DOI: 10.11817/j.issn.1672-7207.2019.04.007

退火温度对纯钛TA1织构及各向异性的影响

张贵华,江海涛,吴波,杨永刚,田世伟,郭文启

(北京科技大学 工程技术研究院,北京,100083)

摘要:通过X线衍射(XRD)和电子背散射衍射(EBSD)等分析技术,研究退火温度对冷轧态TA1钛板显微组织及织构的影响规律。研究结果表明:TA1钛板冷轧退火后,微观组织发生再结晶并形成典型的双峰分裂基面织构特征。在退火温度不大于700 ℃时,组织变化主要以回复与再结晶的形核生长为主,生成 和

和 类型再结晶织构组分,此时轧制织构组分逐渐消失;当退火温度达到800 ℃时,晶粒变化以合并长大为主,再结晶织构组分

类型再结晶织构组分,此时轧制织构组分逐渐消失;当退火温度达到800 ℃时,晶粒变化以合并长大为主,再结晶织构组分 和

和 的强度也继续增强。同时,织构组分对板材的各向异性有着直接影响,由于棱锥型织构

的强度也继续增强。同时,织构组分对板材的各向异性有着直接影响,由于棱锥型织构 和

和 再结晶织构组分特征的作用,可开动的滑移系统分别为易激活的柱面滑移和较难开动的基面滑移或棱锥面滑移,从而导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低,从而产生较大的板面各向异性。

再结晶织构组分特征的作用,可开动的滑移系统分别为易激活的柱面滑移和较难开动的基面滑移或棱锥面滑移,从而导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低,从而产生较大的板面各向异性。

关键词:TA1钛板;织构;退火;再结晶;各向异性;电子背散射衍射(EBSD)

中图分类号:TG146.23 文献标志码:A 文章编号:1672-7207(2019)04-0806-08

Effect of annealing temperature on texture and anisotropy of mechanical properties of pure titanium(TA1) sheet

ZHANG Guihua, JIANG Haitao, WU Bo, YANG Yonggang, TIAN Shiwei, GUO Wenqi

(Institute of Engineering Technology, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: The effect of evolution of microstructure and texture of commercially pure titanium (TA1) annealed at different temperatures was investigated by X-ray diffraction (XRD), and electron backscattered diffraction (EBSD). The results show that recovery and recrystallization of the cold rolled TA1 titanium sheet occur during the annealing process, and typical TD-split basal texture was formed. When the annealing temperature is below 700 ℃, the microstructure is characterized by recovery and recrystallization, and recrystallization texture components are presented. The as-rolled texture component is gradually weakened and disappears with the increase of the heat treatment temperature. When the annealing temperature reaches 800 ℃, the grain growth is dominated by merged-growth and the intensity of  and

and  recrystallized texture component continue to increase. In addition, anisotropy of mechanical properties of TA1 sheet is related to the texture components. Due to pyramid textures

recrystallized texture component continue to increase. In addition, anisotropy of mechanical properties of TA1 sheet is related to the texture components. Due to pyramid textures  and

and  recrystallization textures, the cylinder slip is respectively easier to be activated and the base slip or pyramidal plane slip becomes more difficult to be activated respectively, which leads to greater tensile strength in the TD direction than the RD direction of the sheet. As a result, the anisotropy of mechanical properties of TA1 sheet is caused.

recrystallization textures, the cylinder slip is respectively easier to be activated and the base slip or pyramidal plane slip becomes more difficult to be activated respectively, which leads to greater tensile strength in the TD direction than the RD direction of the sheet. As a result, the anisotropy of mechanical properties of TA1 sheet is caused.

Key words: TA1 titanium sheet; texture; annealing; recrystallization; anisotropy; electron backscattered diffraction (EBSD)

工业纯钛在航空航天、舰船、核能等高科技领域均有广泛的用途[1-4],在实际的应用中,除了固有的腐蚀性能外,其机械性能也是设计的重要标准。众所周知,在室温下纯钛是一种密排六方结构金属,具有低的晶格结构对称性和较少独立的变形系统,使其在变形热处理加工过程中极易形成强烈的织构,织构对纯钛的力学性能有着非常大的影响,导致严重的各向异性,为了控制纯钛的性能,对于研究其织构类型和晶界取向差异性具有非常重要的意义[5-11]。热加工处理能够诱发材料晶体织构的变化,产生具有特定塑性变形的织构特征[12],变形后的晶体再经退火处理发生重新再结晶,再结晶晶粒的形核会受到变形织构的影响[13-16]。LIU等[17]研究发现经常规冷轧退火处理后钛板具有较强的各向异性,再经循环相变处理后,各向异性得到了明显降低,其织构组成类型也发生了明显变化。徐国富等[18-19]也阐述了退火中晶粒长大过程中织构的变化情况,长大前期织构变化显著,但随长大和退火时间的延长,织构变化越来越慢。当然,虽然前人对于纯钛在经退火处理有了一定的研究基础,但纯钛中的α相是一种滑移系较少、对称性较差的密排六方结构金属,在加工或形变过程中不可避免地要产生晶体择优取向;另一方面,钛的织构又是一般工艺方法难以消除的,而针对钛的研究主要集中在再结晶初始阶段的晶粒尺寸变化和初始织构的形成方面[20],有关经冷轧处理后再不同退火温度对冷轧纯钛带的再结晶织构影响的研究较少,在纯钛组织与织构的演变相互关系、织构对各向异性的影响规律还需要进一步研究。本文作者通过X线衍射(XRD)和电子背散射衍射技术(EBSD)等手段,从宏观和微观方面系统研究TA1热轧板在轧制退火工艺处理过程中织构的演化规律,对比和讨论微观组织结构的变化过程中与织构间的变化关系,并对板材不同方向进行力学性能测试,研究分析织构类型和分布对各向异性的影响机制,为纯钛TA1的加工应用提供理论基础。

1 试验

试验用料是长×宽×厚为500 mm×500 mm×4.0 mm纯钛TA1热轧板,其成分如表1所示。

TA1板经单轧程冷轧至1.2 mm,随后进行退火处理。退火工艺在箱式电阻炉中进行,温度分别为600,650,700和800 ℃,保温60 min,冷却方式为空冷。通过Carl Zeiss型光学显微镜观察各个试样的金相,侵蚀剂体积配比为V(HF):V(HNO3) V(H2O)=3:6:91,侵蚀时间为10~20 s;利用D8 Advance型X线衍射仪和ZEISS SUPRA 55型热场发射扫描电镜EBSD分别测量其织构特征,测试前样品经机械和电解抛光处理。电解抛光参数如下:电压为30 V,电流为1.5 A,抛光时间为40~60 s,抛光液选用体积分数为5%高氯酸+95%酒精的混合液。

表1 TA1钛板化学成分(质量分数)

Table 1 Chemical composition of TA1 titanium plate %

室温拉伸性能试验在CMT5105万能力学试验机上进行,拉伸样尺寸及测试方法按照国标GB/T 228—2002“金属材料室温拉伸试验方法”实行。拉伸试验参数设定如下:拉伸力为98 kN,夹头位移速度为2 mm/min,轴向引伸仪标距为50 mm,引伸仪测量误差为0.3%。

2 结果与讨论

2.1 初态组织

图1所示为经冷轧后TA1钛材的金相组织照片。从图1可以发现:轧后组织晶粒严重破碎并被拉长,呈现出典型的纤维状态形貌特征,沿轧制方向平行排列,未发现明显的动态回复与再结晶。

图1 冷轧态TA1钛板微观组织

Fig. 1 Microstructure of cold-rolled TA1 titanium plate

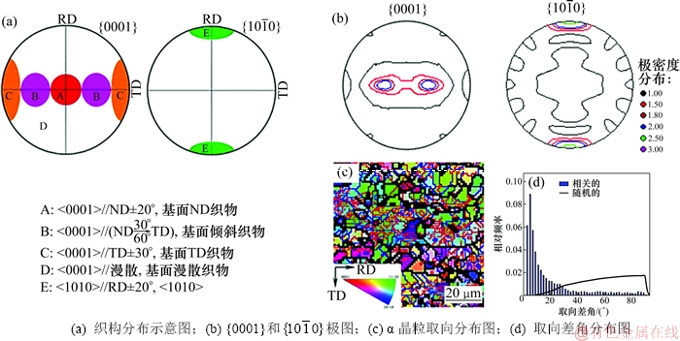

图2(a)所示为纯钛在{0001}和 极图上典型织构分布示意图[21]。经变形后各晶粒会发生大幅度扭曲转动,变形时各晶粒转动的结果往往会使晶粒取向聚集到某一或某些取向附近,从而形成织构。图2(b)所示为TA1冷轧态组织极图特征,从{0001}极图可以观察到明显的双峰织构,从法向(ND)向横向(TD)偏转35°左右,为典型的倾-基面织构类型,强度峰值为2.0,可表示为(0001)±35°TD;

极图上典型织构分布示意图[21]。经变形后各晶粒会发生大幅度扭曲转动,变形时各晶粒转动的结果往往会使晶粒取向聚集到某一或某些取向附近,从而形成织构。图2(b)所示为TA1冷轧态组织极图特征,从{0001}极图可以观察到明显的双峰织构,从法向(ND)向横向(TD)偏转35°左右,为典型的倾-基面织构类型,强度峰值为2.0,可表示为(0001)±35°TD; 极图显示为织构

极图显示为织构 //RD(见图2(b)),其织构强度峰值达到了2.5,此时板材仅以冷轧织构组分分布为主。由于钛板中各晶粒的取向各不相同,因而,在变形过程中,各晶粒的变形行为也会各不相同,且互相干扰和制约,其取向变化过程非常复杂,图2(c)中晶粒的不同颜色表现出晶粒间的取向关系,同一颜色的晶粒具有相同或相近的取向,红色晶界线为孪晶界,蓝色晶界线为亚晶界。图2(d)所示为冷轧过程产生大量的小角度晶界(其取向差角大量集中在0°~10°间),有大量的孪晶和亚晶界生成,已有相关报道指出纯钛TA1在冷轧过程中易出现压缩及拉伸孪晶[14-15],孪晶和基体在变形过程中由于位错滑移,晶界被破碎,从而产生大量亚晶界[21]。

//RD(见图2(b)),其织构强度峰值达到了2.5,此时板材仅以冷轧织构组分分布为主。由于钛板中各晶粒的取向各不相同,因而,在变形过程中,各晶粒的变形行为也会各不相同,且互相干扰和制约,其取向变化过程非常复杂,图2(c)中晶粒的不同颜色表现出晶粒间的取向关系,同一颜色的晶粒具有相同或相近的取向,红色晶界线为孪晶界,蓝色晶界线为亚晶界。图2(d)所示为冷轧过程产生大量的小角度晶界(其取向差角大量集中在0°~10°间),有大量的孪晶和亚晶界生成,已有相关报道指出纯钛TA1在冷轧过程中易出现压缩及拉伸孪晶[14-15],孪晶和基体在变形过程中由于位错滑移,晶界被破碎,从而产生大量亚晶界[21]。

2.2 微观组织演变

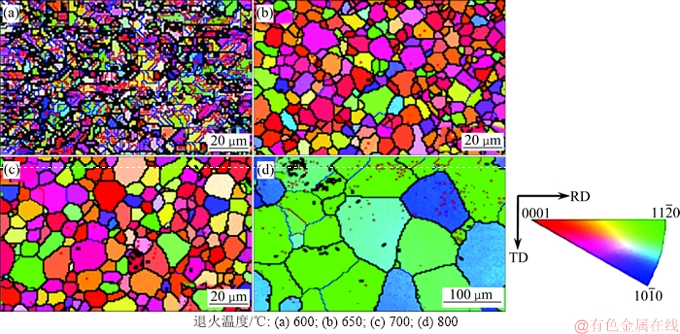

图3所示为不同退火温度条件下的微观组织形貌。TA1钛板经过冷变形后,变形组织中会存在以位错为主的晶体缺陷,这使得变形钛板内残留了一定的储存能,并成为再结晶的驱动力[22]。在温度为600 ℃退火条件下(如图3(a)所示),仅发生了回复现象,其驱动力还达不到再结晶条件,从形貌上观察还部分保留着轧态形貌特征;而当退火温度达到650 ℃时(如图3(b)所示),晶粒等轴化,可以明显地观察到再结晶晶粒,但晶界模糊,说明发生了未完全再结晶,此时带状组织结构已完全消除。

当退火温度达到700 ℃时(如图3(c)所示),晶粒晶界清晰,且均匀分布,此时发生完全再结晶,平均晶粒粒径约为18 μm;当退火温度升至800 ℃时(如图3(d)所示),晶粒迅速粗化,平均晶粒粒径达到182 μm,且各晶粒粒径差异明显。这是因为当再结晶完成后,晶粒后续正常长大的驱动力主要是晶界能,同时α晶粒的表面能和晶粒内部残留的少量应变能也成为了驱动力的一部分,退火温度越高,驱动力越大,晶粒极易长大。

图4所示为不同退火温度条件下TA1钛板成像取向图,其中晶粒颜色的差异代表着晶粒的取向不同,当颜色单一或者多样化说明了各晶粒的取向差异性大小。分析发现,退火温度对经冷轧变形后的微观组织的亚结构有着重要影响。在经600 ℃退火后(如图4(a)所示),亚晶界、条状组织并未完全消失,其晶粒取向还保留着部分与冷轧类似的特征;当温度达到650 ℃后(如图4(b)所示),亚晶界、条状组织等形貌特征已经完全消失。值得注意的是,从颜色分布观察,图4(a)所示的晶粒位向分布特征与轧态类似;在图4(b)和(c)中,颜色呈多样性分布;当温度达到800 ℃后(如图4(d)所示),晶粒位向颜色分布趋于 及

及 的位向所占比例超过90%以上,且颜色分布单一,这表明在较高的退火温度条件下,新晶粒在趋于

的位向所占比例超过90%以上,且颜色分布单一,这表明在较高的退火温度条件下,新晶粒在趋于 及

及 位向有较高的生长速率,同时抑制了{0001}基面晶粒的生长。

位向有较高的生长速率,同时抑制了{0001}基面晶粒的生长。

图2 冷轧态TA1钛板织构表征

Fig. 2 Texture characterization of cold-rolled TA1 titanium plate

图3 在不同退火状态下TA1钛板的显微组织

Fig. 3 Microstructure of TA1 titanium plate at different annealing temperatures

图4 TA1钛板α相晶粒随退火温度变化的取向分布图

Fig. 4 Orientation distribution of α-phase grains in TA1 titanium plate changing with annealing temperatures

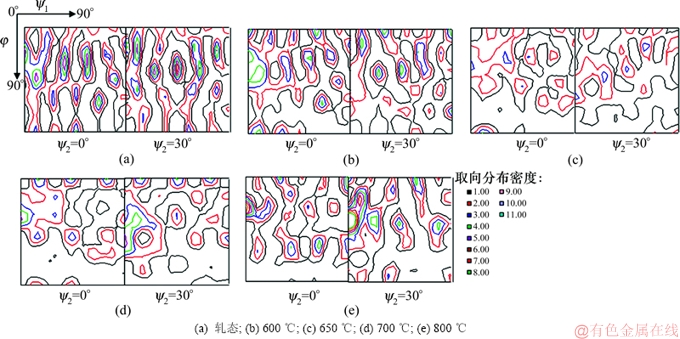

图5所示为通过XRD获得在不同退火温度工艺条件下计算{0001}极图和 极图。从图5可见:在较低退火温度600 ℃时(如图5(a)所示),织构的分布相对于轧态(如图2(a)所示)未有明显改变,但织构(0001)±35°TD强度略微上升到2.7,

极图。从图5可见:在较低退火温度600 ℃时(如图5(a)所示),织构的分布相对于轧态(如图2(a)所示)未有明显改变,但织构(0001)±35°TD强度略微上升到2.7, //RD降低到2.0;当退火温度从600 ℃上升至650 ℃时,(0001)±35°TD强度减弱至1.6,

//RD降低到2.0;当退火温度从600 ℃上升至650 ℃时,(0001)±35°TD强度减弱至1.6, //RD强度继续降低(如图5(b)所示);而当温度达到700 ℃时(如图5(c)所示),双峰织构(0002)±35°TD强度增加至4.1,织构的强度会对性能有着重要的影响。从图5(c)和5(d)可知:退火温度达到800 ℃时,织构强度极速增加,其(0001)±35°TD织构强度达到了8.1,而且

//RD强度继续降低(如图5(b)所示);而当温度达到700 ℃时(如图5(c)所示),双峰织构(0002)±35°TD强度增加至4.1,织构的强度会对性能有着重要的影响。从图5(c)和5(d)可知:退火温度达到800 ℃时,织构强度极速增加,其(0001)±35°TD织构强度达到了8.1,而且 极图上织构分布变化明显,两端织构由RD向ND偏转(如图5(d)所示)。

极图上织构分布变化明显,两端织构由RD向ND偏转(如图5(d)所示)。

hcp型工业TA1的主要织构取向位于Ψ2=0°和Ψ2=30°的ODF恒Ψ2截面上[23],图6所示为冷轧态和不同退火态试样的恒Ψ2截面ODF图。如图6(a)所示,冷轧TA1板的织构主要以冷轧织构(0001) ,(0001)

,(0001) ,

, 和

和 等织构组分为主,其中织构组分

等织构组分为主,其中织构组分 强度较高,是主要的织构类型。经退火处理,在退火温度为600 ℃时(如图6(b)所示),冷轧织构组分强度开始减弱,此时没有发现有较强的再结晶织构生成。

强度较高,是主要的织构类型。经退火处理,在退火温度为600 ℃时(如图6(b)所示),冷轧织构组分强度开始减弱,此时没有发现有较强的再结晶织构生成。

从图6可知:由于提高退火温度会促使再结晶织构的转变,在当退火温度达到650 ℃后(如图6(c)所示),冷轧织构继续变弱,此时生成了

和

和 织构组分,这主要是由于经退火处理,其晶粒择优形核,并且进行生长,从而使得某些稳定取向的晶粒的生长趋势被增强[24];当退火温度为700 ℃时(如图6(d)所示),轧制织构基本消失,

织构组分,这主要是由于经退火处理,其晶粒择优形核,并且进行生长,从而使得某些稳定取向的晶粒的生长趋势被增强[24];当退火温度为700 ℃时(如图6(d)所示),轧制织构基本消失,

和

和 2种类型再结晶织构强度也开始升高;随着退火温度继续提高(如图6(e)所示),除了晶粒吞并长大以外,一些亚稳取向的晶粒继续会向着稳定的取向的晶粒转动,

2种类型再结晶织构强度也开始升高;随着退火温度继续提高(如图6(e)所示),除了晶粒吞并长大以外,一些亚稳取向的晶粒继续会向着稳定的取向的晶粒转动,

和

和 这2种织构迅速增强,其强度分别达到8.05和11.83,同时未发现其他较强烈的织构类型生成。

这2种织构迅速增强,其强度分别达到8.05和11.83,同时未发现其他较强烈的织构类型生成。

图5 在不同退火条件下TA1钛板的实测{0001}极图和 极图

极图

Fig. 5 {0001} and  pole figure of α-phase grains in TA1 titanium plate at different annealing temperatures

pole figure of α-phase grains in TA1 titanium plate at different annealing temperatures

图6 在不同退火条件下TA1钛板的恒Ψ=0°和Ψ=30°ODF图

Fig. 6 Constant Ψ=0° and Ψ=30° ODF chart at different annealing temperatures

2.3 织构对各向异性的影响规律

图7所示为各状态下轧向(RD)、横向(TD)和与轧向成45°方向上力学性能的测试结果。退火处理有效地提高了TA1的塑性性能,但其强度也有明显的下降。为了更好地对比各个方向上在不同工艺处理下力学性能各向异性的差异,提出以下2个表达力学性能各向异性的参数。

强度异性度为

(1)

(1)

伸长率异性度为

(2)

(2)

式中: 为钛板轧制方向上强度;

为钛板轧制方向上强度; 为钛板横向方向上强度;

为钛板横向方向上强度; 为钛板与轧制成45°方向上强度;

为钛板与轧制成45°方向上强度; 为钛板轧制方向上伸长率;

为钛板轧制方向上伸长率; 为钛板横向方向上伸长率;

为钛板横向方向上伸长率; 为钛板与轧制成45°方向上伸长率。

为钛板与轧制成45°方向上伸长率。

通过式(1)和式(2)得到图8所示的力学异性度曲线图,曲线中异性度越大,其力学性能各向异性越明显。在较低退火温度600 ℃条件下,由于组织和织构类型还保留着轧态形貌特征,强度异性度比较高,各向异性非常强烈;当退火温度达到650 ℃时,强度和伸长率各向异性度达到了最低值,各向异性此时最弱;伴随着退火温度的继续上升,强度和伸长率异性度曲线呈现了上升趋势,材料的各向异性也随之不断增强。

一般地,多晶体内各向异性主要受单晶体本身各向异性和多晶体取向分布即织构的双重影响[25]。在较低的退火温度600 ℃下,由于仅发生回复现象,此时未形成再结晶织构组分,还保留着比较强的冷轧织构组分,力学各向异性度大,各向异性强烈;伴随退火温度的升高,冷变形态TA1钛板会发生回复与再结晶,而再结晶包括了再结晶晶核的形成,以及涉及大角度晶界的迁移的晶核生长过程。再结晶的晶核生长过程进行到新生成的晶粒互相接触,完成或基本上取代高缺陷密度的变形基体为止[26]。在退火温度650 ℃条件下,生成了以 和

和 为主的再结晶织构类型,晶粒形貌此时与轧态也有明显不同,冷轧织构

为主的再结晶织构类型,晶粒形貌此时与轧态也有明显不同,冷轧织构 ,

, ,

,

和

和 等组分强度开始降低,由于此时冷轧织构组分和新生成的再结晶织构组分最弱,力学各向异性度曲线也处于最低点,力学性能各向异性也最弱(如图8所示);当退火的温度达到800 ℃后,晶粒变化由最初的回复与再结晶形核方式向晶粒间的合并长大转变,新生成的织构类型

等组分强度开始降低,由于此时冷轧织构组分和新生成的再结晶织构组分最弱,力学各向异性度曲线也处于最低点,力学性能各向异性也最弱(如图8所示);当退火的温度达到800 ℃后,晶粒变化由最初的回复与再结晶形核方式向晶粒间的合并长大转变,新生成的织构类型

和

和 组分强度迅速上升,力学各向异性度曲线(特别是伸长率各向异性度曲线)斜率迅速也随之增大。从这些结果不难看出:由于存在织构,板材力学性能具有各向异性,织构越强越集中,各向异性越明显。

组分强度迅速上升,力学各向异性度曲线(特别是伸长率各向异性度曲线)斜率迅速也随之增大。从这些结果不难看出:由于存在织构,板材力学性能具有各向异性,织构越强越集中,各向异性越明显。

图7 TA1钛板在不同方向上的力学性能

Fig. 7 Mechanical properties of TA1 titanium plate in different directions

图8 TA1钛板力学性能异性度曲线

Fig. 8 Anisotropy curves of mechanical properties of TA1 titanium plate

同时,纯钛的塑性变形主要通过柱面滑移来协调,基面滑移作用次之,棱锥面滑移作用最弱[27],TA1板材退火处理后主要织构成分为棱锥型织构 和

和 再结晶织构组分,沿RD或TD方向形变,可开动的滑移系统分别为易激活的柱面滑移和较难开动的基面滑移或棱锥面滑移[28],这样导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低(如图7所示),从而产生了较大的板面各向异性。

再结晶织构组分,沿RD或TD方向形变,可开动的滑移系统分别为易激活的柱面滑移和较难开动的基面滑移或棱锥面滑移[28],这样导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低(如图7所示),从而产生了较大的板面各向异性。

3 结论

1) 冷轧变形TA1钛板经退火处理,组织变化主要以回复与再结晶的形核生长为主,随着温度升高,超过700 ℃,晶粒开始合并长大;在退火温度为800 ℃时,晶粒粗化,粒径达到了182 μm。

2) TA1板经退火处理,织构生成了以

和

和 类型为主织构类型,伴随温度的升高,冷轧织构逐渐消失。

类型为主织构类型,伴随温度的升高,冷轧织构逐渐消失。

3) 棱锥型织构

和

和

再结晶织构组分特征,会导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低,这种织构类型不利于改善各向异性。

再结晶织构组分特征,会导致板面内TD方向的拉伸强度比RD方向的拉伸强度大,而45°方向强度最低,这种织构类型不利于改善各向异性。

参考文献:

[1] SCHUTZ R W, WATKINS H B. Recent developments in titanium alloy application in the energy industry[J]. Materials Science and Engineering A, 1998, 243: 305-315.

[2] SHABANI M O, MAZAHERY A. Application of GA to optimize the process conditions of Al Matrix nano-composites[J]. Composites Part B, 2013, 45: 185-191.

[3] 邵娟. 钛合金及其应用研究进展[J]. 稀有金属与硬质合金, 2007, 35(4): 61-65.

SHAO Juan. Application and development of titanium alloys[J]. Rare Metals and Cemented Carbides, 2007, 35(4): 61-65.

[4] 钱九红. 航空航天用新型钛合金的研究发展及应用[J]. 稀有金属, 2005, 24(3): 218-223.

QIAN Jiuhong, Application and development of new titanium alloys for aerospace[J]. Chinese Journal of Rare Metals, 2005, 24(3): 218-223.

[5] BOZZOLO N, CHAN L, ROLLETT A D. Misorientations induced by deformation twinning in titanium[J]. Journal of Applied Crystallography, 2010, 43: 596-602.

[6] RANDLE V, OWEN G. Mechanisms of grain boundary engineering[J]. Acta Materialia, 2006, 54: 1777-1783.

[7] SINGH A K, SCHWARZER R A. Texture and anisotropy of mechanical properties in titanium and its alloys[J]. Zeitschrift Fur Metallkunde, 2000, 91: 702-716.

[8] ZAEFFERER S. A study of active deformation systems in titanium alloys: dependence on alloy composition and correlation with deformation texture[J]. Materials Science and Engineering A, 2003, 344(1/2): 20-30.

[9] PANDA S, SAHOO S K, DASH A, et al. Orientation dependent mechanical properties of commercially pure (cp) titanium[J]. Materials Characterization, 2014, 98: 93-101.

[10] SINHA S, GHOSH A, GURAO N P. Effect of initial orientation on the tensile properties of commercially pure titanium[J]. Philosophical Magazine, 2016, 96: 1485-1508.

[11] UNIWERSA A, WR

A, WR BEL M, WIERZBANOWSKI K, et al. Microstructure, texture and mechanical characteristics of asymmetrically rolled polycrystalline copper[J]. Materials Characterization, 2016, 118: 575-583.

BEL M, WIERZBANOWSKI K, et al. Microstructure, texture and mechanical characteristics of asymmetrically rolled polycrystalline copper[J]. Materials Characterization, 2016, 118: 575-583.

[12] HUMPHREYS F J, HATHERLY M. Recrystallisation and related annealing phenomenon[M]. 2nd ed. London: Elsevier, 2004: 1-658.

[13] ZHONG Y, YIN F, NAGAI K. Role of deformation twin on texture evolution in coldrolled commercial-purity Ti[J]. Journal of Materials Research, 2008, 23: 2954-2966.

[14] CHUN Y B, YU S H, SEMIATIN S L, et al. Effect of deformation twinning on microstructure and texture evolution during cold rolling of CP-titanium[J]. Materials Science and Engineering A, 2005, 398: 209-219.

[15] BOZZOLO N, DEWOBROTO N, WENK H R, et al. Microstructure and microtexture of highly cold-rolled commercially pure titanium[J]. Journal of Materials Science, 2007, 42: 2405-2416.

[16] SAHOO S K, PANDA S, SABAT R K, et al. Effect of pre-annealing strains on annealing texture developments in commercially pure (CP) titanium[J]. Philosophical Magazine, 2015, 95: 1105-1124.

[17] LIU M, CHEN G, CHOU S. On the deformation texture of square-shaped deep-drawing commercially pure Ti sheet[J]. Materials Chemistry and Physics, 2002, 77: 765-772.

[18] 徐国富, 崔雪敏, 彭小燕, 等. 冷轧工业纯钛的退火再结晶行为[J]. 稀有金属材料与工程, 2013, 42(11): 2263-2268.

XU Guofu, CUI Xuemin, PENG Xiaoyan, et al. Annealing heat treatment behavior in CP-Ti[J]. Rare Metal Materials and Engineering, 2013, 42(11): 2263-2268.

[19] SEWARD G G E, CELOTTO S, POND R C, et al. In situ SEM-EBSD observations of the HCP to BCC phase transformation in commercially pure titanium[J]. Acta Materialia, 2004, 52(4): 821-832.

[20] BOZZOLO N, DEWOBROTO N, GROSDIDIER T, et al. Texture evolution during grain growth in recrystallized commercially pure titanium[J]. Materials Science and Engineering A, 2005, 397: 346-355.

[21] WANG Ying, HE Weijun, LIU Na, et al. Effect of pre-annealing deformation on the recrystallized texture and grain boundary misorientaion in commercial pure titanium[J]. Material Characterization, 2018, 136: 1-11.

[22] 李军, 于辉, 史庆南, 等. 纯钛高温变形行为及其在精轧板中的应用[J]. 中南大学学报(自然科学版), 2016, 47(6): 1888-1894.

LI Jun, YU Hui, SHI Qingnan, et al. Hot deformation behavior of pure titanium and its application in hot sheet finish rolling[J]. Journal of Central South University (Science and Technology), 2016, 47(6): 1888-1894.

[23] WANG Y N, HUANG J C. Texture analysis in hexagonal materials[J]. Materials Chemistry and Physics, 2003, 81: 11-26.

[24] HAYAMA A O F, SANDIM H R Z. Annealing behavior of coarse-grained titanium deformed by cold rolling[J]. Materials Science and Engineering A, 2006, 418: 182-192.

[25] 詹从堃, 陈志永, 唐林. 退火纯钛板压缩力学性能的各向异性[J]. 中南大学学报(自然科学版), 2012, 43(11): 4253-4258.

ZHAN Congkun, CHEN Zhiyong, TANG Lin. Anisotropy of compressive mechanical properties of annealed pure titanium sheet[J]. Journal of Central South University (Science and Technology), 2012, 43(11): 4253-4258.

[26] ATASI G, AMIT S, GURAO N P. Effect of rolling mode and annealing temperature on microstructure and texture of commercially pure-titanium[J]. Material Characterization, 2017, 125: 83-93.

[27] PARTRIDGE P G. The crystallography and deformation modes of hexagonal close-packed metals[J]. Metal Review, 1967, 12: 169–194.

[28] 朱知寿, 顾家琳, 陈南平. 钛的织构与力学性能各向异性关系研究[J]. 机械工程材料, 1994, 18(2): 23-25.

ZHU Zhishou, GU Jialin, CHEN Nanping. Research on the relationship between texture and mechanical property anisotropy in commercially pure titanium sheets[J]. Materials for Mechanical Engineering, 1994, 18(2): 23-25.

(编辑 杨幼平)

收稿日期:2018-05-15;修回日期:2018-08-27

基金项目(Foundation item):国家重点研发计划项目(2016YFB0101605) (Project(2016YFB0101605) supported by the National Key Research and Development Program of China)

通信作者:江海涛,博士,教授,从事金属材料方面研究;E-mail:jianght@ustb.edu.cn