文章编号:1004-0609(2014)03-0773-06

水溶性环氧树脂的锆钛酸铅压电陶瓷凝胶注模成型

赵 阳,谢 睿,张 妍,周科朝,张 斗

(中南大学 粉末冶金国家重点实验室,长沙410083)

摘 要:分别以聚丙烯酸铵(NH4PAA)和海因环氧树脂为分散剂和凝胶剂,制备锆钛酸铅陶瓷浆料,研究分散剂及固相含量对浆料流变性能、生坯和烧结样品物理性能的影响。结果表明:当分散剂含量(质量分数)为0.6%时,浆料黏度最低;当固相含量(体积分数)高达57.5%时,浆料仍保持良好的流动性;当固相含量为55%时,陶瓷生坯和烧结坯的强度均达到最大值,分别为34.1和77.8 MPa;与传统模压成型工艺对比表明,采用凝胶注模成型工艺制备的样品具有更优异的物理和压电性能。

关键词:凝胶注模成型;锆钛酸铅;水溶性环氧树脂;流变性

中图分类号:TN304 文献标志码:A

Gelcasting of lead zirconate titanate prepared by water-soluble epoxy resin

ZHAO Yang, XIE Rui, ZHANG Yan, ZHOU Ke-chao, ZHANG Dou

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The lead zirconate titanate slurry was prepared using polyacrylic acid amine (NH4PAA) and Hydantion epoxy resin as dispersant and gelling agent, respectively. The influences of the dispersant content and the solid loading on the rheological properties and physical properties of the green and sintered bodies were investigated. The results show that the viscosity of the slurry is the lowest when the dispersant content is 0.6% (mass fraction). The slurry maintains good fluidity as the solid loading reaches as high as 57.5% (volume fraction). The highest strengths of green and sintered bodies are 34.1 and 77.8 MPa, respectively, as the solid loading of the slurry is 55%. Compared with the die pressing, the gelcast sample exhibits better physical and piezoelectric properties.

Key words: gelcasting; lead zirconate titanate; soluble epoxy resin; rheological property

压电陶瓷作为智能材料的一种,具有良好的介电、压电和热释电性能[1-2],目前广泛应用于电声、水声、超声换能器、传感器、智能材料与智能结构等许多领域[3]。传统的陶瓷部/器件制备方法主要包括机加工 法[4]、注模成型法[5]和粉浆浇注法[6]等。这些方法在成型复杂陶瓷部/器件上均存在较大的缺陷,如机加工法虽能通过加工陶瓷烧结样品获得复杂形状的陶瓷部/器件,但加工成本昂贵;注模成型法则需要较长的排胶时间(一般为7 d),且产品的尺寸受到严格的限制(直径小于3 cm);而粉浆浇注法的生坯固化成形时间长,且由于浆料的黏度高,会导致填模不充分。

凝胶注模成型工艺是20世纪90年代由美国橡树岭国家重点实验室的OMATETE等[7-9]发明的一种新颖的陶瓷材料近净成型技术,其基本过程是将陶瓷粉末、有机单体、交联剂以及分散剂球磨混合得到低黏度、高固相含量的陶瓷浆料,在引发剂和催化剂的作用下,有机单体聚合反应形成三维网络聚合物,使陶瓷颗粒原位固化成形,从而得到高强度的陶瓷生坯。该工艺具有成本低、操作简单、可以净尺寸成形复杂形状部件及成型生坯密度和强度高等特点[10],近年来得到了迅速的发展。清华大学的郭栋等[11-12]采用丙烯酸胺凝胶体系进行锆钛酸铅(PZT)凝胶注模成型,获得的生坯强度高达18 MPa,但是由于该体系具有神经毒性,无法满足工业化应用的需求。ROY等[13]采用蛋白体系,该体系克服了丙烯酰胺体系毒性大的缺点,但是获得的生坯强度仅为3 MPa,无法满足精细结构成型以及后续生坯加工的强度需求,因此其应用上受到了极大的限制。

水溶性环氧树脂作为一种新颖的凝胶体系,具有毒性低、成本低、水溶性好和强度高等优点,因此受到了广泛的关注。中国科学院上海硅酸盐研究所的研究人员[14-17]初步研究了水溶性环氧树脂体系的陶瓷凝胶注模成型工艺,发现该体系能够制备出低黏度浆料,其生坯致密度可达59%。前期研究结果表明[18],采用一种新的环氧树脂体系—海因环氧树脂,可以获得强度高达43 MPa的氧化铝生坯,具有较好的应用前景。因此,本文作者采用这种新型的环氧树脂体系,通过PZT-海因环氧树脂的凝胶注模成型工艺,系统地研究分散剂含量和固相含量对浆料的流变性能、生坯物理性能以及烧结坯物理性能和压电性能的影响。

1 实验

1.1 实验原料及过程

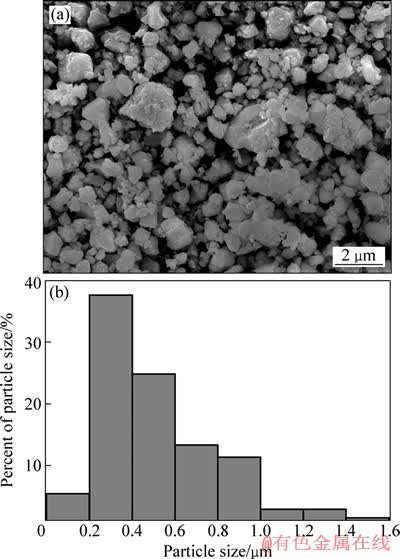

采用商用PZT-5(河北保定宏声有限公司生产)粉末作为原料,其颗粒形貌和粒度分布如图1(a)和(b)所示,水溶性海因环氧树脂(Hydantion resin epoxy, MHR154,无锡美华公司生产)及其固化剂3,3-二氨基二丙胺(DPTA, 99%,日本梯希爱公司生产)作为凝胶体系,聚丙烯酸铵(Disper AG165, 40%,相对分子质量为2000,海润化工生产)作为分散剂。所有溶液的配制均采用去离子水。实验中将分散剂、水、PZT粉以及树脂混合,其中分散剂和树脂添加量分别相对于PZT粉和去离子水的质量,加入1~2滴的正辛醇作为消泡剂,球磨48 h后,加入质量分数(相对于海因环氧树脂的含量)为17.6%的固化剂3,3-二氨基二丙胺,抽真空除去气泡,然后将浆料浇注至模具,样品在80 ℃条件下干燥20 h,脱模获得PZT生坯。同时将PZT粉体在200 MPa下进行干压成型,获得模压生坯。最后在1200 ℃条件下烧结1 h获得PZT陶瓷样品。将PZT陶瓷样品涂上银电极后,在110~120 ℃下进行直流高压油浴极化处理,所加电压为2~3 kV/mm,极化时间为15 min。

图1 PZT5-1粉末的SEM形貌和颗粒分布

Fig. 1 SEM image (a) and particle size distribution (b) of PZT5-1 powder particles

1.2 实验仪器及测试方法

采用直径为40 mm的AR2000 EX平板旋转流变仪(美国TA公司生产)对浆料的流变性能进行测试,测试前采用剪切速率为100 s-1对浆料进行预剪切1 min,剪切速率变化范围为0~1000 s-1。采用凯强力(KQL) KD11-2型微机控制电子万能试验机测量生坯的力学性能,其中压头的移动速率设定为0.5 mm/min。采用Agilent 4294A型阻抗分析仪(美国Agilent公司生产)以及ZJ-4AN准静态压电测试仪(中国科学院声学研究所生产)对凝胶注模PZT陶瓷样品和干压PZT陶瓷样品的介电常数(εr)、机电耦合系数(kp)、介电损耗(tan δ)以及压电常数(d33)进行测量。采用NOVA NANOSEM 230场发射扫描电镜对生坯和烧结陶瓷断面微观结构进行观察。

2 结果与讨论

2.1 分散剂含量对PZT浆料流变性能的影响

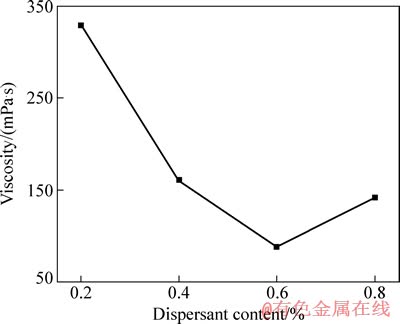

图2所示为海因环氧树脂含量(质量分数)为15%、PZT粉体固相含量为45%、剪切速率为100 s-1时,浆料黏度随分散剂加入量的变化。从图2中可知,当分散剂含量低于0.6%时,随着分散剂含量的增加,浆料的黏度急剧下降,当分散剂含量高于0.6%时,所得浆料的黏度缓慢增加。当分散剂含量为0.6%时,PZT浆料体系的黏度最低,其黏度为88.2 mPa·s (100 s-1)。产生该现象的原因是,当分散剂加入量不足时(<0.6%),PZT颗粒表面不能完全被聚丙烯酸根离子包覆,使得颗粒之间的空间位阻和静电位阻作用不足以克服颗粒之间的范德华力,PZT颗粒之间距离减小,易产生团聚,从而导致浆料黏度的增加;当分散剂含量为0.6%时,PZT颗粒表面刚好完全被聚丙烯酸根离子包覆,此时浆料体系的黏度达到最小值;当继续增加分散剂含量时(>0.6%),一方面由于聚丙烯酸铵本身黏度高,过量的聚丙烯酸铵会导致浆料黏度增加,另一方面过量的聚丙烯酸铵会对PZT颗粒的双电层起到压缩作用,导致PZT颗粒之间的距离减小,从而加剧了颗粒之间的团聚,浆料体系的黏度又会出现缓慢增加的趋势。因此,当分散剂含量为0.6%时,浆料具有最佳的分散性能和较好的流动性,这有利于获得结构均匀、力学性能良好的陶瓷生坯。

图2 分散剂加入量对PZT浆料黏度的影响

Fig. 2 Influence of dispersant content on viscosities of PZT suspensions

2.2 PZT粉体固相含量对浆料流变性能的影响

图3所示为分散剂含量为0.6%、海因环氧树脂含量为15%、不同PZT粉固相含量及剪切速率为1~1000 s-1下浆料的黏度变化。从图3中可以看出,当固相含量从45%增加55%时,浆料黏度也随之增加,且所有的浆料都具有剪切变稀的特性。当固相含量继续增加至57.5%时,浆料呈现剪切变稠的特性,即在高剪切速率的条件下,浆料的黏度随着剪切速率的增加而增加。当浆料固相含量低于55%时,浆料中的局部团聚受到剪切力作用而解聚,同时粒子由初始无序的状态转向流动方向,使其排列有序化,当剪切速率增加时,解聚和有序化程度提高,浆料的黏度随之降低[19-21]。当浆料固相含量高于57.5%时,由于在剪切力作用下高固相含量促进了浆料中粒子簇的生成,降低了颗粒之间空间结构的有序程度,当剪切力增大时,粒子簇随之增大,其对流体的阻碍作用也就变大,因此体系的黏度增大,即剪切变稠现象[22]。该现象也存在于其他高固相含量的陶瓷浆料体系中[23]。

图3 剪切速率对不同固相含量PZT浆料粘度的影响

Fig. 3 Influence of shear rate on viscosity of PZT suspension with different volume fractions of PZT solid loading

2.3 固相含量对PZT陶瓷生坯性能的影响

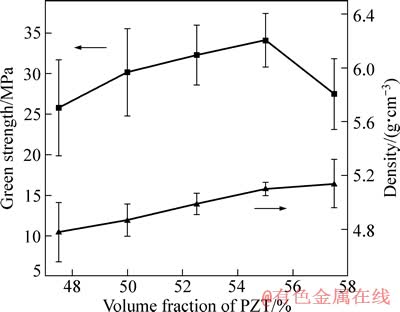

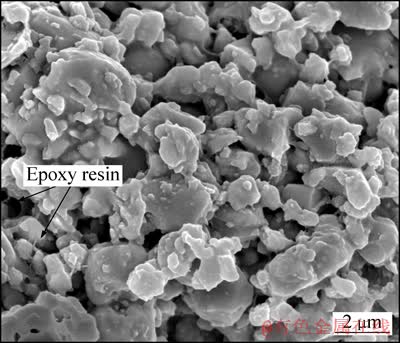

图4所示为海因环氧树脂含量为15%、不同固相含量PZT浆料经定量的DPTA固化后,陶瓷生坯平均强度和平均密度随固相含量的变化。当固相含量从47.5%增加至55%时,生坯的平均强度从(25.8±5.91) MPa增加至(34.1±3.31) MPa,但当固相含量从55%增加至57.5%时,生坯的平均强度反而急剧下降。当固相含量为57.5%时,其生坯平均强度达到(27.5±4.36) MPa。当固相含量从45%增加至57.5% 时,其平均密度从(4.78±0.22) g/cm3缓慢增加至(5.14±0.18) g/cm3。当固相含量较低时,生坯中存在大量的孔洞,获得的陶瓷生坯相对密度较低,因而强度较低;随着固相含量的提高,生坯中孔洞的数量减少,其相对密度随之提高,从而生坯的强度随之提高。但当固相含量增加至55%时,由于初始获得的陶瓷浆料存在大量的缺陷如颗粒团聚,这些缺陷被直接保留到陶瓷生坯中,导致其生坯强度呈现出下降的趋势。图5所示为海因树脂含量为15%、固相含量为52.5%的PZT浆料经定量的DPTA固化后,陶瓷生坯断面的SEM像。从图5中可以看出,生坯内部组织均匀,无较大颗粒团聚现象,陶瓷颗粒被环氧树脂聚合形成的三维网络胶结在一起,这与XIE等[24]和MA等[25]所研究的Al2O3凝胶注模体系中有着近似的生坯断面形貌。

图4 陶瓷生坯平均强度和平均密度随固相含量的变化

Fig. 4 Average strength and density of green body with different volume fractions of PZT solid loading

图5 陶瓷生坯断面的SEM像

Fig. 5 SEM image of fracture surface of green body

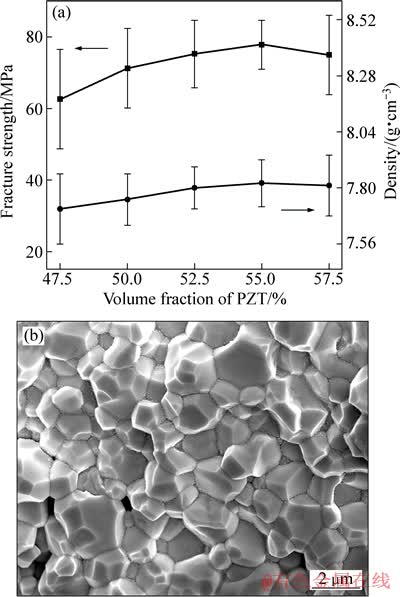

2.4 固相含量对PZT陶瓷烧结坯性能的影响

图6(a)所示为海因环氧树脂含量为15%、不同固相含量PZT生坯经1200 ℃烧结1 h后陶瓷烧结坯平均强度和平均密度随固相含量的变化。由图6(a)可知,当固相含量从47.5%增加到55%,烧结坯的平均强度从(62.6±13.9) MPa增加到至(77.8±6.8) MPa,平均密度则从(7.71±0.15) g/cm3增加至(7.85±0.10) g/cm3,但当固相含量继续增加到57.5%时,烧结坯的平均强度反而下降至(75.0±11.1) MPa,平均密度下降至(7.83±0.13) g/cm3。其原因是当固相含量低于55%时,烧结坯的致密度随着固相含量的增加而增加,即烧结坯中的缺陷如孔洞等随着固相含量的增加而不断减少;但当固相含量继续增加时,PZT浆料中颗粒的间距不断减小,粉末形成团聚体的数量增加,这些缺陷也将直接保存到烧结坯中,从而导致烧结坯性能下降,因此,烧结坯的强度呈现出先增加后降低的趋势,这与LIU等[26]所研究的Al2O3-ZrO2体系中烧结坯的性能变化趋势一致。图6(b)所示为海因环氧树脂含量为15%、固相含量为55%的生坯经1200 ℃烧结1 h后陶瓷烧结坯断口的SEM像。从图6(b)中可以看出,烧结坯的颗粒大小均匀,其尺寸分布在1~3 μm,无明显晶粒异常长大现象,烧结致密,材料的断裂形式以沿晶断裂为主。

图6 陶瓷烧结坯平均强度和平均密度随固相含量的变化及陶瓷烧结样品断口的SEM像

Fig. 6 Average fracture strength and density of sintered bodies with different volume fractions of PZT solid loading (a) and SEM image of fracture surface of sintering sample (b)

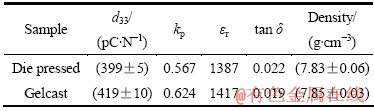

2.5 凝胶注模PZT样品与干压样品性能的比较

为了研究采用水溶性环氧树脂为凝胶剂的凝胶注模成型工艺对压电陶瓷材料性能的影响,将其与传统的干压方法进行了对比。表1所列为在相同的烧结工艺下分别采用凝胶注模成型工艺和传统干压工艺所得PZT样品的压电性能,其凝胶注模制备的样品选用固相含量为55%烧结后的陶瓷样品。

从表1中数据可以看出,采用凝胶注模成型获得的样品的压电性能略优于采用传统干压工艺所得PZT样品的压电性能。这主要是因为在传统干压方法中,样品在压制过程中受到模具侧壁的摩擦作用,使得样品压制过程中压力分布不均匀,从而降低了样品的均匀性;而凝胶注模所制备的样品,由于浆料在浇注过程中粉体颗粒分布均匀,所以制备的样品具有更高的相对密度并且均匀性更好。因此,采用水溶性环氧树脂为凝胶剂的凝胶注模工艺是一种工业化生产陶瓷零部件的很有前景的制备方法。

表1 模压成型和凝胶注模成型样品性能的比较

Table 1 Comparison of properties of gelcast PZT samples and die pressed ones

3 结论

1) 聚丙烯酸铵是一种适合PZT粉体的分散剂,当其含量为0.6%时,浆料的黏度达到最小值88.2 mPa·s。

2) 固相含量对于浆料流变性能的影响结果表明,当浆料固相含量低于55%时,浆料呈现剪切变稀特性;当固相含量高于55%时,浆料呈现剪切变稠特性;浆料固相含量在45%~57.5%均适合于浇注。

3) 固相含量对陶瓷生坯和烧结坯强度具有较大的影响,最佳固相含量为55%。采用海因环氧树脂为15%和固相含量为55%的浆料浇注制备得到的PZT样品,其生坯和烧结坯的强度分别可高达34.1和77.81 MPa。

REFERENCES

[1] ROGERS C A. Intelligent material systems—The dawn of a new materials age[J]. Journal of Intelligent Material Systems and Structures, 1993, 4(1): 4-12.

[2] SAITO Y, TAKAO H, TANI T, NONOYAMA T, TAKATORI K, HOMMA T, NAGAYA T, NAKAMURA M. Lead-free piezoceramics[J]. Nature, 2004, 432(7013): 84-87.

[3] TRESSLER J F, ALKOYl S, DOGAN A, NEWNHAM R E. Functional composites for sensors, actuators and transducers[J]. Composites (Part A): Applied Science and Manufacturing, 1999, 30(4): 477-482.

[4] MOHRI N, FUKUZAWA Y, TANI T, SAITO N, FURUTANI K. Assisting electrode method for machining insulating ceramics[J]. CIRP Annals—Manufacturing Technology, 1996, 45(1): 201-204.

[5] EDIRISINGHE M J, EVANS J R G. Review: Fabrication of engineering ceramics by injection moulding. I: Materials selection[J]. International Journal of High Technology Ceramics, 1986, 2(1): 1-31.

[6] TILLER F M, TSAI C D. Theory of filtration of ceramics. I: Slip casting[J]. Journal of the American Ceramic Society, 1986, 69(12): 882-887.

[7] OMATETE O O, JANNEY A M. Method for molding ceramic powders using a water-based gel casting processing: US, 5028362[P]. 1991-07-02.

[8] YOUNG A C, OMATETE O O, JANNEY A M, MENCHHOFER P A. Gelcasting of alumina[J]. Journal of the American Ceramic Society, 1991, 74(3): 612-618.

[9] OMATETE O O, JANNEY A M, STREHLOW A R. Gelcasting: a new ceramic forming process[J]. American Ceramic Society Bulletin, 1991, 70(10): 1641-1649.

[10] 王小锋, 王日初, 彭超群, 李婷婷, 罗玉林, 王 超, 刘 兵. 凝胶注模成型技术的研究与进展[J]. 中国有色金属学报, 2010, 20(3): 496-509.

WANG Xiao-feng, WANG Ri-chu, PENG Chao-qun, LI Ting-ting, LUO Yu-lin, WANG Chao, LIU Bing. Research and development of gelcasting[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 496-509.

[11] GUO Dong, CAI Kai, LI Long-tu, NAN Ce-wen, GUI Zhi-lun. Gelcasting of PZT[J]. Ceramics International, 2003, 29(4): 403-406.

[12] 郭 栋, 蔡 锴, 李龙土, 南策文, 桂治轮. 用凝胶注模成型制备压电陶瓷体及其电学性能研究[J]. 无机材料学报, 2003, 18(5): 1045-1050.

GUO Dong, CAI Kai, LI Long-tu, NAN Ce-wen, GUI Zhi-lun. Proessing and electrical properties of piezoelectric ceramics formed by gelcasting[J]. Journal of Inorganic Materials, 2003, 18(5): 1045-1050.

[13] ROY S, RAO B S S C, SUBRAHMANYAM J. Water-based gelcasting of lead zirconate titanate and evaluation of mechanical properties of the gelcast samples[J]. Scripta Materialia, 2007, 57(9): 817-820.

[14] MAO Xiao-jian, SHIMAI Shun-zo, DONG Man-jian, WANG Shi-wei. Investigation of new epoxy resins for the gel casting of ceramics[J]. Journal of the American Ceramic Society, 2008, 91(4): 1354-1356.

[15] 董满江, 毛小建, 张兆泉, 刘 茜. 水溶性环氧树脂为凝胶体系的SiC凝胶浇注成型[J]. 硅酸盐学报, 2008, 27: 376-380.

DONG Man-jiang, MAO Xiao-jian, ZHANG Zhao-quan, LIU Qian. Gelcasting of SiC with epoxy resin as gel former[J]. Bulletin of the Chinese Ceramic Society, 2008, 27: 376-380.

[16] CHEN Bi-qin, JIANG Dong-liang, ZHANG Jing-xian, DONG Man-jiang, LIN Qing-ling. Gel-casting of β-TCP using epoxy resin as a gelling agent[J]. Journal of the European Ceramic Society, 2008, 28(15): 2889-2894.

[17] MAO Xiao-jian, SHIMAI Shun-zo, DONG Man-jian, JIN Ling-ling. Rheological characterization of a gelcasting system based on epoxy resin[J]. Ceramics International, 2009, 35(1): 415-420.

[18] XIE Rui, ZHANG Dou, ZHANG Xiao-yong, ZHOU Ke-chao, BUTTON T W. Gelcasting of alumina ceramics with improved green strength[J]. Ceramics International, 2012, 38(8): 6923-6926.

[19] CROSS M M. Relation between viscoelasticity and shear-thinning behaviour in liquids[J]. Rheologica Acta, 1979, 18(5): 609-614.

[20] HU Yong, HE Bo-lin, YAN Hong. Rheological behavior of semi-solid Mg2Si/AM60 magnesium matrix composites at steady state[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(3): 883-887.

[21] 伍秋美, 阮建明, 黄伯云, 周忠诚, 邹俭鹏. 低固相含量SiO2分散体系流变性研究[J]. 化学学报, 2006, 64(15): 1543-1547.

WU Qiu-mei, RUAN Jian-ming, HUANG Bai-yun, ZHOU Zhong-cheng, ZOU Jian-peng. Study on the rheological behavior of SiO2 dispersions with low volume fraction[J]. Acta Chimica Sinica, 2006, 64(15): 1543-1547.

[22] WILLEM H, BOERSMA J L, HANS N. Shear thickening (dilatancy) in concentrated dispersions[J]. American Institute of Chemical Engineers Journal, 1990, 36(3): 321-332.

[23] LINDE H. Hydrodynamics of dispersed media[J]. Zeitschrift für Physikalische Chemie, 1991, 173(Part 1): 121-122.

[24] XIE Rui, ZHOU Ke-chao, GAN Xue-ping, ZHANG Dou. Effects of epoxy resin on gelcasting progress and mechanical properties of alumina ceramics[J]. Journal of the American Ceramic Society, 2013, 96(4): 1107-1112.

[25] MA Jing-tao, XIE Zhi-ping, MIAO He-zhuo, HUANG Yong, CHENG Yi-bing, YANG Wei-you. Gelcasting of alumina ceramics in the mixed acrylamide and polyacrylamide systems[J]. Journal of the European Ceramic Society, 2003, 23(13): 2273-2279.

[26] LIU Xiao-lin, HUANG Yong, YANG Jin-long. Effect of rheological properties of the suspension on the mechanical strength of Al2O3-ZrO2 composites prepared by gelcasting[J]. Ceramics International, 2002, 28(2): 159-164.

(编辑 陈卫萍)

基金项目:国家自然科学基金面上项目(51072235);高等学校博士学科点专项科研基金资助项目(20110162110044);湖南省自然科学基金资助项目(11JJ1008)

收稿日期:2013-05-29;修订日期:2013-11-30

通信作者:张 斗,教授,博士;电话:0731-88877196;E-mail:dzhang@csu.edu.cn