文章编号:1004-0609(2009)04-0727-06

甲基丙烯酸甲酯原位聚合包覆铜金粉

刘 辉1, 2,易健宏1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 中南大学 化学化工学院,长沙 410083)

摘 要:为了提高铜金粉的耐腐蚀性能,采用甲基丙烯酸甲酯(MMA)原位聚合对铜金粉进行了有机聚合物的包覆,以吸光度、光泽度与接枝率为主要评价指标,探讨单体用量、引发剂用量、偶联剂用量对原位聚合过程的影响,并采用IR、SEM和XRD等手段对包覆前后的铜金粉进行表征。结果表明:当m(MMA)/m(Cu)=0.2时,表面包覆PMMA后的铜金粉具有良好的耐腐蚀性能与光泽度;当m(AIBN)/m(MMA)=0.05时,耐腐蚀性能最佳,而此时的接枝率也达到最高点,即耐腐蚀性能与接枝率之间存在一定的对应关系;偶联剂MPS的加入有利于提高铜金粉的耐腐蚀性能,这是由于其分子结构中具有甲氧基(OCH3)与碳碳双键(C=C),形成具有特殊功能的“分子桥”所致,从而将铜金粉与PMMA通过化学键牢固地结合起来。

关键词:甲基丙烯酸甲酯;原位聚合;包覆;铜金粉;耐腐蚀性能

中图分类号:TB 383 文献标识码: A

Bronze powder encapsulated by in-situ polymerization of methyl methacrylate

2LIU Hui1, 2, YI Jian-hong1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China)

Abstract: In order to improve its corrosion resistance, bronze powder was encapsulated by in-situ polymerization of methyl methacrylate (MMA). Using the absorbance, gloss and concentration of grafting as the main targets, the effect of monomer amount, initiator (AIBN) amount and coupling agent (MPS) amount on the polymerization was studied. The unencapsulated and encapsulated bronze powders were characterized by IR, SEM, and XRD. The results show that the encapsulated sample has good corrosion resistance and gloss synchronously when m(MMA)/m(Cu) is 0.2. Furthermore, when m(AIBN)/m(MMA) is 0.05, the corrosion resistance reaches the highest value, and the concentration of grafting also reaches the maximum, which implies that the corresponding relationship exists between the corrosion resistance and the concentration of grafting. The addition of MPS is helpful to improve the anticorrosion property of bronze powder, which is due to that there are OCH3 and C=C in the structure of MPS. Because the molecular bridge with special function can be formed, bronze powder is firmly combined with PMMA by chemical bonding.

Key words: methyl methacrylate; in-situ polymerization; encapsulation; bronze powder; corrosion resistance

铜金粉又称铜粉,是以铜和锌为主要原料,经过特殊机械加工与表面化学处理制成的粒径为5~20 μm的鳞片状金属粉体颜料,由于其具有较高的金属光泽和特殊的随角异色效应,被广泛应用于塑料、高级画报、高档包装、香烟外壳以及证券印刷等行业[1-4]。然而,铜金粉在酸性介质中容易受到腐蚀,使其鲜艳的金属光泽遭到破坏,从而缩短其使用寿命。因此,为了改善铜金粉的耐腐蚀性能,对其进行表面处理成为当前铜金粉技术领域的研究热点之一[5-6]。朱丽霞 等[7]应用物理法和化学法在铜金粉表面进行了缓蚀剂的有机与无机包覆,并采用差热分析方法研究了不同包覆处理的铜金粉在高温下的抗氧化性能。王蓉等[8]利用硬脂酸类表面活性剂对片状铜金粉进行了表面处理,并探讨了处理后铜金粉的耐腐蚀性能与光泽度的变化情况。这些表面处理方法大都应用表面活性剂进行简单的混合处理,其与铜金粉的结合力不强,在后续的使用过程中容易发生脱落从而使铜金粉耐腐蚀性能下降。RUSU[9]在高温(160 ℃)条件下通过阴离子开环聚合制备了尼龙6/铜金粉复合粒子,并考察了其在酸性条件下的耐腐蚀性能,然而在高温制备过程中铜金粉很有可能受到腐蚀或氧化,对最终产品的性能造成不利的影响。

为此,本文作者试图在较低温度(80 ℃左右)下对铜金粉进行表面有机聚合物处理,考虑到聚甲基丙烯酸甲酯(PMMA)具有良好的透光性能,有利于保护铜金粉的光泽度,因此,采用甲基丙烯酸甲酯(MMA)原位聚合包覆铜金粉,在不大幅度降低铜金粉光泽度的前提下改善其耐腐蚀性能。

1 实验

1.1 原位聚合过程

在装有搅拌器、回流冷凝管、恒压滴液漏斗、温度计的500 mL四口烧瓶中加入50 g铜金粉(Cu)、300 mL正丁醇、1 g聚乙烯吡咯烷酮(PVP)、1.25 g硅烷偶联剂(MPS)、10 g预处理过的甲基丙烯酸甲酯(MMA),充分搅拌,在氮气保护下使瓶内温度升至70 ℃,在此温度下将偶氮二异丁腈(AIBN)的甲苯溶液由恒压滴液漏斗缓慢滴加至烧瓶中,然后升温至80 ℃反应5 h,冷却、抽滤得到PMMA包覆的铜金粉。

1.2 测试与表征

为了检测包覆前后铜金粉防腐性能的变化,采用吸光度来表示包覆效果的好坏,吸光度越小,耐腐蚀性能越好。将0.25 g包覆后的铜金粉加入到50 mL质量浓度为2%的稀硝酸溶液中,0.5 h后取3 mL上述溶液转移至50 mL容量瓶中,往其中加入25 mL 0.2 mol/L EDTA溶液和15 mL pH=6醋酸-醋酸钠缓冲溶液,用蒸馏水定容、摇匀。采用752 N型紫外/可见分光光度计、在波长730 nm处,测定溶液的吸光度[10]。

将包覆前后的铜金粉、光油和稀释剂按照1?3?2的质量比分散均匀,刮板于白色检测纸上,待自然干燥后,用WGG-60型光泽度仪测定其光泽度。

为了去除MMA的均聚产物,称取一定量的PMMA包覆的铜金粉分散于丙酮中,在10 000 r/min下离心0.5 h,滤饼用丙酮抽提24 h得到PMMA接枝的铝粉,干燥后将其浸泡于王水中,在不同时间点测定吸光度直至铜金粉反应完全,过滤、反复水洗,得到分离出来的聚合物质量,从而按照式(1)计算PMMA在铜金粉表面的接枝率(Preontage of grafting, PG)[11-14]:

将包覆前后的铜金粉进行KBr压片制膜,然后用AVATAR360型红外光谱仪进行测定。

采用日本JSM-6360LV型扫描电子显微镜对包覆前后的铜金粉进行分析。采用日本RIGAKU D/max X射线衍射仪对包覆前后的铜金粉进行XRD测试,测试条件为:管电压36 kV,管电流30 mA,Cu Ka辐射,扫描速度为8 (?)/min,扫描角度范围20?~90?。

2 结果与分析

2.1 单体MMA用量对铜金粉耐腐蚀性能与光泽度的影响

耐腐蚀性能与光泽度是铜金粉的两个重要的性能指标[15]。图1所示为单体(MMA)用量对吸光度与光泽度的影响。其中,吸光度越小,耐腐蚀性能越好。m(MMA)/m(Cu)=0即为包覆前的铜金粉,与之相比,包覆后铜金粉的吸光度显著降低,即耐腐蚀性能显著增强,这说明表面包覆PMMA是提高铜金粉耐腐蚀性能的有效方法。由图1还可见,随着单体用量的增大,铜金粉的耐腐蚀性能增强,与此同时其光泽度却呈下降的趋势。因此,找到耐腐蚀性能与光泽度的平衡点成为实验的关键。由图1可知,当m(MMA)/m(Cu)=0.2时,表面包覆PMMA后的铜金粉同时具有良好的耐腐蚀性能与光泽度。

图1 MMA用量对吸光度与光泽度的影响

Fig.1 Effect of MMA amount on absorbance and gloss

2.2 引发剂AIBN的用量对铜金粉耐腐蚀性能与接枝率的影响

由于采用原位聚合方法在铜金粉表面进行PMMA的包覆,因此,引发剂用量必然会对制备过程产生重要的影响。图2所示为引发剂用量对吸光度与接枝率的影响。由图2可见,当m(AIBN)/m(MMA)= 0.05时,吸光度达到最小,即此时铜金粉的耐腐蚀性能最好。一般认为,对于一般的自由基聚合反应,引发剂的浓度对产率和相对分子质量都有较大的影响,引发剂浓度太小,则聚合反应不完全、包覆不均匀;而当引发剂用量过大时,所得聚合物的相对分子质量变小,也不利于PMMA在铜金粉表面的包覆。与之对应的是,当m(AIBN)/m(MMA)=0.05时,接枝率PG达到最高点,这表明耐腐蚀性能(吸光度)与接枝率之间存在一定的对应关系,即接枝率的增大有利于改善铜金粉的耐腐蚀性能。事实上,根据接枝率的定义可知,接枝率越大,则包覆在铜金粉表面的聚合物层越厚,耐腐蚀性能自然会越强。

图2 引发剂用量对吸光度与接枝率的影响

Fig.2 Effect of initiator amount on absorbance and PG

需要说明的是,在MMA原位聚合包覆铜金粉的过程中,引发剂的用量远大于MMA常规聚合反应时的用量,这是由于当聚合反应中加入铜金粉后,会延长自由基进攻单体的路径[16],使有效引发剂的浓度下降,为了保持一定的反应速度,需要大幅度增加引发剂的用量。

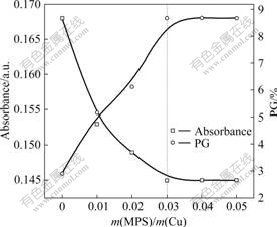

2.3 偶联剂MPS用量对铜金粉耐腐蚀性能与接枝率的影响

为了使更多的聚合反应能够原位发生在铜金粉表面,在聚合体系中加入了硅烷偶联剂MPS。图3所示为MPS用量对吸光度与接枝率的影响。由图3可看出,与未添加MPS相比,添加MPS后,其吸光度显著减小、即耐腐蚀性能显著提高,相似的情况也发生在MPS对接枝率影响的曲线中。MPS的加入能够增强铜金粉的耐腐蚀性能可归结于其特殊的分子结构[17-18]。由于铜金粉表面都含有一定数目的羟基,而MPS具有两个官能团,其中分子一端的甲氧基(OCH3)能够与铜金粉表面的羟基发生缩合,而其分子另一端的碳碳双键(C=C)能与有机单体MMA发生共聚反应,形成具有特殊功能的“分子桥”,从而将铜金粉与PMMA通过化学键牢固地结合起来,其作用机理示意图如图4所示。

图3 MPS用量对吸光度与接枝率的影响

Fig.3 Effect of MPS amount on absorbance and PG

图4 MPS 在原位聚合包覆过程中的作用示意图

Fig.4 Schematic diagram of function of MPS in in-situ polymerization encapsulation

由图3还可以发现,当m(MPS)/m(Cu)超过0.03时,其吸光度下降达到饱和状态、接枝率也增至饱和状态,这是由于铜金粉表面的羟基数目有限,过多的MPS也不能有效地改善PMMA与铜金粉的结合状况。

2.4 红外光谱(IR)分析

采用IR光谱定性地判定包覆前后铜金粉表面基团的变化情况,其结果如图5所示。从图5中可看出,在包覆前的铜金粉IR谱上,在3 500 cm-1左右存在大量的羟基特征峰,这也验证了铜金粉表面羟基的存在;而在包覆后铜金粉的IR曲线上,2 950 cm-1处CH2的吸收峰、1 710 cm-1处的C=O伸缩振动吸收峰、 1 390 cm-1处的C—H面内弯曲吸收峰都证明了铜金粉表面PMMA的存在,即通过原位聚合已经在铜金粉表面包覆了一层PMMA。

图5 包覆前后铜金粉的IR谱

Fig.5 IR spectra of unencapsulated (a) and encapsulated (b) bronze powders

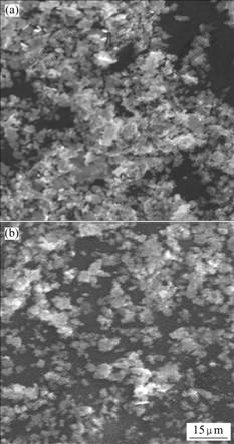

2.5 扫描电镜(SEM)分析

图6所示为包覆前后的铜金粉的SEM像。由图6可看出,相对于未包覆的铜金粉,经MMA原位聚合包覆后的铜金粉分散性更好,外观比原料铜金粉光滑,粒度分布比较平均,其边缘处较为模糊,表面确实存在一层聚合物包覆膜。

图6 包覆前后铜金粉的SEM像

Fig.6 SEM images of unencapsulated (a) and encapsulated (b) bronze powders

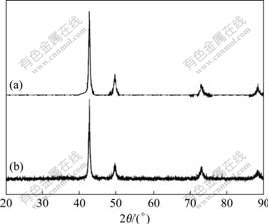

2.6 X射线衍射(XRD)分析

为了进一步证实铜金粉表面有机聚合物的存在,采用XRD对物相进行分析,其结果如图7所示。由图7可知,包覆前后铜金粉的晶体结构非常清晰,都存在铜金粉的典型特征晶面;不过与包覆前相比,包覆后的铜金粉的曲线中出现了毛刺,不平滑,这是由于其中含有非晶型的PMMA[19],因此,在XRD谱中产生了相对应的非晶包。

图7 包覆前后铜金粉的XRD谱

Fig.7 XRD patterns of unencapsulated (a) and encapsulated (b) bronze powders

3 结论

1) 当m(MMA)/m(Cu)=0.2时,表面包覆PMMA后的铜金粉同时具有良好的耐腐蚀性能与光泽度。

2) 当m(AIBN)/m(MMA)=0.05时,吸光度达到最低点,即耐腐蚀性能最佳,而此时的接枝率也达到最高点,即耐腐蚀性能(吸光度)与接枝率间存在一定的对应关系。

3) 偶联剂MPS的加入有利于提高铜金粉表面的耐腐蚀性能,其主要原因是由于其分子结构中具有甲氧基(OCH3)与碳碳双键(C=C),能形成具有特殊功能的“分子桥”,从而将铜金粉与PMMA通过化学键牢固地结合起来。

4) IR、SEM与XRD分析都表明,通过原位聚合成功地将PMMA包覆在铜金粉的表面,显著地改善了铜金粉的耐腐蚀性能。

REFERENCES

[1] 赵麦群, 张 颢. 凹印用铜金粉的物理性能[J]. 中国有色金属学报, 2002, 12(4): 749-752.

ZHAO Mai-qun, ZHANG Hao. Physical properties of bronze powder in intaglio printing[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(4): 749-752.

[2] 赵麦群, 张 颢, 苏小娟. 铜金粉的颜色及其影响因素[J]. 中国有色金属学报, 2003, 13(5): 1232-1237.

ZHAO Mai-qun, ZHANG Hao, SU Xiao-juan. Color of bronze powder and its influence factors[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1232-1237.

[3] KOBAYASHI T, MARUYAMA T, YASUDA T. Sliding properties of composite sprayed coating between bronze powder and solid lubricant[J]. Materials Transactions, 2003, 44(5): 1024-1028.

[4] MANN M, SHTER G E, REISNER G M, GRADER G S. Synthesis of tungsten bronze powder and determination of its composition[J]. Journal of Materials Science, 2007, 42(3): 1010-1018.

[5] TANG C H, CHENG F T, MAN H C. Laser surface alloying of a marine propeller bronze using aluminium powder: Part I: Microstructural analysis and cavitation erosion study[J]. Surface and Coatings Technology, 2006, 200(8): 2602-2609.

[6] TANG C H, CHENG F T, MAN H C. Laser surface alloying of a marine propeller bronze using aluminium powder: Part Ⅱ: Corrosion and erosion–corrosion synergism[J]. Surface and Coatings Technology, 2006, 200(8): 2594-2601.

[7] 朱丽霞, 赵麦群, 金文峰. 表面包覆处理对铜金粉抗氧化性能的影响[J]. 粉末冶金技术, 2006, 24(4): 287-290.

ZHU Li-xia, ZHAO Mai-qun, JIN Wen-feng. Effect of surface coating on inoxidizability of bronze powder[J]. Powder Metallurgy Technology, 2006, 24(4): 287-290.

[8] 王 蓉, 赵麦群, 白艳霞. 铜金粉表面改性技术的研究[J]. 中国粉体技术, 2005, 11(5): 20-23.

WANG Rong, ZHAO Mai-qun, BAI Yan-xia. Study on surface modification of bronze powder[J]. China Powder Science and Technology, 2005, 11(5): 20-23.

[9] RUSU G. Polyamide 6/bronze powder composites obtained in situ via anionic polymerization of epsilon-caprolactam in presence of bronze powder[J]. Material Plastics, 2007, 42(3): 1010-1018.

[10] 邹宗祥. EDTA分光光度法测定铸造锌合金中铜[J]. 四川有色金属, 1999(2): 35-37.

ZOU Zong-xiang. Spectrophotometric determination of copper in casting zinc alloy[J]. Sichuan Nonferrous Metals, 1999(2): 35-37.

[11] LIU H, YE H Q, ZHANG Y C, TANG X D. Preparation and characterization of poly(trimethylolpropane triacrylate)/flaky aluminum composite particle by in situ polymerization[J]. Dyes and Pigments, 2008, 79(3): 236-241.

[12] BOURGEAT-LAMI E, LANG J. Encapsulation of inorganic particles by dispersion polymerization in polar media 2: Effect of silica size and concentration on the morphology of silica–polystyrene composite particles[J]. Journal of Colloid and Interface Science, 1999, 210(2): 281-289.

[13] LIU P. Hyperbranched aliphatic polyester grafted attapulgite via a melt polycondensation process[J]. Applied Clay Science, 2007, 35(1/2): 11-16.

[14] LUNA-XAVIER J L, GUYOT A, BOURGEAT-LAMI E. Synthesis and characterization of silica/poly(methyl methacrylate) nanocomposite latex particles through emulsion polymerization using a cationicazo initiator[J]. Journal of Colloid and Interface Science, 2002, 250(1): 82-92.

[15] LIU H, YE H Q, TANG X D. Aluminum pigment encapsulated by in situ copolymerization of styrene and maleic acid[J]. Applied Surface Science, 2007, 254 (2): 616-620.

[16] LIU H, YE H Q, ZHANG Y C. Preparation and characterization of PMMA/flaky aluminum composite particle in the presence of MPS[J]. Colloids and Surfaces A: Physicochemical Engineering Aspects, 2008, 315(1): 1-6.

[17] BOURGEAT-LAMI E, LANG J. Encapsulation of inorganic particles by dispersion polymerization in polar media 1: Silica nanoparticles encapsulated by polystyrene[J]. Journal of Colloid and Interface Science, 1998, 197(2): 293-308.

[18] LIU P, GUO J S. Polyacrylamide grafted attapulgite (PAM-ATP) via surface-initiated atom transfer radical polymerization (SI-ATRP) for removal of Hg(Ⅱ) ion and dyes[J]. Colloids and Surfaces A: Physicochemical Engineering Aspects, 2006, 282/283: 498-503.

[19] 刘 辉. 原位聚合制备聚丙烯酸酯/氧化铝或金属铝复合粒子及性能研究[D]. 长沙: 中南大学, 2007: 50-51.

LIU Hui. Preparation and property of polyacrylate/alumina or aluminum composite particles by in-situ polymerization[D]. Changsha: Central South University, 2007: 50-51.

基金项目:中国博士后科学基金资助项目(2008044987);中南大学博士后科学基金资助项目(1332-74341015109);中南大学粉末冶金国家重点实验室开放课题资助项目(2008023)

收稿日期:2008-06-30;修订日期:2008-12-02

通讯作者:刘 辉,讲师,博士;电话:0731-8876605;传真:0731-8879616;E-mail: liuhui@mail.csu.edu.cn

(编辑 李艳红)