文章编号:1004-0609(2011)09-2195-07

Al-Cu合金凝固微观组织的三维模拟及优化

卜晓兵1, 2, 李落星1, 2, 张立强2, 朱必武2, 王水平2

(1. 湖南大学 汽车车身先进设计与制造国家重点实验室,长沙 410082;

2. 湖南大学 材料科学与工程学院,长沙 410082)

摘 要:采用CA-FE模型,对同一铸件不同尺寸的Al-2%Cu合金凝固微观组织进行三维模拟及预测,并引入空位形成能对固相扩散系数进行了优化。结果表明,当铸件直径分别为20、40和60 mm时,柱状晶占总晶体比率分别为65.2%、52.1%和21.4%,逐渐减少,而等轴晶所占比率逐渐增加;当换热系数由500 W/(m2·K)增大到5 000 W/(m2·K)时,同一铸件中不同直径的铸件凝固组织中柱状晶组织比例显著增大。模拟结果与实验结果吻合较好,能够较为准确地反映等轴晶和柱状晶的分布位置、比例和大小。

关键词:Al-Cu合金;3D元胞自动机;固相,扩散系数;凝固组织

中图分类号:TG292 文献标志码:A

Three-dimensional numerical simulation and optimization of solidification structure of Al-Cu alloy

BU Xiao-bing1, 2, LI Luo-xing1, 2, ZHANG Li-qiang2, ZHU Bi-wu2, WANG Shui-ping2

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body,

Hunan University, Changsha 410082, China;

2. College of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: A 3D cellular automaton-finite element (CA-FE) method was used to predict the solidification structure of Al-Cu alloy at different casting radii, and optimized the solution diffusion coefficient in solid phase. The results show that when the casting radius changes from 10 mm to 30 mm, the proportion of columnar grains changes from 65.2% to 21.4%. With increasing heat transfer coefficient from 500 W/(m2·K) to 5 000 W/(m2·K), the proportion of columnar grains also gradually increases. The simulated results are in accord with the experimental ones well, and can accurately reflect the distribution, proportion, size of equiaxed and columnar grains.

Key words: Al-Cu alloy; 3D cellular automation method; solid phase; solution diffusion coefficient; solidification structure

铸件中的细小晶粒能够提高材料的强度与韧性,因而预测微观组织形成是控制晶粒尺寸、形貌和铸件产品质量的重要前提。自OLDFIELD等对微观组织模拟开展研究以来,微观组织数值模拟的研究经历了由定性模拟到定量模拟,再由单纯金属凝固组织模拟到多元合金凝固组织模拟的历程,并形成了不同模拟方法:确定性模拟、随机性模拟、相场法等[1-4]。

元胞自动机法是一种随机性模拟,该方法以形核过程的物理机制和晶体生长动力学理论为基础,可以得到晶粒的尺寸、大小及分布,也可以描述柱状晶、等轴晶的形成及柱状晶向等轴晶的转变过程。该方法模拟的微观组织不依赖计算过程中的单元网格划分结构。RAPPAZ等[2]把晶粒的形核与长大的物理机制引入到模型中,提出采用基于高斯分布的连续性形核方法分别处理型壁和液体中形核,并考虑了晶核的晶体学位向关系和枝晶尖端的生长动力学,成功预测了从柱状晶到等轴晶的转变并得到了实验验证;GANDIN等[5-8]将宏观温度场与微观组织形成相结合来模拟在宏观温度场下微观组织的形成与演化。康秀红等[9]、许庆彦等[10]也开展了相应的工作,考虑了凝固过程中温度场的分布、凝固过程溶质再分配以及对流等因素的影响,实现了对金属凝固组织的计算机模拟。ZHU等[11-21]改进了CA方法,将枝晶尖端生长所需的过冷度用KGT模型来描述,修正了枝晶尖端生产仅依赖于热过冷的模型。

本文作者采用元胞自动机耦合有限差分的方法(CA-FE),模拟了同一铸件不同半径Al-2%Cu合金凝固组织的形貌,探究并模拟同一铸件中不同壁厚对晶粒大小、密度形核参数等对柱状晶向等轴晶转变的影响;预测金属凝固过程中柱状晶等轴晶的转变;计算合金的固相扩散系数时,通过引入了空位形成能提高了模拟的准确性。

1 固相溶质扩散系数的优化

凝固过程中,溶质分布是影响枝晶生长和形貌的重要因素,溶质扩散的模拟是进行微观组织模拟的一个重要方面。

模拟溶质扩散时,可以采用下面两种方法。

1) 溶质扩散采用Scheil模型:假设固相中不存在扩散,液相完全混合。

Scheil模型表达式为

(1)

(1)

式中: 为固液界面上液相平衡浓度;k为平衡溶质分配系数;c0为合金初始浓度;fL为液相份数。

为固液界面上液相平衡浓度;k为平衡溶质分配系数;c0为合金初始浓度;fL为液相份数。

固相扩散系数是CA模拟中重要的晶体生长参数,影响浓度场的计算。物质的迁移可通过对流和扩散两种方式进行。但实际凝固过程中固相中是存在扩散的,固体中不发生对流,扩散是唯一的物质迁移方式。为了提高模拟的准确性,采用下面的方法。

2) 用液相扩散系数和固相扩散系数描述液相和固相扩散过程。在固相晶体中存在空位,这些空位的存在使原子迁移变得更容易,从而产生原子空位跳跃迁移能,该迁移能等于原子的扩散激活能Q,通过菲克第一定律可以计算出固相扩散系数。

(2)

(2)

而实验测得的Al-Cu合金固相扩散系数和菲克定律计算的值差别很大,这个差别可以用铜在铝中以空位机制扩散解释,除了考虑空位迁移能外,还必须考虑扩散原子近旁空位的形成能。铜原子周围空位形成的几率可用空位平衡浓度(ne/N)表示,所以真正的扩散系数应为

(3)

(3)

式中: ,ne为平衡空穴的数目;N为阵点总数;?Ef为空位形成能。

,ne为平衡空穴的数目;N为阵点总数;?Ef为空位形成能。

因此,真正的固相扩散系数应该修改为 ,?Ef测量值约为96.3 kJ/mol。铜在铝基体合金中的扩散常数为0.84×10-5 m2/s。在计算铝铜合金的固相扩散系数时,要引入空位形成能。固相扩散系数计算结果参见表1。

,?Ef测量值约为96.3 kJ/mol。铜在铝基体合金中的扩散常数为0.84×10-5 m2/s。在计算铝铜合金的固相扩散系数时,要引入空位形成能。固相扩散系数计算结果参见表1。

2 基于CA方法的宏-微观耦合模拟

2.1 宏观温度场的计算

温度场的模拟计算是微观组织模拟的前提。液体金属充满铸型以后,金属和铸型之间的导热主要以不稳定的导热方程进行。宏观温度场的计算采用有限元方法(FE)求解,三维宏观温度场不稳定导热方程为

(4)

(4)

式中:ρ为密度,g/cm3;cp为定压比热容,J/(kg·℃);θ为温度,℃;t为时间,s;λ为热传导率,W/(m·℃);

Q为热源项, ;L为熔化潜热,J/kg;φs为固相率;x,y和z为坐标值,m。

;L为熔化潜热,J/kg;φs为固相率;x,y和z为坐标值,m。

辐射换热按照Stefen-Boltzman定律: ,T为表面的绝对温度,ε为辐射黑度;

,T为表面的绝对温度,ε为辐射黑度; 为Stefen-Boltzman常数。

为Stefen-Boltzman常数。

2.2 形核模型

形核采用RAPPAZ等[22-23]提出的基于高斯分布的连续形核模型,利用统计方法,假设形核现象发生在一系列不同的形核位置上(忽略形核本身所需要的时间,即形核是瞬时出现),这些形核位置由连续非离散的分布函数dn/d(?T)来描述。在某一过冷度?T所形成的晶粒密度n(?T)即可由对该分布曲线的积分求得:

(5)

(5)

式中:dn/d(?T′)的表达式为

(6)

(6)

式中:?TN为平均形核过冷度;?Tσ为标准曲率过冷度;nmax为异质形核衬底的数目。

2.3 生长模型

生长模型采用由KURZ等[24]提出的枝晶尖端生长动力学模型,即KGT模型

(7)

(7)

(8)

(8)

(9)

(9)

式中:?Tc 为溶质扩散引起的成分过冷度;?Tt 为热扩散引起的过冷度;?Tk 为动力学过冷度;?Tr 为固/液界面引起的曲率过冷度。

在正常凝固条件下,后三项数值较小,近似有?T=?Tc,Ω为枝晶尖端溶质过饱和度,R为枝晶尖端半径,Gc为枝晶前沿液相中的溶质浓度梯度,G为温度梯度,Γ为Gibbs-Thompson系数,m为液相线斜率,Pe为溶质的Peclet数的函数,在低速生长时取1,D为液相内的溶质扩散系数,v为枝晶尖端生长速度。

3 实验

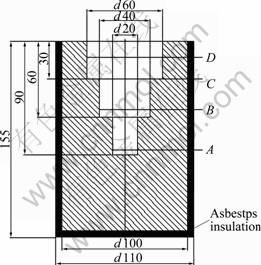

铸锭材料选择Al-2%Cu合金。铸型形状及尺寸如图1所示。为了减少纵向热对流对微观组织的影响,铸型材料选用钢板,铸型底部和四周用保温石棉包好,产生绝热效果。冷却过程采取空冷方式。图1中A、B、C位置沿横切面剖开,分别对同一铸件中直径为20、40和60 mm的横切面进行粗磨、细磨和抛光后采用氢氟酸进行腐蚀5 s,便可以观察到不同直径的晶粒 组织。

图1 铸型形状示意图

Fig.1 Shape and dimensions of experimental casting mold(unit: mm)

4 模拟结果及分析

采用CAF?模型,计算尺寸与实验铸件一致。铸件尺寸为600 mm×100 mm×150 mm,宏观网格划分为1 mm,微观计算时网格再细分为100×100×100。在模拟宏观温度场时,铸件和铸型之间的换热系数设置为2 kW/(m2·K),铸型顶部与空气的换热系数设置为100 W/(m2·K)。形核参数如表1所列。

表1 所使用材料的性能和模拟参数

Table 1 Material properties and model parameters used in simulations

4.1 不同铸造半径下凝固组织的模拟分析

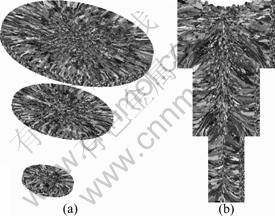

铸件尺寸是影响凝固组织的重要因素,由图2可以看出,铸件微观组织由表层细晶区,柱状晶区和中心等轴晶区3部分组成。

图2 铸件横切面三维凝固组织和纵切面三维凝固组织模拟图

Fig.2 Transverse (a) and upright section (b) of three- dimensional results

液态Al-Cu合金注入铸型后,由于型壁温度低,与型壁接触的一层很薄熔液产生强烈过冷,同时型壁还可作为非均匀形核的基底,导致立刻形成大量的晶核,并且这些晶核迅速长大,互相接触,形成细小、方向杂乱的等轴晶粒。这些晶核很快就因彼此碰撞而无法继续生长,由图2(a)可以看出,在不同铸件尺寸的表面均形成一层很薄很细的等轴晶区。

随着细晶区外壳的生成,铸件的型壁被熔液加热而不断升温,使剩余液体的冷却速度变慢,并且由于结晶释放潜热,细晶区前沿液体的过冷度减小,形核变得困难,只有细晶区中现有的晶体向液体中生长,且只有一次轴垂直于型壁(散热最快的方向)的晶体才能得到优先生长,而其他取向的晶粒,由于受邻近的限制而不能发展。因此,这些与散热相反方向的晶体择优生长而形成柱状晶区。随着铸造尺寸的增加,柱状晶占总晶体比率减小,分别为65.2%、52.1%和21.4%,而等轴晶比率增加。这是由于柱状晶生长到一定程度,越小尺寸的前沿液体越远离型壁,散热困难,冷却速度变慢,而且熔液中的温差随之减小,这将阻止柱状晶的快速生长,当整个熔液温度降到熔点以下时,熔液中出现许多晶核并沿着各个方向生长,形成等轴晶区。

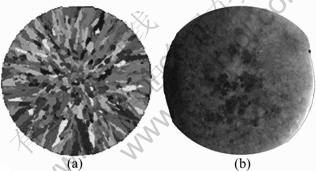

如果铸型不加热,采用室温,则熔体冷却速度快,凝固过程中,已形核的晶粒根据其不同的相对位置和择优取向,邻近枝晶较早开始相互接触形成晶界并制约了对方的生长,使晶粒没有足够的时间长大,故形成的晶粒较为细小,在铸造尺寸较小时(20 mm),以等轴晶为主。而实验中铸型加热至250 ℃,铸造冷却速度慢,形核率低,晶核具有充足的时间生长,因此形成的晶粒比较粗大。在铸件尺寸较小时,以柱状晶为主。

4.2 不同冷却强度下凝固组织的预测

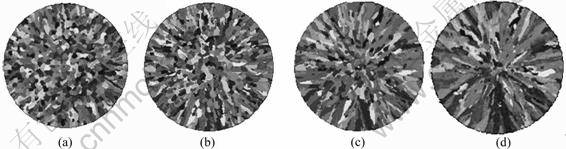

冷却强度也是影响铸件凝固组织的主要因素之一,常被用来控制凝固组织的形成。实验中,铸件壁面与铸型的换热系数设置为2 kW/(m2·K),并且分别在不同换热系数下对直径20、40和60 mm的铸件进行了模拟。

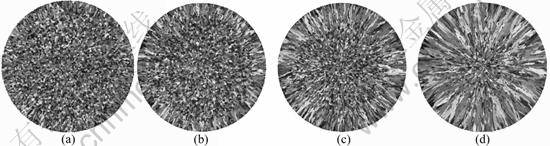

对比图3~5可以看出,随着换热系数(h)从500 W/(m2·K)增大到5 000 W/(m2·K),不同半径的铸件凝固组织中柱状晶比例显著增大,而同样半径的铸件中晶粒度变化并不大。这是由于当换热系数较小时,液体金属在铸型壁上形成稳定凝固壳层的时间较长,晶体从铸型壁处游离出来的过程也较长,游离晶粒增多,而游离到液体中的晶粒又可以阻止柱状晶的形成,进而使柱状晶区域变小;反之,当换热系数较大时,液态金属在铸型壁上形成稳定的凝固壳层时间较短,一旦稳定的凝固壳层形成,柱状晶就直接由表面细等轴晶凝固层中的晶粒为基底向内生长,发展成由外向内生长的柱状晶区,有利于柱状晶的形成。

图3 直径20 mm铸件的凝固组织模拟图

Fig.3 Predicted grain structures of d20 mm casting: (a) h=500 W/(m2·K); (b) h=1 000 W/(m2·K); (c) h=2 000 W/(m2·K); (d) h= 5 000 W/(m2·K)

图4 直径40 mm铸件的凝固组织模拟图

Fig.4 Predicted grain structures of d40 mm casting: (a) h=500 W/(m2·K); (b) h=1 000 W/(m2·K); (c) h=2 000 W/(m2·K); (d) h=5 000 W/(m2·K)

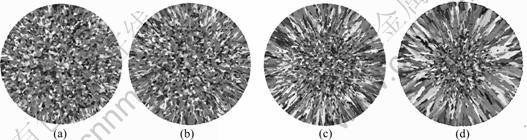

图5 直径60 mm铸件的凝固组织模拟图

Fig.5 Predicted grain structures of d60 mm casting: (a) h=5 00 W/(m2·K); (b) h=1 000 W/(m2·K); (c) h=2 000 W/(m2·K); (d) h=5 000 W/(m2·K)

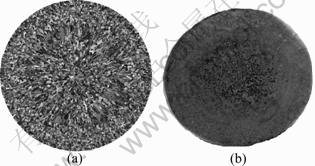

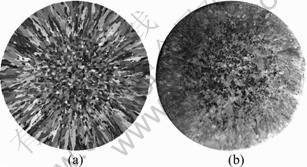

4.3 凝固组织模拟实验验证

铸件尺寸如图1所示,由3个不同壁厚和半径的圆柱组成:1) 壁厚150 mm,直径60 mm;2) 壁厚450 mm,直径40 mm;3) 壁厚750 mm,直径20 mm。铸件的浇注温度720 ℃,铸型温度250 ℃, 铸件三维凝固组织模拟结果如图2所示,截面厚度均为4 mm。比较图6~8可以发现,采用CAF?模型进行模拟的结果与实验结果能较好吻合,能够较为准确的反应出等轴晶和柱状晶的分布位置、比例和大小等。如图6所示,对直径60 mm的横截面进行微观组织模拟时,横截面为图1中C位置(高125 mm处,直径60 mm和直径40 mm的交界面)断面。此横截面外侧20 mm厚的部分直接铸型接触,形成较粗的等轴晶;而与直径40 mm铸件直接接触的部分,先形成柱状晶,再形成较细的等轴晶。所以,三维CAF?模型是模拟铸件凝固组织的一种有效模型,应用CAF?模型研究了浇注温度和冷却强度对晶粒组织的影响。

图6 直径60 mm铸件凝固组织的模拟结果和实验结果

Fig.6 Predicted (a) and experimental(b) solidification grain structures of d60 mm casting

图7 直径40 mm铸件凝固组织的模拟结果和实验结果

Fig.7 Predicted (a) and experimental (b) solidification grain structures of d40 mm casting

图8 直径20 mm铸件凝固组织的模拟结果和实验结果

Fig.8 Predicted (a) and experimental (b) solidification grain structures of d 20 mm casting

5 结论

1) 采用有限元和元胞自动机结合的CA-FE模型,通过加入空位形成能的固相扩散系数,对Al-Cu合金的凝固组织进行了三维模拟和预测,其结果能够准确地反映等轴晶和柱状晶的分布位置、比例和大小等。

2) 随着铸件尺寸的增加,铸件凝固组织中柱状晶占总晶体比率减小,分别为65.2%、52.1%和21.4%,而等轴晶比率增加。

3) 当换热系数由从500W /(m2·K)增大到5 000 W/(m2·K)时,铸件凝固组织中柱状晶比例显著增大,而同样铸造半径的晶粒度变化并不大。

REFERENCES

[1] OLDFIELD W. A quantitative approach to casting solidification: Freezing of cast iron[J]. ASM Trans, 1966, 59(2): 945-960.

[2] RAPPAZ M, GANDIN C A. DESBIOLLES J L, THEVOZ P H. Prediction of grain structures in various solidification processes[J]. Metallurgical and Materials Transactions A, 1996, 27(3): 695-705.

[3] ZHU P P, SMITH R W. Dynamic simulation of crystal growth by Monte-Carlo method[J]. Acta Metall, 1992, 40(12): 3369-3379.

[4] PENROSE O, FIFE P C. Thermodynamically consistent models of phase field type for the kinetics of phase transitions[J]. Physical D, 1990, 43(10): 44-62.

[5] GANDIN C A, DESBIOLLES J L, RAPPAZ M, THEVOZ P H. A three-dimensional cellular-finite element model for the prediction of solidification grain structures[J]. Metall Master Trans A, 1999, 30(12): 3153-3165.

[6] GUILLEMOT G, GANDIN, C A, BELLET M. Modeling of casting, welding and advanced solidification processes Ⅺ[M]. Warrendale, PA: TMS, 2006: 307-314.

[7] GUILLEMOT G, GANDIN C A, COMBEAU H. Modeling of macrosegregation and solidification grain structures with a coupled cellular automation finite element model[J]. ISIJ Int, 2006, 46: 880-895.

[8] GUILLEMOT G, GANDIN C A, BELLET M. Interaction between single grain solidification and macroseg-regation: Application of a cellular automaton-finite element model[J]. Crystal Growth, 2007, 303(1): 58-68.

[9] 康秀红, 杜 强, 李殿中, 李依依. 用元胞自动机与宏观传输模型耦合方法模拟凝固组织[J]. 金属学报, 2004, 40(5): 452-456.

KANG Xiu-hong, DU Qiang, LI Dian-zhong, LI Yi-yi. Modeling of the solidification microstructure evolution by coupling cellular automaton with macrotransport model [J]. Acta Metallrugica Sinica, 2004, 40(5): 452-456.

[10] 许庆彦, 冯伟明, 柳百成, 熊守美. 铝合金枝晶生长的数值模拟[J]. 金属学报, 2002, 38(8): 799-803.

XU Qing-yan, FENG Wei-ming, LIU Bai-cheng, XIONG Shou-mei. Numerical simulation of dendrite growth of aluminum alloy[J]. Acta Metallrugica Sinica, 2002, 38(8): 799-803.

[11] ZHU M F, HONG C P. A modified cellular automation model for the simulation of dendritic growth in solidification of alloys[J]. ISIJ Int, 2001, 41(5): 436-445.

[12] 陈 晋, 朱鸣芳, 孙国雄. 用CA方法模拟过冷熔体中自由树枝晶的生长[J]. 金属学报, 2005, 41(8): 799-803.

CHEN Jin, ZHU Ming-fang, SUN Guo-xiong. Numerical simulation on free dendrite growth in undercooled melt using cellular automaton method[J]. Acta Metallurgica Sinica, 2005, 41(8): 799-803.

[13] 朱鸣芳, 于 金, 戴 挺. 金属凝固过程数值模拟的最新进展[J]. 铸造, 2005, 54(2): 115-120.

ZHU Ming-fang, YU Jin, DAI Ting. Recent progress in numerical modeling of solidification processes[J]. Foundry, 2005, 54(2): 115-120.

[14] 陈 晋, 朱鸣芳, 孙国雄. 过冷熔体中的树枝晶分枝机制模拟[J]. 铸造, 2005, 54(9): 895-898.

CHEN Jin, ZHU Ming-fang, SUN Guo-xiong. Numerical simulation on dendrite branching in undercooled melt[J]. Foundry, 2005, 54(9): 895-898.

[15] 苏 敏, 孙东科, 朱鸣芳. Lattice Boltzmann方法在枝晶生长模拟中的应用[J]. 机械工程材料, 2007, 31(2): 75-78.

SU Min, SUN Dong-ke, ZHU Ming-fang. Application of Lattice Boltzmann method in modeling of dendritic growth[J]. Materials For Mechanical Engineering, 2007, 31(2): 75-78.

[16] ZHU M F, CAO W, CHEN S L, HONG C P, CHANG Y A. Modeling of microstructure and microsegregation in solidification of multi-component alloys[J]. Phase Equilibria and Diffusion, 2007, 28(1): 130-138.

[17] ZHU M F, STEFANESCU D M. Virtual front tracking model for the quantitative modeling of dendritic growth in solidification of alloys[J]. Acta Mater, 2007, 55(5): 1741-1755.

[18] ZHU M F, HONG C P, STEFANESCU D M, CHANG Y A. Computational modeling of microstructure evolution in solidification of aluminum alloys[J]. Metall Mater Trans B, 2007, 38(4): 517-524.

[19] ZHU M F, DAI T, LEE S Y, HONG C P. Modeling of solutal dendritic growth with melt convection[J]. Computers and Mathematics with Applications, 2008, 55(7): 1620-1628.

[20] 杨朝蓉, 孙东科, 潘诗琰, 戴 挺, 朱鸣芳. CA-LBM模型模拟自然对流作用下的枝晶生长[J]. 金属学报, 2009, 45(1): 43-50.

YANG Chao-rong, SUN Dong-ke, PAN Shi-yan, DAI Ting, ZHU Ming-fang. CA-LBM model for the simulation of dendritic growth under natural convection[J]. Acta Metallurgica Sinica, 2009, 45(1): 43-50.

[21] PAN S Y, ZHU M F. A three-dimensional sharp interface model for the quantitative simulation of solutal dendritic growth[J]. Acta Materialia, 2010, 58(1): 340-352.

[22] RAPPAZ M, GANDIN C A. Probabilistic modeling of microstructure formation in solidification processes[J]. Acta Materialia, 1993, 41(12): 345-360.

[23] GANDIN C A, RAPPAZ M. A coupled finite element-celluar automaton model for the prediction of dendritic grain structure in solidification processes[J]. Acta Metall Mater, 1994, 42(7): 2233-2246.

[24] KURZ W, GIOVANOLA B, TRIVEDI R. Theory of microstructural development during rapid solidification[J]. Acta Metall Mater, 1986, 34(5): 823-830.

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51075132);湖南省杰出青年基金资助项目(09JJ1007);高等学院博士点专相科研基金资助项目(20090161110027);湖南大学汽车车身先进设计制造国家重点实验室自主研究课题项目(60870005)

收稿日期:2010-07-19;修订日期:2010-12-28

通信作者:李落星;教师,博士;电话:0731-88821445; E-mail:llxly2000@163.com