DOI: 10.11817/j.issn.1672-7207.2017.12.031

不同粗糙度下锚固节理破坏机理宏细观研究

张永政1, 2,王刚1, 2,马明1,赵志鹏1,赵云鹏1,孙昭晖1

(1. 山东科技大学 山东省土木工程防灾减灾重点实验室,山东 青岛,266590;

2. 山东科技大学 矿山灾害预防控制省部共建国家重点实验室培育基地,山东 青岛,266590)

摘要:为了研究不同粗糙度下锚固节理岩体的破坏特征和锚固机理,利用二维颗粒流程序PFC2D生成6种不同粗糙度的锚固节理面,并对这6种粗糙度的锚固节理模型在5种法向荷载下进行剪切实验,探讨JRC值和颗粒摩擦因数对锚固节理抗剪强度的影响。并从宏细观角度分析不同节理粗糙度的形貌破坏和裂纹扩展演化特征。研究结果表明:当剪切试验中节理面的微凸体没有发生太大的破坏时,锚固体系的峰值剪切强度随粗糙度的增加而不断变大,但是当微凸体剪断破坏后峰值抗剪强度会有小幅的衰减,同时随着节理面摩擦因数的增加,锚固体系的峰值剪切强度也相应变大,并呈现很好的线性关系;细观裂纹开始主要在节理面的微凸体处产生,随后在锚杆周围快速大量产生,并且逐步扩展到模型的内部,产生的裂纹以张拉裂纹为主;锚固节理上的颗粒间接触力的数量和方位角的分布区域随剪切过程的进行逐渐衰减,并且接触方位角逐渐向剪切荷载施加的方向发生偏转。

关键词:粗糙度;离散元;剪切实验;接触力;细观裂纹;接触方位角;颗粒旋转角度

中图分类号:TU458 文献标志码:A 文章编号:1672-7207(2017)12-3373-11

Macro-micro study on failure mechanism of rock mass anchorage joints under different roughness

ZHANG Yongzheng1, 2, WANG Gang1, 2, MA Ming1, ZHAO Zhipeng1, ZHAO Yunpeng1, SUN Zhaohui1

(1. Shandong Provincial Key Laboratory of Civil Engineering Disaster Prevention and Mitigation,Shandong University of Science and Technology, Qingdao 266590, China;

2. State Key Laboratory of Mining Disaster Prevention and Control Co-founded by Shandong Province and

the Ministry of Science and Technology, Shandong University of Science and Technology, Qingdao 266590, China)

Abstract: In order to research the microscopic anchoring mechanism of different roughness in jointed rock mass, a model of anchoring joints with six different roughness was built by using the particle flow code in two-dimensions(PFC2D), and a series of numerical simulation direct shear tests under five different constant loads were carried out. And the influence of JRC value and particle friction coefficient of anchoring joint on the anchoring joint shear strength was analyzed. At the same time, the damage process of asperities on rough surface and the corresponding microscopic cracks development was also monitored in the numerical direct shear tests. The results show that the micro convex body is slightly damage in the joint shear test, the peak shear stress of anchoring joints increases with the increase of anchoring joint roughness and the particle frictional coefficient of the anchoring joints, but the peak shear stress has a little decay with the damage of the micro convex body. Microscopic cracks produce firstly in the convex joint surface, and with the shear displacement increasing, the number of microcracks increases rapidly around the bolt and the microcracks are not only on the surface of the anchoring joint plane, but also happen inside the model. The produced cracks are mainly tensile cracks. The number of the contact force and the distribution range of contact azimuth angle of the anchoring joint decrease with the shear displacement increasing, and the direction of the contact azimuth angle is gradually changed to the direction of shear load.

Key words: roughness; distinct element method; direct shear experiment; contact force; microscopic crack; contact azimuth angle; rotation radian

自然界中由于地质的变化在岩体中存在大量的裂隙,断层、节理,这些具有很低抗拉强度的层面统称为结构面[1]。为了保证大型岩体工程的稳定性和安全性,国内外都普遍采用锚杆来进行加固,以此来限制节理面之间的相对滑移。由于节理面的不规则性和岩体的岩性也不尽相同,其锚固机理也就比较复杂。随着地铁、海底隧道等重大工程建设的逐步实施,我国将修建更多的地下大型洞室群、长大隧道以及高陡边坡等大型岩体工程。这些大型岩土工程不可避免地会大量采用锚杆来进行加固。因此研究其锚固机理非常有意义。目前,国内外的很多学者已经从理论研究、模型试验和现场观测方面对锚杆的锚固机理进行了大量的研究,总结出大量的锚杆加固机理[2-11]。近年来,由于计算机的发展,采用离散元方法的颗粒流数值软件PFC[12]研究岩土工程的破坏问题越来越成熟,对岩石节理的力学性质的研究已经取得许多的成果[13-17],它有效的弥补了真实岩块不可重复的不足。在节理岩体的粗糙度方面也进行了一些研究,如:夏才初等[18]通过离散元PFC2D软件对不加锚原岩进行了剪切实验的数值模拟分析了粗糙节理的直剪特性。周喻等[19]结合已有节理实验结果,通过离散元PFC软件从宏细观角度分析了剪切过程中岩体的破裂演化特征。曹日红等[20]利用PFC生成不同粗糙程度的剪切实验模型,从细观角度探讨了粗糙度对无锚节理表面形态的影响特征。通过以上分析可知,现有的研究主要是对无锚节理面中粗糙度对剪切的宏细观行为进行了研究,但在锚固岩体中既没有研究粗糙度对加锚节理中抗剪强度的影响,也没有研究加锚节理破坏的宏细观特征及锚固性能随粗糙度系数JRC变化所产生的影响。为了更好地研究节理粗糙度对岩体中锚杆的加固机理,本文作者在研究粗糙节理的基础上,采用离散元PFC2D软件建立了6种不同节理表面粗糙度的锚固节理模型,并对其在不同法向压力下进行了剪切实验;同时还研究了节理粗糙度系数对抗剪强度的影响,通过分析锚固体系的颗粒接触力分布、颗粒接触方位角、裂纹的分布范围及剪切过程中颗粒的旋转等角度从宏细观角度深入研究了节理面粗糙度对锚固体系的影响。

1 PFC2D基本简介及模型细观参数的确定

1.1 PFC2D基本简介

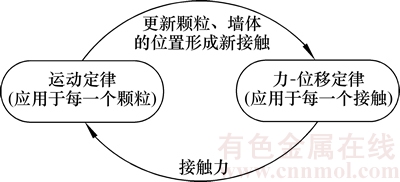

PFC是一款基于离散元理论开发的软件。它是用圆盘颗粒(PFC2D)或者圆球颗粒(PFC3D)来表示介质。以对介质材料的力学和变形问题进行模拟分析,由于其在细观层次可以对介质的裂纹萌生和扩展方面进行定量细化的研究,现已被广泛地应用于岩土工程领域,用来模拟连续和非连续材料的各种宏细观力学行为特征。在模拟过程中,颗粒通过接触实现力的作用,影响他们力的传递的基本模型包括接触刚度模型、滑动模型和黏结模型,其中黏结模型又包括接触黏结模型(CBM)和平行黏结模型(PBM)。PFC计算的基本原理如图1所示。

图1 PFC计算循环过程

Fig. 1 Calculation cycle in particle flow code

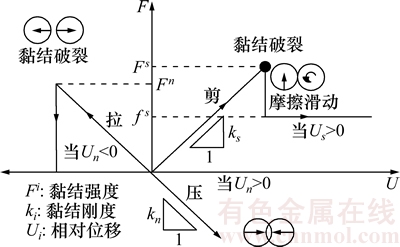

在PFC计算过程中,颗粒体的运动始终满足牛顿运动定律和力-位移的关系。其中,黏结模型与颗粒聚集体的细观损伤有关,它通过给黏结模型设置法向的抗拉强度和切向的抗剪强度用来表示介质的强度属性。当外力在黏结上产生的应力大于其极限抗拉强度和极限抗剪强度时,颗粒之间的黏结键就会断裂,然后在黏结断裂的位置分别产生张拉裂纹和剪切裂纹,颗粒黏结破坏的机理[21]如图2所示。借助于软件内置FISH语言,可以实现细观损伤的定量化表示。颗粒流在细观损伤的表示方面采用的是突出颗粒流在细观损伤研究方面的优势。

图2 颗粒平行黏结模型破坏原理图[21]

Fig. 2 Illustration of yielding process for parallel bond model[21]

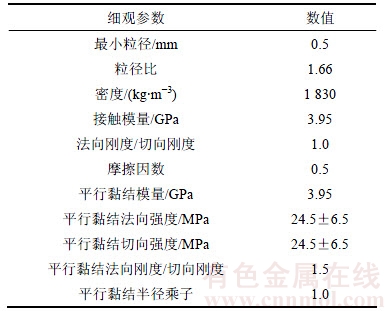

1.2 试件细观参数的确定

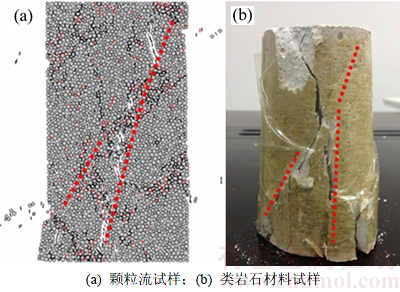

由于在室内试验中像颗粒粒径、颗粒刚度、颗粒接触模量和黏结强度等力学性质的细观参数无法直接获得,而在PFC模拟中需要给细观变量赋值,为了准确地模拟岩石实际的破坏形态,通过一系列的三轴压缩试验来进行岩石参数的标定。当建立的颗粒流双轴模型进行压缩数值试验得到岩石的弹性模型、泊松比和单轴抗压强度等宏观参数与试验中得到的结果基本一致时,确定的细观参数就是满足要求的,本文参数标定过程主要采用“试错法”来实现[22],最终确定类岩石材料的细观参数如表1所示。选用的试件为软岩的类岩石试件,试件尺寸(直径×长度)为50 mm×100 mm。室内三轴压缩试验采用TAW-2000电液伺服岩石三轴试验机进行。图3所示为单轴压缩条件下试样破坏失效形态。

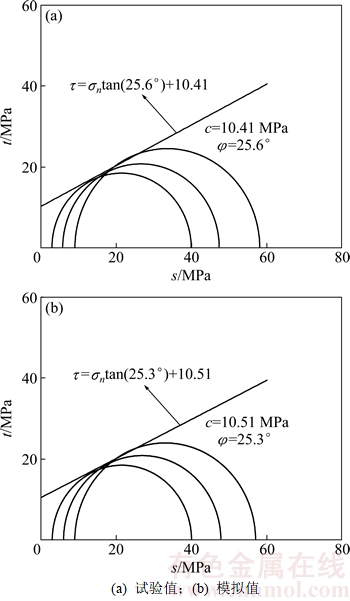

应用上述校准的细观力学参数分别在围压3,6和9 MPa作用下进行了类岩石压缩试验模拟,利用校准的参数建立模型得到的结果和试验结果分别绘制摩尔-库仑强度包络线如图4所示,该参数下得到试件的内聚力为10.51 MPa,内摩擦角为25.3°。单轴抗压强度计算值为33 MPa。在数值模拟中得到的内聚力比试验中偏大,内摩擦角比试验值小,造成差异的原因主要是由于建立的双轴实验模型是由圆形颗粒构成的[23]。综合上述分析,模拟结果与试验结果具有很好的一致性。

表1 类岩石试件细观力学参数

Table 1 Micro-mechanical parameters of rock-like specimen

图3 单轴压缩条件下试样破坏失效形态

Fig. 3 Failure patterns of cylinder sample under uniaxial compression

图4 摩尔-库仑强度包络线

Fig. 4 Envelope of Mohr-Coulomb strength

2 加锚节理直剪数值试验

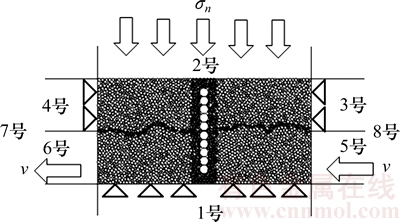

本文中不同粗糙度的加锚数值剪切模型是基于BPM(bonded-particle model method)方法建立,首先利用PFC2D建立一个长×宽为100 mm×50 mm剪切盒模型,剪切盒基本模型主要由8面墙体组成,其中2号、3号、4号墙体构成上部剪切盒,2号墙体作为伺服墙体,对模型施加恒定的法向荷载,加载墙体为5号和6号墙体,使下部剪切盒可以水平运动,下部剪切盒固定不动,7号和8号墙体的主要作用是防止剪切过程中颗粒的逃逸,这也比较符合具体实验的情况。本文建立加锚模型的主要部分包括上下块体、锚杆、注浆体和粗糙节理面。初始模型由程序随机生成3 012个颗粒形成,初始模型中颗粒的最小半径为0.4 mm,本文黏结模型选用平行黏结,该模型能很好地模拟岩体断裂产生局部损伤和刚度相应降低的特性[24]。粗糙节理面生成首先通过生成节理墙,并通过FISH语言判断与其接触的例子并赋予不同属性,最后删除节理墙,生成节理。粗糙度为18~20的粗糙节理面加锚模型如图5所示。

与此同时,还需要对加锚剪切模型的参数进行重新赋值。岩石选用的参数如表1所示。将注浆体的平行黏结强度在岩体的基础上增加50%,粗糙节理面上的颗粒平行黏结的黏结强度、颗粒法向、切向黏结刚度全部设为0。主要是为了弱化节理面强度以形成软弱结构面,节理面的粗糙度系数设为0.05。

图5 JRC为18~20的加锚节理剪切数值模型

Fig. 5 Numerical model for bolted join with JRC of 18-20

3 不同粗糙度的锚固节理宏观剪切行为分析

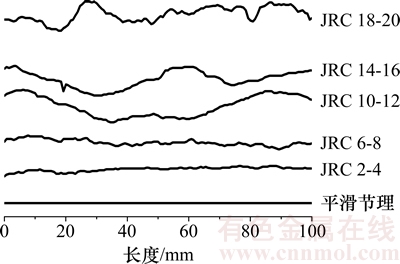

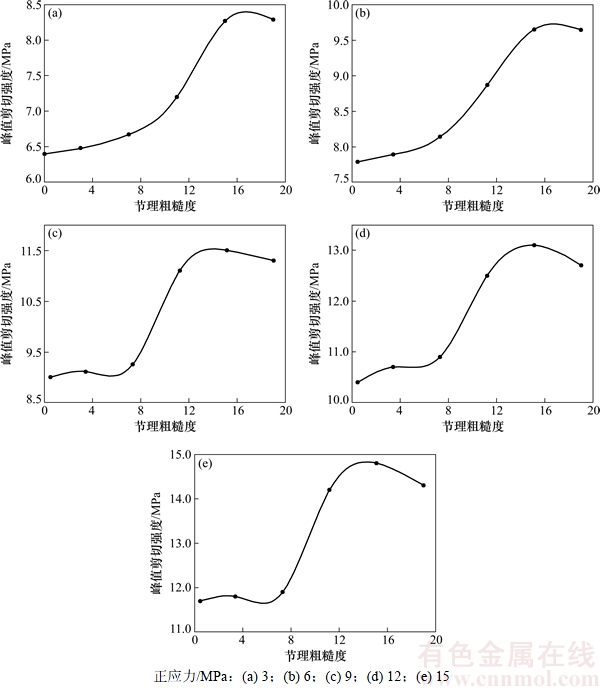

粗糙度加锚剪切试验模型采用6种不同粗糙程度的节理曲线,加锚节理面采用的曲线如图6所示。分别在法向应力分别为3,6,9,12和15 MPa作用下进行剪切实验,得到的不同法向应力下峰值剪切强度-节理粗糙度曲线如图7所示。

图6 节理曲线图

Fig. 6 Curve of joint

从图6可以看出:随着节理面粗糙度的增加,节理面开始越来越不平整,到JRC为18~20时节理面不平整的同时还有很多小突起。从图7可以看出:当节理面粗糙度较低时,随着节理粗糙度的增大,峰值剪切强度随着节理粗糙度的增大呈现不断增大的趋势,当节理粗糙度JRC为18~20时,锚固模型的峰值剪切强度比JRC为14~16的锚固模型的小。这主要是由于随着粗糙度的增加,节理面的细小微凸体也开始增多,在剪切过程中发生断裂,造成粗糙度的降低从而使锚固模型峰值剪切强度相对减小。同时,在不同法向荷载下,结构面的峰值剪切强度最大值对应的粗糙度也不同,呈现反相关关系。造成这种现象的原因主要是由于法向应力的增加加速了微凸体的破坏。

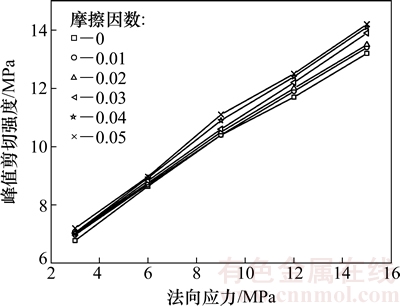

上述结果的研究均是设定节理面的摩擦因数为0.05时,而摩擦因数的变化也会在一定程度上影响节理面的抗剪强度,为此本文以节理面JRC为10~12的锚固模型为例,研究了5种不同节理面颗粒摩擦因数的剪切试验,摩擦因数的变化为0~0.05。试验得到的结果如图8所示。

由图8可知:节理面颗粒的摩擦因数与节理面的峰值剪切强度呈现正相关关系,即节理面摩擦因数越大,相应的节理面峰值抗剪强度越大。这主要是由于随着节理颗粒间摩擦因数的增加,颗粒运动中产生的摩擦力越大,节理颗粒的黏结破坏需要更大的外力,而且摩擦因数变大阻碍了剪切过程中节理面的相对错动。

图7 不同法向应力下峰值剪切强度随节理粗糙度的演化曲线

Fig. 7 Evolution curves of peak shear strength with joint roughness under different normal stresses

图8 节理面颗粒摩擦因数与峰值抗剪应力变化

Fig. 8 Variation of friction coefficient and peak shear stress of joint

4 粗糙节理的锚固模型细观力学响应及其破坏机理

为了进一步说明粗糙节理面锚固的破坏机理,本文以粗糙度系数JRC为10~12的锚固节理模型为例从颗粒间接触力以及接触力的方位、颗粒旋转角度和裂纹的演化等细观角度研究锚固体系的破坏机制。

4.1 不同法向荷载下锚固模型破坏机制分析

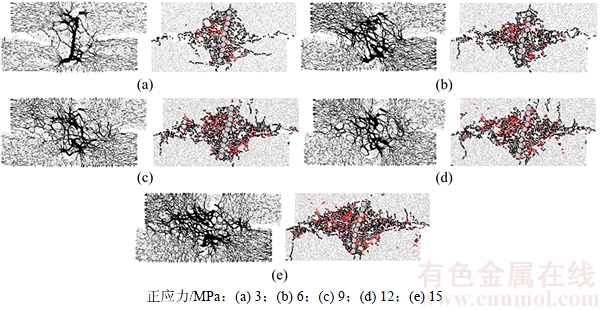

利用PFC内部的fish语言设定检测圆在粗糙节理面的锚固直剪试验内部的颗粒间接触力和细观裂纹的生成分布进行了动态监测。图9所示为在法向应力为3,6,9,12和15 MPa法向应力下,当剪切位移达到7 mm时锚固模型检测的的颗粒间接触力和裂纹分布情况。

图9 不同法向应力下颗粒接触力和裂纹分布图

Fig. 9 Distribution of contact force and crack under different normal stresses

从图9可知:加锚模型中接触力主要分布在锚杆的周围和和节理面相对比较不平的地方,同时这部分的颗粒主要受到压力作用,较大接触力分布的区域也是裂纹分布的区域并且张拉裂纹数量远大于剪切裂纹数量,这与“挤压导致张拉裂纹”的力学机制也是比较符合的。随着法向应力的增加,上下节理面的咬合作用也更加剧烈,接触力在节理面的接触范围也开始增多,裂纹也随法向应力的增加由锚杆周围到节理面上不断发展增多,开始向锚固体系的纵深方向发展。

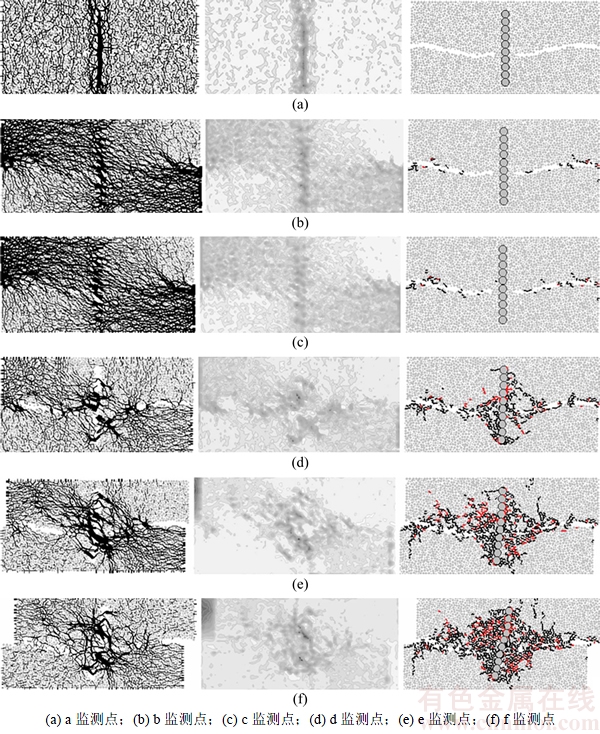

4.2 颗粒间接触力及细观裂纹演化特征分析

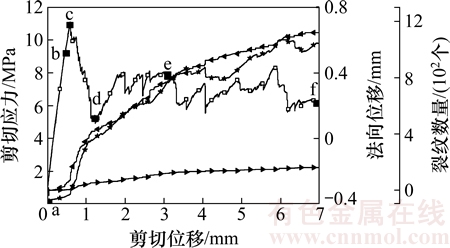

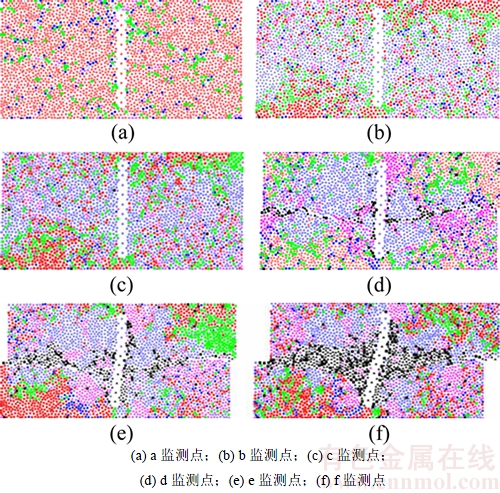

JRC为10~12的试样在9 MPa恒定法向荷载下的剪切应力、竖向位移、裂纹数随剪切位移的变化情况如图10所示。为了准确研究随着剪切位移的增加,锚固体系中颗粒间接触力和细观裂纹的演化特征,设置6个监测点,其中a点对应剪切位移的起始点,c点对应剪切应力的峰值点,监测点a~f的应剪切位移分别为0,0.500,0.593,1.200,3.000和7.000 mm。图11所示为选取的监测点a~f对应的颗粒间接触力分布和裂纹分布。

图10 剪切应力、裂纹数、法向位移随剪切位移变化

Fig. 10 Variations of shear stress, crack number,normal displacement with shear displacement

从图10和图11可以看出:锚固体系的颗粒间接触力是应力不断变化并且重分布的过程。接触力分布图中黑色线条的密集和粗细程度表示了接触力的大小,黑色线条越密集,颗粒挤压越剧烈相应的颗粒之间的力会越大。当剪切过程中剪切位移在a点时,只有法向应力,颗粒主要受到压力,接触力分布较大的区域主要发生在锚杆周围,只是安装锚杆与周围颗粒挤压造成的,其他岩体处接触力分布比较均匀,此时锚固体中并没有细观裂纹产生,颗粒间接触力最大值为99.438 kN。随着剪切的进行,当剪切位移由b点到达c点时,接触力主要集中分布在2个加载端和锚杆周围,此时节理面的凸起处开始有少量的裂纹产生,锚杆周围还没有裂纹分布,此时接触力最大值为115.452 kN。当剪切应力-剪切位移曲线到达d点后,此时剪切应力-剪切位移曲线开始进入了残余阶段,由于节理面有很多微凸体,随着剪切的进行,微凸体被剪断,节理面多发生摩擦滑移,从而使剪切曲线表现出波动特征。此后接触力主要集中在锚杆和节理面的相交处,裂纹开始在锚杆周围大量产生,并且张拉裂纹的数量远大于剪切裂纹的数量,这是由于锚杆与周围的颗粒挤压十分剧烈,导致颗粒黏结发生断裂,这一点符合挤压导致张拉裂纹作用机理,如图12所示。与此同时节理面的裂纹数量也相应增加,并且向节理面内部纵深处发展。

图11 不同监测点颗粒接触力等值线及裂纹演化图

Fig. 11 Evolution graph of contact force contour lines and at different special points

图12 张拉裂纹生成原理

Fig. 12 Mechanism diagram of tension cracks formation

4.3 节理面颗粒接触方位演化分析

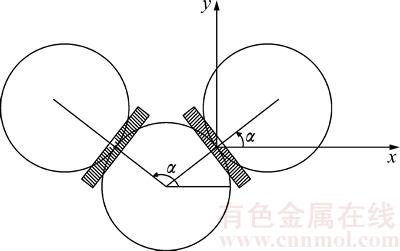

锚固体系中的颗粒间接触力通过颗粒的接触产生,由于接触颗粒方位的不同,接触力的方向也不完全一样,颗粒间接触方位角如图13所示。由于组成锚固体系的颗粒大小不尽相同而且剪切过程中接触力的方向和大小都是不断发生变化的,本文利用PFC内部的FISH语言编程对节理面的颗粒接触方位角进行动态检测并计算得到不同位置的颗粒接触方位角,研究剪切过程中颗粒的旋转和平动对接触方位角的影响,从而理解锚固体系的变形机理,这对于从细观角度研究加锚特性也是有意义的。

图13 颗粒间接触方位示意图

Fig. 13 Illustration of contact orientation between particles

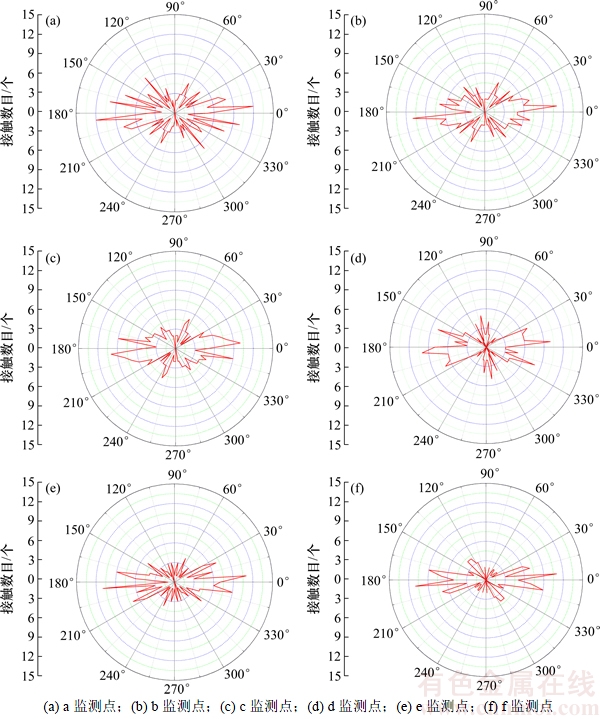

图14所示为不同监测点下节理面颗粒接触方位演化图。从图14可以看出:在开始剪切的初始阶段即a监测点,加锚体系此时受法向荷载作用,此时上下节理面颗粒接触比较充分,但接触力分布并不均匀,接触方位角主要集中在30°~330°和150°~210°的区间。曲线包围的面积越大,在该接触方位角的接触力越多。从图14可以看出:随着剪切位移的进行,接触力的大小和方位角不断发生变化,整体呈现出解除数目不断减小的趋势,这主要是由于剪切过程会导致节理面的剪胀,并且由于粗糙节理面微凸体的剪断节理面自由颗粒也相应增多,导致节理面组构发生改变引起的。接触方位角也发生相应改变,并逐渐向剪切方向发生一定的偏转,个别颗粒由于成为自由粒子导致接触方位角发生较大变化。综上所述,在整个锚固体系剪切过程中,随着剪切位移的增加,锚固节理面上的颗粒的接触数量及接触方位角的分布区域会呈现逐渐变小的趋势,而颗粒间接触方位角逐渐向剪切荷载施加的方向发生偏转。

图14 不同监测点节理面颗粒接触方位演化图

Fig. 14 Evolution graph of contact azimuth angle between particles in joint at different monitoring points

4.4 颗粒旋转角度演化分析

锚固模型中的颗粒在剪切滑移过程中会伴随着颗粒的旋转,颗粒旋转在PFC中可以用颗粒旋转角度在进行表征,并规定逆时针旋转时为正值,顺时针旋转时为负值。由于颗粒旋转会加剧颗粒之间发生相对错动,当旋转角度较大时就会导致颗粒之间的平行黏结键发生断裂,从而导致裂纹的产生。图15所示为锚固模型中颗粒的旋转角度在不同监测点的演化情况。

图15 不同监测点颗粒旋转角度演化图

Fig. 15 Evolution of particle rotation at various special points

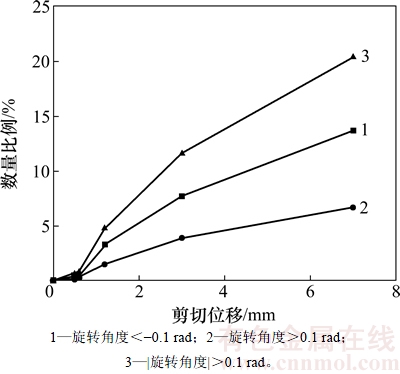

由图15可知:在剪切位移在a点时颗粒旋转角度都比较小,锚固模型中有94.6%的颗粒旋转角度位于-0.000 5~0.000 5 rad之间,只有个别颗粒旋转角度偏大,其中颗粒旋转角度介于-0.100 0~-0.000 5 rad的颗粒仅占2.6%,介于0.000 5~0.100 0 rad的颗粒仅占2.8%,并且均匀的分布在锚固模型中。随着剪切位移的增加,颗粒旋转角度逐渐变大,并且逐步呈现较为明显的层次效应,旋转角度绝对值大于0.1 rad的颗粒主要分布在节理面的凸起处,造成这种现象很大程度上是由于剪切破坏了节理表面的微凸体,使其发生了断裂,同时锚杆周围的颗粒旋转角度绝对值大于0.1 rad的颗粒也出现分布集中现象,说明剪切过程中锚杆和周围颗粒的挤压非常剧烈。与图11对比可以得到,模型中颗粒旋转角度较大的颗粒与和剪切裂纹分布基本一致,可见,颗粒旋转直接造成了剪切裂纹的生成。

图16所示为颗粒旋转角度超过0.1 rad的颗粒数量比例演化图。从图16可知:不论颗粒是顺时针旋转还是逆时针旋转,伴随着剪切试验的进行,旋转角度也在不断增大尤其很多颗粒的旋转角度大于0.1 rad,同时顺时针旋转角度超过0.1 rad的数量比例多于逆时针旋转角度超过0.1 rad的数量比例,这主要是由于剪切过程中加载方向导致的。

图16 颗粒旋转角度超过0.1 rad的数量比例演化图

Fig. 16 Quantitative proportion variation of rotation radian exceed 0.1 rad

5 结论

1) 在相同法向荷载作用下,节理面的峰值剪切强度整体随着粗糙度的增加而不断增大,但是当粗糙节理面微凸体较多时,峰值剪切强度会有一定程度的下降。对同一剪切模型而言,峰值剪切强度与法向荷载的呈现正相关关系,并且锚固节理面摩擦因数对锚固节理面的峰值剪切强度的提高也有明显的效果。

2) 锚固体系中颗粒的接触力集中现象只要发生在节理面凸起处和锚杆周围,并且主要以接触压力为主;相应的,细观裂纹也主要产生在节理面凸起和锚杆周围,并且张拉裂纹数量大于剪切裂纹数量。随着法向应力的增加,接触力集中的区域也开始增大,裂纹数目也开始迅速增加,并且裂纹开始向节理面的纵深处发展。

3) 在剪切的初始阶段,接触力主要集中在锚杆周围,体系内部并没有裂纹产生,随着剪切位移的增加,裂纹首先在节理面的凸起处产生并逐渐在锚杆周围大量产生,裂纹的数量以张拉裂纹为主。在整个剪切过程中,裂纹的发展主要是稳定产生、急速产生、稳定产生3个阶段。

4) 锚固体系在剪切试验的过程中,节理面颗粒的接触方位角会发生一定程度的改变,接触力的方向分布并不均匀,主要集中在30°~330°和150°~210°的角度区间;在此后的阶段,锚固节理颗粒间接触力的数量和方位角的分布区域逐渐减小,接触方位角逐渐向剪切荷载施加的方向发生偏转。

5) 剪切过程中同样会发生颗粒的旋转,在剪切初始阶段大部分的颗粒旋转角度位于-0.000 5~0.000 5 rad之间,随着剪切的进行在节理面的凸起和锚杆周围开始有旋转角度很大的颗粒产生并迅速增加,颗粒旋转角度较大的颗粒与剪切裂纹分布十分吻合,这也说明了旋转导致剪切裂纹的产生。

参考文献:

[1] 夏才初, 孙宗颀. 工程岩体节理力学[M]. 上海: 同济大学出版社, 2002: 35.

XIA Caichu,SUN Zongqi. Engineering rock mass joints mechanics[M]. Shanghai: Tongji University Press, 2002: 35.

[2] BARTON N, CHOUBEY V. The shear strength of rock joints in theory and practice[J]. Rock Mechanics and Rock Engineering, 1977, 10(1/2): 1-54.

[3] PELLET F, EGGER P. Analytical model for the mechanical behavior of bolted rock joints subjected to shearing[J]. Rock Mechanics and Rock Engineering, 1996, 29(2): 73-97.

[4] 朱维申, 李术才, 陈卫忠. 节理岩体破坏机理和锚固效应及工程应用[M]. 北京: 科学出版社, 2002.

ZHU Weishen, LI Shucai, CHEN Weizhong. Failure mechanism and anchorage effect of jointed rockmass and its application in engineering[M]. Beijing: Chinese Science Press, 2002.

[5] AZIZ N, HOSSEIN J, HADI M S N. The effect of rock strength on shear behavior of fully grouted bolts[C]//Proceedings Fifth International Symposium on Ground Support in Mining and Underground Construction. Perth, Australia, 2004: 243-251.

[6] WONG R H C, LAWCM, CHAUKT, et al. Crack propagation from 3D surface fractures in pmma and marble specimens under uniaxial compression[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41: 37-42.

[7] YI XIAO, ISHIKAWA T. Bearing strength and failure behavior of bolted composite joints[J]. Composites Science and Technology, 2005, 65: 1032-1043.

[8] JALALIFAR H, AZIZ N. Experimental and 3D numerical simulation of reinforced shear joints[J]. Rock Mech Rock Eng, 2010, 43(1): 95-103.

[9] 葛修润, 刘建武. 加锚节理面的抗剪性能研究[J]. 岩土工程学报, 1988, 10(1): 8-19.

GE Xiurun, LIU Jianwu. Study of the shear resistance behaviour of bolted rock joints[J]. Chinese Journal of Geotechnical Engineering, 1988, 10(1): 8-19.

[10] 温进涛, 朱维申, 李术才. 锚索对结构面的锚固抗剪效应研究[J]. 岩土工程学报, 2003, 22(10): 1699-1703.

WEN Jintao, ZHU Weishen, LI Shucai. Research on anchoring and shearing effect of anchoring cable[J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(10): 1699-1703.

[11] 王平, 冯涛, 朱永建, 等. 加锚预制裂隙类岩体锚固机制试验研究及其数值模拟[J]. 岩土力学, 2016, 37(3): 793-801.

WANG Ping, FENG Tao, ZHU Yongjian, et al. Experimental study and numerical simulation of anchoring mechanism of anchored rocklike material with prefabricated fracture[J]. Rock and Soil Mechanics, 2016, 37(3): 793-801.

[12] Itasca Consulting Group. PFC2D users guide[R]. Minneapolis: Itasca Consulting Group, 2008: 42.

[13] 周健, 池永. 颗粒流方法及PFC2D程序[J]. 岩土力学, 2000, 21(3): 271-274.

ZHOU Jian, CHI Yong. The method of particle flow and PFC2D code[J]. Rock and Soil Mechanics, 2000, 21(3): 271-274.

[14] JIANG M J, ZHU H H. Strain localization analyses of Idealised sands in biaxial tests by distinct element[J]. Frontiers of Structural and Civil Engineering in China,2010, 4(2): 208-222.

[15] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41(8): 1329-1364.

[16] CHO N, MARTIN C D, SEGO D C. Development of a shear zone in brittle rock subjected to direct shear[J]. International Journal of Rock Mechanics and Mining Sciences, 2008, 45(5): 1335-1346.

[17] ZHAO Z H, JING L R, IVARS N. Particle mechanics model for the effects of shear on solute retardation coefficient in rock fractures[J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 52(3): 92-102.

[18] 夏才初, 宋英龙, 唐志成, 等. 粗糙节理剪切力学性质的颗粒流值模拟[J]. 岩石力学与工程学报, 2012, 31(8): 1545-1552.

XIA Caichu, SONG Yinglong, TANG Zhicheng, et al. Particle flow numerical simulation for shear mechanical characteristics of rough joints[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(8): 1545-1552.

[19] 周喻, MISRA A, 吴顺川, 等. 岩石节理直剪试验颗粒流宏细观分析[J]. 岩石力学与工程学报, 2012, 31(6): 1245-1256.

ZHOU Yu, MISRA A, WU Shunchuan, et al. Macro and meso-analyses of rock joint direct shear test using particle flow theory[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1245-1256.

[20] 曹日红, 曹平, 林杭, 等. 不同粗糙度的节理直剪颗粒流分析[J]. 岩土力学, 2013, 34(Supp.2): 456-464.

CAO Rihong, CAO Ping, LIN Hang, et al. Particle flow analysis of direct shear tests on joints with different roughnesses[J]. Rock and Soil Mechanics, 2013, 34(Supp.2): 456-464.

[21] POTYONDY D O, CUNDALL P A. A bonded-particle model for rock[J]. International Journal of Rock Mechanics and Mining Sciences, 2004, 41: 1329-1364.

[22] Itasca Consulting Group Inc. Manual of particle flow code in 2-dimension (Version 3.10)[M]. Minneapolis: Itasca Consulting Group Inc, 2005.

[23] CHO N, MARTIN C D, SEGO D C. A clumped particle model for rock[J]. International Journal of Rock Mechanics & Mining Sciences, 2007, 44(7): 997-1010.

[24] 徐士良, 朱合华. 公路隧道通风竖井岩爆机制颗粒流模拟研究[J]. 岩土力学, 2011, 32(3): 885-890.

XU Shiliang, ZHU Hehua. Particle flow simulation of rock burst mechanism for highway tunnel ventilation shaft[J]. Rock and Soil Mechanics, 2011, 32(3): 885-890.

(编辑 赵俊)

收稿日期:2016-12-11;修回日期:2017-03-02

基金项目(Foundation item):国家自然科学基金资助项目(51279097,51479108);山东省博士后基金资助项目(201402014);中国博士后科学基金资助项目(2015M580599)(Projects(51279097, 51479108) supported by the National Natural Science Foundation of China; Project(201402014) supported by the Postdoctoral Foundation of Shandong Province; Project(2015M580599) supported by the National Science Foundation of Post-doctoral Scientist of China)

通信作者:王刚,博士,副教授,从事岩石力学与工程研究;E-mail:wanggang1110@gmail.com