Thermal expansion and mechanical properties of high reinforcement content SiCp/Cu composites fabricated by squeeze casting technology

CHEN Guo-qin(陈国钦)1, XIU Zi-yang(修子扬)1, MENG Song-he(孟松鹤)2,

WU Gao-hui(武高辉)1, ZHU De-zhi(朱德志)1

1. School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China;

2. Center for Composite Materials, Harbin Institute of Technology, Harbin 150001, China

Received 10 August 2009; accepted 15 September 2009

Abstract: High reinforcement content SiCp/Cu composites (φp=50%, 55% and 60%) for electronic packaging applications were fabricated by patent cost-effective squeeze-casting technology. The composites appear to be free of pores, and the SiC particles are distribute uniformly in the composites. The mean linear coefficients of thermal expansion (CTEs, 20-100 ℃) of as-cast SiCp/Cu composites range from 8.8×10-6 ℃-1 to 9.9×10-6 ℃-1 and decrease with the increase of SiC content. The experimental CTEs of as-cast SiCp/Cu composites agree well with the predicted values based on Kerner model. The CTEs of composites reduce after annealing treatment due to the fact that the internal stress of the composite is released. The Brinell hardness increases from 272.3 to 313.2, and the modulus increases from 186 GPa to 210 GPa for the corresponding composites. The bending strength is larger than 374 MPa, but no obvious trend between bending strength and SiCp content is observed.

Key words: SiCp/Cu composites; electronic packaging; thermal expansion coefficient; mechanical properties

1 Introduction

Packaging materials should have low coefficient of thermal expansion (CTE), high thermal conductivity and high mechanical strength. With the rapid development of the electronic technology, traditional electronic packing materials, such as Cu, Al, Mo, W, Kovar alloy and Invar alloy, could not meet the demands, and electronic packing materials with higher properties should be developed[1-3]. Therefore, exploration of material fabrication and development of new packaging materials have received growing attention.

Particulate reinforced copper matrix composite combines the benefits of compatible and tailorable CTE, high thermal conductivity, enhanced specific strength and stiffness. So, it has been identified as an ideal candidate for electronic packing material[4-5]. Al2O3/Cu, SiC/Cu, W/Cu and Mo/Cu are developed for electronic packing application, and according to rule of mixture (ROM), high volume fraction of reinforcement should be introduced into copper matrix to obtain low CTE matching ceramic substrates and semiconductors. However, if volume fraction of reinforcement exceeds 40%, the composite fabricated by conventional powder metallurgy would be poor in machining property and has high porosity, which would decrease their mechanical, electrical and thermal conductivity properties[6-7].

In this study, SiCp/Cu composites with the reinforcement content of 50%, 55% and 60%(volume fraction) were fabricated by the patent squeeze casting technology, and their thermal expansion and mechanical properties were tested and analyzed.

2 Experimental

2.1 Materials preparation

The reinforcement selected in the study is the high pure silicon particles with nominal diameter of 10 μm. The matrix alloy is the commercially available pure copper (T3), whose nominal compositions (mass fraction, %) are 0.01% As, 0.05% Fe, 0.20% Ni, 0.01% Pb, 0.05% Sn, 0.1% O, and balance Cu. Table 1 shows the basic properties of SiC particles and T3 pure copper. The SiCp/Cu composite was fabricated by the patent squeeze casting process.

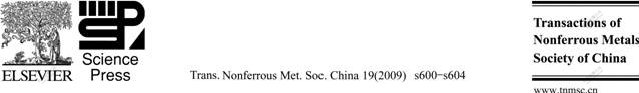

Table 1 Properties of SiC particles and Cu

2.2 Experimental

The fabricated composite specimen was examined by Hitachi-S4700 SEM. The composites were annealed in vacuum at 700 ℃ for 1.5 h and furnace cooled in order to release residual stress within the composites. The CTEs of SiCp/Cu composites were measured on a DIL 402C (NETZSCH Corp.) at heating rate of 5 ℃/min. According to GB4339—84, the linear CTEs were gained between 0 ℃ and 100 ℃ based on the measured curves of relative length changes versus temperature. To diminish systematic errors, the dilatometer was calibrated by measuring an alumina sample under identical condition.

Brinell hardness (HB) tests were performed on a HBV-30 double-purpose tester with a 1 mm ball indenter. A load of 300 N was applied and maintained for 30 s. Three-point bending tests with 30 mm span were carried out at room temperature on an Instron5569 universal electron tension testing system. The specimens were all 3 mm in width, 4 mm in thickness and 36 mm in length. Fractography observations were carried out also on S-570 SEM.

3 Results and discussion

3.1 Microstructure

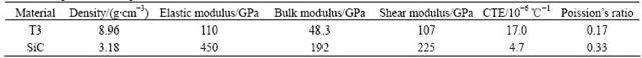

Figs.1(a), (b) and (c) show the microstructures of as-cast SiCp/Cu composites with reinforcement content of 50%, 55% and 60%, respectively. SiC particles have irregular shape and are distributed uniformly in the composites, without any particle clustering. As the result of the high pressure employed during composite fabrication, the molten aluminum alloy infiltrated the particle preform entirely. Consequently, the composite material appeared to be free of pores. A dense microstructure could improve its thermal conductivity, dimensional stability as well as strength, which leads to an improvement in service life[8].

3.2 Thermal expansion properties

The measured CTEs of as-cast SiCp/Cu composites are 9.9×10-6, 9.4×10-6 and 8.8×10-6 ℃-1 for the 50%, 55% and 60% composites, respectively. The CTEs reduce with the increase of SiC content. They are close to that of Si chip and can greatly meet the CTE requirement in electronic packaging. In SiCp/Cu composite, the thermal expansion of copper matrix would be restricted by SiC particles via interfacial restriction effect, and the effect increases with the increase of reinforcement content, which leads to the decrease of the CET of composite[9].

Fig.1 Microstructures of SiCp/Cu composites: (a) 50%SiCp/Cu; (b) 55%SiCp/Cu; (c) 60%SiCp/Cu

The CTEs of 50%, 55%, and 60%SiCp/Cu composites after annealing treatment are 9.2×10-6, 8.3×10-6 and 7.6×10-6 ℃-1, decreasing by 0.7×10-6, 1.1×10-6 and 1.2×10-6 ℃-1 compared with as-cast composite, respectively. Annealing treatment leads to a lower value of CTE because it lessens the residual thermal stress induced during fabricating process[10].

The SiCp/Cu composites were fabricated by squeeze casting process. The CET difference between Cu matrix and SiC particles is very large. However, the thermal expansion behaviour of Cu matrix is not free during composite fabricating process because of SiC/Cu interfacial restriction, which imposes residual tensile stress on matrix around SiC particles. Afterwards, the temperature variation ΔT would generate residual strain during thermal expansion testing. In elastic state, it would generate complex internal stress and corresponding strain.

Therefore, the expansion of composite comprises two parts: expansion from ROM and expansion generated by internal stress[11-12].

Neglecting shear stress, Cu matrix only undertakes normal stress σx, σy and σz, and with particles distributed uniformly in composite, then σx=σy=σz=σ(σ is average internal stress). According to the generalized Hooke’s Law, there is

(1)

(1)

where Em is elastic modulus, v is Poission’s ratio.

Thus, the expansions generated by internal stress are same in all directions. Hence, considering x direction, the composite expansion could be expressed as follows:

(2)

(2)

where αROM is CET from ROM.

Let σ=σ0+σΔT, then

(3)

(3)

where σ0 is residual stress in matrix at room temperature, σΔT is average internal stress in matrix when the temperature change is ΔT.

The CTE of composite could be expressed as follows:

(4)

(4)

The CTE of composite is composed of CTE from ROM and CTE from internal stress. The CTE from internal stress is related to residual stress in matrix and average internal stress in matrix during temperature rising process. The residual stress in matrix decreases after annealing treatment, which leads to decrease of the CTE from internal stress, and decrease of the CTE of composite.

Composite comprises reinforcement and matrix, which affect its thermal expansion behaviour. When temperature is changed, the expansion of matrix is restricted by reinforcement, and vice versa. Furthermore, CTE difference between constituents would generate internal stress, which would increase or decrease the CTE of composite[13].

The main theoretical models for the CTEs of a composite include[14-16]:

1) Rule of mixture (ROM)[14]:

(5)

(5)

2) Turner model[15]: Turner considers the uniform hydrostatic stresses and gives the CTE of a composite as

(6)

(6)

3) Kerner model[16]: Both the normal and shear stress are taken into account in Kerner model, and the CTE of a composite is expressed as

(7)

(7)

where αc, αm and αp are the CTEs of composite, matrix and particle reinforcement, respectively; Km and Kp are the bulk modulus of matrix and reinforcement; φm and φp are the fractions of matrix and reinforcement; Gm is the shear modulus of matrix.

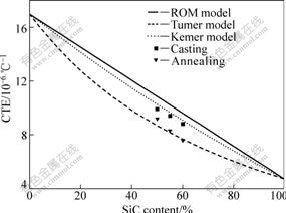

In the present study, the calculated results are compared with the measured results in Fig.2. It is obvious that the experimental CTEs of as-cast composite are close to Kerner model while CTEs of annealed composite are close to Turner model. This is because that the internal stress decreases greatly after annealing treatment, which is close to Turner model that composite undertakes isostatic pressure.

Fig.2 Comparisons between theoretical predictions and experimental CTEs

3.3 Mechanical properties

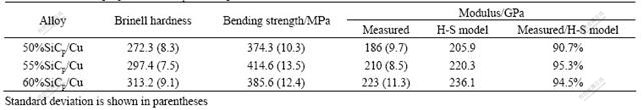

The mechanical properties of SiCp/Cu composites are shown in Table 2. As shown in Table 2, the hardness of SiCp/Cu composites increases with the increase of SiC content. This could be attributed to the fact that the effective loading volume increases as the volume fraction of SiC increases.

Table 2 Mechanical properties of SiCp/Cu composites

The bending strengths of SiCp/Cu composites are larger than 370 MPa, But no obvious trend between bending strength and SiC content is observed. It is believed that larger SiC particles in the higher φp of composites tend to fracture brittlely because larger SiC particles have many larger defects and the bending stress of SiC is dominated by the largest flaw. Therefore, besides SiC content concerned, some other factors such as particle size and particle defects would influence the bending strength of the composite. Fig.3 shows the bending fractographs of SiCp/Cu composites. The matrix fails in a ductile manner, especially in the 50%SiCp/Cu composite, as shown in Fig.3(a). The SiC particles

Fig.3 SEM bending fractographs of SiCp/Cu composites: (a) 50%SiCp/Cu; (b) 55%SiCp/Cu; (c) 60%SiCp/Cu

fracture brittlely, and some facets are found in the larger SiC particle, indicating that fracture propagates through the particles with shear mode.

However, the module of SiCp/Cu composites increases as the volume fraction of SiC increases. A Hashin-Shtrikman model (H-S model)[17] was used to predict the modulus of SiCp/Cu composites. In this model, the modulus Ec of a composite is expressed as

(8)

(8)

The calculated data were also presented in Table 2. It could be found that the measured modulus is lower than the theoretical values, but reach 90% of them, indicating that H-S model is valid for the prediction of composite modulus.

4 Conclusions

1) High reinforcement content SiCp/Cu composites (φp=50%, 55% and 60%) were fabricated by squeeze casting technology. The composites are free of pores, and SiC particles distribute uniformly in the composite.

2) CTEs of as-cast SiCp/Cu composites between 20 ℃ and 100 ℃ range from 8.8×10-6 to 9.9×10-6 ℃-1 and decrease with the increase of SiCp content. The experimental CTEs of as-cast SiCp/Cu composites agree well with the predicted values based on Kerner model. Annealing treatment can lessen the residual thermal stress in matrix and decrease the CTE of composite. The experimental CTEs of annealed SiCp/Cu composites agree well with the predicted values based on Turner model.

3) The Brinell hardness and modulus of SiCp/Cu composites increase with the increase of the volume fraction of SiCp, and the bending strength is larger than 370 MPa, but no obvious trend between bending strength and SiCp content is observed.

References

[1] ZWEBEN C. Advances in composite materials for thermal management in electronic packaging [J]. Journal of the Minerals, Metals and Materials Society, 1998, 50(6): 47-51.

[2] HE H, FU R L, SHEN Y, HAN Y C, SONG X F. Preparation and properties of Si3N4/PS composites used for electronic packaging [J]. Composites Science and Technology, 2007, 67(11/12): 2493-2499.

[3] RASHID E S A, ARIFFIN K, KOOI C C, AKIL H M. Preparation and properties of POSS/epoxy composites for electronic packaging applications [J]. Materials and Design, 2009, 30(1): 1-8.

[4] SCHUBERT T H, TRINDADE B, WEIBG?RBER T, KIEBACK B. Interfacial design of Cu-based composites prepared by powder metallurgy for heat sink applications [J]. Materials Science and Engineering A, 2008, 475A(1/2): 39-44.

[5] HO P W, LI Q F, FUH J Y H. Evaluation of W-Cu metal matrix composites produced by powder injection molding and liquid infiltration [J]. Materials Science and Engineering A, 2008, 485A(1/2): 657-633.

[6] SCHUBERT T H, BRENDEL A, SCHMID K, KOECK T H, CIUPI?SKI ?, ZIELI?SKI W, WEIBG?RBER T, KIEBACK B. Interfacial design of Cu/SiC composites prepared by powder metallurgy for heat sink applications [J]. Composite Part A: Applied Science and Manufacturing, 2007, 38(12): 2398-2403.

[7] ZHANG L, QU X H, HE X B, DUAN B H, REN S B, QIN M L. Thermo-physical and mechanical properties of high volume fraction SiCp/Cu composites prepared by pressureless infiltration [J]. Materials Science and Engineering A, 2008, 489A: 285-293.

[8] CHEN Guo-qing, JIANG Long-tao, WU Gao-hui, ZHU De-zhi, XIU Zi-yang. Fabrication and characterization of high dense Mo/Cu composites for electronic packaging applications [J]. Trans Nonferrous Met Soc China, 2007, 17(s1): 580-583.

[9] ZHANG Q, WU G H, JIANG L T, CHEN G Q. Thermal expansion and dimensional stability of Al-Si matrix composite reinforced with high content SiC [J]. Materials Chemistry and Physics, 2003, 82(3): 780-785.

[10] XIU Zi-yang, WU Gao-hui, ZHANG Qiang, SONG Mei-hui, TIAN Shou-fu. Microstructure and electric properties of Sip/Al composites for electronic packaging applications [J]. Trans Nonferrous Met Soc China, 2007, 17(s1): 1034-1038.

[11] PARK C S, KIM M H, LEE C M. A theoretical approach for the thermal expansion behavior of the particulate reinforced aluminum matrix composite [J]. Journal of Materials Science, 2001, 36: 3579-3587.

[12] SHU K M, Tu G C. The microstructure and the thermal expansion characteristics of Cu/SiCp composites [J]. Materials Science and Engineering A, 2003, 349: 236-247.

[13] XIU Zi-yang, WU Gao-hui, ZHANG Qiang, SONG Mei-hui. Thermo-physical properties of Sip/LD11 composites for electronic packaging [J]. Trans Nonferrous Met Soc China, 2005, 15(s2): 227-230.

[14] ZHAO L Z, ZHAO M J, CAO X M, TIAN C, HU W P, ZHANG J S. Thermal expansion of a novel hybrid SiC foam-SiC particles-Al composites [J]. Composites Science and Technology, 2007, 67(15/16): 3404-3408.

[15] TURNER P S. Thermal expansion stresses in reinforced plastics [J]. Journal of Research of the National Bureau of Standards, 1946, 37: 239-248.

[16] KERNER E H. The elastic and thermo-elastic properties of composite media [P]. Proceedings of the Physical Society, 1956, 69: 808-815.

(Edited by CHEN Ai-hua)

Foundation item: Project(20080430895) supported by China Postdoctoral Science Foundation; Project(2003AA5CG041) supported by the High-tech Research and Development Program of Harbin City, China

Corresponding author: CHEN Guo-qin; Tel: +86-451-86402372-5058; E-mail: chenguoqin@hit.edu.cn