文章编号:1004-0609(2007)03-0428-06

高强高导纳米复合材料CuCrZr/AlN的组织与性能

邓景泉,吴玉程,王文芳,黄新民

(合肥工业大学 材料学院,合肥 230009)

摘 要:采用粉末冶金方法制备高强高导铜合金基纳米复合材料(CuCrZr/AlN),用TEM、SEM等方法研究不同工艺条件如温度、压力、复压压力及复烧温度对复合材料组织与性能的影响。结果表明:烧结后的试样密度随压力、烧结温度的升高而增大,复压复烧后致密度达98%;试样抗弯强度随密度的增大而增大,复压复烧后,试样最大抗弯强度达到417 MPa;600 MPa复压950 ℃复烧试样的软化温度大于600 ℃;烧结温度为950和900 ℃,相对应的晶粒尺寸分别是0.26~0.44 μm和0.1~0.21 μm;材料的电导率随着密度的增大而增大,复压复烧后可以达到62%(IACS)。

关键词:CuCrZr/AlN;纳米复合材料;粉末冶金;电导率

中图分类号:TB 331; TF 125.2 文献标识码:A

Microstructure and properties of copper alloy based nano-AlN composite

DENG Jing-quan, WU Yu-cheng, WANG Wen-fang, HUANG Xin-min

(School of Materials and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The spot welding copper alloy based composite was prepared using PM method with high strength and high conductivity. The different preparing conditions such as pressure, sintering temperature, repressure and resintering temperature influences on microstructure and properties were also studied using TEM and SEM. The results show that the density increases with increasing pressure and sintering temperature and the buckling strength increases with increasing density. After repressure and resintering, the highest buckling strength reaches 417 MPa. The conductivities of the materials increase with increasing densities within certain range and reach 62%(IACS). The sintering temperatures are 950 and 900 ℃ and their grain sizes are 0.26-0.44 μm, 0.1-0.21 μm, respectively. Its softening temperature is bigger than 600 ℃.

Key words: CuCrZr/AlN; nano-composite; powder metallurgy; conductivity

铜及铜合金具有良好的力学性能,优良的耐 蚀、导热、导电性能。随着高新技术产业的发展,对铜及铜合金的综合性能要求越来越高,铜基复合材料应运而生[1-3],高强高导是铜基复合材料的基本要 求[4-5]。目前商用电极铜合金多为CuCr和CuCrZr,它们的极限抗拉强度在550 MPa左右,导电率在85%(IACS), 强度小,出现熔敷现象[6], 每辆汽车约有7 000~12 000个焊点[7],电极需频繁维护和更换, 生产效率降低和生产成本增加,所以研究铜电极复合材料具有实际意义。复合材料的制备方法有热化学法[8]、原位生成法[9]、电冶法[10]、冷变形法[11]和快速冷凝 法[12]等。但这些方法只停留在实验室阶段,离工业化生产还有一定距离。铸造方法生产的产品,组织及成分不均匀,特别是第二相陶瓷粒子分布不均匀,其高温热稳定性难以达到使用要求。粉末冶金是一种近净成型工艺,材料利用率高,可以有效消除组织和成分偏析,特别是第二相强化粒子分布相对均匀,而且其成分可以在较大范围内调整,通过优化工艺可制备出高性能、低成本的复合材料。AlN是一种新型陶瓷材料,六方纤锌矿结构的共价键化合物,其热导率高达320 W/(m?K),接近纯铜的热导率(398 W/(m?K)),是Al2O3热导率的12倍左右,比其他陶瓷粒子的热导率高20倍左右,分解温度2 200~2 250 ℃,而增强导热性能可相对提高导电率,所以AlN陶瓷粒子是强化基体但不显著降低其导电导热性能的最佳选择。

本文作者采用常规粉末冶金方法,结合复压复烧工艺,充分利用铜铬锆基体导电性好和氮化铝导热率高的优点,制备纳米AlN颗粒强化的高强高导铜合金复合材料。

1 实验

将Cu粉(粒径47 μm,纯度99%)、Cr粉(4~6 ?m,纯度99.99%)、Zr粉(4~6 ?m,纯度98%)和纳米AlN粉(~50 nm)按质量比96.9?2.5?0.5?0.1混合,在GN-2型高能球磨机上进行球磨。每次球磨粉量20 g。磨球采用经过调质处理的GCr15轴承钢球,球料比为10?1,球磨时用氩气保护。实验用球磨10 h的粉末,压制 使用769YP-40C压片机。在SK2-4-12管式烧结炉中烧结,用H2气氛保护,烧结时氢气流量控制在25~30 mL/s,在加热前先通10 min H2,然后加热,升温速率控制在10 ℃/min左右,烧结温度分别为950和900 ℃,烧结时间都是90 min。对900 ℃烧结的试样进行复 压复烧,复压压力比原生坯压力增加100 MPa,复 烧温度950 ℃,复烧时间90 min。按照国家标准 GB1999.14-88测量试样的密度。测硬度用NH5-3显微硬度计和HB-3000C电子布氏硬度计,实验中硬度值均取相似3个点的平均值;抗弯实验采用MTS 809 Axial/Torsional Test System仪器。试样电阻用凯尔文双臂电桥测量,然后换算为电导率;断口形貌用Sirion 200型场发射扫描电镜观察;组织形貌用日产透射电镜H800观察。

2 结果与分析

2.1 粉末的组织形貌

图1所示是铜、铬、锆和纳米AlN粉末球磨10 h后的TEM像。由图可知,通过高能球磨,粉末的颗粒尺寸明显减小,由于主要成分铜粉比较软,粉末颗粒呈现絮状。本实验过程中铜、铬、锆粉末经过高能球磨可能发生固溶,形成合金化粉末,粉末合金化可以活化烧结过程[13],细化的晶粒使粉末处于高能状态,能降低烧结温度,缩短烧结时间[14],提高生产效率。

图1 铜铬锆氮化铝粉末的TEM像

Fig.1 TEM image of CuCrZr-AlN powder

2.2 压制压力及烧结温度对密度的影响

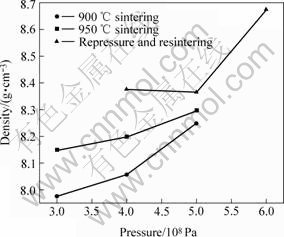

本实验中复合材料的理论密度为8.804 7 g/cm3。烧结前生坯的密度与粉末的性能、压制压力、每次的装粉量及模型内腔的粗糙度有关。经过球磨后,合金化和细化的粉末硬度提高,压制性能降低,为了提高成型能力,所以压制前对粉末进行去应力退火,以降低硬度。在同一模具且装粉量一定的前提下,压制压力分别为300、400和500 MPa时,生坯的相对密度分别为67%、70%和75%左右,孔隙率很大。试样经过900和950 ℃烧结后,其密度比烧结前的生坯增大,因为烧结过程中颗粒间的原子扩散使烧结颈的长大,烧结体的空隙减小。由图2可知,相同的压制压力下,烧结温度越高,烧结后的密度越大。随着压制压力的提高,烧结温度对密度的影响愈来愈小。复压复烧后的密度显著提高。600 MPa复压、950 ℃复烧后试样的相对密度达到98%。

图2 压制压力与密度的关系

Fig.2 Curves of density vs pressure

2.2 烧结温度对硬度的影响

在0.25 N保持10 s时,900 ℃烧结试样基体的显微硬度是85,950 ℃烧结试样基体的显微硬度是87;复压950 ℃复烧结后试样基体的显微硬度是86。从以上基体相的硬度值比较可看出,其变化不大;强化相增强体的硬度值变化相对较大,可能是不同强化相如Cr2Zr、Cr、Cu5Zr和Cu3Zr等所致。在烧结温度不同的情况下,基体的平均硬度值变化不大,说明原子高温固溶后,在随后的降温过程中发生时效脱溶而且达到了室温下的平衡状态,所以基体的平均硬度值变化不大。复压950 ℃复烧后的基体硬度值与950 ℃烧结的试样的基体硬度值近似,说明孔隙率大小对基体显微硬度影响不大。

实验中将直径2.5 mm的压头在压力625 N时保压30 s后,测量复合材料的布氏硬度。压力500 MPa,烧结温度900 ℃时,复合材料的硬度为HB145;烧结温度950 ℃,其硬度HB152,950 ℃复烧后其硬度是HB171。在压力相同时,材料的布氏硬度随烧结温度的提高而增大,一方面是因为随温度升高析出更多的强化相,另一方面是因为随温度升高材料密度提高的原因。同样的烧结温度,复压后试样的布氏硬度增大也说明是由于材料密度提高。

2.3 压制压力及烧结温度对抗弯强度的影响

由图3可知:烧结温度相同时,抗弯强度随着压制压力的增大而增大,主要是因为孔隙率降低,有效承载面积提高;压制压力相同时,随烧结温度的提高抗弯强度也逐渐增加,虽然随烧结温度的提高,晶粒越来越大,强度将降低,同时,孔隙率也将降低,有效承载面积提高。经过复压复烧工艺,可以显著提高试样的抗弯强度。可见,复压复烧工艺是提高材料抗弯强度的有效途径。根据经验公式[4],抗弯强度约为极限抗拉强度的一半大小,所以950 ℃复烧试样的极限抗拉强度大约为834 MPa。对于致密金属,晶粒尺寸大而强度降低。对于粉末冶金制品,致密度或间隙率、晶粒尺寸与强度的关系有待于进一步研究。

图3 压制压力与抗弯强度的关系

Fig. 3 Curves of bend strength vs pressure

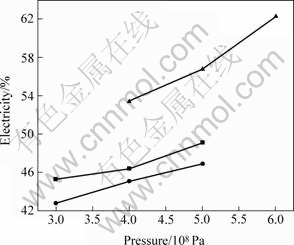

2.4 压制压力及烧结温度对电导率的影响

图4所示是压力与电导率的关系图,由图可知:相同烧结温度下,随着压制压力的增大,电导率增大,因为孔隙是影响电导率的主要因素,随着压制压力的增大,孔隙减少,导电面积增加。压制压力相同时,950 ℃烧结试样的导电率比900 ℃烧结试样的大,其原因是:一方面是孔隙率变小,导电面积的增加;另一重要原因是合金元素以固溶态存在时,将引起晶格畸变,对电子的散射作用大,从而降低合金的导电率,在烧结后的降温过程中,随着固溶元素Cr和Zr的析出,晶格畸变降低,对电子的散射作用小,提高了电导率。烧结温度高,晶粒进一步长大,晶界相对减少,界面的散射电阻减小,对电流的阻碍作用减小,电导率增大。

图4 压制压力与电导率的关系

Fig.4 Curves of conductivity vs pressure

试样经过复压复烧后,其导电率有很大提高。首先复压复烧有效地降低孔隙率,提高密度,导电面积增加;复压复烧过程中,发生了回复再结晶,强化相更加均匀分布,降低其散射电阻,位错密度的降低也使位错对电子的散射作用降低。综合分析,该合金的电导率在62% (IACS)之间时,导电性好[15]。

2.5 温度对微观组织性能的影响

2.5.1 金相分析

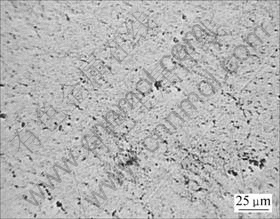

图5所示是铜复合材料烧结试样未侵蚀时的金相照片,观察未经侵蚀的金相试样可以了解铜复合材料中氮化物第二相以及空隙缺陷的分布。由图5可知,白色的是基体,黑色的为第二相或者是烧结后留下的孔洞,黑色相弥散均匀分布在基体中,根据Owan强化机制,强化相可以起到很好的强化效果,同时说明球磨使纳米AlN均匀分布。

图5 未浸蚀烧结试样的金相照片

Fig.5 Metallograph of sample without erosion

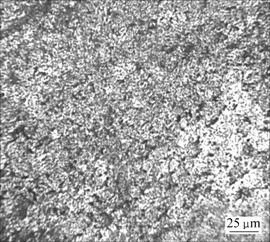

试样用FeCl3盐酸水溶液侵蚀,图6中样品的烧结温度为900 ℃,金相组织相对细密,图7中样品的烧结温度为950 ℃,晶粒进一步长大,金相组织致密性较差,颗粒分布不均匀,并带有块状的结构。烧结温度升高,孔隙变小,烧结体变得更为致密。图8中,白色的条状区域大致呈几何对称分布,是孪晶组织。孪晶的形成与堆垛层错有密切关系,它阻碍了位错的运动,可以达到强化的效果[3, 8]。所以孪晶强化也是该合金强化机制之一。

图6 900 ℃烧结试样的金相照片(500 MPa)

Fig.6 Metallograph of sample sintered at 900 ℃

图7 950 ℃烧结试样金相照片(500 MPa)

Fig.7 Metallograph of sample sintered at 900 ℃ and 500 MPa

图8 950 ℃烧结试样金相(500 MPa)

Fig.8 Metallograph of sample sintered at 950 ℃

2.5.2 TEM分析

图9所示是950 ℃烧结试样的晶粒形貌,晶粒尺寸的范围是0.26~0.44 μm,图10所示是900 ℃烧结试样的晶粒形貌,晶粒尺寸范围是0.10~0.21 μm。从图9和10可以看出随着烧结温度的升高,晶粒进一步长大,空隙有一定圆化。压制压力不高是产生空隙的原因之一,即使压制压力很高基体Cu与纳米AlN之间的界面不润湿也是产生空隙的原因。如何改善基体Cu与纳米AlN之间的界面润湿性有待于研究。对物相进行电子衍射分析,分析可知黑色颗粒是面心立方结构,是铜基体。在烧结温度不同的情况下,基体的平均硬度值变化不大。金属原子高温固溶后,在随后的降温过程中发生完全脱溶,产生了过时效,基体基本上是纯铜,所以平均硬度值变化不大。

图9 950 ℃烧结试样的TEM像

Fig.9 TEM image of sintering sample at 950 ℃

图10 900 ℃烧结试样的TEM像

Fig.10 TEM image of sintering sample at 900 ℃

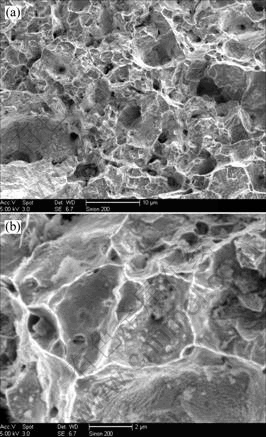

2.5.3 断口分析

由试样的宏观断口形貌可知:孔隙率大时,断口平齐,无明显塑性变形,呈现脆性断裂特点;孔隙率小时,有明显塑性变形,表面呈纤维状粗糙不平,表面颜色灰暗无结晶颗粒无金属光泽,呈现延性断裂特点。由图11(a)所示的典型韧窝断口可以看出存在很多黑洞,说明存在孔隙。图11(b)表明韧窝底部有第二相粒子存在,可能是Cr2Zr、Cr、Cu5Zr和Cu3Zr等。夹杂物或第二相在韧窝断裂中起重要作用。

图11 试样的断口SEM像

Fig.11 Fractural SEM images of sample

3 结论

1) 复压复烧工艺有效提高试样致密度,当其达到 98%时,抗拉强度达到800 MPa。

2) 铜合金复合材料(CuCrZr/AlN)经复压复烧后,最大电导率为62%(IACS)。

3) 铜合金复合材料(CuCrZr/AlN)断口呈现塑性断裂特点,韧窝底部有第二相分布。

REFERENCES

[1] Moustafa S F, Abdel-Hamid Z, Abd-Elhay A M. Copper matrix SiC and Al2O3 particulate composites by powder metallurgy technique[J]. Materials Letters, 2002, 53: 244-249.

[2] Ma Z Y, Tjong S C. High temperature creep behavior of in-situ TiB2 particulate reinforced copper-based composite[J]. Mater Sci Eng A, 2000, A284: 70-76.

[3] Leprince-Wang Y, Han K, Huang Y, et al. Microstructure in Cu-Nb microcomposites[J]. Mater Sci Eng A, 2003, A351: 214-223.

[4] Dadras M M, Morris D G. Examination of some high-conductivity copper alloys for high-temperature applications[J]. Scripta Materialia, 1997, 38(2): 199-205

[5] ZHAN Yong-zhong, ZHANG Guo-ding. The effect of interfacial modifying on the mechanical and wear properties of SiCp/Cu composites[J]. Materials Letters, 2003, 57(29): 4583-459.

[6] Tsai H C, Yan B H, Huang F Y. EDM performance of Cr/Cu-based composite electrodes[J]. International Journal of Machine Tools & Manufacture, 2003, 43: 245-252.

[7] Huh H, Kang W J. Electrothermal analysis of electric resistance spot welding processes by a 3-D finite element method[J]. Journal of Materials Processing Technology, 1997, 63: 672-677.

[8] Lee D W, Kim B K. Nanostructured Cu-Al2O3 composite produced by thermochemical process for electrode application[J]. Materials Letters, 2004, 58: 378-383.

[9] Motta M S, Jena P K, Brocchi E A, et al. Characterization of Cu-Al 2O 3 nano-scale composites synthesized by in situ reduction[J]. Mater Sci Eng C, 2001, 15: 175-177.

[10] ZHU Jian-hua, LIU Lei, HU Guo-hua, et al. Study on composite electroforming of Cu/SiCp composites[J]. Materials Letters, 2004, 58: 1634-1637.

[11] Lopes F, Reyes J, Campillo B. Rapid solidification of copper alloys with high strength and high conductivity[J]. Journal of Materials Engineering and Performance, 1997, 6(5): 611-614.

[12] Choi H L, Lee K Y, Kwun S I. Fabrication of high strength and high conductivity copper alloys by rod milling[J]. Journal of Materials Science Letters, 1997, 16(1): 1600-1602.

[13] Balaz P, Gock E. Preparation of nanocrystalline materials by high-energy milling[J]. Mater Sci Eng A, 1999, A266(3/4), 442-446.

[14] Zarrinfar N, Kennedy A R, Shipway P H. Reaction synthesis of Cu-TiCx master-alloys for the production of copper-based composites[J]. Scripta Materialia, 2004, 50: 949-952.

[15] Chang Shou-Yi, Chen Chi-Fang, Lin Su-Jien, Theo Z. Kattamis. Electrical resistivity of metal matrix composites [J]. Acta Materialia, 2003, 51(20): 6191-6197.

基金项目:安徽省“十五”二期科技攻关资助项目(040020392);合肥市重点科技攻关资助项目(20051044)

收稿日期:2006-09-04;修订日期:2007-01-15

通讯作者:吴玉程,教授;电话:0551-2905085; E-mail: ycwu@hfut.edu.cn

(编辑 龙怀中)