文章编号:1004-0609(2014)06-1393-08

基于材料参数修正的6013铝合金热变形本构模型优化

肖 罡1, 2,李落星1, 2,叶 拓1, 2

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,长沙 410082;

2. 湖南大学 机械与运载工程学院,长沙 410082)

摘 要:为建立精确描述材料变形时热力学参数间重要关系的数学模型,采用Gleeble-3500热模拟机测试研究6013铝合金在温度为340~500 ℃、应变速率为0.001~10 s-1范围内的平面应变热压缩变形行为,讨论材料参数对幂函数(PF)和双曲正弦函数(HS)本构模型(CM)精度的影响,对比分析优化后两类本构模型各自的优势。结果表明:温度系数(b)的修正对反求参数(a)的优化效果显著,将直接影响PFCM的预测精度;通过指数函数替换多项式对HSCM参数进行修正,可在保证预测精度的同时大幅减少计算工作量;PFCM在 ≥0.01 s-1时的预测精度较高,平均相对误差仅为5.209%;HSCM在

≥0.01 s-1时的预测精度较高,平均相对误差仅为5.209%;HSCM在 ≤0.01 s-1时的预测精度较高,平均相对误差仅为5.226%。

≤0.01 s-1时的预测精度较高,平均相对误差仅为5.226%。

关键词:6013铝合金;平面热压缩;流变应力;本构模型;材料参数修正

中图分类号:TG146 文献标志码:A

Optimization of constitutive equation during hot deformation of 6013 aluminum alloy based on modified material parameters

XIAO Gang1, 2, LI Luo-xing1, 2, YE Tuo1, 2

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body, Hunan University,

Changsha 410082, China;

2. College of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China)

Abstract: In order to develop a precise constitutive model to describe the relationships among material thermodynamic parameters during hot deformation, the hot plane compression deformation behavior of 6013 aluminum alloy was investigated on Gleeble-3500 thermal-mechanical simulating tester in the temperature range from 340 to 500 ℃ and strain rate range from 0.001 to 10 s-1. The influences of material parameters on the accuracies of the power function (PF) and hyperbolic sine (HS) constitutive model (CM) were discussed. Additionally, the advantages of two kinds of optimized constitutive models were comparatively analyzed. The results show that the corrected value of temperature coefficient (b) has an obvious effect on the parameter (a) obtained by an inverse method, and directly impacts the accuracy of PFCM. It is indicated that the computational-workload can be reduced significantly with high accuracy, through modifying the material parameters of HSCM by power function instead of polynomial function. Under the deformation condition ( ≥0.01 s-1), the developed method of PFCM has higher precision of prediction, and the average relative error is only 5.209%; on the contrary, the proposed method of HSCM has higher precision of prediction under the deformation condition (

≥0.01 s-1), the developed method of PFCM has higher precision of prediction, and the average relative error is only 5.209%; on the contrary, the proposed method of HSCM has higher precision of prediction under the deformation condition ( ≤0.01 s-1), and the average relative error is only 5.226%.

≤0.01 s-1), and the average relative error is only 5.226%.

Key words: 6013 aluminum alloy; hot plane compression; flow stress; constitutive equation; material parameter modification

在金属塑性成形过程中,精确的本构模型可有效指导成形工艺的制定。目前,铝合金热变形的本构模型主要分为两类[1-2]:一类模型以Zuzin-Browman关系式为经典代表,用幂函数结合指数函数来表征材料流变性能各参数间的特定关系;另一类模型则借助于包含Zener-Hollomon参数的双曲正弦函数,结合幂函数和指数函数表征材料流变力学规律。

双曲正弦本构模型(HSCM)结合高、低应力水平的分析,具有较宽的适用范围,但该本构模型无法描述材料变形过程中应力随应变增大的动态变化。LI等[3]及WU等[4]分别在研究T24铁素体钢和7050铝合金的流变行为时,将各材料参数修正为关于应变的多项式函数,优化了HSCM,但使得求解计算量也相应成倍增加。另外,针对幂函数本构模型(PFCM)温度适用范围较窄的局限性问题[5-7],CHENG等[8]通过修正温度项的表达形式来实现本构模型优化,但效果仍不佳;KLEPACZKO等[9]将各项材料参数修正为包含温度T的函数,虽然达到了一定的优化效果,但模型形式复杂,实现难度较大,仍存在一定局限性。

为了建立能更精确地表征材料变形特性的数学模型,简化计算步骤,特别是拓宽PFCM的温度适用范围,本文作者通过研究6013铝合金热变形流变应力行为,分析材料参数对幂函数和HSCM精度的影响,探讨合理的材料参数优化及函数关系拟合方式,对比分析得出两类本构模型各自的较佳适用范围。

1 实验

1.1 实验过程

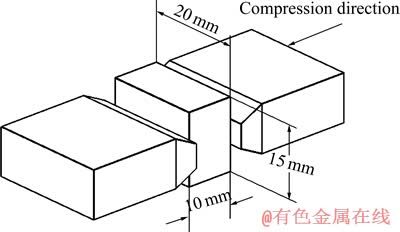

采用10 kg电阻式坩埚炉熔炼,合金成分为Al-0.95Mg-0.75Si-0.9Cu-0.35Mn-0.3Fe (质量分数,%),浇注温度为730 ℃,铸锭尺寸为250 mm×250 mm×40 mm。将铸锭加工成20 mm×15 mm×10 mm的长方体试样(高度为铸锭厚度方向),经540 ℃、15 h均匀化处理并水淬固溶后,进行平面热压缩实验。

在Gleeble-3500热模拟机上进行等温热压缩实验(压缩方式见图1)。为减小摩擦的影响,试样两侧涂抹润滑剂并覆盖减磨石墨片,润滑剂为75%石墨+20%机油+5%硝酸三甲苯脂(质量分数)。实验设定的变形温度分别为340、380、420、460、500 ℃,以10 ℃/s的速度加热后保温60 s;应变速率分别为0.001、0.01、0.1、1和10 s-1,总应变量为0.8(真应变)。

图1 试样平面应变热压缩示意图

Fig. 1 Schematic diagram of hot plane compression of specimen

1.2 实验结果

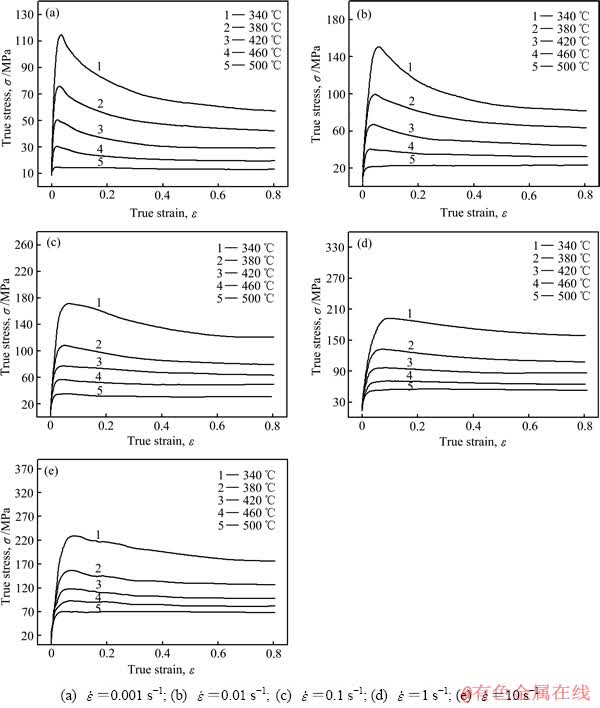

6013铝合金在不同变形条件下的真应力-真应变曲线如图2所示。由图2可知,流变应力随着变形温度的降低和应变速率的增大显著增大;变形初期,应力随应变的增加迅速增大,达到峰值后逐渐减小,表现出流变软化特征,当曲线趋于水平时基本保持恒定,此时,加工硬化与流变软化达到动态平衡。

2 分析与讨论

2.1 PFCM的优化与求解

研究表明[5-8],金属高温塑性变形的“应力-应变-应变速率-温度”间的特定关系,可采用幂函数及温度项来描述:

(1)

(1)

式中:σ为真应力;ε为真应变; 为应变速率;T为变形温度;p为应变硬化指数;q为应变速率敏感系 数;b为温度系数;a为与材料相关的经验常数。

为应变速率;T为变形温度;p为应变硬化指数;q为应变速率敏感系 数;b为温度系数;a为与材料相关的经验常数。

对式(1)取自然对数后求偏微分可得:

(2)

(2)

(3)

(3)

(4)

(4)

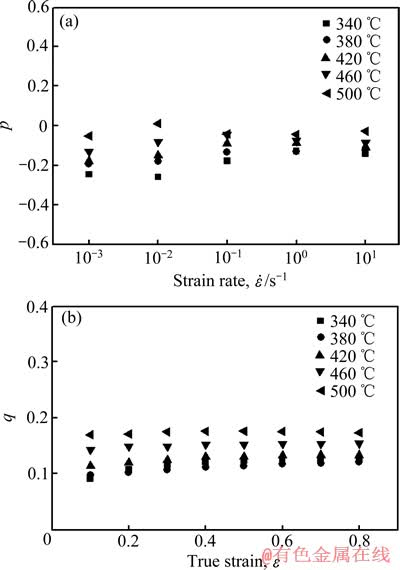

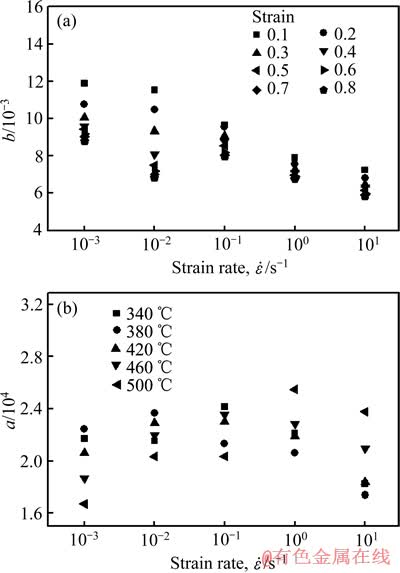

根据图2数据及式(2)~(4)可分别求得真应变为0.1、0.2、0.3、0.4、0.5、0.6、0.7和0.8时,不同变形条件下的p、q和b值,并反求出不同变形条件下的a值,结果分别如图3和4所示。

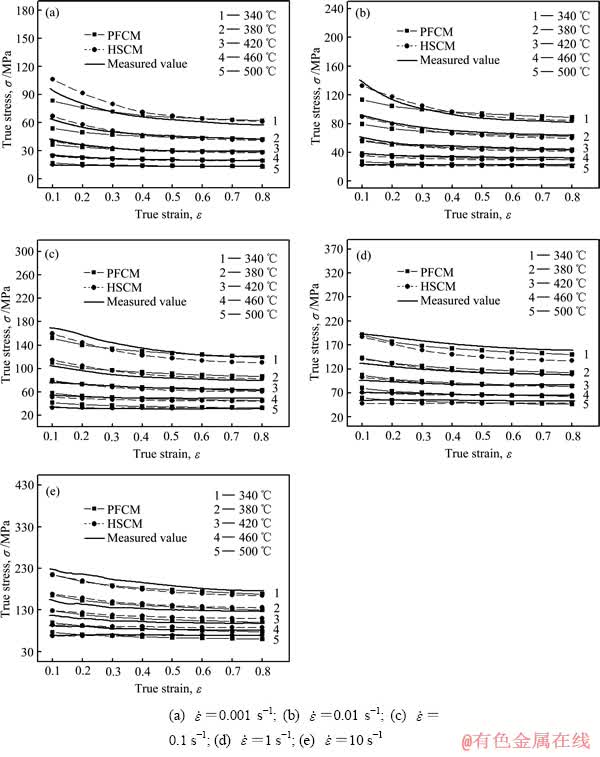

图2 不同热变形条件下6013铝合金的真应力-真应变曲线

Fig. 2 True stress-true stain curves of 6013 aluminum alloy under different deformation conditions

由图3可知,6013铝合金的应变硬化指数p和应变速率敏感系数q在不同变形条件下,均具有在同一值附近上下浮动的变化趋势,可认为p和q为常数,求平均值可得p=-0.1163,q=0.1376。由图4观察可知,式(1)认为的经验常数b(温度系数)和a值,并未呈现出收敛至某一常数的趋势,尤其是a值,变化趋势几乎无规律可循,由此进一步说明,仅凭借对a值的修正很难达到本构模型的优化效果;另外,因a值为反求得出,本构模型的预测精度将受其准确性的直接影响。综上所述,式(1)的确存在适用温度范围较窄的严重缺陷,温度系数b值的修正,将可能成为提高PFCM精度的关键环节。

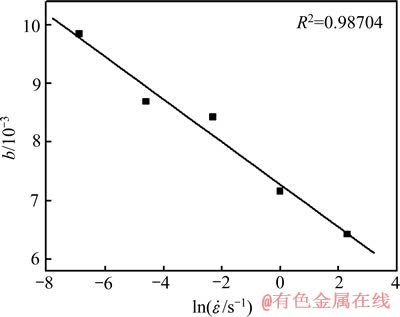

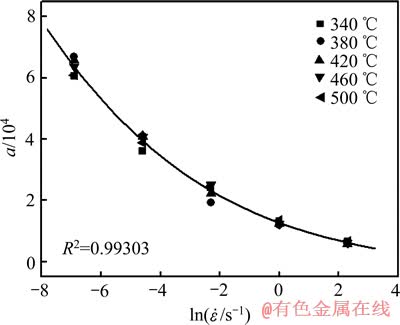

根据b值的求解方程(4)可知,修正b值的唯一途径是找出其与应变速率之间的特定关系。取相同应变速率下的平均b值与 值作图,结果见图5。由图5可知,b值与

值作图,结果见图5。由图5可知,b值与 值呈良好的线性关系,采用最小二乘法可拟合得到

值呈良好的线性关系,采用最小二乘法可拟合得到 ,反求得出新的a值,如图6所示。由图6中显示的计算结果可看出,b值的修正可较好地改善a值随应变速率的变化趋势,并使其规律明显。采用最小二乘法多项式拟合可得到精度较高的

,反求得出新的a值,如图6所示。由图6中显示的计算结果可看出,b值的修正可较好地改善a值随应变速率的变化趋势,并使其规律明显。采用最小二乘法多项式拟合可得到精度较高的 ,本构模型的预测精度将随着a值准确度的提高而相应得到大幅度提升。

,本构模型的预测精度将随着a值准确度的提高而相应得到大幅度提升。

图3 不同条件下6013铝合金的p和q值

Fig. 3 p(a) and q(b) values of 6013 aluminum alloy under different conditions

图4 不同条件下6013铝合金的b和a值

Fig. 4 b(a) and a(b) values of 6013 aluminum alloy under different conditions

图5 6013铝合金的b值与 的关系

的关系

Fig. 5 Relationship between b and  of 6013 aluminum alloy

of 6013 aluminum alloy

由以上分析可知,金属材料热变形流变应力的PFCM可优化为如下形式:

(5)

(5)

代入图5和6中的曲线拟合结果,可得6013铝合金热变形流变应力的幂函数本构模型为

(6)

(6)

图6 优化后6013铝合金的a值与 的关系

的关系

Fig. 6 Relationship between revised value of a and

2.2 HSCM的优化与求解

相关研究指出[3-4, 10-11],可采用以下函数描述金属材料的高温塑性变形:

<0.8时,

<0.8时,

(7)

(7)

>1.2时,

>1.2时,

(8)

(8)

所有应力状态下,

(9)

(9)

(10)

(10)

其中, 、β和n三者之间满足关系式:

、β和n三者之间满足关系式:

(11)

(11)

式中:A1、A2、A、n1、n、 和β均为与温度无关的常数,A1、A2和A为结构因子;n1和n为应力指数;

和β均为与温度无关的常数,A1、A2和A为结构因子;n1和n为应力指数; 为应力水平参数;R为摩尔气体常数;Q为热变形激活能。

为应力水平参数;R为摩尔气体常数;Q为热变形激活能。

研究表明[3-4],求解出准确的 、n(ε)、Q(ε)和A(ε),可优化HSCM,从而较好地描述材料的高温流变特性。

、n(ε)、Q(ε)和A(ε),可优化HSCM,从而较好地描述材料的高温流变特性。

(1) 求解 、β和n值

、β和n值

对式(7)~(9)取自然对数后求偏微分可得:

(12)

(12)

(13)

(13)

(14)

(14)

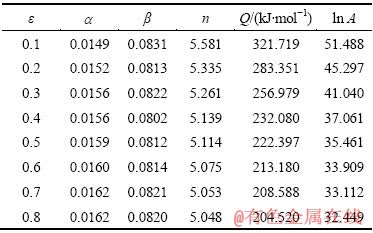

根据式(12)~(14)可求得不同真应变时 、β和n的值,结果见表1。

、β和n的值,结果见表1。

(2) 求解Q和A值

对式(9)取自然对数后求偏导数可得:

(15)

(15)

对式(10)取自然对数可得:

(16)

(16)

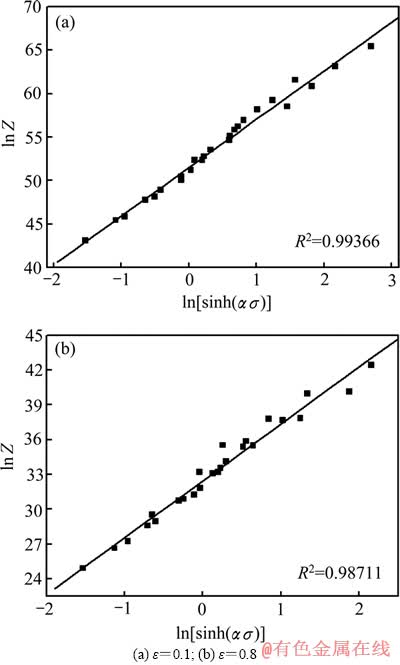

由式(16)可知, 为直线

为直线 -

- 的截距。当真应变分别为0.1和0.8时

的截距。当真应变分别为0.1和0.8时 与

与 的关系如图7所示。由图7可知,材料不同变形程度时,在不同变形条件下的应力与Z参数均呈现良好的线性关系,表明6013铝合金的热变形流变应力行为符合双曲正弦函数关系。同时,根据式(15)和(16)可求出不同真应变下的Q和

的关系如图7所示。由图7可知,材料不同变形程度时,在不同变形条件下的应力与Z参数均呈现良好的线性关系,表明6013铝合金的热变形流变应力行为符合双曲正弦函数关系。同时,根据式(15)和(16)可求出不同真应变下的Q和 值,结果如表1所示。

值,结果如表1所示。

表1 6013铝合金的HSCM参数

Table 1 Material parameters of 6013 aluminum alloy used in HSCM

根据表1数据,可分别求得 、n(ε)、Q(ε)和A(ε),结果如图8所示。在采用最小二乘法拟合时发现,用指数函数替换多项式拟合,在简化拟合方程的同时,得到的相关性系数仍较大,由此说明,用指数函数不但可以较好地修正材料参数、优化HSCM,而且可以有效简化拟合方程,减少求解及计算工作量。

、n(ε)、Q(ε)和A(ε),结果如图8所示。在采用最小二乘法拟合时发现,用指数函数替换多项式拟合,在简化拟合方程的同时,得到的相关性系数仍较大,由此说明,用指数函数不但可以较好地修正材料参数、优化HSCM,而且可以有效简化拟合方程,减少求解及计算工作量。

图7 不同应变条件下Zener-Hollomon参数(Z)与6013铝合金流变应力的关系( -

- )

)

Fig. 7 Relationship between Zener-Hollomon parameter (Z) and flow stress of 6013 aluminum alloy at different strains ( -

- )

)

图8 6013铝合金的参数 、n、Q和A值与ε的关系

、n、Q和A值与ε的关系

Fig. 8 Relationships among  (a), n(b), Q(c), A(d) and ε of 6013 aluminum alloy

(a), n(b), Q(c), A(d) and ε of 6013 aluminum alloy

根据图8中曲线拟合结果,可得6013铝合金流变应力的双曲正弦本构模型为

(17)

(17)

(18)

(18)

(19)

(19)

(20)

(20)

(21)

(21)

2.3 本构模型误差分析及优势对比

根据优化的PFCM和HSCM,预测出6013铝合金不同热变形条件下的流变应力,图9所示为两种本构模型预测值与实测值的对比情况。

根据图9数据及图2的进一步分析不难看出,当变形温度高于340 ℃时,预测值与实测值均吻合较好;在340 ℃下,当 >0.01 s-1时,预测值相对实测值均偏低,表明加工硬化趋势过大;而当

>0.01 s-1时,预测值相对实测值均偏低,表明加工硬化趋势过大;而当 ≤0.01 s-1时,预测值相对实测值均偏高,呈现流变软化过大趋势。相关研究表明[12-15],低温变形时,原子热振动不强,热激活作用较弱,原子间临界切应力增大,滑移系减少,导致材料变形抗力峰值较高温变形时有较大幅度提高;在变形温度一定时,随着应变速率的降低,原子的运动能力有所增强,位错的可动距离随之增大,位错的相互销毁和重组将更加彻底,使得位错增殖和销毁的平衡向低位错密度方向移动,导致材料在低应变速率下变形的动态软化能力相对较强。6013铝合金在340 ℃时的变形受到原子热激活能力较弱的影响较大,合金在变形过程中的变形储能相对较大,动态软化机制开启的驱动力充足,但位错运动能力受变形温度限制,由此产生了与较高温度变形时不同的流变软化规律:准静态变形时,变形时间较长,动态软化程度会随着真应变的增加而显著增大,动态软化机制逐步占据主导地位,以致流变软化程度相对较大;在较高应变速率下,动态软化能力相对较弱,且变形时间也有较大幅度的缩短,动态软化行为难以完全抵消加工硬化作用,从而呈现出流变软化效果不够明显的现象。

≤0.01 s-1时,预测值相对实测值均偏高,呈现流变软化过大趋势。相关研究表明[12-15],低温变形时,原子热振动不强,热激活作用较弱,原子间临界切应力增大,滑移系减少,导致材料变形抗力峰值较高温变形时有较大幅度提高;在变形温度一定时,随着应变速率的降低,原子的运动能力有所增强,位错的可动距离随之增大,位错的相互销毁和重组将更加彻底,使得位错增殖和销毁的平衡向低位错密度方向移动,导致材料在低应变速率下变形的动态软化能力相对较强。6013铝合金在340 ℃时的变形受到原子热激活能力较弱的影响较大,合金在变形过程中的变形储能相对较大,动态软化机制开启的驱动力充足,但位错运动能力受变形温度限制,由此产生了与较高温度变形时不同的流变软化规律:准静态变形时,变形时间较长,动态软化程度会随着真应变的增加而显著增大,动态软化机制逐步占据主导地位,以致流变软化程度相对较大;在较高应变速率下,动态软化能力相对较弱,且变形时间也有较大幅度的缩短,动态软化行为难以完全抵消加工硬化作用,从而呈现出流变软化效果不够明显的现象。

图9 不同变形条件下6013铝合金流变应力实测值与预测值的比较

Fig. 9 Comparison between measured and predicted flow stresses of 6013 aluminum alloy under different deformation conditions

为了更好地且宏观地评价实测与预测值间的误差情况,借助平均相对误差辅助分析:

(22)

(22)

式中: 为流变应力实测值;

为流变应力实测值; 为流变应力预测值。

为流变应力预测值。

根据式(22)可得,优化后PFCM和HSCM的平均相对误差分别为5.447%和5.706%;进一步计算及分析可知,PFCM在 ≥0.01 s-1时精度相对较高,平均相对误差为5.209%,HSCM在

≥0.01 s-1时精度相对较高,平均相对误差为5.209%,HSCM在 ≤0.01 s-1时精度较高,平均相对误差为5.226%;PFCM在

≤0.01 s-1时精度较高,平均相对误差为5.226%;PFCM在 ≥ 0.2时精度较高,平均相对误差为4.735%。

≥ 0.2时精度较高,平均相对误差为4.735%。

根据式(6)与式(17)~(21)的计算结果,结合前文对两类本构模型的优化与求解过程综合对比可知,经优化后,PFCM的温度适用范围得到了较大程度的拓宽,且具有更加简便的优化、求解及计算过程,同时,在大样本整体预测精度上略高于优化后的HSCM。

3 结论

1) 通过修正幂函数本构模型中的温度系数b,对反求参数a的优化效果显著,不但大幅提高了该本构模型的预测精度,而且较大程度地拓宽了其温度适用范围;采用指数函数替代多项式拟合方法对双曲正弦本构模型的各项材料参数进行修正,可在较好地优化该本构模型未包含应变项的不足的同时,大幅减少计算工作量,提高工程运算效率。

2) 优化后的幂函数本构模型与双曲正弦本构模型均具有较高的流变应力预测精度,平均相对误差分别为5.447%和5.706%;其中,幂函数本构模型在 ≥0.01 s-1时的预测精度相对较高,而双曲正弦本构模型在

≥0.01 s-1时的预测精度相对较高,而双曲正弦本构模型在 ≤0.01 s-1时的预测精度相对较高,平均相对误差分别为5.209%和5.226%;另外,相较于双曲正弦本构模型,幂函数本构模型具有更加简便的优化、求解及计算过程,工程应用前景更加广阔。

≤0.01 s-1时的预测精度相对较高,平均相对误差分别为5.209%和5.226%;另外,相较于双曲正弦本构模型,幂函数本构模型具有更加简便的优化、求解及计算过程,工程应用前景更加广阔。

REFERENCES

[1] LIN Y C, CHEN X M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working[J]. Materials and Design, 2011, 32(4): 1733-1759.

[2] GUO J H, ZHAO S D, MURAKAMI R I, DING R X, FAN S Q. Modeling the hot deformation behavior of Al alloy 3003[J]. Journal of Alloys and Compounds, 2013, 566(14): 62-67.

[3] LI Hong-ying, WEI Dong-dong, HU Ji-dong, LI Yang-hua, CHEN Shao-lin. Constitutive modeling for hot deformation behavior of T24 ferritic steel[J]. Computational Materials Science, 2012, 53(1): 425-430.

[4] WU B, LI M Q, MA D W. The flow behavior and constitutive equations in isothermal compression of 7050 aluminum alloy[J]. Materials Science and Engineering A, 2012, 542: 79-87.

[5] PARSA M H, OHADI D. A constitutive equation for hot deformation range of 304 stainless steel considering grain sizes[J]. Materials and Design, 2013, 52(12): 412-421.

[6] RUSINEK A, KLEPACZKO J R. Shear testing of a sheet steel at wide range of strain rates and a constitutive relation with strain rate and temperature dependence of the flow stress[J]. International Journal of Plasticity, 2001, 17(1): 87-115.

[7] YU Hai-dong, GUO Yong-jin, ZHANG Kai-zhi, LAI Xin-min. Constitutive model on the description of plastic behavior of DP600 steel at strain rate from 10-4 to 10-3 s-1[J]. Computational Materials Science, 2009, 46: 36-41.

[8] CHENG Y Q, ZHANG H, CHEN Z H, XIAN K F. Flow stress equation of AZ31 magnesium alloy sheet during warm tensile deformation[J]. Journal of Materials Processing Technology, 2008, 208(1/3): 29-34.

[9] KLEPACZKO J R. A practical stress-strain-strain rate- temperature constitutive relation of the power form[J]. Journal of Mechanical Working Technology, 1987, 15(2): 143-165.

[10] 李 超, 张晓泳, 唐仁波, 周科朝. Ti-5Al-5Mo-5V-1Cr-1Fe合金的高温塑性变形行为[J]. 中国有色金属学报, 2012, 22(7): 1914-1920.

LI Chao, ZHANG Xiao-yong, TANG Ren-bo, ZHOU Ke-chao. Plastic deformation behavior of Ti-5Al-5Mo-5V-1Cr-1Fe alloy at high temperature[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(7): 1914-1920.

[11] 张 毅, 刘 平, 田保红, 陈小红, 刘 勇. Cu-Ni-Si-P-Cr合金高温热变形行为及动态再结晶[J]. 中国有色金属学报, 2013, 23(4): 970-976.

ZHANG Yi, LIU Ping, TIAN Bao-hong, CHEN Xiao-hong, LIU Yong. Hot deformation behaviors and dynamic recrystallization of Cu-Ni-Si-P-Cr alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 970-976.

[12] 陈学海,陈康华,梁 信,陈送义,彭国胜. 热变形温度对7085铝合金组织和性能的影响[J]. 中国有色金属学报, 2011, 21(1): 88-94.

CHEN Xue-hai, CHEN Kang-hua, LIANG Xin, CHEN Song-yi, PENG Guo-sheng. Effects of hot deformation temperature on microstructure and properties of 7085 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 88-94.

[13] QUAN Guo-zheng, LIU Ke-wei, ZHOU Jie, CHEN Bin. Dynamic softening behaviors of 7075 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2009, 19(S): s537-s541.

[14] HUANG Chang-qing, DIAO Jin-peng, DENG Hua, LI Bing-ji, HU Xing-hua. Microstructure evolution of 6016 aluminum alloy during compression at elevated temperatures by hot rolling emulation[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1576-1582.

[15] LUO J, LI M Q, WU B. The correlation between flow behavior and microstructural evolution of 7050 aluminum alloy[J]. Materials Science and Engineering A, 2011, 530: 559-564.

(编辑 陈卫萍)

基金项目:国家“十二五”科技支撑计划资助项目(2011BAG03B02);国家自然科学基金面上项目(51075132);长沙市科技重大专项(K1204008-11-1);车身先进设计与制造国家重点实验室基金资助项目(61075005)

收稿日期:2013-11-05;修订日期:2014-04-20

通信作者:李落星,教授,博士;电话:0731-88821571;E-mail: luoxing_li@yahoo.com