文章编号:1004-0609(2010)S1-s0183-05

TB10钛合金的焊接组织与性能

张 翥,于 洋,惠松骁,叶文君,尤振平

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:研究电子束焊接态TB10钛合金的显微组织和力学性能。结果表明:TB10板材焊区经过固溶及双重时效后,可得到较好的强度配合以及优异的显微组织和力学性能;焊接和焊接前的热处理工艺使焊区的抗拉强度、屈服强度和塑性均有所下降;经过(725 ℃, 1 h, FC)固溶处理后经双重时效处理后,焊区的冲击断裂韧性达到31.3~45.6 J/cm2;固溶+双重时效处理后,合金基体和焊区的显微组织由β相、粗大的初生α相、短小细长的针状次生α相组成;热处理后,合金元素在不同相中的重新分布使各相变得更加稳定。

关键词:TB10钛合金;热处理;焊接组织;力学性能

中图分类号:TG116.23 文献标志码:A

Microstructure and mechanical properties of

TB10 titanium alloy after welding

ZHANG Zhu, YU Yang, HUI Song-xiao, YE Wen-jun, YOU Zhen-ping

(State Key Laboratory for Fabrication and Processing of Non-ferrous Metals,

General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: The microstructure and mechanical properties of electron beam welding of TB10 titanium alloy were investigated. The results show that, after solution treatment and twice aging treatment, the weld zone of TB10 plate obtains the best combinations of strengths, and showing excellent microstructure and mechanical properties. The processing of weld and post weld heat treatment decreases the tensile strength, yield strength and ductility of weld zone. After (725 ℃, 1 h, FC) solution treatment and twice aging treatment, the weld zone impact toughness is 31.3-45.6 J/cm2. After solid solution treatment and twice aging treatment, the microstructures of the base metal and weld consist of toughness β phase, coarsening primary α phase, short and minimum needle-shape secondary α phase. After heat treatment, alloy elements redistributions in different phases of alloy become more stable than before.

Key words: TB10 titanium alloy; heat treatment; welding microstructure; mechanical properties

近β型钛合金Ti-5Mo-5V-2Cr-3Al[1],含有3% α稳定元素Al,5%同晶型β稳定元素Mo和V,2%共析型β稳定元素Cr,Kβ=1.10,简称Ti-5523合金,合金牌号为TB10[2-3]。该合金中,β稳定元素总含量在临界浓度附近,使得合金兼有α+β型和亚稳定β型钛合金的性能特征,具有比强度高,断裂韧度和冲击韧性好[4],淬透性高,加工性能优异等一系列优点,在航空、航天、兵器及民用领域有着广泛的应用前景。

采用优质、高效和经济的电子束焊连接手段,来提高大厚壁结构件的整体性能,是十分必要的。本文作者介绍了TB10合金电子束焊接组织与性能,为近β型钛合金TB10大厚壁结构件的实际应用提供依据。

1 实验

1.1 实验用料

采用工业规模合金锭型3 t,其合金铸锭化学分析结果见表1。铸锭经多火次锻造成直径75 mm的棒材,再精锻成35 mm×70 mm×1 200 mm板条料。将35 mm×70 mm×1 200 mm精锻板条料切割成35 mm×70 mm×120 mm若干条。采用淬火金相法测得转变温度tβ为815 ℃,经两相区固溶处理(见表2)后加工,得到电子束焊接用实验料。

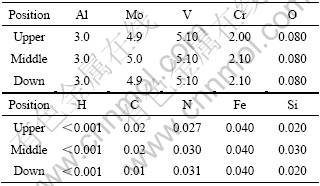

表1 合金铸锭的化学成分

Table 1 Chemical composition of ingot (mass fraction, %)

表2 焊接坯料板条材的固溶处理

Table 2 Solution treatment of TB10 weld plate billet

1.2 实验方法

采用ELA-30型真空电子束焊机对TB10板料进行焊接。在33 mm×55 mm×120 mm板条的宽度中心沿长度方向焊一条纵向焊缝,研究焊缝的横向性能。在33 mm×70 mm×120 mm板条的宽度中心和间隔15 mm处沿长度方向焊3条纵向焊缝,研究焊缝的纵向性能。焊接后的试样经热处理后(热处理制度见表3)对其横、纵向力学性能进行测试,采用金相显微镜及JEM 2000FX透射电镜对其微观组织进行观察。

表3 试样热处理制度

Table 3 Heat treatment of specimens

2 结果与讨论

2.1 合金的微观组织

2.1.1 母材的基体组织

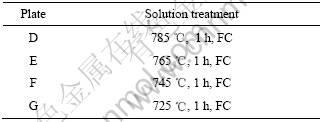

用金相显微镜、JEM-2000FX分析型透射电镜观察经R3热处理后试样的微观组织(见图1)。由图1可知,金相组织由β相和弥散析出的α相组成。

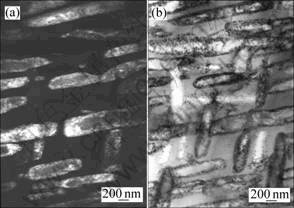

经R3热处理后合金的微观组织如图2所示。由图2可知,合金的微观组织是由β相、粗而长的针状初生α和短而小的针状次生α相组成的。

图1 R3热处理合金的微观组织

Fig.1 Microstructures of TB10 alloy after R3 heat treatment

图2 R3处理后合金的TEM像

Fig.2 EM images of TB10 alloy after R3 treatment: (a) Bright field image; (b) Dark field image

2.1.2 电子束焊接后的焊缝组织

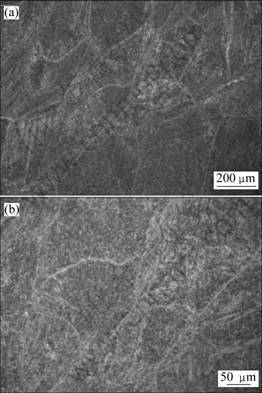

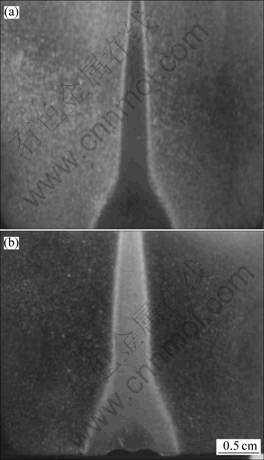

经过电子束焊接后焊缝的组织如图3所示。

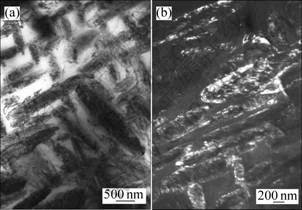

焊缝的TEM像如图4所示。由图4可知:合金焊缝经R4热处理制度处理后的组织由铸态β相、 粗而长的初生α相和弥散分布的短而小的针状次生α相组成。与图2对比可知,焊接组织的针状次生α相比母材的变粗变长。

图3 起弧端及收弧端焊缝的组织

Fig.3 Macrostructures of weld zone: (a) Begin weld; (b) Finish weld

图4 R4热处理后合金焊缝的TEM像

Fig.4 TEM images of weld zone after R4 treatment: (a) Bright field image; (b) Dark field image

2.2 合金的力学性能

2.2.1 合金母材的力学性能

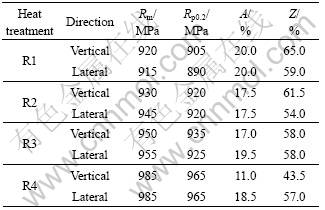

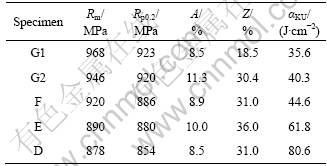

从35 mm×70 mm×120 mm板条一边切取的纵向母材试样研究合金的纵向力学性能。从35 mm×58 mm×120 mm板条切取的横向母材试样研究合金的横向力学性能。试样经热处理后对其力学性能进行测试,其结果如表4所列。

从表4中合金的横、纵向性能可以看出,合金的强度随固溶处理温度的降低而增大,塑性随固溶处理温度的降低而降低;经R3热处理后,试样的纵向综合性能较好;经R4热处理后,试样的横向综合性能较好。

表4 合金母材的力学性能

Table 4 Mechanical properties of alloy

2.2.2 电子束焊焊接性能

用35 mm×70 mm×120 mm板条材研究TB10合金的纵向焊接性能,将固溶处理后加工好的33 mm×70 mm×120 mm,在宽度中心和间隔15 mm处沿长度方向焊3条纵向焊缝,研究合金的纵向焊缝性能。焊后经热处理后对其拉伸性能进行测试。测试结果见表5。

由表5中数据可以看出:纵向试样在两相区经固溶+二次时效处理后,塑性较高,其强度随两相区固溶温度的降低而提高。而经R4制度热处理后,试样的拉伸性能最好;经 R3制度热处理后,试样的拉伸性能次之。

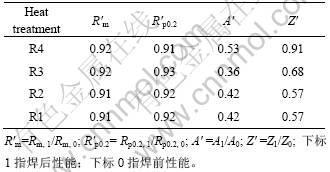

合金的纵向焊缝焊接系数(焊接后性能与焊接前性能的比值)如表6所列。由表6可知,经R4制度处理后,合金的综合性能最好。

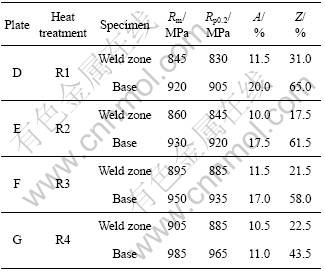

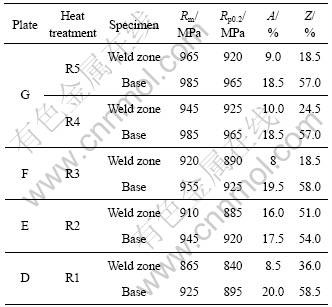

用35 mm×57 mm×120 mm板条材研究TB10合金的横向焊接性能,将固溶处理后加工的33 mm×55 mm×120 mm板材在宽度中心焊一条纵向焊缝。焊接后的板条进行不同制度的热处理后合金的横向性能如表7所列。

表5 合金焊缝的纵向性能

Table 5 Mechanical properties of alloy weld zone at vertical direction

表6 合金焊缝的纵向焊接系数

Table 6 Welding coefficient of joint of alloy at vertical direction

表7 板条横向焊接接头的力学性能

Table 7 Mechanical properties of weld zone of plate at lateral direction

由表7可以看出,横向试样经两相区固溶+二次时效处理后,其性能为中强、高塑性,其强度随两相区固溶温度的降低而提高。而采用R4制度热处理后,试样的拉伸性能最好;经R3制度热处理后,试样的拉伸性能次之。

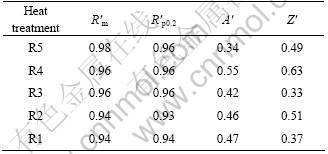

不同热处理制度处理后合金焊缝横向焊接系数如表8所列。由表8可知,经R4制度热处理后,合金综合性能最好。

表8 合金焊缝的横向焊接系数

Table 8 Welding coefficient of joint of alloy at lateral direction

2.4.3 合金焊缝横向焊接接头的冲击性能

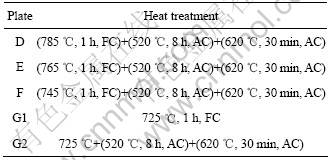

根据合金焊缝横向焊接接头力学性能研究结果,采用焊接+固溶+二次时效的热处理制度研究合金焊缝横向接头冲击性能。不同板材焊后的热处理制度如表9所列。

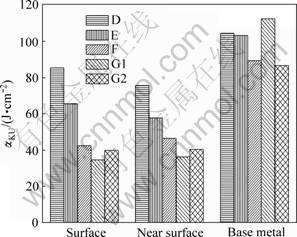

不同热处理制度处理后材料的冲击性能如图5所示。从图5可以看出,根据热处理制度的不同焊接接头其冲击韧性αKU在34.8~85.4 J/cm2之间,基体的冲击韧性αKU在86.7~104.4 J/cm2之间。随着固溶温度的升高,焊接接头(板材表面和近表面)的冲击韧性随之增高,焊接接头的冲击韧性明显低于母材的冲击韧性,焊后的冲击韧性约为母材的30%~50%。

由以上分析可以得到合金横向焊接接头不同强度级别的Rm-αKU的匹配关系,结果如表10所列。从表10可以看出,经R4制度处理后,焊接接头的Rm与αKU匹配关系最好;经R3制度处理后,焊接接头的Rm与αKU匹配关系其次。

表9 板材焊后热处理制度

Table 9 Postweld heat treatment of plate

图5 不同板材焊后的热处理冲击韧性

Fig.5 αKU of different plate after postweld heat treatment

表10 合金横向焊接接头Rm和αKU的匹配关系

Table 10 Relationship between Rm and αKU2 of alloy at horizontal direction

3 结论

1) 母材和焊缝的组织均由β相、粗而长的针状初生α和短而小的针状次生α相组成。与母材组织相比,焊接组织中的针状次生α相变粗变长。

2) TB10合金母材板条经固溶+二次时效处理后获得中强、高塑性能,纵向及横向力学性能的强度均随固溶处理温度的降低而增大,塑性随固溶处理温度的降低而降低。

3) 随着固溶温度的升高,焊接接头(板材表面和近表面)的冲击韧性增大,焊接接头的冲击韧性明显低于母材的冲击韧性,焊后的冲击韧性约为母材的30%~50%。

4) 在中强状态下,725 ℃+(520 ℃, 8 h, AC)+ (620 ℃, 30 min, AC)制度(R4)处理后焊接接头的Rm与αKU匹配关系最好。

REFERENCES

[1] ZHANG Zhu, CHEN Hai-shan, HAO Rui-xin. Near beta Ti-5Mo-5V-2Cr-3Al alloy[C]//Proceedings of the Eighth World Conference on Titanium. UK: International Convention Centre Birmingham, 1995.

[2] 黄伯云, 李成功, 石力开, 等. 中国材料工程大典(第4卷): 有色金属材料工程(上)[M]. 第1版. 北京: 化学工业出版社, 2006: 684-688.

HUANG Bai-yun, LI Cheng-gong, SHI Li-kai, et al. Ceremony of China Materials Engineering Materials Engineering Metals (Volume 4)[M]. 1st ed. Beijing: Chemical Industry Press, 2006: 684-688.

[3] GB/T 3620.1—2007. 钛及钛合金牌号和化学成分[S].

GB/T 3620.1—2007. Designation and composition of titanium and titanium alloys[S].

[4] 张 翥, 惠松骁, 刘 伟. 高强高韧TB10钛合金棒材研究[J]. 稀有金属, 2006, 30(2): 221-225.

ZHANG Zhu, HUI Song-xiao, LIU Wei. High strength and high toughness TB10 titanium alloy bars[J]. Rare Metal, 2006, 30(2): 221-225.

(编辑 龙怀中)

通信作者:张 翥,教授;电话:010-62033927;E-mail: zhangzhu1938@126.com