Influence of aging on microstructure and mechanical properties of AZ80 and ZK60 magnesium alloys

LI Yan1, ZHANG Zhi-min1, XUE Yong1, 2

1. School of Materials Science and Engineering, North University of China, Taiyuan 030051, China;

2. School of Mechanical Engineering and Automation, Beihang University, Beijing 100191, China

Received 25 September 2010; accepted 20 December 2010

Abstract: The effect of aging on the microstructure and mechanical properties of AZ80 and ZK60 wrought magnesium alloys was studied with optical microscope and mechanical testers. The results demonstrate that both the tensile strength and elongation of AZ80 alloy increase firstly and then decrease as the aging temperature rises, the peak values appear when the aging temperature is 170 °C. The hardness of ZK60 alloy increases firstly and then decreases as the aging temperature rises, and the hardness reaches its peak value at 170 °C. However, the toughness of the alloy is just the opposite. Moreover, ZK60 alloy has good performances in both impact toughness and other mechanical properties at the aging temperature from 140 °C to 200 °C.

Key words: AZ80 magnesium alloy; ZK60 magnesium alloy; aging; microstructure; mechanical properties

1 Introduction

As the lightest material for manufacturing metal components, magnesium has so far been widely used in the fields like aerospace industry, automobile industry and military industry[1]. At present, the mainstream magnesium alloys include but not limited to AZ91 alloy for casting purpose and AZ31 alloy for deforming purpose, which are magnesium alloys with aluminum as major additive element. These alloys, however, have comparatively low strength; so high strength magnesium alloy like AZ80 and ZK60 for deforming purpose are therefore developed[2-3].

Nowadays, many researchers have investigated the effect of the texturing process and alloy element on structure and property. For example, MUKAI et al[4] made an attempt to improve the ductility of magnesium alloy by controlling the crystal-grain structure of alloy. SOMEKAWA and MUKAI[5] studied the mechanical property of AZ31 magnesium alloy by using the equal channel extrusion technology. SONG et al[6]studied the microstructure and the mechanical properties of magnesium alloy by reciprocating extrusion of magnesium alloy ingot. The aging precipitation behavior, microstructure, and the mechanical properties of the magnesium alloy were studied by adding alloy[7-9]. Other researchers made attempt to improve the properties of magnesium alloy through heat treatment. MA et al[10] studied the effect of heat treatment on the microstructure of ZK60 magnesium alloy. WANG et al[11] studied the aging process of Mg-Al alloys. DULY et al[12] studied the solution process of the Mg-Al alloys. The precipitated way of the Mg17Al12 phase of the Mg-AI alloys was studied[13-14]. However, research efforts on the effects of solution and aging on the microstructures and mechanical properties of AZ80 and ZK60 wrought magnesium alloys are rather limited.

There seem to be two major problems concerning these researches on the heat treatment of magnesium alloys: the first is that these researches fail to touch the optimization of the treatment process of magnesium alloys; and the second is that the mechanical properties of the magnesium alloys proposed above seem to be insufficient for producing high-performance products. There is no report on the yield strength, and the relationship between the indicators characterizing the reliability and the impact properties and other indicators, in particular. These defects may, affect application of the deforming magnesium alloy components to industrial production.

Therefore, the objective of the present work was to investigate the effects of solution and aging on the microstructures and mechanical properties of AZ80 and ZK60 wrought magnesium alloys. So that the laws of structure formation of the products could be understood, which should provide guidance for the alteration and control of the structure of the product phases.

2 Experimental

Mg-8.9%Al-0.53%Zn alloy and Mg-(5.0%-6.0%) Zn-(0.3%-0.9%)%Zr (mass fraction) alloy ingots with an outer diameter of 300 mm were adopted as the materials for experiment. Firstly, intercept along the axial direction of the ingot, a piece of slab with a thickness of 15 mm was obtained as sample material. Secondly, heat the slab with a heating rate of 15 °C/min for homogenization annealing, including heating the slab to 400 °C and insulating it for 12 h and air-cooling it to room temperature (ACRT)[15]. The third step is solution treatment of ingot: solution treatment of AZ80 alloy includes heating the ingot to 420 °C, insulating it for 5 h, and ACRT; solution treatment of ZK60 alloy includes heating the ingot to 500 °C, insulating it for 2 h, and ACRT. The final step is aging: after solution treatment, divide each of the AZ80 and ZK60 alloy samples into five groups, and each group includes 6 samples. Heat each group separately to 110, 140, 170, 200, and 230 °Cass fraction]nd EPC Mg-11Gd-3Y f Metals, emperature on the fluidity of cast magnesium alloyr of AM50 alloys , insulate them for 10 h, and then ACRT.

After heat treatment, the slabs were machined into standard tensile specimens and their mechanical properties of each specimen were measured using WEW-E100D electronic universal testing machine. Impact test was conducted on these specimens in XJJ-50 strut-beam impact machine at room temperature. Their hardness was tested using HB-3000 Brinell hardness tester. After grinding and polishing, the metallographic samples were eroded by using 2% (volume fraction) oxalic acid plus 2% (volume fraction) nitric acid, and the microstructures, of these samples were observed under ZEISS digital microscope.

3 Results

3.1 Effect of aging temperature on mechanical properties of AZ80 and ZK60

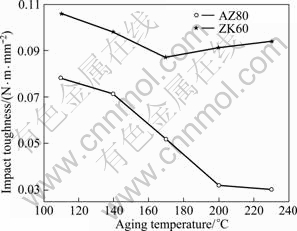

Figure 1 illustrates that though impact toughness of AZ80 decreases as aging temperature rises, aging temperature has a great effect on its impact toughness. For ZK60 alloy, its impact toughness decreases as aging temperature rises between 110 and 170 °C, but increases as aging temperature rises between 170 and 230 °C. At 170 °C, its impact toughness reaches its minimum value.

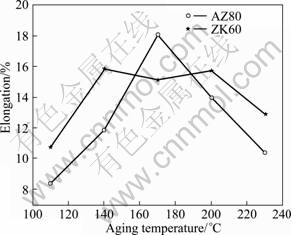

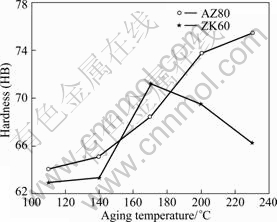

Figure 2 shows that aging temperature has similar impact on the tensile strength of AZ80 and ZK60 alloys. The tensile strength first increases and then decreases as aging temperature rises, and the tensile strength curve of ZK60 alloy varies more gently than that of AZ80 alloy. At 170 and 200 °C, the tensile strengths of AZ80 and ZK60 alloys reach their peak values, respectively. Normally speaking, ZK60 alloy has a higher tensile strength than AZ80 alloy. Figure 3 illustrates that aging temperature has similar impact on the elongation of AZ80 and ZK60 alloys. The elongation first increases and then decreases as aging temperature rises, and the elongation curve of ZK60 alloy varies more gently than that of AZ80 alloy. In addition, in low-temperature interval (between 110 and 140 °C) and high-temperature interval (between 200 and 230 °C), the elongation of ZK60 alloy is greater than that of AZ80 alloy. Figure 4 illustrates that the hardness of AZ80 alloy increases as aging temperature rises, but the hardness of ZK60 alloy first inclines and then declines as aging temperature rises, and at 170 °C the hardness of AZ80 alloy reaches its peak value. In low-temperature interval (between 110 and 140 °C) and high-temperature interval (between 200 and 230 °C), the hardness of AZ80 alloy is greater than that of ZK60 alloy.

Fig.1 Effect of aging temperature on impact toughness of AZ80 and ZK60 alloys

Fig.2 Impact of aging temperature on tensile strength of AZ80 and ZK60

Fig.3 Effect of aging temperature on elongation of AZ80 and ZK60 alloys

Fig.4 Effect of aging temperature on hardness of AZ80 and ZK60 alloys

3.2 Effect of aging temperature on microstructures of AZ80 and ZK60

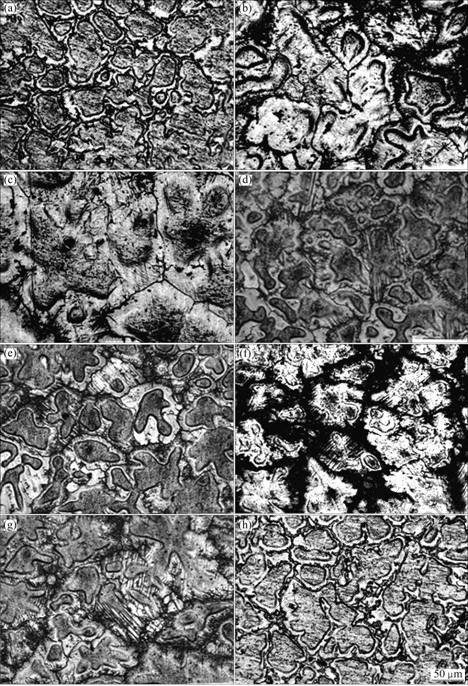

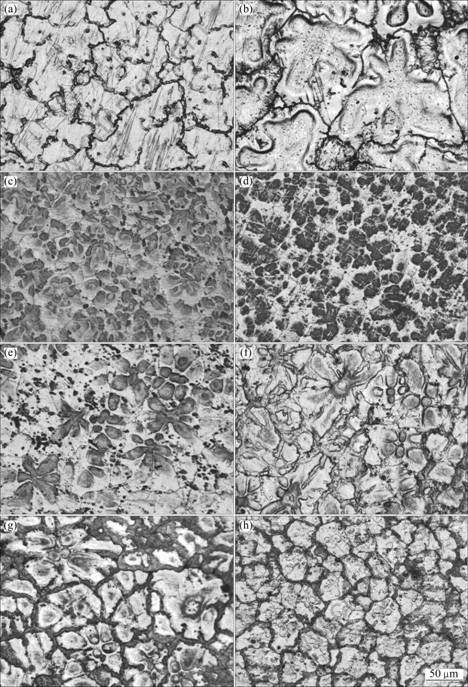

Figure 5(a) shows that the microstructures of the as-cast magnesium alloy are characterized by the uneven network structures with the serious segregations; and the eutectics are distributed mainly along crystal boundary. After homogenization treatment (Fig.5(b)), the structure of the as-cast magnesium is uniformed and the segregation is eliminated. After solid-solution treatment (Fig.5(c)), the majority of eutectics are dissolved, forming a homogeneous solid solution. During low-temperature aging (Figs.5(d) and (e)), a portion of the quadratic phase is precipitated in irregular-bone distribution or irregular- petal distribution along crystal boundary, which is accompanied by the formation of aging twins. As aging temperature rises, quadratic-phase precipitation increases and the aging twins become big; at 170 °C (Fig.5(f)), quadratic-phase precipitation reaches its peak value and most of the precipitates are uniform tiny sheet. As aging temperature rises continuously, quadratic-phase crystal grains grow significantly (Fig.5(g)); and at the temperature of 230 °C, the structure turns into network distribution (Fig.5(h)).

Figure 6 illustrates that quadratic-phase precipitates are in a lower level at low temperature (see Fig.6(d)); it increases as temperature rises: the precipitates reach the biggest value at 200 °C (see Fig.6(g)). As the temperature rises continuously, the precipitates begin to reduce. Textural evolution of ZK60 alloy is similar to that of AZ80, the as-cast structure of ZK60 alloy is also in network distribution. But at the same aging temperature, the structure of ZK60 is smaller than that of AZ80.

4 Discussion

For AZ80 magnesium alloy during aging process, β-Mg17Al12 phase precipitates from supersaturated α-Mg solid solution, and a number of β phases discontinuously precipitated along crystal-grain boundary as well as continuously precipitated inside crystal grain [16]. In addition, the precipitated β phase is apparently smaller than that of as-cast alloy and its morphological structure changes greatly, which accounts for the significant improvement of tensile strength of the alloy, and subtle improvement of yield strength of the alloy. As aging process continues, the alloy plastic indicator δ declines significantly; under aging condition of 200 °C and 32 h, the alloy elongation is even lower than that of the alloy in its as-cast state. This is because, as aging process continues, the precipitated β phase impedes dislocation movement, which leads to accumulation of large number of dislocations. Greater stress among these dislocations may cause cracks, decreasing the alloy plasticity.

When the equilibrium phase β-Mg17Al12 is in diffuse thin sheet, its surface is parallel to the base surface of the matrix, improving the alloy strength[11]. β-phase will increase as Al content increases; but since the β-Mg17Al12 is soft at 120-130 °C in low-temperature aging, it has no pinning effect on crystal-grain boundary, making the alloy have a comparatively higher toughness and lower hardness. As aging temperature rises, β-Mg17Al12 gradually becomes hard, decreasing the alloy toughness. When aging temperature remains at around 230 °C, nucleation becomes very easy for crystal-grain refinement, increasing the alloy hardness.

Fig.5 Microstructures of AZ80 alloy under different states: (a) As-cast state; (b) After homogenizing; (c) After solid solution treatment; (d) Aging at 110 °C; (e) Aging at 140 °C; (f) Aging at 170 °C; (g) Aging at 200 °C; (h) Aging at 230 °C

In its as-cast structure, ZK60 magnesium alloy contains large number of eutectic structure, which consists of α-Mg and irregular-shaped MgZn[12]. There are various eutectic structures that may occur along crystal-grain boundary, and also occur inside crystal grain. They may be of petal-shaped pattern and strip-shaped pattern. In addition, the precipitated phases have a fixed locational relation to their matrixes: some are parallel to their matrixes, while others are vertical to their matrixes. The joint effect of these factors accounts for the variation of ZK60 alloy in mechanical properties and microstructures, as mentioned above.

Figure 6 shows that the as-cast structure of ZK60 alloy is network structure, and the alloy has a comparatively lower strength and plasticity. As aging temperature rises, there occurs second-phase grain- distribution precipitates which grow gradually and forms networks at 170 °C. At this time, the second phase reaches its peak, thus the alloy has the greatest hardness while its toughness decreases. As new phases precipitate along crystal-grain boundary, these phases are in uniform distribution, making the toughness of the alloy increase. As temperature rises in a further step, the primary-precipitated phases grow up. This may cause overaging, and reduce the alloy hardness.

Fig.6 Microstructures of ZK60 alloy under different states: (a) As-cast state; (b) After homogenizing; (c) After solid solution treatment; (d) Aging at 110 °C; (e) Aging at 140 °C; (f) Aging at 170 °C; (g) Aging at 200 °C; (h) Aging at 230 °C

5 Conclusions

1) For the ZK60 magnesium alloy, the hardness firstly increases and then decreases as the aging temperature rises. On the contrary, the impact toughness firstly decreases and then increases as the aging temperature rises. At aging temperature of 170 °C, the alloy has the maximum hardness and minimum impact toughness. The tensile strength and elongation of the alloy firstly increase and then decrease as the aging temperature rises.

2) For the AZ80 magnesium alloy, the hardness increases and the plasticity decreases as the aging temperature rises. The tensile strength and elongation firstly increase and then decrease as the aging temperature rises.

3) The optimum aging temperature for AZ80 magnesium alloy is 170 °C, and for the ZK60 magnesium alloy is 200 °C. At the same aging temperature, ZK60 alloy has a better performance than AZ80 alloy.

References

[1] MORDIKE B L, EBERT T. Magnesium properties: applications potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[2] AGHION E, BRONFIN B. Magnesium alloys development towards the 21st century[J]. Materials Science Forum, 2000, 350-351: 19-28.

[3] BAGHNI I M, WU Yin-shun, LI Jiu-qing, DU Cui-wei, ZHANG Wei. Mechanical properties and potential applications of magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(6): 1253-1259.

[4] MUKAI T, YAMANOI M, WATANABE A, HIGASHI K. Ductility enhancement in AZ31 magnesium alloy by controlling its grain structure[J]. Scripta Materialia, 2001, 45(1): 89-94.

[5] SOMEKAWA H, MUKAI T. Fracture toughness in Mg-Al-Zn alloy processed by equal-channel-angular extrusion[J]. Scripta Materialia, 2006, 54(4): 633-638.

[6] SONG Pei-wei, JING Xiao-tian, GUO Xue-feng. Structure refinement and mechanical properties of Mg-4Al-2Si Mg alloy by reciprocating extrusion[J]. The Chinese Journal of Nonferrous Metals, 2007, 17 (1): 111-117. (in Chinese)

[7] BALASUBRAMANI N, SRINIVASAN A, PILLAI U T S, PAI B C. Effect of Pb and Sb additions on the precipitation kinetics of AZ91magnesium alloy[J]. Materials Science and Engineering A, 2007, 457: 275-281.

[8] WANG J, MENG J, ZHANG D P, TANG D X. Effect of Y for enhanced age hardening response and mechanical properties of Mg-Gd-Y-Zr alloys[J]. Materials Science and Engineering A, 2007, 456: 78-84.

[9] YUAN Guang-yin, SUN Yang-shan, ZENG Xiao-qin, LU Yi-zhen, WANG Qu-dong, DING Wen-jiang. Influence of bismuthon the aging kinetics of AZ91 magnesium alloy[J]. Journal of Shanghai Jiaotong University, 2001, 35(3): 451-456. (in Chinese)

[10] MA Yan-long, PAN Fu-sheng, ZUO Ru-lin, ZHANG Jin, YANG Ming-bo. Effects of heat-treatment on microstructure of wrought magnesium alloy ZK60[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: 1888-1891.

[11] WANG Hui-min, CHEN Zhen-hua, YAN Hong-ge, LIU Ying-ke. Heat-treatment of magnesium alloys[J]. Heat Treatment of Metals, 2005, 30(11): 49-54. (in Chinese)

[12] DULY D, SIMON J P, BREEHET Y. On the competition between continuous and discontinuous precipitation in binary Mg-Al alloys[J]. Acta Metallurgic Materialia, 1995, 43(l): 101-106.

[13] PORTER D A, EDINGTON J W. Microanalysis and cell boundary velocity measurements for the cellular reaction in a Mg9% Al alloy[J]. Proceeding of the Royal Society of London Series A, 1978, 358(1694): 335-350.

[14] XIAO Xiao-lin, LUO Cheng-ping, LIU Jiang-wen, WU Dong-xiao, NIE Jian-feng, BARRY C M. Structure of HCP/BCC interphase boundaries in AZ91 Mg-Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(l): 15-20. (in Chinese)

[15] VOLKOVA EF. Effect of deformation and heat treatment on the structure and properties of magnesium alloys of the Mg-Zn-Zr system[J]. Metal Science and Heat Treatment, 2006, 48(11-12): 508-512.

[16] CELOTTO S. TEM study of continuous precipitation in Mg-9wt%Al-1wt% Zn alloy[J]. Acta Materialia, 2000, 48(8): 1775-1787.

时效处理对AZ80和ZK60镁合金微观组织和

力学性能的影响

李 艳1, 张治民1, 薛 勇1, 2

1. 中北大学 材料科学与工程学院,太原030051;

2. 北京航空航天大学 机械工程与自动化学院,北京100191

摘 要:借助光学显微镜和力学性能测试仪器,研究时效处理对AZ80和ZK60锻造镁合金的微观组织和力学性能的影响规。结果表明:AZ80镁合金的抗拉强度和伸长率随着时效温度的升高呈现先增加后下降的趋势,当时效温度为170 °C时,其抗拉强度和伸长率达到最大;ZK60镁合金的硬度随着时效温度的升高呈现先增加后下降的趋势,当时效温度为170 °C时,其硬度达到最大,而其韧性正好呈现相反的趋势。此外,在140-200 °C的时效温度范围内,ZK60镁合金比AZ80镁合金具有更好的冲击韧性与其他力学性能。

关键词:AZ80镁合金;ZK60镁合金;时效;微观组织;力学性能

(Edited by LI Xiang-qun)

Foundation item: Projects (50735005, 50605059) supported by the National Natural Foundation of China; Project (2007021026) supported by the Shanxi Provincial Science Foundation for Youths, China; Project (20081027) supported by the Development for Science and Technology in Higher Educational Institutes, China

Corresponding author: XUE Yong; Tel: +86-351-3921398; E-mail: forge54@163.com

DOI: 10.1016/S1003-6326(11)60774-7