DOI: 10.11817/j.issn.1672-7207.2017.06.008

大过冷工艺下珠光体钢亚结构组织及力学性能

向嵩1, 2,沈涛1,冀宣名1,梁宇1, 2

(1. 贵州大学 材料与冶金学院,贵州 贵阳,550025;

2. 贵州省材料结构与强度重点实验室,贵州 贵阳,550025)

摘要:采用TEM和MTS Landmark试验机研究盐浴大过冷工艺下SWRS82B珠光体钢亚结构组织变化及其力学性能,从热力学、动力学和碳原子扩散等方面探索最优热处理工艺。研究结果表明,大过冷工艺下珠光体亚结构组织明显细化,珠光体团尺寸细化至2.39μm,最小片层间距为62.11nm,且出现粒径55nm左右的纳米级渗碳体,三者受大过冷工艺的过冷温度和时间的影响较复杂;珠光体钢强度主要由珠光体片层间距决定,而塑性主要受团尺寸影响,二者均受纳米级渗碳体影响,随大过冷工艺的过冷温度和时间的变化而变化。最优大过冷工艺参数为300℃/3s+550℃。

关键词:大过冷;亚结构;纳米渗碳体;位错密度;力学性能

中图分类号:TG142.1 文献标志码:A 文章编号:1672-7207(2017)06-1465-08

Substructure and mechanical properties of pearlite steel with super-cooling technology

XIANG Song1, 2, SHEN Tao1, JI Xuanming1, LIANG Yu1, 2

(1. School of Materials and Metallurgy, Guizhou University, Guiyang 550025, China;

2. The Key Laboratory for Mechanical Behavior and Microstructure of Materials, Guiyang 550025, China)

Abstract: With TEM and MTS Landmark tester, the changes of pearlite microstructure during supercooling and the effect on the mechanical property were researched, and the optimal heat treatment process was explored based on thermodynamics, kinetics and carbon atom diffusion and so on. The results show that the substructure of pearlite after supercooling is refined significantly, the pearlite colony size is equal to 2.39μm and the interlamellar spacing is decreased to 62.11nm, and nanoscale cementite with size of 55nm appears, the above three are complexly influenced by the supercooling temperature and time. The strength is mainly determined by the interlamellar spacing and the reduction of area by the colony, while both the strength and reduction of area are affected by nanoscale cementite, changing according to the supercooling temperature and time. The optimal process of supercoiling is 300℃/3s+550℃.

Key words: supercooling; substructure; nanoscale cementites; dislocation density; mechanical properties

珠光体钢力学性能与珠光体微观组织关系密切,国内外学者对珠光体钢力学性能与珠光体团和片层间距等参数的关系进行了研究。KAZEMINEZHAD等[1-2]对共析珠光体钢进行研究发现,细小的片层间距有利于强度的提高,是控制强度的主要因素。KORDA等[3-4]通过试验指出,细珠光体团能有效阻碍裂纹扩展直至断裂的过程,使得材料塑性提高。根据Hall-Petch关系[5],珠光体片层间距和团尺寸越小,其强度和塑性越好,因此,采用细化珠光体亚结构组织来提高材料综合力学性能已成为一种趋势。以往的研究表明,片层间距与过冷奥氏体的转变工艺有关,主要由珠光体相变温度决定[6];而XU等[7]认为珠光体片层间距取决于珠光体形核率和长大速率。珠光体团尺寸不仅与珠光体相变温度有关,而且受原奥氏体晶粒粒径的影响[8]。另外,等温温度及珠光体晶界形核率的变化也会影响珠光体团尺寸,且不同等温温度下片层间距有较大改变[9-10]。对大过冷工艺的探索试验发现,过冷温度和过冷时间也会对珠光体显微组织、渗碳体形态等造成影响。因此,弄清大过冷机理,控制工艺参数得到细小的亚结构组织具有重要意义。目前,细化珠光体团尺寸均是通过细化原奥氏体晶粒以及降低珠光体相变温度来实现,本文作者采用盐浴大过冷工艺替代传统铅浴工艺,通过增加过冷度的方式提高珠光体形核率,细化珠光体团;不改变等温温度情况下通过控制过冷温度和过冷时间,观察珠光体亚结构组织应力学性能变化并进行分析,探索最优热处理工艺,获得强塑性较好的珠光体钢。

1 实验材料与方法

实验材料为某钢绳股份公司提供的SWRS82B珠光体钢盘条,直径为4.4mm,主要成分(质量分数,%)为:0.80C,0.23Si,0.79Mn,0.20Cr,余量Fe。

1.1 热处理工艺路线

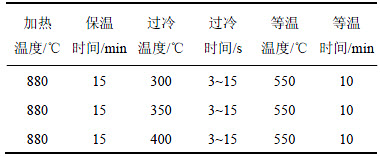

将截取的试样分成若干组,每组5根平行试样。采用箱式电阻炉加热,使其完全奥氏体化;首先将完全奥氏体化的试样在300~400℃盐槽中等温3~15s,然后快速进入550℃盐槽中保温10min后水淬。通过前期对盐浴大过冷热处理的实验结果分析,制定热处理工艺见表1。

通过对过冷温度和时间的控制,观察珠光体亚结构组织变化及其与力学性能的关系,探索最优大过冷工艺参数。

表1 SWRS82B钢热处理工艺

Table 1 Heat treatment process

1.2 微观组织参量分析

使用JEM-1200EX(120KV)型透射电镜(TEM)观察试样的显微组织,把经过热处理的试样制成直径×厚度为4.4mm×0.6mm试样,手工减薄至厚度在50μm以下,在体积分数为7%的高氯酸酒精溶液中进行双喷电解减薄,电解电压为30V,液氮冷却,温度为253K。观察珠光体亚结构组织形貌及位错等分布。片层间距及团尺寸等采用多张TEM照片通过截线法测得并取平均值。

1.3 力学性能的测定

由于试样弯曲且直径较小,无法机加工成标准试样,根据GB/T 228—2002[11],实验选择非标准试样尺寸,其取样规格如图1所示,在MTS Landmark万能试验机测试其力学性能。

图1 拉伸试样尺寸

Fig. 1 Size of tensile test piece

2 实验结果

2.1 力学性能

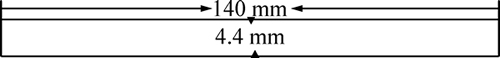

图2所示为SWRS82B珠光体钢经不同大过冷工艺处理后力学性能的变化。由图2(a)可以看出:除过冷时间为3s外,随过冷温度降低,抗拉强度呈先下降后上升的趋势;当过冷温度为300℃时,在3~10s,随过冷时间延长,抗拉强度降低,但当过冷时间继续增加到15s时,抗拉强度反而升高,在300℃/3s时,抗拉强度最大,为1 287.28MPa。由图2(b)可知:当过冷时间为3~7s时,随过冷温度升高,断面收缩率降低,而过冷时间延长至10~15s,随过冷温度升高,断面收缩率先增加后降低;当过冷温度不变时,随过冷时间延长,断面收缩率表现为先减小后增大,350℃/15s时,断面收缩率最大,为37.08%。

2.2 微观组织

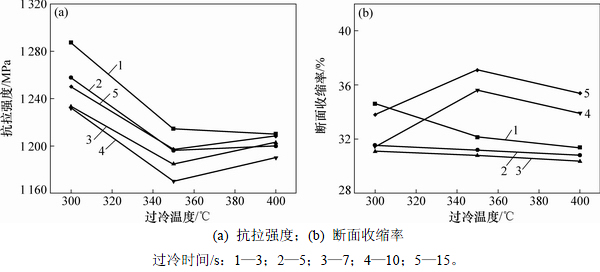

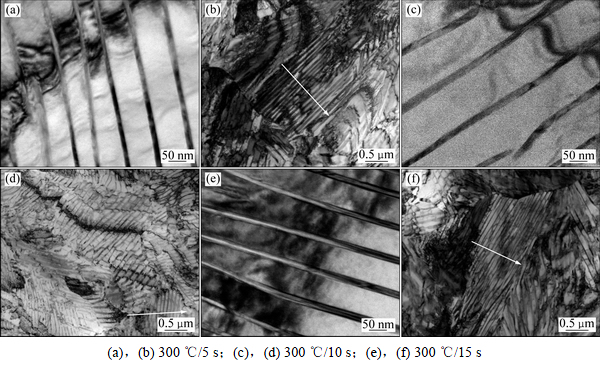

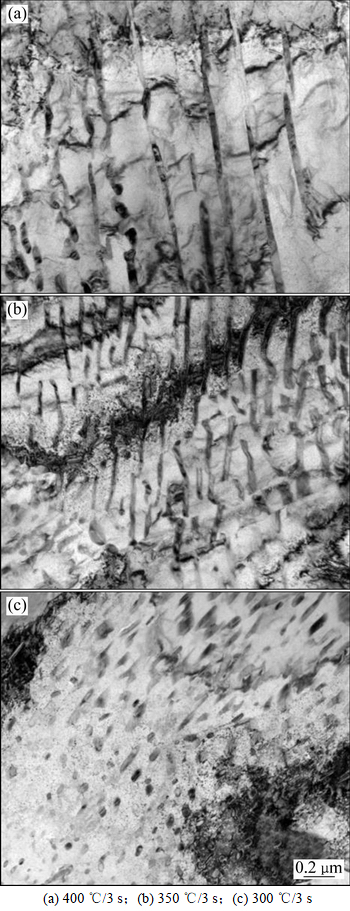

图3所示为过冷时间为3s不同过冷温度试样的TEM图。从图3可以看出:组织为共析组织。随过冷温度的升高,珠光体片层间距呈增大趋势,但当过冷温度在350~400℃之间变化时,珠光体片层间距增大不明显。随过冷温度的升高,珠光体团尺寸也呈增大的趋势。

图2 大过冷工艺参数对力学性能的影响

Fig. 2 Influence of large degree cooling process parameters on mechanical properties of steel

图3 不同过冷温度下微观组织TEM照片

Fig. 3 TEM images of steel at different super-cooling temperatures

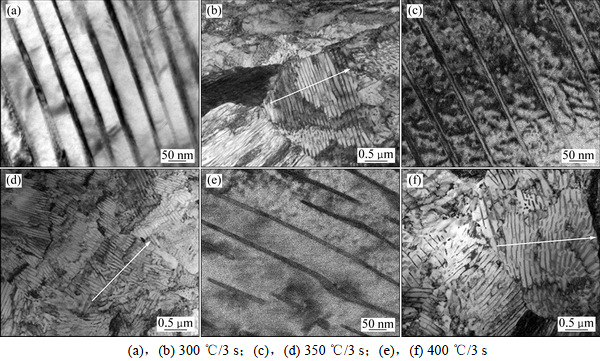

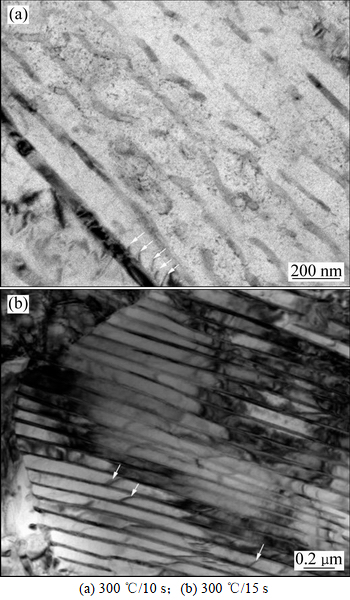

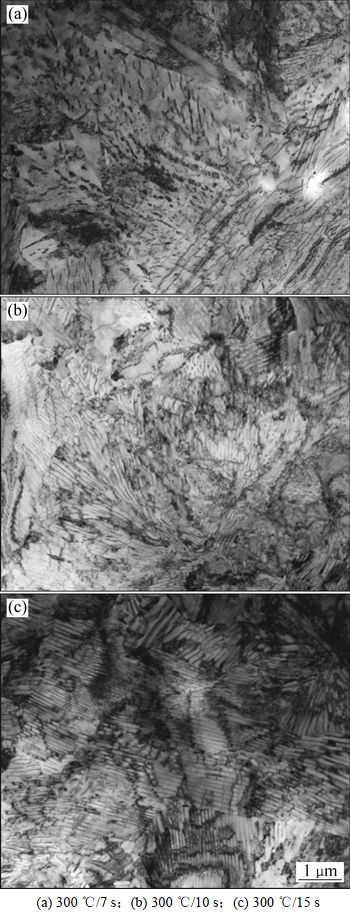

图4所示为过冷温度为300℃不同过冷时间试样的TEM照片。从图4可以看出:组织为共析组织。随过冷时间的延长,珠光体片层间距是先增大后下降;当过冷时间从3s增加到5s时,珠光体团尺寸略微增大,而过冷时间延长至10s及以上时,珠光体团尺寸减小且组织连续性变好。

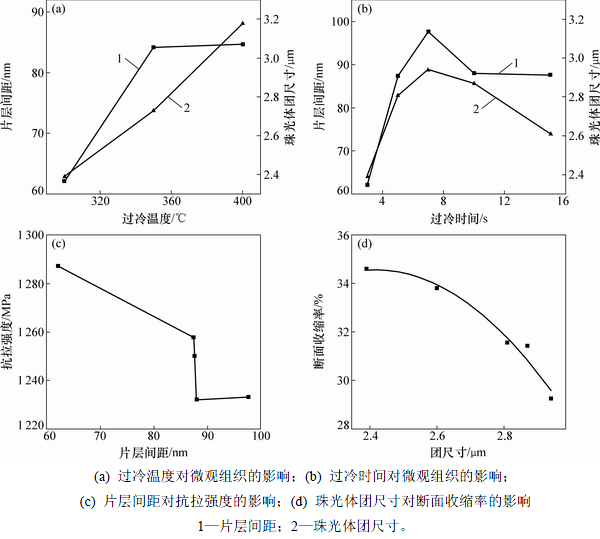

图5所示为大过冷工艺参数与珠光体钢亚结构组织及对力学性能的影响。由图5(a)和5(b)可知:随过冷温度降低,珠光体片层间距小幅度减小后大幅度降低,珠光体团尺寸呈单调递减;随过冷时间增加,珠光体片层间距和团尺寸变化均呈现先增加后减小的趋势,两者表现出一定的一致性。总结微观组织与力学性能联系,由图5(c)和5(d)可知:珠光体片层间距越小,强度越高;珠光体团尺寸越小,断面收缩率越大。

图4 不同过冷时间下微观组织TEM照片

Fig. 4 TEM images of steel super-cooling at 300℃ for different time

图5 大过冷工艺参数对珠光体钢亚结构组织及力学性能的影响

Fig. 5 Effect of super-cooling technology parameters on substructure and mechanical properties of pearlite steel

3 分析讨论

3.1 强度

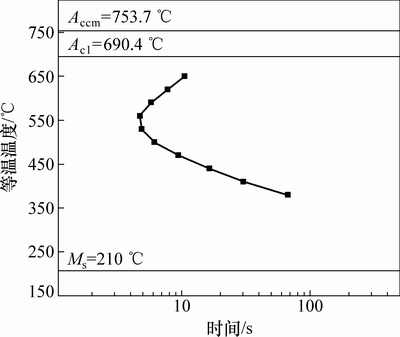

原奥氏体晶粒粒径一致情况下,钢丝抗拉强度主要与珠光体片层间距有关,而珠光体片层间距主要由珠光体相变温度控制。采用膨胀法测得了国产SWRS82B钢的TTT曲线图,如图6所示。由此可知,当过冷速度足够大,低温盐槽短时停留立刻进入高温盐槽等温的试样将在550℃附近发生珠光体相变。

图6 SWRS82B钢的TTT曲线

Fig. 6 TTT curves of SWRS82B rod

由图2(a)可知:不同过冷温度下试样的抗拉强度呈现一定梯度变化,当过冷时间一定(3s和5s除外)时,抗拉强度随过冷温度的降低先小幅度下降而后快速升高。统计数据发现,5s以后珠光体片层间距的平均值随过冷温度降低先增加后减小。这是因为经880℃温度完全奥氏体化后的试样快速进入400℃盐槽中等温7s时,珠光体转变已在晶界缺陷处开始发生,而试样进入350℃盐槽中等温50s以后才发现珠光体存在,导致盐浴大过冷试样在350℃盐槽短时停留后快速进入550℃中等温,珠光体转变在更接近550℃发生。所以,在大过冷工艺下,400℃盐槽等温7s以后试样的片层间距平均值较350℃盐槽中等温相等时间试样的片层间距平均值略小,从而抗拉强度随过冷温度降低(400~350℃)表现为小幅度下降;而当过冷时间较短(低于5s)时,试样抗拉强度随过冷温度降低单调增加,原因可以从3个方面来分析。

首先,珠光体转变属于扩散型相变,受温度和时间影响较大[12]。根据经验公式S0=(8.02/△T)×103 nm,珠光体片层间距S0和过冷度△T呈反比例关系,温度越低,过冷度越大,片层间距越小。经典珠光体形核率公式[13]为

(1)

(1)

式中:I为珠光体形核率;I0为形核常数;Q为原子扩散激活能;T为温度;k为玻尔兹曼常数;△G1*为临界形核功。由式(1)可知,过冷度较大时形核率受激活能Q控制,而激活能Q随温度的降低而急剧下降。所以,试样在300℃过冷时,过冷度大幅度提高,激活能降低,形核率急剧增加,形核位置在相变早期趋于饱和,此时,若过冷时间较短,得到试样的片层间距较小(见图3(a),3(c)和3(e)),从而抗拉强度随过冷温度降低单调增加。

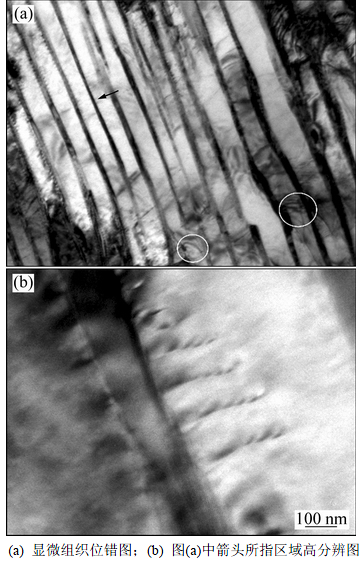

其次,试样高温完全奥氏体化后直接在低温盐浴中短时间淬火,应力集中导致大量位错的产生。图7(a)所示为300℃/3s工艺下试样的选区微观组织。从图7(a)可以看到:铁素体中产生大量位错,一部分位错发生缠结,另一部分位错弓出于铁素体/渗碳体两相界面,这2类位错均能提高强度。图7(b)所示为图7(a)中箭头处的高分辨图。从图7(b)可以看到位错垂直排列,这是因为低温下位错密度较大,能量较高,位错通过运动及重新分布释放应变能,一部分位错有序化形成位错网或位错墙。随温度升高,内应力减小,位错通过滑移相互抵消,位错密度不断减小,在400℃/3s工艺下试样微观组织中几乎看不到位错存在。

图7 300℃/3s热处理工艺下显微组织TEM照片

Fig. 7 TEM micrographs of 300℃/3s heat treatment

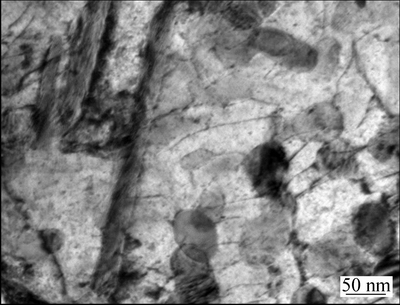

最后,低温淬火时,产生的大量弥散第二相纳米级渗碳体提高了强度[14]。图8所示为过冷时间3s、不同过冷温度下渗碳体形态。从图8可以看出:随过冷温度降低,渗碳体形态经历了从连续片状到断续短棒状最终以颗粒形态分散于铁素体基体中。对图8(c)中渗碳体颗粒进行测量,其粒径平均值为55nm。过冷温度越低,更容易出现纳米级渗碳体。这可从2个方面分析:一方面,过冷奥氏体是亚稳相,温度越低,过冷度越大,奥氏体转变为珠光体的自由能差和相变驱动力大大提高,同时,临界形核尺寸r*和临界形核功△G*减小。一旦过冷奥氏体中存在的贫碳区和富碳区满足临界形核条件时,则在贫碳区形成铁素体核胚,富碳区形成渗碳体核胚,当温度较小、时间较短时,碳原子的扩散速率和距离受限,部分渗碳体核胚被保留。另一方面,试样从高温状态下直接低温淬火,在晶粒内部产生大量位错。位错附近畸变能较高,溶质原子常在位错线上偏聚,很容易满足形核时的成分起伏,导致位错处较易形核。而当纳米级渗碳体在位错附近形核时,位错缺陷部分消失,位错能量降低,反过来又为纳米渗碳体形核提供了驱动力[15]。如图9所示为沿位错附近的纳米渗碳体TEM图片。

图8 不同过冷温度下纳米渗碳体明场TEM照片

Fig. 8 Bright-field TEM images of nanoscale cementite with different super-cooling temperatures

图9 沿位错附近的纳米渗碳体TEM照片

Fig. 9 TEM image of nanoscale cementite precipitation along and in vicinity of dislocations

综合以上因素可以解释图2(a)中抗拉强度随过冷温度变化的规律。而过冷时间对抗拉强度的影响主要通过影响珠光体片层间距和位错密度等。

由图2 (a)可知:当温度为300℃时,随过冷时间的延长,抗拉强度表现为先下降后升高的趋势。其原因是一方面在7s以前,珠光体片层间距随过冷时间延长,片层间距增大。而当过冷时间延长到10s时,片层间距又开始减小,这是因为随过冷时间增加,端向长大的过程中很容易接触到其他团组织,因此,当端向长大停止时,已形成的贫碳区和富碳区只能通过侧向长大完成整个相变过程,珠光体片层间距增大;而随时间进一步延长到10s以后,理论上,片层间距应该增加,但当时间延长到一定阶段时,根据图6中SWRS82B钢的TTT曲线,在大过冷过程中的二次盐浴等温时,珠光体转变可能在低于550℃发生,导致珠光体片层间距实际偏小,图4(a),4(c)和4(e)中珠光体片层间距与抗拉强度变化能较好地对应。另一方面,过冷时间延长,应力发生松弛,应变能下降,位错密度不断减小,与过冷温度升高作用类似。当过冷时间延长至7s,即300℃/7s工艺下试样微观组织中几乎已看不到位错存在,位错强化作用随过冷时间增加而减弱。再者,过冷时间进一步延长至10s,碳原子扩散距离增加,铁原子和置换原子以热激活跃迁方式沿着界面位移,实现晶格改组[16],产生的下贝氏体对强度有所贡献。由于在相变过程中,铁素体与碳化物长大呈相互竞争机制且铁素体的长大速度远高于碳化物,所以,下贝氏体碳化物形态呈短棒状、纤维状、楔形等[17],图10所示为下贝氏体碳化物的TEM照片。从图10可见碳化物呈短棒状或楔形,且同一宽面的碳化物近似于平行排列,与铁素体长轴方向交角50°~60°。

图10 下贝氏体碳化物的TEM照片

Fig. 10 TEM images of lower bainite carbide

3.2 塑性

由图2(b)可见:过冷时间分别为3,5,7s时,随过冷温度的降低,断面收缩率提高。这是因为大过冷能提高瞬时过冷度,增加形核质点,提高珠光体形核率,细化亚结构,珠光体团尺寸减小。结合图3(b),3(d)和3(f)的微观组织可以看出:当过冷时间为3s时,随过冷温度降低,珠光体团尺寸大大细化。由图5(d)可知:珠光体团尺寸越细小,断面收缩率越高。因此总结大过冷工艺,在一定时间范围内,过冷温度越低,断面收缩率越大。

而过冷时间延长至10~15s时,断面收缩率随过冷温度升高表现为先增大后减小。其原因是:因为温度升高,弥散分布的纳米渗碳体颗粒减少,使珠光体组织连续性变好(图8(a),8(b),8(c));温度升高,铁素体和渗碳体两相界面形成的较密集的位错密度降低,早期裂纹萌生概率降低[18]。另外,过冷时间增加,端向长大使珠光体团尺寸增大,但当过冷时间延长至10~15s时,珠光体团尺寸又减小,其原因与过冷时间对片层间距影响的原因相同。根据得到的SWRS82B钢的TTT曲线,过冷时间增加到一定阶段(15s),进入550℃盐槽等温时珠光体转变在低于550℃就开始发生,相变温度降低使得珠光体团尺寸较10s之前更细小(图4(b),4(d),4(f));再者,随着过冷时间进一步延长,碳原子扩散距离增加,形成贫碳区和富碳区的连续能力提高,渗碳体不连续行为减少,当过冷时间延长至15s时,纳米级渗碳体的存在量很少,珠光体组织的连续性明显较好(图11(a),11(b),11(c));最后,当过冷时间延长至10s后,出现少量下贝氏体组织使断面收缩率有所提高。

图11 不同过冷时间下珠光体组织及纳米渗碳体明场TEM图片

Fig. 11 Bright-field TEM images of pearlite and nanoscale cementite with different super-cooling time

4 结论

1) 过冷温度越低,过冷度增大,瞬时形核率提高,珠光体团尺寸明显细化,且易出现纳米级渗碳体。随过冷时间增加,珠光体团尺寸和片层间距均增大,铁素体和渗碳体两相界面位错密度下降;而随过冷时间进一步延长,珠光体团尺寸和片层间距又开始减小,珠光体亚结构组织连续性变好,且出现少量下贝氏体组织。

2) 在过冷温度为300℃,过冷时间为3s时,珠光体团尺寸和片层间距最小,分别为2.39μm和62.11nm,且出现了55nm左右的纳米级渗碳体。力学性能主要受片层间距和珠光体团尺寸影响,但具体还受纳米级渗碳体、位错、亚结构组织连续性以及下贝氏体等影响。

3) 当大过冷工艺为300℃/3s+550℃时,珠光体亚结构组织最细小,综合力学性能较好,考虑到冷拉拔线材的原材料以全珠光体钢最佳,排除贝氏体相影响,并结合实际生产应用,大过冷最优工艺参数为300℃/3s+550℃。

参考文献:

[1] KAZEMINEZHAD M, TAHERI A K. The effect of controlled cooling after hot rolling on the mechanical properties of a commercial high carbon steel wire rod[J]. Materials & Design, 2003, 24(6): 415-421.

[2] ELWAZRI A M, WANJARA P, YUEA S. The effect of microstructural characteristics of pearlite on the mechanical properties of hypereutectoid steel[J]. Materials Science and Engineering A, 2005, 404(1/2): 91-98.

[3] KORDA A A, MUTOHA Y, MIYASHITA Y. Effects of pearlite morphology and specimen thickness on fatigue crack growth resistance in ferritic pearlitic steels[J]. Materials Science and Engineering A, 2006, 428(1/2): 262-269.

[4] NAM W J, BAE C M, OH S J, et al. Effect of interlamellar spacing on cementite dissolution during wire drawing of pearlitic steel wires[J]. Scripta Materialia, 2000, 42(5): 457-463.

[5] PETCH N J. The fracture of metals[J]. Progress in Metal Physics, 1954(5): 1-52.

[6] 李俊杰, ANDREW G, 刘伟. 奥氏体化与冷却速率对过共析钢组织的影响[J]. 金属学报, 2013, 49(5): 583-592.

LI Junjie, ANDREW G, LIU Wei. Effect of austenitization and cooling rates om the microstructure in a hypereutectoid steel[J]. Acta Metallurgica Sinica, 2013, 49(5): 583-592.

[7] XU Jinqiao, LIU Yazheng, ZHOU Shumei. Calculation models of interlamellar spacing of pearlite in high-speed 82B rod[J]. Journal of Iron and Steel, Research, International, 2008(15): 57-60.

[8]  F, et al. The fracture toughness of a ultrahigh carbon steel containing 1.5 wt% C[J]. Fatigue & Fracture of Engineering Materials & Structures, 2006, 29(9/10): 817-828.

F, et al. The fracture toughness of a ultrahigh carbon steel containing 1.5 wt% C[J]. Fatigue & Fracture of Engineering Materials & Structures, 2006, 29(9/10): 817-828.

[9] 吴庆辉, 杨忠民, 陈颖, 等. 相变温度对珠光体轨钢组织和性能的影响[J]. 热加工工艺, 2012, 41(10): 67-70.

WU Qinghui, YANG Zhongmin, CHEN Ying, et al. Effect of transformation temperature on microstructure and properties of fully pearlite rail steel[J]. Hot Working Technology, 2012, 41(10): 67-70.

[10] 梁宇, 余凌峰, 梁益龙. 珠光体钢微观组织与拉伸性能关系[J]. 材料热处理学报, 2013, 34(7): 73-77.

LIANG Yu, YU Lingfeng, LIANG Yilong. Relationship between microstructure and tensile properties of a pearlitic steel[J]. Transactions of Materials and Heat Treatment, 2013, 34(7): 73-77.

[11] GB/T 228—2002, 金属材料室温拉伸试验方法[S].

GB/T 228—2002, Metallic materials tensile testing method at room temperature[S].

[12] 刘宗昌, 袁泽喜, 刘永长. 固态相变[M]. 北京: 机械工业出版社, 2010: 128-130.

LIU Zongchang, YUAN Zexi, LIU Yongchang. Solid phase transformation[M]. Beijing: China Machine Press, 2010: 128-130.

[13] 胡赓祥. 材料科学基础[M]. 3版. 上海: 上海交通大学出版社, 2000: 230-232.

HU Gengxiang. Foundation of materials science[M]. 3rd ed. Shanghai: Shanghai Jiaotong University Press, 2000: 230-232.

[14] MICHAEL D, DAVID N. Nanoscale co-precipitation and mechanical properties of a high-strength low-carbon steel[J]. Acta Materialia, 2011(59): 1881-1897.

[15] WANG Bin, LIU Zhenyu, MISRA R D K, et al. Precipitation behavior of nanoscale cementite in hypoeutectoid steels during ultra fast cooling (UFC) and their strengthening effects[J]. Materials Science and Engineering A, 2013, 575(13): 189-198.

[16] 刘宗昌, 王海燕, 王玉峰, 等. 贝氏体碳化物的形貌及形成机制[J]. 材料热处理学报, 2008, 29(1): 32-37.

LIU Zongchang, WANG Haiyan, WANG Yufeng, et al. Morphology and formation mechanism of bainitic carbide[J]. Transactions of Materials And Heat Treatment, 2008, 29(1): 32-37.

[17] 方鸿生, 冯春, 郑燕康, 等. 下贝氏体中碳化物的析出[J]. 金属学报, 2007, 43(6): 583-588.

FANG Hongsheng, FENG Chun, ZHENG Yankang, et al. Precipitation of the carbides in lower bainite[J]. Acta Metallurgica Sinica, 2007, 43(6): 583-588.

[18] 黄孝瑛, 郭薇, 潘天喜, 等. 珠光体钢微观结构和断裂过程的TEM研究[J]. 金属学报, 1987, 23(3): 200-204.

HUANG Xiaoying, GUO Wei, PAN Tianxi. TEM study of pearlitic steel microstructure and fracture process[J]. Acta Metallurgica Sinica, 1987, 23(3): 200-204.

(编辑 赵俊)

收稿日期:2016-06-21;修回日期:2016-08-16

基金项目(Foundation item):国家自然科学基金资助项目(51361004,51461007,51661006);贵州省百层次创新型人才项目(20164014);贵州省科技计划项目(20147001,20142003,2016021)(Projects(51361004, 51461007, 51661006) supported by the National Natural Science Foundation of China; Project(20164014) supported by the “100 Innovative Talents Project” of Guizhou Province; Projects(20147001, 20142003, 2016021) supported by Guizhou Provincial Science and Technology Program)

通信作者:向嵩,博士,教授,从事高性能金属结构材料的开发研究;E-mail:sxiang@gzu.edu.cn