文章编号:1004-0609(2010)S1-s0028-04

辊模拉伸Ti6A14V钛合金丝材的力学性能分析

范 珂,陶海林,周书成,王建斌,王 田

(宝鸡钛业股份有限公司,宝鸡 723014)

摘 要:研究辊模拉伸TC4钛合金丝材的组织和性能,并与传统拉伸工艺相比较。结果表明:由于二者拉伸过程中丝材所受的摩擦力大小及摩擦力形式不同,使得经过辊模拉伸生产的丝材表面光亮,内部组织更加均匀、细小;而传统工艺生产的丝材表面易出现划伤、粘模等加工缺陷,其内部的晶粒较大。将两种不同拉伸工艺生产出的产品经过再结晶退火后处理,发现辊模拉伸生产出的丝材具有强度高、塑形好等优点,其力学性能远远高于采用传统工艺生产的同规格丝材。

关键词:TC4钛合金;辊模拉丝;力学性能;组织

中图分类号:TG 356.4 文献标志码:A

Analysis of mechanical properties of Ti6Al4V wire produced by roll-die drawing

FAN Ke, TAO Hai-lin, ZHOU Shu-cheng, WANG Jian-bin, WANG Tian

(Baoji Titanium Industry Co., Ltd., Baoji 723014, China)

Abstract: The relationship between the mechanical properties and microstructures of Ti6Al4V alloy wire manufactured by roll-die drawing was discussed, and the difference between the traditional process and the new manufacturing method was compared. The results show that, because of the differences of frictional forms under two production ways, the wire manufactured by cold roll-die drawing has brighter surface and the microstructure is also finer. The wire produced by new method doesn’t have drawing imperfections, such as pitting, scratching, showing much higher mechanical properties after annealing.

Key words: TC4 titanium alloy; roll-die drawing; mechanical property; microstructure

钛及钛合金丝材由于具有耐蚀性好、比强度高、无磁性、生物相容性高、对超声波的阻抗较小、透声系数较高、储氢及较好的形状记忆功能等优点,在航空航天、石油化工、医疗卫生、汽车、建筑以及体育、休闲用品等诸多领域均有重要用途[1]。

TC4钛合金丝材应用比较广泛,传统拉伸工艺生产的钛合金丝材表面质量差,拉伸力大,在加工过程中易造成断线等缺点。辊模拉伸可以改善丝材加工时的润滑条件,提高丝材的表面质量,减少污染,且加工率有较大提升。

本文作者分析比较采用两种拉伸工艺生产的合金丝材组织与性能的差异。

1 实验

1.1 材料与设备

试验所使用的材料为宝鸡钛业股份有限公司线材厂生产的TC4钛合金丝材,坯料规格为d4.00~5.5 mm。

本次试验所使用的设备有进口辊模拉丝机和倒立式拉丝机牵引。分别取5组数据d3.50~4.0 mm、d3.00~3.50 mm、d2.60~3.00 mm、d2.50~2.70 mm和d2.20~2.50 mm,将辊模拉丝与眼模拉伸工艺生产的丝材进行比较。

1.2 拉伸试验工艺

首先对TC4钛合金丝材坯料进行真空退火处理,退火制度为750 ℃保温1 h,压力为13 mPa[2]。退火后的丝材经检查表面无裂纹、起皮等缺陷后,准备开始碾头;然后,利用倒立式拉丝机做牵引进行辊模拉伸。拉伸完成后进行表面检查并取样,为后来进行的力学性能测试做准备。

再将同一锭号的TC4钛合金丝材使用传统眼模拉伸方法进行拉伸,同样将丝材由d4.0 mm分别拉伸成与辊模拉伸相同规格的丝材。每道次拉伸完成后均截取试样进行力学性能检测。

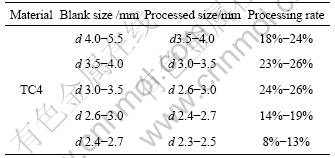

辊轧匣座每道次的变形数据如表1所列。

表1 辊模拉伸各个道次变形数据

Table 1 Deformation data of roll-die drawing in each process

2 数据分析

2.1 力学性能分析

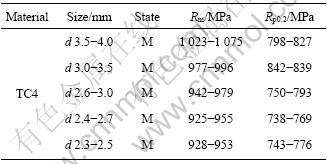

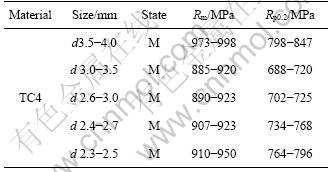

分别对以上两种不同加工工艺生产的5类规格的TC4合金丝材,使用5885电子万能试验机进行抗拉强度及屈服强度的测试,测试结果如表2和表3所列。

表2 辊模拉伸丝材退火处理后的性能

Table 2 Properties of wires produced by cold roll-die drawing

表3 眼模拉伸丝材退火处理后的性能

Table 3 Properties of wires produced by die-model drawing

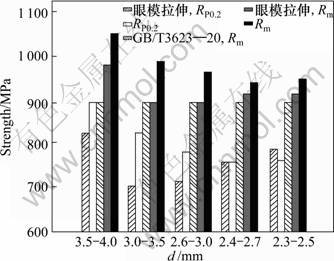

对以上各组数据取平均值后,绘制丝材的应力曲线图,如图1所示。

图1 不同拉伸工艺生产的TC4钛合金丝的性能

Fig.1 Properties of TC4 alloy wires produced by different methods

如表2、表3及图1所示,辊模拉伸及眼模拉伸后的丝材经过真空退火其抗拉强度均能满足GB/ T3623-20标准中的相应强度的要求(GB/T 3623—20中对TC4合金丝材抗拉强度的要求为Rm≥895 MPa)。

从图1可发现,随着拉伸变形的进行,眼模拉伸工艺的力学性能各项参数始终比辊模拉伸工艺生产丝材的力学性能差。

2.2 显微组织分析

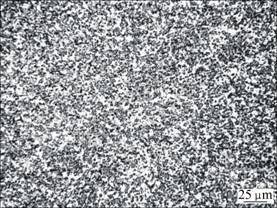

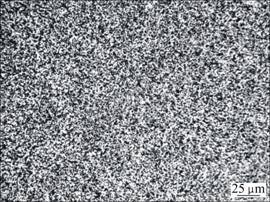

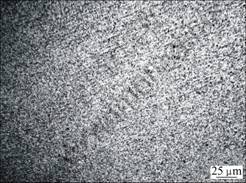

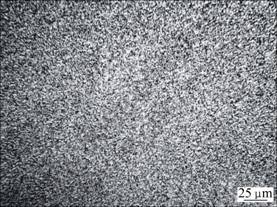

图2~5所示为同锭号、同规格、采用不同生产工艺加工出的TC4合金丝材在冷加工状态及750 ℃再结晶退火(750 ℃,1 h)处理后的金像照片。由图可看出,退火后的组织分布均匀,相的组成成分主要是细小的等轴状α及等轴状β。

图2 眼模拉伸的TC4(Y态)d2. 5mm丝材的横向显微组织

Fig.2 Landscape orientation microstructure of TC4 (Y state) d2.5 mm wire produced by die-model drawing

图3 眼模拉伸的TC4(750 ℃退火保温1 h) d2.5 mm丝材的横向显微组织

Fig.3 Landscape orientation microstructure of TC4 d2.5 mm wire produced by die-model drawing after annealing at 750 ℃ for 1 h

由图3和5可看出,与传统的眼模拉伸工艺相比,经过辊模拉丝拉伸的TC4合金丝经过相同的退火工艺处理后,其内部金相组织的晶粒度比眼模拉伸丝材的晶粒度要高。这是因为在相同拉拔力下,采用两种不同拉伸工艺在加工过程中所受摩擦力形式及大小均不相同。当使用眼模拉伸时,丝材表面与模具工作面接触时产生的摩擦力属于滑动摩擦[3],而使用辊模拉伸丝材时,丝材表面与辊模所受的摩擦力形式为滚动摩擦,其受力远远低于滑动摩擦力。因此,材料在辊模拉伸过程中所受的变形抗力较小。在材料一定、热处理制度相同的条件下,道次加工率就大。道次加工率大则材料内部的金相组织晶粒就越细,即晶粒度就越大。

根据霍尔佩奇公式:

σy=σ0+kd-1/2 (1)

式中:σy表示材料的屈服强度;σ0表示单晶材料的屈服强度;k为常数;d为晶粒尺寸。在塑性变形中金属晶粒越小,材料的强度越高[4]。

图4 辊模拉伸的TC4(Y态) d2.5 mm丝材的横向显微组织

Fig.4 Landscape orientation microstructure of TC4 (Y state) d2.5 mm wire produced by roll-die drawing

图5 辊模拉伸的TC4(750 ℃退火保温1 h) d2.5 mm丝材的横向金相组织

Fig.5 Landscape orientation microstructure of TC4 d2.5 mm wire produced by roll-die drawing after annealing at 750 ℃ for 1 h

因为在多晶体塑性变形中,晶界上的原子阻碍位错的运动,晶粒越细晶界越多,变形抗力越大,强度越高;而且当多晶体金属材料受到外力作用时,晶粒越细,其受力越均匀,变形越分散,减少变形过程中的应力集中,减缓裂纹的形成与发展,更利于后期的冷加工成型。

3 结论

经过辊模拉伸生产的TC4丝材,内部组织均匀,晶粒与传统工艺生产的丝材相比晶粒更细,均匀性更好。再结晶退火处理后,其抗拉强度和塑性与传统拉伸工艺生产的丝材相比要更高。

REFERENCES

[1] 张喜燕, 赵勇庆, 等. 钛合金及应用[M]. 北京: 化学工业出版社, 2005: 81-96.

ZHANG Xi-yan, ZHAO Yong-qing, et al. The application of titanium alloy[M]. Beijing: Chemical Industry Press, 2005: 81-96.

[2] B. K. 亚历山大, 等. 钛合金半成品加工[M]. 稀有金属材料与工程杂志社, 1984: 102-106.

ALEXANDER B K, et al. Titanium alloy semi-finished products processing[M]. Rare Metal Materials and Engineering Magazine Press, 1984: 102-106.

[3] 马怀宪. 金属塑性加工学[M]. 北京: 冶金工业出版社, 1989: 156-160.

MA Huai-xian. Processing of metal shaping[M]. Beijing: Metallurgical Industry Press, 1989: 156-160.

[4] 刘瑞唐, 刘文博, 等. 工程材料力学性能[M]. 哈尔滨: 哈尔滨工业大学出版社, 2002: 19-22.

LIU Rui-tang, LIU Wen-bo, et al. Mechanical properties of engineering materials[M]. Harbin: Harbin Institute of Technology Press, 2002: 19-22.

(编辑 杨 华)

通信作者:范 珂; 电话:0917-3222768;E-mail:fkzt@tom.com