滑动磨损磨粒群的分布规律

来源期刊:中南大学学报(自然科学版)2003年第3期

论文作者:朱真才 戴兴国 陈国安

文章页码:269 - 272

关键词:滑动磨损;磨粒群;分布

Key words:sliding wear; wear particle group; distribution

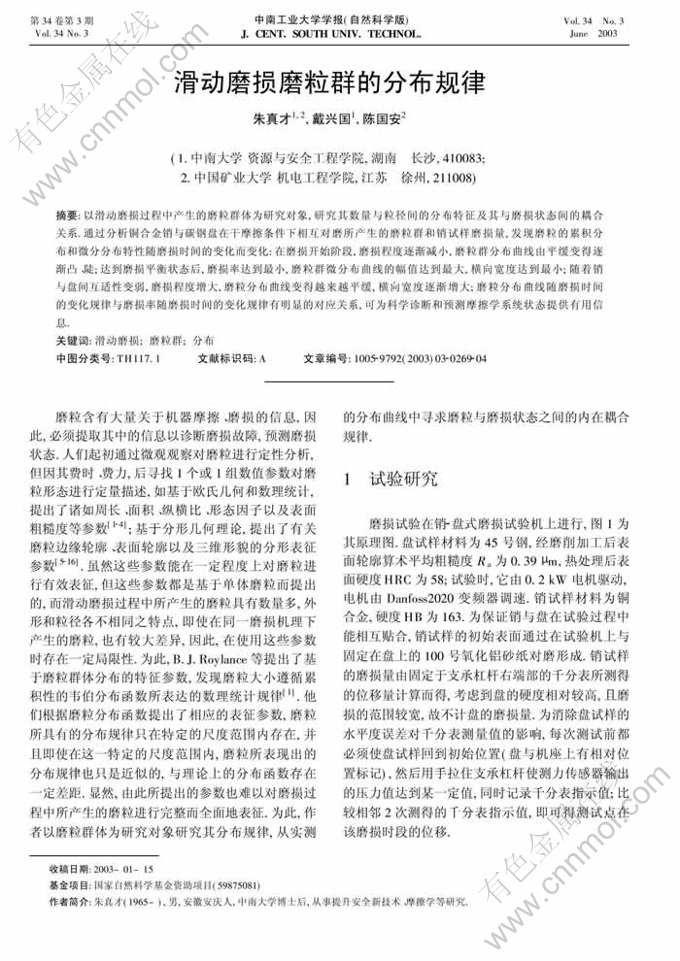

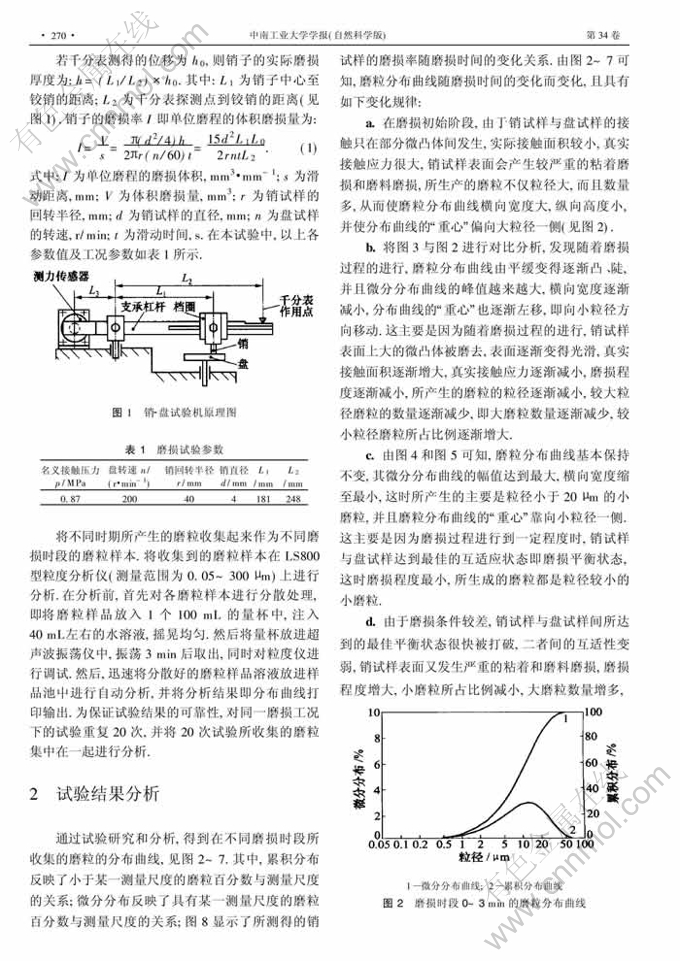

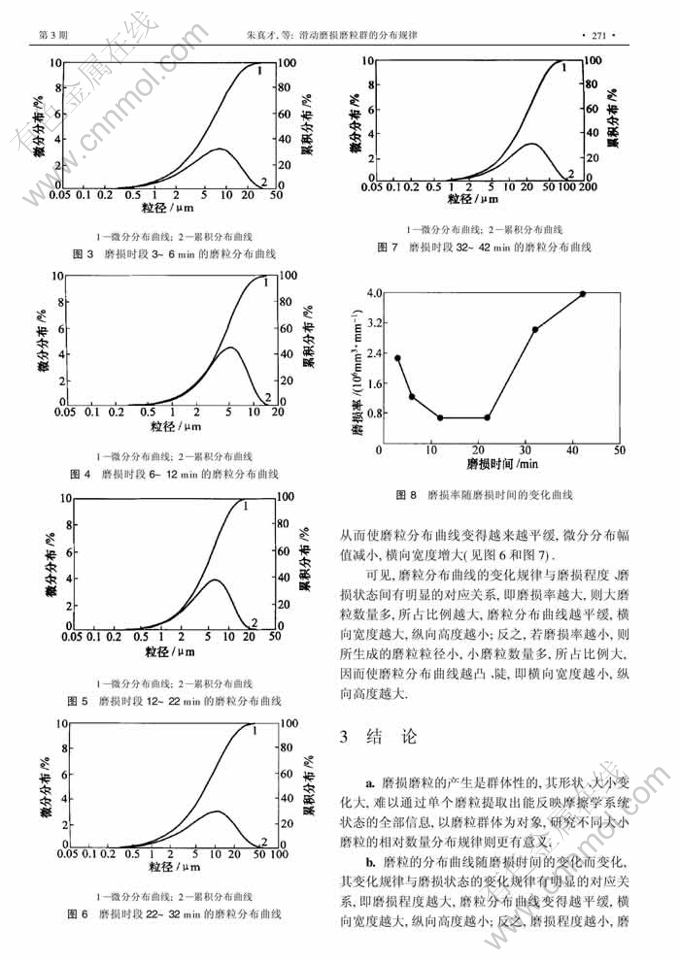

摘 要:以滑动磨损过程中产生的磨粒群体为研究对象,研究其数量与粒径间的分布特征及其与磨损状态间的耦合关系.通过分析铜合金销与碳钢盘在干摩擦条件下相互对磨所产生的磨粒群和销试样磨损量,发现磨粒的累积分布和微分分布特性随磨损时间的变化而变化:在磨损开始阶段,磨损程度逐渐减小,磨粒群分布曲线由平缓变得逐渐凸、陡;达到磨损平衡状态后,磨损率达到最小,磨粒群微分布曲线的幅值达到最大,横向宽度达到最小;随着销与盘间互适性变弱,磨损程度增大,磨粒分布曲线变得越来越平缓,横向宽度逐渐增大;磨粒分布曲线随磨损时间的变化规律与磨损率随磨损时间的变化规律有明显的对应关系,可为科学诊断和预测摩擦学系统状态提供有用信息.

Abstract: The distribution feature of wear particles, its variation law, and coincidence relation between it and wear state were investigated by taking wear particle group as the researching object. The wear experiments were conducted for copper alloy pins and carbon steel discs under dry friction conditions, and the wear particle group produced was analyzed, and the pin specimen’s wear rate was measured. The results show that the cumulative distribution and differential distribution features of wear particles change with wear time. Wear degree decreases, and the wear particle distribution curves become protrusive and precipitous gradually in the initial stage.When an equilibrium condition is achieved and when wear rates reach the minimum, the longitudinal height and transverse width of wear particle distribution curves achieve the maximum and minimum respectively. Then wear rate increases, and wear particle distribution curves become smooth gradually because of the worse mutual adaptability between the pin and disc. It is found that there is a distinct corresponding relation between the variation laws of wear particle distribution and wear status by comparing them. Objective and valid information can be provided for diagnosing and predicting tribological system state based on this relation.