掺合料对硫铝酸盐水泥水化的影响[J]. 新型建筑材料, 2018, 45(5): 84-87.

XU Lu, LIAO Guo-sheng, LIAO Yi-shun. Effect of curing temperature on the hydration of calcium sulphoaluminate cement blended with mineral admixtures[J]. New Building Materials, 2018, 45(5): 84-87.

[23] JIANG H Q, YI H S, YILMAZ E, et al. Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature[J]. Ultrasonics, 2020, 100: 105983.

[24] FALL M, CELESTIN J C, POKHAREL M, et al. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill[J]. Engineering Geology, 2010, 114(3): 397-413.

[25] WANG Y, FALL M, WU A. Initial temperature-dependence of strength development and self-desiccation in cemented paste backfill that contains sodium silicate[J]. Cement & Concrete Composites, 2016, 67: 101-110.

[26] 王培铭, 徐玲琳, 张国防. 0~20 ℃硅酸盐水泥的水化性能[J]. 材料导报, 2012, 26(4): 114-117.

WANG Pei-ming, XU Ling-lin, ZHANG Guo-fang. Hydration properties of portland cement chemistry at 0 ℃ to 20 ℃[J]. Materials Review, 2012, 26(4): 114-117.

[27] KURDOWSKI W. Cement hydration[M/OL]// KURDOWSKI W. Cement and Concrete Chemistry. Dordrecht: Springer Netherlands, 2014: 205-277. https://doi.org/10.1007/978-94-007-7945-7_4.

[28] 姚 燕, 王 昕, 颜碧兰, 等. 水泥水化产物结构及其对重金属离子固化研究进展[J]. 硅酸盐通报, 2012, 31(5): 1138-1144.

YAO Yan, WANG Xin, YAN Bi-lan, et al. The research on heavy metal ions curing and its influence on the cement hydration process[J]. Bulletin of the Chinese Ceramic Society, 2012, 31(5): 1138-1144.

[29] 王彩云. 重金属元素在水泥混凝土中的浸出性及固化机理研究[D]. 北京: 北京工业大学, 2004: 20-25.

WANG Cai-yun. Effect and incorporation mechanism of heavy metal elements in hazardous industrial wastes during clinker formation[D]. Beijing: Beijing University of Technology, 2004: 20-25.

[30] GIERGICZNY Z, KROL A. Immobilization of heavy metals (Pb, Cu, Cr, Zn, Cd, Mn) in the mineral additions containing concrete composites[J]. Journal of Hazardous Materials, 2008, 160(2): 247-255.

[31] 尧璟云, 余其俊, 韦江雄, 等. 铬离子在水泥硬化体中的迁移转换及再分配[J]. 武汉理工大学学报, 2009, 31(14): 5-9.

YAO Jing-yun, YU Qi-jun, WEI Jiang-xiong, et al. Transportation and re-distribution of addition chromium in hardened portland cement[J]. Journal of Wuhan University of Technology, 2009, 31(14): 5-9.

[32] 罗 通, 杨 林, 李彩玉, 等. 磷石膏基充填料的制备及其有害物溶出率的研究[J]. 化工矿物与加工, 2017, 46(5): 39-43.

LUO Tong, YANG Lin, LI Cai-yun, et al. Study on preparation of phosphogypsum-based filling matrials and its leaching rate of harmful substances[J]. Industrial Minerals & Processing, 2017, 46(5): 39-43.

[33] GOUGAR M L D, SCHEETZ B E, ROY D M. Ettringite and C-S-H portland cement phases for waste ion immobilization: A review[J]. Waste Management, 1996, 16(4): 295-303.

[34] DOROZHKIN S V. Calcium orthophosphates (CaPO(4)): Occurrence and properties[J]. Morphologie, 2017, 101(334): 125-142.

[35] SHU J C, CHEN M J, WU H P, et al. An innovative method for synergistic stabilization/solidification of Mn2+, NH4+-N, PO43- and F- in electrolytic manganese residue and phosphogypsum[J]. Journal of Hazardous Materials, 2019, 376: 212-222.

[36] 郭晓栋. 萤石、重晶石、方解石共生非金属矿物的分离测定[J]. 华北自然资源, 2019(3): 115-118.

GUO Xiao-dong. Separation and determination of non-metallic minerals coexisting with fluorite, barite and calcite[J]. North China Natural Resources, 2019(3): 115-118.

[37] LI B, SHU J C, YANG L, et al. An innovative method for simultaneous stabilization/solidification of PO43- and F- from phosphogypsum using phosphorus ore flotation tailings[J]. Journal of Cleaner Production, 2019, 235: 308-316.

[38] DEB S K, MANGHNANI M H, ROSS K, et al. Raman scattering and X-ray diffraction study of the thermal decomposition of an ettringite-group crystal[J]. Physics and Chemistry of Minerals, 2003, 30(1): 31-38.

Temperature-depending characteristics of strength and leaching toxicity of phosphogympsum-based cemented paste backfill

CHEN Qiu-song1, 2, ZHANG Qi1, QI Chong-chong1, 2, ZHANG Qin-li1, FENG Yan1, WANG Dao-lin1, TAO Yun-bo1, LU Run-xia1

(1.School of Resources and Safety Engineering, Central South University, Changsha 410083, China;

2.Sinosteel Maanshan General institute of Mining Research Co., Ltd., Maanshan 243000, China).

Abstract: Aiming at the practical problem of changeable environmental temperature in different time and space of mine, the influence of environmental temperature on strength and leaching toxicity of phosphogypsum cemented filling body was investigated by uniaxial compressive strength test, toxicity leaching test and microscopic analysis under different curing temperature. The results show that the early uniaxial compressive strength (UCS) of phosphogypsum filling is exponentially related to the curing temperature, and the UCS after curing for 3 d at 10 ℃, 20 ℃, 30 ℃ and 40 ℃ are 0.055 MPa, 0.096 MPa, 0.186 MPa and 0.527 MPa respectively, while the later UCS (28 d) of the filling body has no significant relationship with the curing temperature. The leaching amount of total P decreases first and then increases slightly with the curing temperature. And the leaching amount of fluorideis founded to decrease with the increasing of curing temperature (within the studied range). The leaching amount of total P and fluoride are 0.05 mg/L and 8 mg/L at 30 ℃. The early hydration products CH, AFt and C-S-H of phosphogypsum-based filling body increase with the increase of temperature, while the later hydration reaction is hindered by the inclusion of unreacted particles by cementitious products. It can be seen that the temperature will affect the cement hydration reaction and phosphogypsum retarder and thus to influence the UCS and toxicity of backfill, so it is necessary to adjust the proportioning parameters according to the site environment in engineering application.

Key words: phosphogypsum; cemented paste backfill; curing temperature; unconfined compressive strength

Foundation item: Project(2020JJ5718) supported by the Natural Science Foundation of Hunan Province, China; Project(2019-JSKSSYS-02) supported by the Open Project Program of Metal Mine Safety and Health State Key Laboratory, China

Received date: 2020-09-05; Accepted date: 2020-12-11

Corresponding author: QI Chong-chong; Tel: +86-17361393317; E-mail: chongchong.qi@csu.edu.cn

(编辑 龙怀中)

基金项目:湖南省自然科学青年基金资助项目(2020JJ5718);金属矿山安全与健康国家重点实验室开放课题资助项目(2019-JSKSSYS-02)

收稿日期:2020-09-05;修订日期:2020-12-11

通信作者:齐冲冲,教授,博士;电话:17361393317;E-mail:chongchong.qi@csu.edu.cn