Displacement behavior and mechanism of long-term water flooding in sandstone oil reservoirs

来源期刊:中南大学学报(英文版)2021年第3期

论文作者:曹仁义 戴宗 王志凯 王亚会 江俊 李海龙 贾志豪

文章页码:834 - 847

Key words:long-term water flooding; sandstone reservoir; relative permeability curve; wettability

Abstract: Sandstone oil reservoirs with huge bottom water and high permeability are generally developed with high flow rate. After long-term water flooding (LTWF), the water flooding characteristics are quite different from that of original reservoir. In this paper, the effects of the PV number, viscosity, and displacement rate during LTWF are studied through experiments. The mechanism is analyzed based on analysis of changes in oil composition, rock mineral composition and wettability. The oil-water relative permeability curves, oil recovery and wettability were obtained with new experiments methods, which avoids the oil metering error by measuring oil and water separately. The research indicates that when the viscosity increases, the water phase permeability decreases, the residual oil saturation increases, and the water content rate increases earlier. A higher water flooding rate results in a higher ultimate recovery. A higher asphaltene content results in a higher viscosity and more oil-wet reservoir conditions. After LTWF, the wettability tends to water-wet, which is more favorable for heavy oil recovery. Moreover, LTWF reduces the clay content, which creates a more water-wet surface and a larger reservoir pore throat environment. This research provides insightful characteristics of offshore sandstone oil reservoirs, which can be used to enhance oil recovery.

Cite this article as: CAO Ren-yi, DAI Zong, WANG Zhi-kai, WANG Ya-hui, JIANG Jun, LI hai-long, JIA Zhi-hao. Displacement behavior and mechanism of long-term water flooding in sandstone oil reservoirs [J]. Journal of Central South University, 2021, 28(3): 834-847. DOI: https://doi.org/10.1007/s11771-021-4648-3.

J. Cent. South Univ. (2021) 28: 834-847

DOI: https://doi.org/10.1007/s11771-021-4648-3

CAO Ren-yi(曹仁义)1, 2, DAI Zong(戴宗)3, WANG Zhi-kai(王志凯)1, WANG Ya-hui(王亚会)3,

JIANG Jun(江俊)1, LI hai-long(李海龙)3, JIA Zhi-hao(贾志豪)1

1. College of Petroleum Engineering, China University of Petroleum (Beijing), Beijing 102249, China;

2. State Key Laboratory of Petroleum Resources and Prospecting, China University of Petroleum (Beijing), Beijing 102249, China;

3. China National Offshore Oil Corporation, Shenzhen Branch, Shenzhen 518054, China

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Central South University Press and Springer-Verlag GmbH Germany, part of Springer Nature 2021

Abstract: Sandstone oil reservoirs with huge bottom water and high permeability are generally developed with high flow rate. After long-term water flooding (LTWF), the water flooding characteristics are quite different from that of original reservoir. In this paper, the effects of the PV number, viscosity, and displacement rate during LTWF are studied through experiments. The mechanism is analyzed based on analysis of changes in oil composition, rock mineral composition and wettability. The oil-water relative permeability curves, oil recovery and wettability were obtained with new experiments methods, which avoids the oil metering error by measuring oil and water separately. The research indicates that when the viscosity increases, the water phase permeability decreases, the residual oil saturation increases, and the water content rate increases earlier. A higher water flooding rate results in a higher ultimate recovery. A higher asphaltene content results in a higher viscosity and more oil-wet reservoir conditions. After LTWF, the wettability tends to water-wet, which is more favorable for heavy oil recovery. Moreover, LTWF reduces the clay content, which creates a more water-wet surface and a larger reservoir pore throat environment. This research provides insightful characteristics of offshore sandstone oil reservoirs, which can be used to enhance oil recovery.

Key words: long-term water flooding; sandstone reservoir; relative permeability curve; wettability

Cite this article as: CAO Ren-yi, DAI Zong, WANG Zhi-kai, WANG Ya-hui, JIANG Jun, LI hai-long, JIA Zhi-hao. Displacement behavior and mechanism of long-term water flooding in sandstone oil reservoirs [J]. Journal of Central South University, 2021, 28(3): 834-847. DOI: https://doi.org/10.1007/s11771-021-4648-3.

1 Introduction

With the growing worldwide demand for oil, field developments have focused on offshore oilfields [1-3]. Enhanced oil recovery (EOR) processes have been applied for many years. EOR involves the displacement of crude oil by other fluids in a heterogeneous reservoir. Generally, water flooding or chemical flooding is used to improve recovery in an offshore oilfield, and water plays a critical role in the management of operations throughout the life of an oilfield [4-6]. However, offshore sandstone reservoirs usually have strong edge-bottom water, and water flooding is more economical and environmentally friendly than chemical EOR flooding. Thus, more attention has been paid to natural water flooding in offshore oilfield development.

Conventional water flooding, which involves artificial water flooding and natural water flooding, is an important process used to recover additional oil and to maintain reservoir pressure for a longer productive life. CARLL [7] concluded that the water entering sands will flow through the oil sands and increase oil recovery. Until the early 1950 s, water flooding was recognized and generally applied to oil fields. Early researchers extensively investigated the fundamental displacement mechanism behind water flow in porous media and determined that water flooding involves the substitution of water for oil [8, 9]. However, some researchers have found that the different properties of rocks and fluids, such as the wettability and relative permeability, dramatically influence oil recovery [10].

In light of these early methods of water flooding, several studies have found that the quality of water injected into petroleum reservoirs is as important as the quantity injected, which is called low-salinity water flooding (LSWF) [11]. A number of studies have shown that during low-salinity water flooding, ions can be exchanged between the injected water and the rock. This leads to the adsorption of divalent ions and mineral dissolution, which changes the wettability to water-wet and enhances oil recovery [12-15], and it can also lead to changes in the relative permeability [16-20].

Wettability is an important factor, which affects oil recovery in water flooding. In the past, oil reservoirs were commonly interpreted to be strongly water-wet because the water phase is generally the initial fluid in contact with the reservoir rock. However, several researchers have found that many reservoir rocks are not strongly water-wet [21, 22]. The latter results were obtained without considering the natural surfactants in crude oil, such as asphalt and paraffin substances, which are easily absorbed on the solid-liquid interface and change the reservoir rocks to oil-wet [23-25]. BUCKLEY et al [24] used one-dimensional water flooding experiments to confirm that a higher water flooding recovery can be obtained for a strongly water-wet core.

Recently, with the large-scale development of offshore oilfields, an increasing number of scholars have found that wettability can be similarly changed through natural water flooding instead of LSWF. Thus, reservoir engineers came up with the concept of long-term water flooding (LTWF), which means that the pore volume (PV) of water exceeds 100PV [26-28]. One-dimensional displacement experiments with high pore volume (PV) of injected water show that the changes in the wettability and pore structure during long-term water flooding reduced the critical capillary number and the residual oil saturation [29]. Great significance is attached to the proposal of LTWF for increasing fluid production in offshore oilfields. However, the microscopic interaction between the different components of the fluids and rocks has rarely been investigated after long-term water flooding.

In this paper, the conventional water flooding experimental procedures were modified to simulate the process of LTWF in order to investigate the characteristics of the oil-water relative permeability, wettability, and displacement efficiency during the process. Moreover, the influences of the core permeability, oil viscosity, and displacement velocity on these characteristics were also studied. Finally, the contact angle measurement, mercury intrusion method, and SARA (saturates, aromatics, resins, and asphaltenes) analyses were conducted to study the mechanisms of the wettability alteration of heavy oil reservoirs from a microscopic perspective.

2 Materials and methods

2.1 Materials preparation

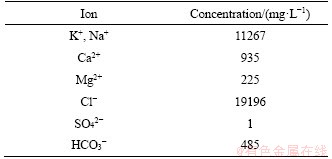

In this study, the brine is formation water with a salinity of 32109 mg/L, and the ion content is shown in Table 1.

Table 1 Ion content and salinity of brine

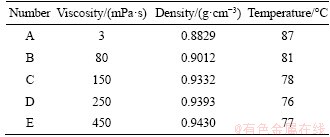

The oil is degassed oil from a reservoir in the eastern South China Sea. The composition and viscosity of the crude oil at the formation temperature are shown in Table 2.

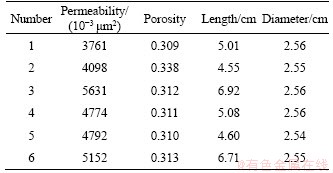

The cores are underground core samples of heavy oil sandstone reservoirs. The basic parameters of the cores are shown in Table 3.

Table 2 Physical properties of crude oil at formation temperature

Table 3 Parameters of cores

2.2 Experimental schemes and procedures

In traditional water flooding experiments, the limit of water flooding is generally selected as the point when 30 multiples of the pore volume (PV number) water are injected. For long-term water flooding, the mirror rule was used to determine the pore volume of the injected water. The bottom water reservoir, which has a 2226 m3/d daily fluid production rate, has been produced for 5 years, and the length and diameter of the core are 6 and 2.5 cm, respectively, so the PV number of the injected water is 2000. In addition, the displacement speed can be obtained as 2 mL/min. To better analyze the LTWF phase, we define the traditional water flooding stage as (0-30)PV and the LTWF stage as (30-2000)PV.

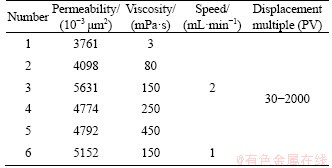

In order to study the effects of the different factors, five viscosities and two displacement speeds were selected. The experimental schemes are shown in Table 4.

Table 4 LTWF experimental design

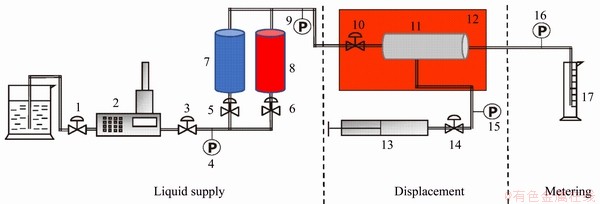

The experiment equipment used for the LTWF experiments consists of a liquid supply system, a displacement system, and a metering system. The liquid supply system includes a high-pressure constant-current pump (500 HP, Teledyne ISCO,. SA), an intermediate water container, and an intermediate oil container (ZR-2, HKY, China). The volume of the intermediate container is 20 L to ensure continuous displacement during the LTWF. The displacement system includes a core holder, a hand pump to provide confining pressure, and an incubator to provide formation temperature. The metering system mainly includes two pressure gauges and an oil-water separator.

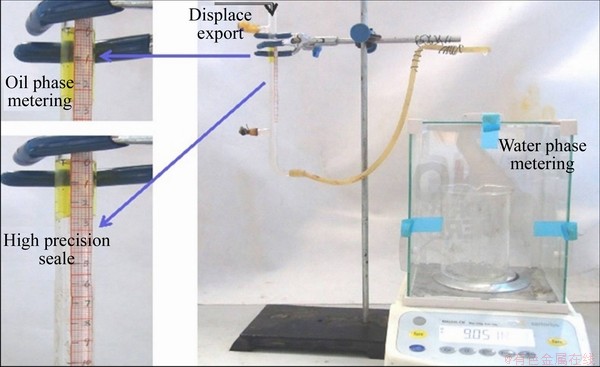

As shown in Figure 2, the oil-water separator system includes an oil phase meter and a water phase meter. The oil and water are measured independently, which avoids the metering error caused by the oil-water mixing zone.

Figure 1 Schematic of LTWF experiment (1, 3, 5, 6, 10, 14-Valves; 2-Constant flow pump; 4, 9, 15, 16-Pressure gauges; 7-Intermediate container (Water); 8-Intermediate container (Oil); 11-Core holder; 12-Incubator; 13-Hand pump; 17-Measuring bottle)

Figure 2 Oil-water separator (The oil and water are measured independently, which avoids the oil metering error caused by the oil-water mixing zone existing in the existing device due to the density difference separation [30])

The detailed procedures for the water flooding experiments are as follows.

1) The cores were completely dried in a 108 °C incubator. Then, their weights, lengths, diameters, and gas permeabilities were measured.

2) The cores were saturated with water for 12 h using a vacuum pump, and then they were driven by formation water for 10PV at low speed with 2 MPa of confining pressure. The wet weights of the cores were measured to determine their porosities.

3) The cores saturated with water were driven by the oil until the bound water saturation had a flow rate of 0.5 mL/min. Then, the cores with established irreducible water saturation were placed in an incubator and aged for 15 d at the formation temperature.

4) The aged cores were driven by the brine to 2000PV at a constant flow rate (1 or 2 mL/min). The breakthrough time, the cumulative oil/fluid production, and the displacement pressure difference at both ends of the core were accurately recorded. The recording density was increased in the initial stage of water flooding. As the oil production decreases, the recording time interval gradually increases.

3 Results and discussion

The effects of LTWF on the reservoir production dynamics are mainly characterized by changes in the oil recovery (△S), the residual oil saturation (Sor), and the water content (fw). In addition, the variation in the relative permeability curves at different water flooding stages can be used to characterize the changes in the interaction between the reservoir rocks and fluids. The production dynamic statistics can be obtained by recording the fluid and oil production during the experiment, and the relative permeability curves can be obtained using the J.B.N (Johnson, Bossler, and Neumann) method.

3.1 Effect of PV number

In order to study the effects of PV number on the reservoir production dynamics and the relative permeability curves, cores with different experimental conditions were selected for analysis.

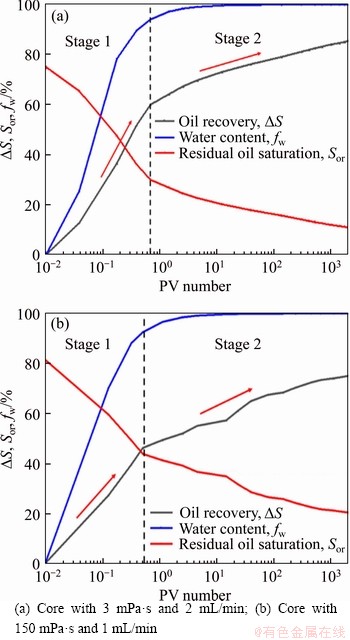

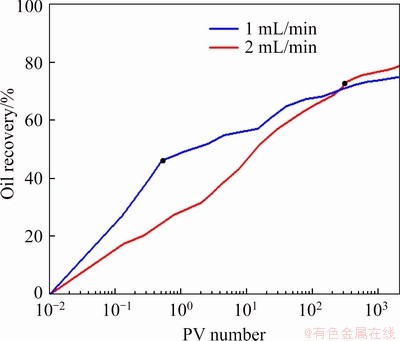

As shown in Figure 3, as the PV number increases, the water content increases rapidly, and the water content has reached 90% or more before the PV number reaches 30PV. At the end of the traditional water flooding stage, the reservoirs are usually already in the high water cut stage. In semi-logarithmic coordinates, the displacement efficiency and residual oil saturation change with the PV number, exhibiting a two-stage characteristic. When the PV number is small, the displacement efficiency increases rapidly. As the PV number increases, the rate of increase of the oil displacement efficiency becomes slower. There are obvious differences in the reservoir production dynamics of the traditional water flooding stage and the LTWF stage.

Figure 3 Effect of PV number on oil recovery/water content/residual oil saturation (fw was measured from the fluid and oil produced, and △S and Sor were measured from the original oil saturation and oil production):

These changes are related not only to the changes in the oil saturation of the reservoir but also to the properties of the crude oil and reservoir rocks. The relative permeability curve is one of the characteristics of the interaction between the reservoir rocks and fluids.

As shown in Figure 4, as the PV number increases, the range of the simultaneous flow increases, the residual oil saturation decreases, and the water phase permeability under the residual oil saturation increases. When the PV number is greater than 30, the tendency of the relative permeability curve to change with PV number becomes slower.

Figure 4 Effect of PV number on relative permeability curve (The relative permeability curves were calculated using the JBN method):

3.2 Effect of displacement rate

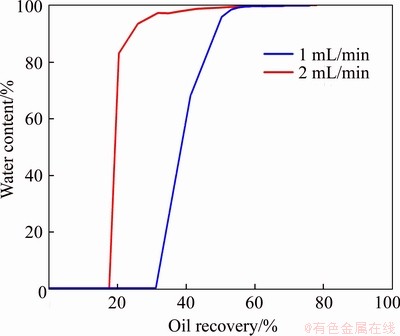

The injection rate is one of the important production system parameters of the reservoir. As shown in Figure 5, when the displacement speed is higher, the breakthrough recovery is lower, and the water-rising rate is faster. The ultimate recovery from a reservoir with a lower speed is slightly lower. However, the two-stage characteristics of the two speeds vary widely.

As shown in Figure 6, the lower the displacement speed, the earlier the characteristic appears, which leads to a higher oil recovery from low-speed water flooding at a lower PV number. This may be due to the fact that the increase in water content is well controlled when the displacement speed is low, and more crude oil can be recovered in the early stage than at a higher displacement rate. This phenomenon led us to investigate the different displacement speeds in the different stages.

Figure 5 Change in water content with oil recovery for different displacement speeds (The experimental parameters of the two groups are the same except for the displacement speed)

Figure 6 Change in oil recovery with PV number for different displacement speeds (The displacement speed is one of the factors influencing the two-stage characteristic)

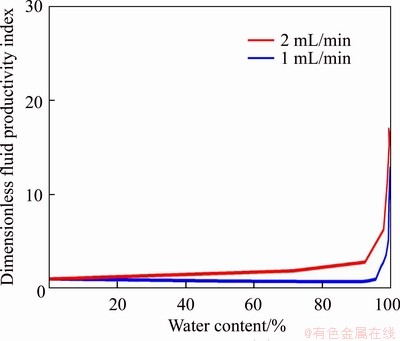

The dimensionless fluid productivity index is the ratio of the fluid productivity index at a certain water content to the initial fluid productivity index, which can be used to evaluate the oilfield’s fluid productivity ability at a certain water content. The characteristic curve characterizes the fluid extraction ability of the oil wells and the optimal fluid extraction timing. As shown in Figure 7, the dimensionless fluid productivity index increases faster, which indicates that the reservoir has a higher fluid extraction ability in the high water content stage. For reservoirs developed by pure water flooding, in the early stage of water flooding development, low-speed water flooding should be used. After the breakthrough, high-speed water flooding can be used.

Figure 7 Dimensionless fluid productivity index of different speed changes with water content

3.3 Effect of oil viscosity

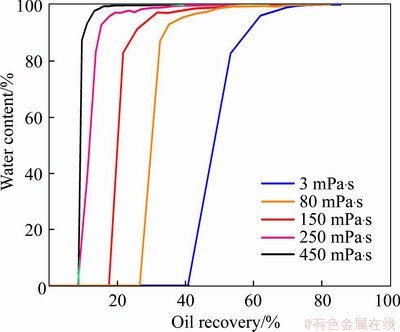

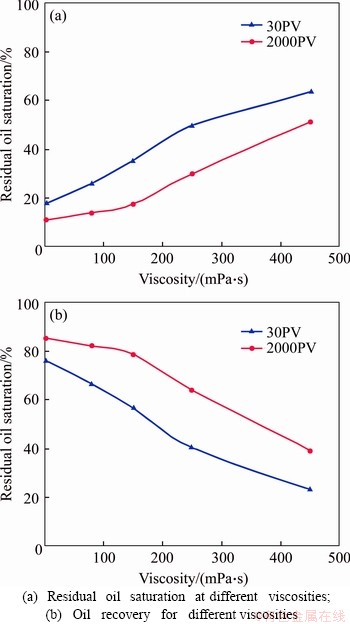

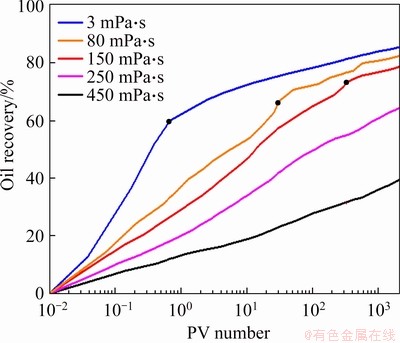

Viscosity is an important factor affecting the reservoir production dynamics in different stages. When the viscosity of crude oil is low, the breakthrough recovery is high, and the increase rate of the water content is slow. The breakthrough recovery is fairly low when the viscosity is larger than 250 mPa·s (Figure 8). At the same PV number (30PV, 2000PV), as the viscosity increases, the oil recovery efficiency decreases continuously, and the residual oil saturation increases accordingly (Figure 9). In addition, the two-stage characteristic appears backward until it disappears (within 2000PV). As shown in Figure 10, when the viscosity is 80 mPa·s, the two-stage characteristic occurs when the PV number is 30. This characteristic disappears when the viscosity of the oil reaches 250 mPa·s. This indicates that the higher the crude oil viscosity, the greater the contribution of the LTWF stage to the oil recovery.

Figure 8 Variation in water content with oil recovery for different viscosities (The PV number corresponding to the endpoint of oil recovery is 2000PV)

Figure 9 Residual oil saturation and oil recovery efficiency at different viscosities for same PV number (30PV and 2000PV):

Figure 10 Change in oil recovery with PV number at different viscosities (The viscosity of crude oil ranges from 30 mPa·s to 450 mPa·s)

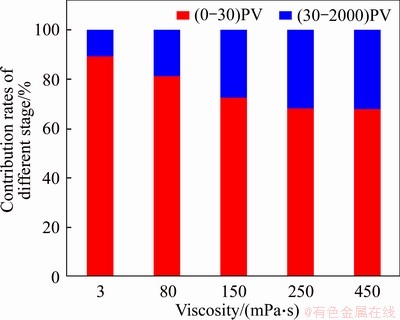

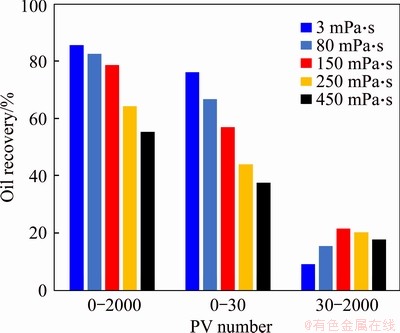

In order to clarify the contribution of the LTWF stage to oil recovery from reservoirs with different viscosities, the oil recovery and the contribution rates of the different water flooding stages are shown in Figrures 11 and 12. Based on the contribution rates of the different stages to the oil recovery (Figure 11), as the viscosity of the crude oil increases, the contribution rate of the LTWF stage ((30-2000)PV) gradually increases, indicating that the effect of LTWF on improving the oil displacement efficiency in reservoirs with a high crude oil viscosity is more significant.

Figure 11 Contribution rates of different stages for different viscosities (The contribution rates of the different stages were calculated as the recovery in the corresponding stage divided by the ultimate recovery)

Figure 12 Oil recovery for different PV number and viscosities (Here, (0-30)PV is traditional water flooding stage, and (30-2000)PV is LTWF stage)

By comparing the absolute value of the oil recovery in different water flooding stages for different oil viscosities (Figure 12), it was found that as the viscosity of the crude oil increases, the ultimate recovery and the oil recovery of the traditional water flooding stage decrease. However, the oil recovery in the LTWF stage initially increases and then decreases when the viscosity increases. This indicates that for certain reservoir conditions, there is an optimal oil viscosity, which results in the highest oil recovery in the LTWF stage.

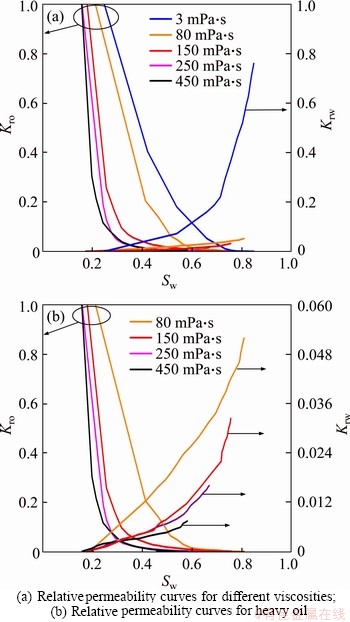

There is also a large difference in the permeability curves for the different viscosities (Figure 13). The higher the crude oil viscosity, the higher the irreducible water saturation, and the lower the water saturation corresponding to the point of equal permeability. The range of the simultaneous flow decreases with increasing crude oil viscosity. The right sides of the water phase permeability curves of crude oils with different viscosities differ significantly, the thin oils are higher, and the heavy oils are extremely low.

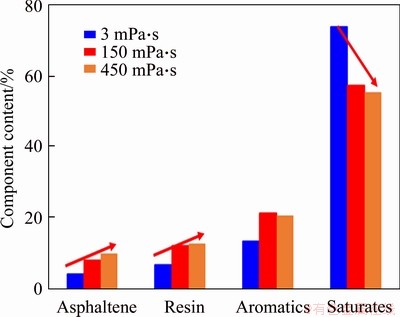

The influence of oil properties is determined by the composition of the oil. In order to analyze the effects of the oil components, the SARA fractions of the oil were obtained using TLC/FID analysis [31].

As shown in Figure 14, the asphaltene and resin content increases, resulting in increasing of crude oil viscosity. Changes in the asphaltene and resin content can also cause dramatic changes in the viscosity-temperature characteristics of the oil [32]. As the resin and asphaltene content increases, the viscosity of the crude oil increases, and the permeability of the oil phase on the relative permeability curve decreases, which contributes to the decrease in oil recovery. Changes in the asphaltene content also affect the wettability of the rock’s surface [33] as well as the characteristics of the water flooding development.

Figure 13 Relative permeability curves for different viscosities (The water phase permeability of thin oil is significantly higher than that of heavy oil):

Figure 14 Saturates-aromatics-resins-asphaltenes (SARA) composition of oil (A higher crude oil viscosity corresponds to higher asphaltene and gum contents)

3.4 Mechanism of fluid-rock property changes during LTWF

As was previously discussed, the production dynamics and relative permeability in the LTWF stage are quite different from those in the traditional water flooding stage. This is due to the modification of the reservoir rock and fluid properties by water flooding. In order to analyze the transformation mechanism, the oil composition, wettability, mineral composition, and pore throat structure were analyzed before and after the LTWF.

3.4.1 Mechanism of water-wet enhancement

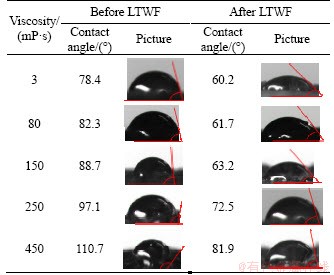

Wettability is one of the important factors affecting the water flooding characteristics. It is generally believed that neutral-wet to slightly water-wet is favorable wetting conditions for water flooding [34]. The wettability is measured using the contact angle measurements [35]. To eliminate surface roughness and the mineral composition of the different core sections , a 5-point fitting method was used to determine the core contact angle [30, 36]. For cores 1-5, the core’s initial wettability was measured before displacement, and then the wettability was measured a second time after 2000PV of continuous displacement to obtain the final wettability. DAI et al [30] performed a separate analysis of the wettability.

As shown in Table 5, the contact angles of the cores increase with increasing viscosity, which indicates that the reservoir becomes more oil-wet as the viscosity increases. This can be explained based on the changes in the composition of the crude oil. As the viscosity increases, the content of polar materials like asphaltenes increase, which experience strong interfacial activity and can be adsorbed onto the rock’s surface, promote oil-wet enhancement [37].

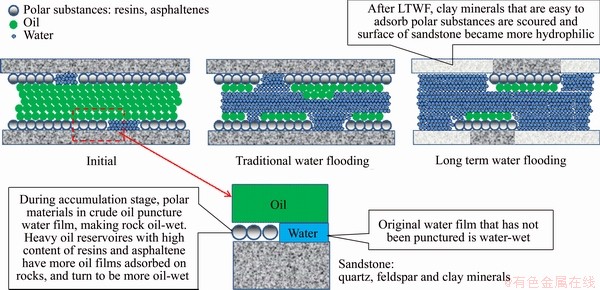

After water flooding, the range of contact angles changes from 78.4°-110.7° to 60.2°-81.9°. This is caused by the scouring and reforming effect of the water on the rock’s surface and the fluid. Prior to water flooding, polar substances are adsorbed onto the rock-fluid interface exhibiting oil-wet characteristics. After the water flooding progresses, the polar materials at the interface are washed away weakening the oil-wet characteristics.

Table 5 Change in contact angle before and after LTWF [30]

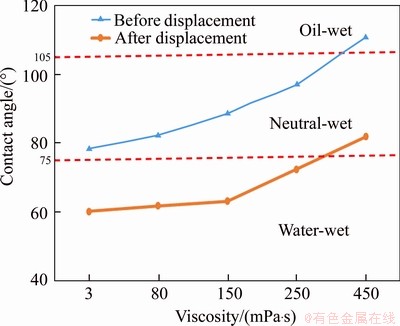

The influence of the changes in wettability is different for the different cores. As shown in Figure 15, for heavy oil reservoirs, as the PV number increases, the wettability gradually changes from oil-wet to neutral-wet, which is always beneficial for EOR. However, for light oil reservoirs, as the PV number increases, the wettability changes from neutral-wet to water-wet, transitioning from favorable for EOR to unfavorable. This indicates that LTWF is more necessary for heavy oil than for light oil.

Figure 15 Effect of crude oil viscosity on contact angle of long-term water flooding (Wettability classification basis: wetting angle <75° (water wet), 75°

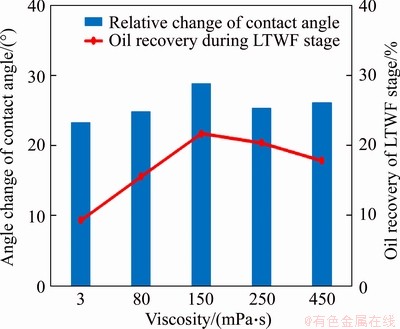

In order to analyze the impact of the changes in wettability on enhanced oil recovery, a plot of viscosity versus the relative change in the contact angle and oil recovery was plotted (Figure 16). The relative change in the contact angle has a good correlation with the oil recovery during the LTWF stage, indicating that the change in wettability is an important factor affecting oil recovery during the LTWF stage.

Figure 16 Effect of viscosity on relative change in contact angle and oil recovery (The relative change in contact angle is the decrease in contact angle divided by original contact angle)

3.4.2 Mechanism of clay mineral composition decrease

The clay mineral composition has an important influence on the reservoir water flooding characters. Many studies have been conducted on the properties of clay minerals before and after water flooding [38]. The variation in the clay mineral content mainly affects the characteristics of water flooding from two aspects: reservoir wettability and reservoir pore throat structure.

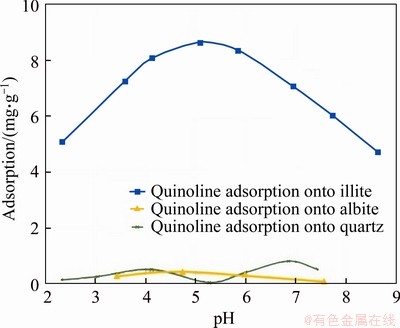

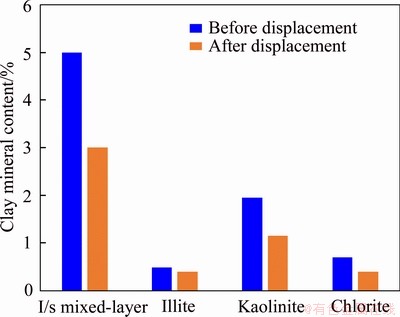

Sandstone consists mainly of quartz, feldspar, and clay minerals. Quinoline adsorption studies on the different mineral components of sandstone were performed by MAMONOV et al [39]. As shown in Figure 17, the clay material (illite) more effectively absorbs the organic material. As the clay content increases, the reservoir surface tends to become more oil-wet. In order to evaluate the changes in the mineral composition during LTWF, core 1 was selected to determine the clay mineral content (Figure 18). The experimental results confirm that the content of the clay minerals (I/s mixed layer,illite, kaolinite, and chlorite) decreased significantly after LTWF, which is an important reason for the enhancement of water-wet conditions.

Figure 17 Comparison of quinoline adsorption onto illite, albite, and quartz (The clay mineral (illite) more effectively adsorbs the organic materials (quinoline) [39])

Figure 18 Changes in clay mineral composition before and after water flooding (The clay mineral content is significantly lower after water flooding)

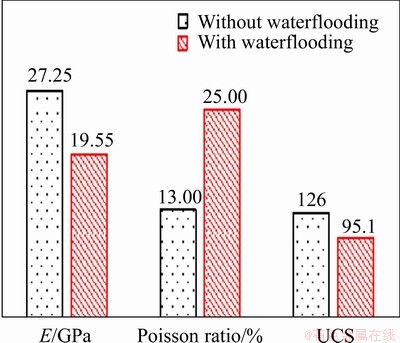

In addition, sandstone cementation is mainly argillaceous cementation, and the clay minerals play an important role in the cementation of the clastic particles. As the clay mineral content decreases, the cohesion and strength of the sandstone decrease (Figure 19). Due to the erosion of water flow, part of the sandstone structure is destroyed, and the pore throats are enlarged [40].

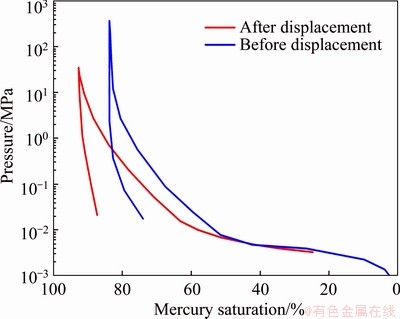

Mercury injection experiments on sandstone cores before and after LTWF have been performed to analyze the influence of LTWF on the pore throat structure (Figure 20). According to the mercury pressure curve, after water flooding, the median pressure and the maximum injection pressure of the core are lower, indicating that the pore throat radius increases.

Figure 19 Average mechanical parameters of samples with and without water flooding (elastic modulus (E), the unconfined compression strength (UCS), and Poisson ratio. After LTWF, the average elastic modulus and the UCS of the formation rocks are lower [40])

Figure 20 Mercury pressure curves before and after water flooding

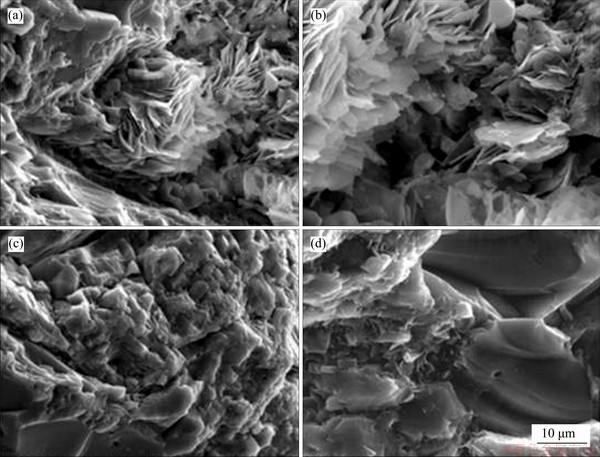

The changes in the mercury injection curves before and after water flooding reflect the changes in the reservoir’s micropore throats. As shown in Figure 21, after LTWF, the content of clay minerals between the rock particles decreases significantly, and the porosity of the rock increases significantly.

The effect of the clay mineral mechanism on the changes in the pore throat structure, water flooding characteristics, and reservoir wettability is similar to the potential mobile fines that TANG et al studied experimentally [41].

Before water flooding, the polar components are adsorbed onto the potentially mobile fines at the oil-water interface, which causes the rock surface to be oil-wet. As the water flooding progresses, some of the fines fall off the pore walls and are distributed in the oil-water interface, which is conducive to the peeling of polar materials off the rock’s surface, enhancing the hydrophilicity of the rock surface and increasing the radius of the rock’s pore throats. As the water flooding progresses further, the fines fall off the wall continuously, which is beneficial to the recovery of residual oil [41]. In contrast to potential mobile fines, clay minerals play a cementing role in sandstone. As the clay minerals fall off, the strength of the sandstone weakens, resulting in a larger variation in the pore throat structure. In addition, the degree of residual oil extraction varies with the stage of water flooding (Figure 22).

During the conventional water flooding stage,the oil produced is mainly from the fraction of oil that has not been adsorbed onto the wall. The oil adsorbed onto the wall is less produced at this stage. With further water flooding, continuous water erosion results in some of the polar material being lost and being produced with the clay minerals, which enhances the rock surface’s hydrophilicity and enlarges the radii of the pore throats. These changes lead to more crude oil being produced during the LTWF stage.

Figure 21 SEM images of samples before (a, b) and after (c, d) water flooding, showing changes in micropores [40]

Figure 22 Comparison of fluid-rock interactions of conventional and long-term water flooding processes (More crude oil is produced during the LTWF stage)

4 Conclusions

In this paper, we analyzed the effects of different factors on the LTWF characteristics, and the mechanism from the microscopic perspective. From the results of this study, we draw the following conclusions.

1) LTWF is conducive to improving oil recovery, and the contribution rate of the LTWF stage gradually increases as the viscosity of the crude oil increases indicating that the effect of LTWF in the EOR of high viscosity crude oil is more significant. When the crude oil viscosity is greater than 250 mPa·s, the contribution rate of the LTWF stage is higher than 30%.

2) Factors affecting of LTWF include displacement parameters and oil properties. Low-speed water flooding is beneficial to the initial water content control, and high-speed water flooding is beneficial to oil recovery with strong scour after breakthrough. When the viscosity becomes higher, the oil recovery after LTWF is lower, and the water content increases faster. During LTWF of thin oil, the flooding efficiency curve with increasing pore volume number exhibits a two-stage characteristic. This characteristic gradually weakens as viscosity increases, indicating that the effect of LTWF in the EOR of high viscosity crude oil is more significant.

3) Under erosion of physical scour and water- rock reaction during LTWF, the content of the clay minerals (I/s mixed layer, illite, kaolinite, and chlorite) in rock and the polar components in oil-water interface decreased significantly, which causes the pore throat to become larger and the rock surface to be more water-wet. These changes are conducive to the enhanced oil recovery of heavy oil.

4) In the process of LTWF experiments, it is necessary to ensure that the water flooding volume multiple is large enough to accurately reflect the changes in the physical properties of the on-site reservoir. Besides, it is necessary to ensure the accurate measurement of oil production and water production to ensure the reliability of the experimental results.

Contributors

The overarching research goals were developed by CAO Ren-yi, DAI Zong and WANG Yan-hui. JIANG Jun and WANG Zhi-kai provided the data of long-term waterflooding, and analyzed the measured data. The initial draft of the manuscript was written by WANG Zhi-kai, LI hai-long and JIA Zhi-hao. All authors replied to reviewers’ comments and revised the final version.

Conflict of interest

CAO Ren-yi, DAI Zong, WANG Zhi-kai, WANG Ya-hui, JIANG Jun, LI Hai-long and JIA Zhi-hao declare that they have no conflict of interest.

References

[1] DAVIS R A, MCELHINEY J E. Desulfated seawater and its impact on t-SRB activity: An alternative souring control methodology [C]// NACE Annual Conference, Corrosion, 2002. Denver, Colorado: Onepetro, 2002: 02028.

[2] BADER M S H. Sulfate removal technologies for oil fields seawater injection operations [J]. Journal of Petroleum Science and Engineering, 2007, 55(1, 2): 93-110. DOI: 10.1016/j.petrol.2006.04.010.

[3] ZHOU Wei, ZHANG Jian, FENG Gui-zhi, JIANG Wei, SUN Fu-jie, ZHOU Shou-wei, LIU Yi-gang. Key technologies of polymer flooding in offshore oilfield of Bohai bay [C]// SPE Asia Pacific Oil and Gas Conference and Exhibition. Perth, Australia: Society of Petroleum Engineers, 2008. DOI: 10.2118/115240-ms.

[4] BADER M S H. Innovative technologies to solve oil-fields water injection sulfate problems [J]. Desalination, 2006, 201(1-3): 121-129. DOI:10.1016/j.desal.2005.09.042.

[5] KANG Xiao-dong, ZHANG Jian, SUN Fu-jie, ZHANG Feng-jiu, FENG Guo-zhi. A review of polymer EOR on offshore heavy oil field in Bohai Bay, China [C]// SPE Enhanced Oil Recovery Conference. Kuala Lumpur, Malaysia: Society of Petroleum Engineers, 2011. DOI: 10.2118/144932-ms.

[6] SU Bao-wei, DOU Mao-wei, GAO Xue-li, SHANG Yan-wu, GAO Cong-jie. Study on seawater nanofiltration softening technology for offshore oilfield water and polymer flooding [J]. Desalination, 2012, 297: 30-37. DOI: 10.1016/j.desal. 2012.04.014.

[7] CARLL J F. The geology of the oil regions of Warren, Venango, Clarion, and Butler counties: Including surveys of the Garland and Panama Conglomerates in Warren and Crawford, and in Chautauqua Co., NY [M]// Descriptions of Oil Well Rigs and Tools, and a Discussion of the Preglacial and Postglacial Drainage of Lake Erie County Board of Commissioners, 1880.

[8] LEVERETT M C. Capillary behavior in porous solids [J]. Transactions of the AIME, 1941, 142(1): 152-169. DOI: 10.2118/941152-g.

[9] WELGE H J. A simplified method for computing oil recovery by gas or water drive [J]. Journal of Petroleum Technology, 1952, 4(4): 91-98. DOI: 10.2118/124-g.

[10] ANDERSON W G. Wettability literature survey-part 1: Rock/oil/brine interactions and the effects of core handling on wettability [J]. Journal of Petroleum Technology, 1986, 38(10): 1, 125-1,144. DOI: 10.2118/13932-pa.

[11] BERNARD G G. Effect of floodwater salinity on recovery of oil from cores containing clays [C]// SPE California Regional Meeting. Los Angeles, California: Society of Petroleum Engineers, 1967: SPE-1725-MS. DOI: 10.2118/ 1725-ms.

[12] LAGER A, COLLINS I R. LoSalTM enhanced oil recovery: Evidence of enhanced oil recovery at the reservoir scale [C]// SPE Symposium on Improved Oil Recovery. Tulsa, Oklahoma, Society of Petroleum Engineers, 2008: SPE-1139676-MS.

[13] VLEDDER P, FONSECA J C, WELLS T, GONZALES I, LIGHTHELM D, PARK K, RIJSWIJK G. Low salinity water flooding: proof of wettability alteration on a field wide scale [C]// SPE Improved Oil Recovery Symposium. Tulsa, Oklahoma: Society of Petroleum Engineers, 2010. DOI: 10.2118/ 129564-ms.

[14] CHANDRASEKHAR S, MOHANTY K K. Effect of brine composition on oil-rock interaction by atomic force microscopy [J]. Journal of Petroleum Science and Engineering, 2018, 164: 289-301. DOI: 10.1016/j.petrol. 2018.02.001.

[15] XIAO Rong, GUPTA R, GLOTZBACH R C, SINHA S, TELETZKE G F. Evaluation of low-salinity waterflooding in Middle East carbonate reservoirs using a novel, field-representative coreflood method [J]. Journal of Petroleum Science and Engineering, 2018, 163: 683-690. DOI: 10.1016/j.petrol.2017.10.070.

[16] WEBB K J, BLACK C J J, AL-AJEEL H. Low salinity oil recovery-log-inject-log [C]// Middle East Oil Show. Tulsa, Oklahoma: Society of Petroleum Engineers, 2003.

[17] WEBB K J, BLACK C J J, EDMONDS I J. Low salinity oil recoveng-the role of reservior condition corefloods [C]// IOR 2005-13th European Symposium on Improved Oil Recovery Budapest, Hungary: European Association of Geoscientists & Engineers, 2005: cp-12-00045.

[18] RIVET S M. Coreflooding oil displacements with low salinity brine [D]. Austin, Texas: Petroleum and Geosystems Engineering of the University of Texas, 2009.

[19] FJELDE I, ASEN S M, OMEKEH A V. Low salinity water flooding experiments and interpretation by simulations [C]// SPE Improved Oil Recovery Symposium. Tulsa, Oklahoma, USA Society of Petroleum Engineers, 2012: SPE- 154142-MS.

[20] NASRALLA R A, MAHANI H, VAN DER LINDE H A, MARCELIS F H, MASALMEH S K, SERGIENKO E, BRUSSEE N J, PIETERSE S G, BASU S. Low salinity waterflooding for a carbonate reservoir: Experimental evaluation and numerical interpretation [J]. Journal of Petroleum Science and Engineering, 2018, 164: 640-654. DOI: 10.1016/j.petrol.2018.01.028.

[21] NUTTING P G. Some physical and chemical properties of reservoir rocks bearing on the accumulation and discharge of oil: Part V. Porosity, permeability, compaction [J]. AAPG Special Volumes, 1934: 825-832.

[22] LEACH R O, WAGNER O R, WOOD H W, HARPKE C F. A laboratory and field study of wettability adjustment in water flooding [J]. Journal of Petroleum Technology, 1962, 14(2): 206-212. DOI: 10.2118/119-pa.

[23] DENEKAS M O, MATTAX C C, DAVIS G T. Effects of crude oil components on rock wettability [J]. Society of Petroleum Engineers, 1959, 216: 330-333. DOI: 10.2118/1276-g.

[24] BUCKLEY J S, LIU Yue, XIE Xi-na, MORROW N R. Asphaltenes and crude oil wetting-The effect of oil composition [J]. SPE Journal, 1997, 2(2): 107-119. DOI: 10.2118/35366-pa.

[25] TAVAKKOLI M, PANUGANTI S R, VARGAS F M, TAGHIKHANI V, PISHVAIE M R, CHAPMAN W G. Asphaltene deposition in different depositing environments: Part 1. Model oil [J]. Energy & Fuels, 2014, 28(3): 1617-1628. DOI: 10.1021/ef401857t.

[26] CAI Yi, YANG Lei, ZHAO Yue-hua, WANG Zhi-zhang. Variation law of the micro-geological features of the reservoir before and after a long term water flooding in He3 reservoir of Shuanghe oilfield [J]. Petroleum Geology & Oilfield Development in Daqing, 2004, 23(1): 24-26. (in Chinese)

[27] GAO Pei-ke, TIAN Hui-mei, LI Guo-qiang, SUN Hong-wen, MA Ting. Microbial diversity and abundance in the Xinjiang Luliang long-term water-flooding petroleum reservoir [J]. Microbiology Open, 2015, 4(2): 332-342. DOI: 10.1002/ mbo3.241.

[28] CAO Ren-yi, SUN Chang-wei, MA Y Z. Modeling wettability variation during long-term water flooding [J]. Journal of Chemistry, 2015, 2015. DOI: 10.1155/2015/ 592951.

[29] JI Shu-hong, TIAN Chang-bing, SHI Cheng-fang, YE Ji-gen, ZHANG Zu-bo, FU Xiu-juan. New understanding on water-oil displacement efficiency in a high water-cut stage [J]. Petroleum Exploration and Development, 2012, 39(3): 362-370. DOI: 10.1016/s1876-3804(12)60052-4.

[30] DAI Zong, JIANG Jun, LI Hai-long, CAO Ren-yi, XIN Jing, LUO Dong-hong. Wetability experiment of core and mico-mechanism during high-multiple water flooding in heavy oil reservoir [J]. Science Technology an Engineering, 2019, 33(19): 157-163. (in Chinese)

[31] YANG Bai-juan, ZHENG Li, ZHANG Kui-ying, CUI Zhi-song, WANG Xiao-ru, LI Xian-chun. Study on SARA composition of crude oil by TCL/FID [J]. Chemical Engineering of Oil & GAS, 2011, 40(2): 201-203, 222, 101. (in Chinese)

[32] ARGILLIER J F, COUSTET C, HENAUT I. Heavy oil rheology as a function of asphaltene and resin content and temperature [C]// SPE International Thermal Operations and Heavy Oil Symposium and International Horizontal Well Technology Conference. Calgary, Alberta, Canada: Society of Petroleum Engineers, 2002.

[33] CROCKER M E, MARCHIN L M. Wettability and adsorption characteristics of crude-oil asphaltene and polar fractions [J]. Journal of Petroleum Technology, 1988, 40(4): 470-474. DOI: 10.2118/14885-pa.

[34] STRAND S, PUNTERVOLD T, AUSTAD T. Water based EOR from clastic oil reservoirs by wettability alteration: A review of chemical aspects [J]. Journal of Petroleum Science and Engineering, 2016, 146: 1079-1091. DOI: 10.1016/ j.petrol.2016.08.012.

[35] WU Jia-wen. Study on wettability change with optical contact angle measuring device [J]. Fualt-Block Oil field, 2011, 18(2): 220-222. (in Chinese)

[36] HUANG Shi-jun, SUN Chang-wei, CHANG Yang, ZHAO Ming-yue. Contact angle alteration for cores under multiplex pore volume water flooding [J]. Science Technology and Engineering, 2016, 16(4): 178-181. (in Chinese)

[37] LI Su-mei, ZHANG Ai-yun, WANG Tie-guan. The absorption of oil polar component and reservoir wettability [J]. Geological Science and Technology Information, 1998(4): 66-71. (in Chinese)

[38] ZHANG Li-hu, LU Xian-cai, LIU Xian-dong, YANG Kan, ZHOU Hui-qun. Surface wettability of basal surfaces of clay minerals: Insights from molecular dynamics simulation [J]. Energy & Fuels, 2016, 30(1): 149-160. DOI: 10.1021/acs. energyfuels.5b02142.

[39] MAMONOV A, PUNTERVOLD T, STRAND S. EOR by smart water flooding in sandstone reservoirs-effect of sandstone mineralogy on initial wetting and oil recovery [C]// SPE Russian Petroleum Technology Conference. Society of Petroleum Engineers, 2017.

[40] ZHAO Bo, ZHANG Guang-qing, BAI Xiao-hui, ZHUANG Jian-man, LIN Ying, LV Yan-jun, NIE Yuan-xun. The effects of long-term waterflooding on the physical and mechanical properties of tight sandstones [C]// 52nd US Rock Mechanics/Geomechanics Symposium. American Rock Mechanics Association, 2018.

[41] TANG Guo-qing, MORROW N R. Influence of brine composition and fines migration on crude oil/brine/rock interactions and oil recovery [J]. Journal of Petroleum Science and Engineering, 1999, 24(2-4): 99-111. DOI: 10.1016/s0920-4105(99)00034-0.

(Edited by HE Yun-bin)

中文导读

长期水驱砂岩油藏的生产动态及变化机理

摘要:强底水砂岩储层通常采用大排量水驱开发,长期水驱后储层水驱特征发生巨大变化。本文采用新的实验方法获得了油水相渗、采收率以及润湿性曲线,并基于试验结果研究了水驱体积倍数、原油黏度及驱替速度对长期水驱的影响。通过对原油组成、岩石矿物组成以及润湿性变化进行分析,明确了长期水驱过程中流固相互作用机理。研究表明,随着原油黏度的增加,水相渗透率降低,剩余油饱和度增加,含水率上升提前。较高的水驱速度会导致较高的最终采收率。沥青质含量越高,黏度越高,储层越偏油湿。长期水驱后后润湿性趋于水湿,更有利于稠油开采。此外,长期水驱降低了粘土含量,形成了更偏水湿的岩石表面以及更大的储层孔喉环境。本研究为海上砂岩油藏开发及提采提供了一定的理论依据。

关键词:长期水驱;砂岩油藏;相渗曲线;润湿性

Foundation item: Project(51674273) supported by the National Natural Science Foundation of China; Project(CNOOC- KJ135ZDXM22LTD02SZ2016) supported by the Major Science and Technology Projects of CNOOC, China

Received date: 2020-04-07; Accepted date: 2020-11-09

Corresponding author: CAO Ren-yi, PhD, Professor; Tel: +86-15201202583; E-mail: caorenyi@126.com; ORCID: https://orcid.org/ 0000-0002-2508-7152