Effect of precipitation on elastic modulus of Al-Zn-Mg-Cu-Li alloys

ZHAO Zhong-kui(赵中魁), ZHOU Tie-tao(周铁涛)2, LIU Pei-ying(刘培英)1,

LI Huan-xi(李焕喜)1, CHEN Chang-qi(陈昌麒)1

1. School of Materials Science and Engineering, Shandong Jianzhu University, Jinan 250101, China;

2. School of Materials Science and Engineering, Beijing University of Aeronautics and Astronautics,

Beijing 100083, China

Received 28 July 2006; accepted 15 September 2006

Abstract: Al-5.6Zn-3.0Mg-1.6Cu-1.1Li-0.24Cr alloys and Al-8.0Zn-2.4Mg-2.4Cu-1.1Li-0.18Zr alloys (mass fraction, %) were aged by different processes. The microstructure and mechanical properties were determined by transmission electron microscopy(TEM), tensile test and Vicker’s hardness test. The experimental results show that the most signified hardening is obtained by double-ageing or multi-ageing for the Al-Zn-Mg-Cu-Li alloys. The yield strength and the elastic modulus of the Li-containing alloys have relationships with ageing processes. The elastic modulus of Li-containing alloys decreases with the increment of precipitates though it is higher than that of Al-Zn-Mg-Cu alloy.

Key words: Al-Zn-Mg-Cu-Li alloys; ageing; precipitates; elastic modulus; yield strength

1 Introduction

Al-Zn-Mg-Cu alloys are widely used for structure application in the aerospace due to their high specific mechanical properties[1-2]. Alloying adjustment and microstructure control have always been taken as efficacious measures in gaining further improvement of the performance of alloys[3-4]. The function and effects of lithium in aluminum alloys have been studied for long time, and 8000 series of aluminum-lithium alloys have been developed and applied in the aerospace industry because of their light mass, high specific strength and high elastic modulus[4-5]. Al-Zn-Mg-Cu-Li alloys have also been studied in recent years. Addition of lithium to Al-Zn-Mg-Cu alloys may lead to precipitation kinetics modified. In order to gain high strength, Al-Zn-Mg- Cu-Li alloys show a different heat-treating process from that of Al-Zn-Mg-Cu alloys[6-11]. Most of these investigations have concerned precipitation and its kinetics [7-13]. There is little investigation on the mechanical properties, especially elastic modulus, although it has been reported that the alloys can be strengthened by a double-ageing process[9-11]. The purpose of the current work is to study the elastic modulus of Al-Zn-Mg-Cu-Li alloys under artificial ageing condition, and the relationship between precipitates and elastic modulus.

2 Experimental

The two alloys investigated in this work were melted in a vacuum furnace and cast into a water cooled mould under argon protective condition, of which the chemical compositions are listed in Table 1. The ingots with diameter of 150 mm were homogenized through two step-heating, 430 ℃ for 24 h and 470 ℃ for 36 h, then hot forged at about 450 ℃ to 10 mm in thickness. Samples were solution treated at 485 ℃ for 1 h, and then artificially aged at the processes as shown in Table 2.

The age behavior and precipitation hardening effect were determined by Vicker’s hardness with the testing load of 9.8 N. The tensile samples, prepared from the plates, were machined to a gauge cross-sectional diameter of 5 mm and a gauge length of 25 mm. The elastic modulus is defined as the slope of the straight line portion of a stress-strain diagram, where elastic modulus equals the ratio of stress vs strain. The microstructure was analyzed by transmission electron microscopy (TEM).

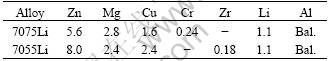

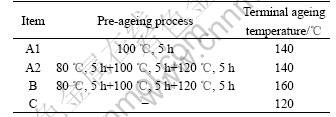

Table 1 Chemical composition of alloys used(mass fraction, %)

Table 2 Ageing processes for alloys in practice

3 Results and discussion

3.1 Hardening behavior

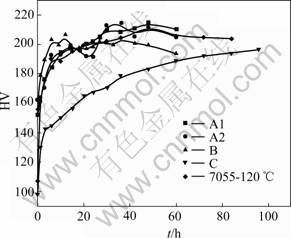

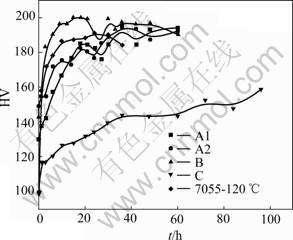

The age hardening curves for the Al-Zn-Mg-Cu-Li alloys and the corresponding Al-Zn-Mg-Cu alloys are shown in Figs.1 and 2. It can be seen from the ageing curves that the ageing behavior of Al-Zn-Mg-Cu-Li alloys is markedly different from that in the Li-free alloys. During single-aged at 120 ℃, the ageing response of the Li-containing alloys is much weaker than that in the Li-free alloys. The hardness peaks were not presented in the hardness curves for the Li-containing alloys during single-ageing for the experimental time. However, the hardening effect can be intensified remarkably for the Li-containing alloys if pre-ageing is taken and then followed by secondary step ageing at 140 ℃ or 160 ℃. From the hardening curves, we can conclude that the hardening effect of the double-aged or multi-age Li-containing alloys is equivalent to that of Li free alloys.

Fig.1 Hardness curves of single-aged, double-aged and multi-aged 7075Li alloys

Fig.2 Hardness curves of single-aged, double-aged and multi-aged 7055Li alloys

3.2 Yield strength and elastic modulus

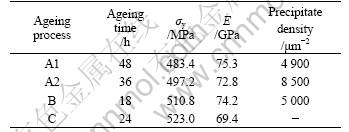

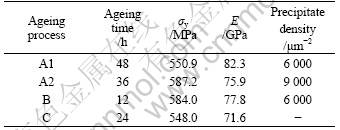

The tensile samples were aged in the corresponding ageing processes for the peak time. The yield strength and elastic modulus of the Li-containing alloys are shown in Tables 3 and 4. The yield strength is listed because it remains the most important property hardened by precipitates. From the tables, it is well known that the yield strength and the elastic modulus of Li-containing alloys have relationship with ageing processes. When pre-aged at 100 ℃ for 5 h, and then aged at 140 ℃ for 48 h (condition A1), both of Li-containing alloys have lower yield strength but higher elastic modulus. The elastic modulus of the Al-Zn-Mg-Cu-Li alloy is 5% higher than that of Al-Zn-Mg-Cu alloys, which is agree to other Al-Li alloys[3]. When pre-aged at 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h, and then aged at 140 ℃ for 36 h (condition A2), the yield strength increases but the elastic modulus decreases. There is an effect of pre-ageing processes on the yield strength and elastic modulus of Al-Zn-Mg-Cu-Li alloys. Compared with the alloys aged under condition A2, the alloys aged under condition B (pre-aged at 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h and then aged at 160 ℃ for 18 h or 12 h) have not only higher yield strength but also higher elastic modulus. We can conclude that the terminal ageing temperature has also effect on the yield strength and elastic modulus of the Li-containing alloys.

The yield strength and the elastic modulus are sensitive to the nature of atomic-scale crystal structure of the precipitate phase, the matrix, and the interface between the two. When adding lithium to the Al-Zn-Mg-Cu alloys, the stiffness of with covalent bonding of Li atoms might well give rise to significant change of the elastic modulus. The yield strength and elastic modulus depend not only on whether the solute is in or on size and dispersion of any precipitated phases.

Table 3 Tensile strength and elastic modulus of multi-aged 7075Li alloys

Table 4 Tensile strength and elastic modulus of multi-aged 7055Li alloy

3.3 Influence of precipates on elastic modulus

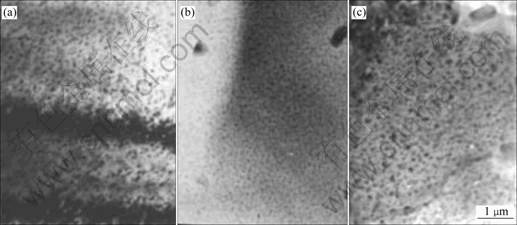

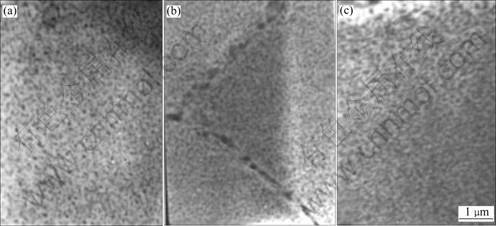

Controlling precipitation of fine particles during the ageing process after the quenching operation is used to develop the mechanical properties of the heat treated alloys. Figs.3 and 4 show the TEM microstructures of the Li-containing alloys aged by the processes as described in Tables 1 and 2. Precipitate density was measured by direct count of number of particles in a selected area. The data, which was interpreted and measured from transmission electron micrographs, is summarized in Tables 3 and 4.

The elastic modulus of the alloys is dependent both on the matrix and the precipitates. If the lithium addition to aluminum forms intermetallic compounds or other phases with aluminum, the elasticity properties of these phases exert their own influence on the modulus of the alloys. Fig.3(a) and Fig.4(a) show the microstructure of the alloys aged at 100 ℃, 10 h+140 ℃, 48 h (condition A1), from which we can found that precipitates are homogeneously distributed and approximately equiaxed, however precipitate number density is lower. For the Li-containing alloys aged at 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h+140 ℃, 36 h (condition A2), finer and denser precipitates disperse in the matrix, as shown in Fig.3(b) and Fig.4(b)). It is well known that the yield strength increases and the elastic modulus decreases when the Li-containing alloys are multi-pre-aged, which attributes to the increase in the the precipitate number. With the increase of the precipitate number density, the strengthening effect of precipitates results from the additional interference with the motion of dislocations when they cut the precipitates, however the elastic modulus does not. The elastic modulus is based on the density, distribution, size of precipitates and lithium level in the matrix. Since the precipitates contain some lithium atoms[6], lithium level in the matrix decreases. The experimental results show that the elastic modulus decreases while the precipitate number density increases. The lithium in the precipitates has almost no contribution to the elastic modulus of the Li-containing alloys.

Fig.3 Morphologies of precipitates in 7075Li alloys aged by: (a) 100 ℃, 5 h+140 ℃, 48 h; (b) 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h+140 ℃, 18 h; (c) 80 ℃, 5h+100 ℃, 5 h+120 ℃, 5 h +160 ℃, 18 h

Fig.4 Morphology of precipitates in 7055Li alloys treated by: (a) 100 ℃, 5 h+140 ℃, 48 h; (b) 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h+140 ℃, 18 h; (c) 80 ℃, 5 h+100 ℃, 5 h+120 ℃, 5 h +160 ℃, 12 h

Take precipitates size into account. The coarser precipitates can be observed in Fig.3(c) and Fig.4(c), where the alloys are aged at 80 ℃, 5 h+100 ℃, 5 h+ 120 ℃, 5 h+160 ℃, 18 h (or 18 h) (condition B). The number density of precipitates is further lower than that of the alloys treated under condition A2, however it is approximately the same as that in the alloys treated under condition A1. The Li-containing alloys aged under condition B have high hardness and yield strength, which indicates that the volume fraction of precipitates is larger. The existence of such coarser phases results in a value of elastic modulus between condition A1 and condition A2.

4 Conclusions

1) The most signified hardening is obtained by double-ageing or multi-ageing for the Al-Zn-Mg-Cu-Li alloys.

2) The elastic modulus is 5% higher than that of Al-Zn-Mg-Cu alloys, however the yield strength and the elastic modulus of the alloys have relationships with ageing processes.

3) Lithium in the precipitates has almost no contribution to the elastic modulus of the alloys. The elastic modulus of Al-Zn-Mg-Cu-Li alloys decreases as the number of precipitates increases.

References

[1] LIU J, KULAK M. A new paradigm in the design of aluminum alloys for aerospace applications [J]. Materials Science Forum, 2000, 331-337: 127-140.

[2] LI Li, ZHOU Tie-tao, LI Huan-xi, CHEN Chang-qi, XIONG Bai-qing, SHI Li-kai. Effect of additional elements on aging behavior of Al-Zn-Mg-Cu alloys by spray forming [J]. Trans Nonferrous Met Soc China, 2006, 16(3): 532-538.

[3] RIOJA R J. Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications [J]. Mater Sci Eng A, 1998, A257: 100-107.

[4] WEI F, ZHAO Z K, LIU P Y, ZHOU T T. Research and development of Al-Zn-Mg-Cu-Li alloys [J]. Materials Forum, 2004, 8: 75-84.

[5] HUANG Z W, LORETTE M H, WHITE J. Influence of lithium additions on precipitation and age hardening of 7075 alloy [J]. Material Science and Technlogy, 1993, 9: 967-980.

[6] HUANG Z W, LORETTE M H, SMALLMAN R E, WHITE J. The mechanism of nucleation and precipitation in 7075-0.7 Li alloy [J]. Acta Materialia et Metallurgica, 1994, 42: 549-559.

[7] DU Zhi-wei, ZHOU Tie-tao, LIU Pei-ying, CHEN Chang-qi, ZHONG Hao, HONG Xin-guo, ZHAO Hui, DONG Bao-zhong. Small angle X-ray scattering used in precipitation in AlZnMgCuLi alloy [J]. Trans Nonferrous Met Soc China, 2003, 13(6): 1301-1305.

[8] BAI Pu-cu, ZHAO Zhong-kui, ZHOU Tie-tao, LIU Pei-ying, ZHANG Yong-gang, CHEN Chang-qi. Influence of Li on precipitation process of 7xxx aluminum alloys [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(Al Special): 176-179. (in Chinese)

[9] ZHAO Z K, DU Z W, ZHOU T T, LIU P Y, CHEN C Q. Effect of double-ageing on precipitation hardening of Li containing Al-Zn-Mg-Cu alloys [J]. Materials Forum, 2004, 8: 429-432.

[10] BAI P C, ZHOU T T, LIU P Y, ZHANG Y G, CHEN C Q. Precipitates in a Li-containing Al8.4Zn1.35Mg1.76Mg (wt%) alloy [J]. Materials Science Forum, 2002, 396/402: 827-832.

[11] ZHAO Zhong-kui, BAI Pu-cun, ZHOU Tie-tao, LIU Pei-ying, CHEN Chang-qi. Effect of 1.0wt%Li on ageing hardening of Al-Zn-Mg-Cu alloys [J]. Journal of Aeronautical Materials, 2003, 23(2): 6-9. (in Chinese)

[12] GU Y J, WAHAB A, HUANG Z, ZHANG Y G; CHEN C Q. The structure transformation in an Al-Zn-Mg-Cu-Zr alloy [J]. Mater Sci Eng A, 2001, A316: 39-45.

[13] JI Yan-li, ZHOU Tie-tao, LIU Pei-ying. Thermodynamics-based constituent design of Li containing 7xxx series aluminum alloys [J]. Materials Science Forum, 2005, 475/479: 325-328.

(Edited by HE Xue-feng)

Foundation item: Project(2001AA332030) supported by the Advanced Materials Committee of China

Corresponding author: ZHAO Zhong-kui; Tel: +86-531-86367285; E-mail: jorezhk@163.com