J. Cent. South Univ. Technol. (2011) 18: 1326-1333

DOI: 10.1007/s11771-011-0841-0

Tribological characteristics and self-repairing effect of hydroxy-magnesium silicate on various surface roughness friction pairs

Zhang Bo(张博)1, 2, Xu Bin-shi(徐滨士)1, Xu Yi(许一)1, Zhang Bao-sen(张保森)1, 3

1. National Key Laboratory for Remanufacturing, Academy of Armored Forces Engineering,Beijing 100072, China;

2. The Chinese People's Liberation Army 91278 Troops, Dalian 116041, China;

3. School of Materials Science and Engineering, Shanghai Jiaotong University, Shanghai 200240, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2011

Abstract: Tribological characteristics and self-repairing effect of hydroxy-magnesium silicate (HMS) dispersed in lubricant oil on steel-to-steel friction pairs with various surface roughness were analyzed. The friction-reduction, anti-wear and self-repairing performance of various surface roughness friction pairs were examined by friction testing machine. An operation comparison was made between SJ10W-40 lubricant with and without HMS. The surface morphology and elementary composition of the grinding cracks were analyzed by scanning electron microscope (SEM) and energy dispersive spectrometer (EDS). The results show that the lubrication state changes from boundary lubrication into mixed lubrication after operation in lubricant with HMS. The friction-reduction, anti-wear and self-repairing performance of the friction pairs with various surface roughness are distinctly different. There is a repairing film whose material is different from substrate material on the grinding cracks. In addition, Si, Mg, O, Al and other elements are deposited on the repairing film which contains nanocrystals of these elements. And HMS self-repairing material possesses superior performance of friction-reduction, anti-wear and self-repairing effects.

Key words: hydroxy-magnesium silicate; surface roughness; friction; wear; self-repairing

1 Introduction

Wear is a phenomenon appearing when the surface material of friction pairs constantly loses with the increase of friction time and it is the definite outcome of friction [1]. About 950 billion RMB? was lost because of friction and wear in 2006, China [2]. Wear generally starts with slight surface tiny damage at the early stage, then grows into severe surface damage inducing conjugate parts failure. The original position dynamic self-repairing of surface tiny damage is a new technology developed in recent years, essentially different from the conventional maintenance mode which represents static maintaining to the inoperative components. It proceeds the original position dynamic maintainance to the tiny damage on worn surfaces without disassembly to achieve the effect of preventing or restraining the components failure [3]. Self-repairing technology of metals (SRTM) is one of the technologies of original position dynamic self-repairing of surface tiny damage, which adopts a sort of hydroxy-magnesium silicate (HMS) powder combined in lubricants. The HMS has no chemical reaction with lubricants, does not change the viscosity and property of lubricants, has no negative effect in use and no nocuity to environment and human body [4-11]. Lubricants with HMS can generate a self-repairing film on the machine elements surfaces during wear and friction, so as to achieve the original position dynamic self-repairing purpose [12-18].

Surface roughness is a denivellation describing the micro-protuberances spacing of the processing surface, which can affect the tribological characteristics of machine parts. Lower surface roughness value will increase the parts fitting-in quality and reduce the wear- out, which can extend the service life of the processing parts. But the cost of the processing parts will raise with the improvement of surface roughness. Therefore, it is very important to select the correct and reasonable surface roughness [19-20]. In the process of parts production, the surface roughness is determined by the working environments of the friction pairs. Consequently, lubricating materials with various surface roughness friction pairs will present different performances of friction-reduction.

In this work, the HMS self-repairing material was dispersed in lubricants. The friction-reduction, anti-wear and self-repairing performance on various surface roughness friction pairs lubricated with HMS self- repairing material were investigated, and the mechanism of self-repairing film was discussed.

2 Experimental

2.1 Experimental materials

The natural serpentine material, from Xiuyan, Liaoning Province, China, was made into ultrafine powders with average diameter about 0.5 μm, through coarse and fine grinding and dryness. Then, the ultrafine powders surface was modified with borate and made into HMS self-repairing material. The chemical ingredient (mass fraction) is 43.49% SiO2, 41.00% MgO, 1.18% Al2O3, 0.64% CaO, 0.25% FeO, 0.33% K2O, 12.66% H2O, and 0.32% MnO, and its ideal molecular formula is Mg3[Si2O5](OH)4. HMS is a kind of phyllosilicates which has tetrahedron layer and octahedron layer of 1:1 crystal structure.

The Great Wall brand gas machine lubricant oil SJ10W-40 was used as the basic oil, whose dynamical viscosity (100 °C) is 14.3 mm2/s, and the open flash point is 211.4 °C. 5% HMS self-repairing material was dispersed into SJ10W-40 (A oil), by ultrasonic dispersion for 60 min, making the experimental oil sample (B oil), whose dynamical viscosity (100 °C) is 14.4 mm2/s, and the open flash point is 222.2 °C.

2.2 Friction and wear experiments

The tribological tests were performed on a MM-10W multifunctional friction testing machine using steel-steel model pairs by a standard “plane-on-plane” configuration. The tribological characteristics of three friction pairs with different surface roughness values were examined with A oil and B oil, respectively. The working mechanism of MM-10W tester is shown in Fig.1. The test material is 45# steel with hardness of HV 128.4. Three surface roughness values are Ra1=0.636 μm (machine processing), Ra2=0.229 μm (refined processing) and Ra3=0.022 μm (ultrafine processing), respectively. Testing time was 1 h, rotation speed was 500 r/min, and load was 1 000 N, so the unit load on the friction surface was 5 N/mm2.

2.3 Surface morphology and elementary composition analysis

After the friction test, frictional samples were washed to remove surface impurity by ultrasonic cleaner in acetone and ethanol solution, respectively, and they were dried in the heating oven. The grinding and original surface roughness values were detected with a TR240 roughmeter, produced by Time Group Company. The scanning electron microscope (SEM) and energy dispersive spectrometer (EDS) were adopted to analyze the surface morphology and elementary composition of the frictional samples lubricated with A oil and B oil.

Fig.1 Working mechanism of MM-10W

3 Results and discussion

3.1 Friction coefficient, lubrication state and surface roughness

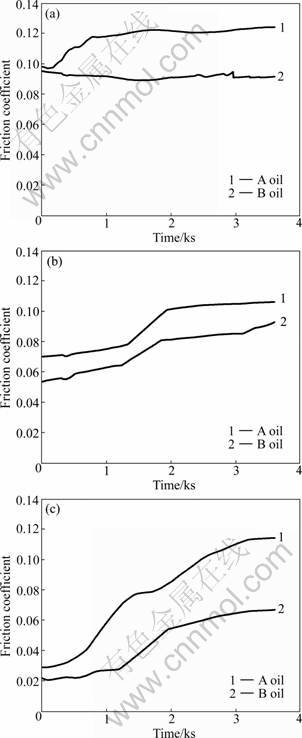

According to the Stribeck lubrication curve [21], the friction pairs with friction coefficient μ=0.10 are in boundary lubrication, and those with 0.001<μ<0.10 are in mixed lubrication. Figure 2 shows the relationship curves describing the friction coefficient varying with time. It can be seen that all the friction coefficients of the friction pairs lubricated with A oil are higher than those lubricated with B oil. In all testing course, friction pairs whose surface roughness value is Ra1=0.636 μm (machine processing) are in boundary lubrication when lubricated with A oil, and after lubricated with HMS self-repairing material (B oil), the friction coefficient is lower than 0.1, which indicates that the friction pairs are always in mixed lubrication, as shown in Fig.2(a). The lubrication state of friction pairs whose surface roughness values are respectively Ra2=0.229 μm (refined processing) and Ra3= 0.022 μm (ultrafine processing) is a mutative process when lubricated with A oil, which presents that mixed lubrication is changed into boundary lubrication. But friction pairs lubricated with B oil are always in mixed lubrication, as shown in Figs.2(b) and (c). This illuminates that HMS self-repairing material, in lubrication courses, can improve the lubrication state of friction pairs. The result shows that boundary lubrication changes into mixed lubrication, so that the friction-reduction function can be achieved.

Fig.2 Friction coefficient of different-roughness surface: (a) Machine processing; (b) Refined processing; (c) Ultrafine processing

From friction pairs lubricated with A oil, the friction coefficients show an upward trend except for the testing sample with machine processing surface whose friction coefficient is steady in boundary lubrication. But the lubrication state of later two changes in the last part, as shown in Fig.2. The reason is that, in the testing course, the roughness value of machine processing surface is a little high, leading to frequent shearing of the micro-protuberances on friction pairs surface, so it is difficult to form a continue and certain thickness oil film, thus the friction pairs are in boundary lubrication; on the contrary, roughness values of refined processing and ultrafine processing surface are much lower in the early testing time, then the oil film can be easily formed, and the friction pairs are in mixed lubrication. But with the testing time increasing, the surface morphology of the friction pairs is destroyed, the roughness values raise and the amount of micro-protuberances on surface increases; consequently, the oil film is destroyed, and all these induce mixed lubrication changing into boundary lubrication.

While lubricated with B oil, the friction coefficients display the same trend as A oil, but all the lubrication states are in mixed lubrication. The reason is that, the surface roughness value Ra of machine processing surface is similar to the average diameter of HMS powders, then HMS particles would effectively prevent the continue and certain thickness oil film from being destroyed in the tribological course. But the other two surface roughness values Ra are lower than the average diameter, then the powder particles would bring a certain grain abrasion in the tribological course. So, with the testing time increasing, the frictional force would become higher and higher, and the surface morphology of friction pairs would be destroyed, so the surface roughness value Ra of grinding crack increases to a new value which is higher than that before test and lower than that of machine processing surface; therefore, the friction coefficients display a trend of climbing up continuously.

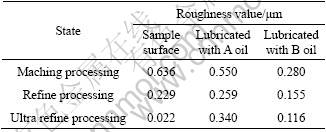

Table 1 lists the measuring surface roughness values of three different samples surfaces and grinding cracks. Analyzing the surface roughness value Ra of the three group experiments lubricated with B oil, it can be seen that the Ra values of all grinding cracks are lower than those with A oil, which illuminates that the contact status of friction pairs can be improved by HMS self-repairing material. Compared to A oil, the surface roughness values of grinding cracks lubricated with B oil decreases, so the friction coefficients are lower than those with A oil, as shown Fig.2, and it helps to gradually smooth the friction pairs surface in all friction process and achieves the function of friction-reduction.

Table 1 Surface roughness values of sample surface and ground surface

At the same time, the Ra value of grinding crack of machine processing surface lubricated with B oil is lower than that of the sample surface. From the analysis on the result, the roughness value of the machine processing surface (Ra=0.636 μm) is close to the average diameter of the powder particles. During the friction process, the micro-nano scale HMS particles with huge adsorption energy are carried to the friction pairs surface by lubricant oil flow. The powder particles whose diameter value is less than 0.5 μm can directly be adsorbed and deposited into the pits on the friction pairs surface and the height of micro sharp peaks is reduced, so that micro sharp peaks cannot shear with each other frequently and the possibility of clinging wear is reduced consequently. In this sense, HMS self-repairing material, through absorbing and depositing HMS particles, can repair the tiny damages and furrows formed in the parts processing. The powder particles with diameter larger than 0.5 μm, whose volume size is similar to the friction surface micro- protuberances, could play a role of supporting the surface protuberances of friction pairs, scatter the load on the protuberances, reduce the frequency of protuberances directly contacting with each other and squeeze pressure. Ultimately, the effect of reducing grain wear can be achieved. Meanwhile, the powder particles larger than 0.5 μm will be rolled and broken to the same order of magnitude with the micro-pits due to mechanical force in the friction process, and will be involved in the filling of micro-pits.

On the contrary, the roughness values of refined processing and ultrafine processing surface are less than the average diameter of the particles. With the help of HMS crystals interlayer sliding friction, the friction coefficients of friction pairs lubricated with B oil are lower than those with A oil, as shown in Fig.2. However, because the surface roughness value of friction pairs is low and Ra value is much smaller than the diameter of the powder particles, in the friction process, the size of irregular geometry powder particles is too larger than the pits and protuberances size to be absorbed directly in the pits. Consequently, a certain degree of grain abrasion occurs. The result illuminates that worn surface roughness value is higher than that of the sample surface, as shown in Table 1. However, HMS self-repairing materials make the worn surface roughness value smaller than that of worn surface lubricated with A oil.

3.2 Wear-resistant and self-repairing performance

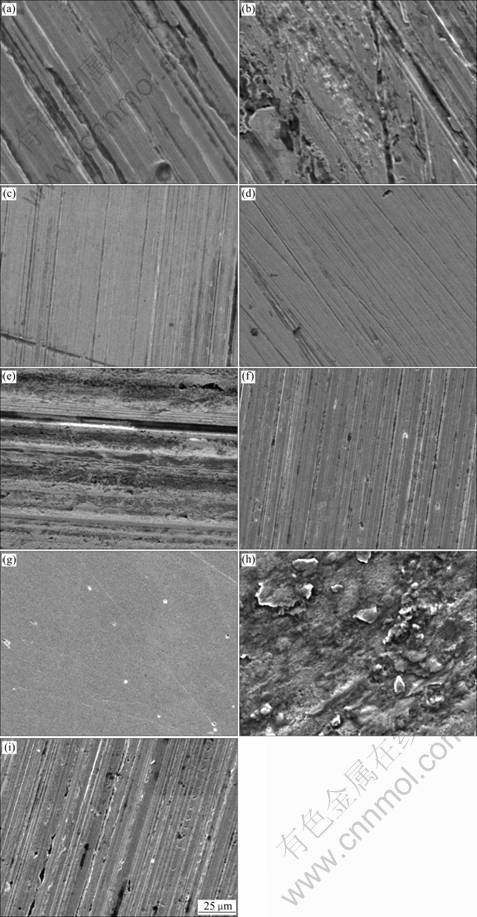

Figure 3 shows the SEM images of three sets of test

pieces. It can be seen from Fig.3 that the lubrication states of friction pairs are improved significantly when lubricated with B oil, and the worn surface becomes smooth. Lubricated with A oil, there are a large number of typical grain abrasion, fatigue wear which are furrows, spalling pits, pitting pits on the worn surface; lubricated with B oil, worn surface becomes smooth and there are no flakes falling off and no pitting pits on the worn surface. Only furrows resulted from grain abrasion appear on the worn surface, whose width and depth are smaller than those lubricated with A oil.

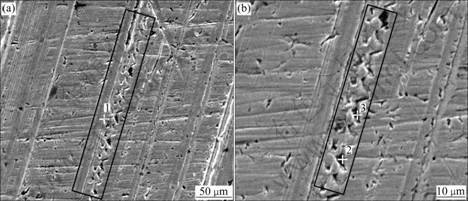

Analyzing the worn surface morphology of ultrafine processing surface lubricated with B oil (Fig.4), traces of furrows filled and repaired on the friction pairs surface can be found along the rubbing direction, but the repair is not complete. There are some micropores in the rectangle region, as shown in Fig.4. From the EDS analysis in Fig.5, it can be found that the main element is Fe in the position 1 in Fig.4, which is characterized by smooth. The main elements are Mg and O in the position 2, which is characterized by the black pits. The main elements are Fe, Mg, O and Si in the position 3, which is characterized by connecting the position 1 to position 2. HMS particles fill the furrows or micro-cracks, at the same time they are rich in magnesium oxides, so the furrows are compensated and become shallow and narrow. The particles which fill into the furrows later, will deposit near the protuberance tip on the friction surface. Under the action of friction flash temperature, phase change will occur near the protuberance particles. At the same time, the metal ions brought by HMS will cause replacement action with Fe ions brought by friction pairs, to produce ferric silicate salts (such as iron olivine). Therefore, furrows or micro-cracks which are filled with magnesium oxides and the HMS particles will be covered by a ferric silicate salt “lid” which has a chemical bond joining with the friction substrate material, so it binds the substrate material closely and solidly. Repeating the above process, the HMS self-repairing material will compensate micro-damages on the friction surface.

Base on the above analysis, it can be concluded that the friction coefficient can be reduced by adding HMS self-repairing materials into lubricant oil. For the refined and ultrafine processing surfaces of friction pairs (Ra<0.5 μm), the HMS particles whose average diameter is 0.5 μm, will bring a certain degree of grain abrasion on the friction surface in the anti-friction and self-repairing process. However, for the surface of machine processing pieces applied in engineering (Ra>0.5 μm), HMS self- repairing material is able to demonstrate good anti- friction and self-repairing properties, making the surface of machine processing pieces smooth.

Fig.3 SEM images of test pieces: (a) Machine processing surface; (b) Machine processing surface lubricated with A oil; (c) Machine processing surface lubricated with B oil; (d) Refined processing surface; (e) Refined processing surface lubricated with A oil; (f) Refined processing surface lubricated with B oil; (g) Ultrafine processing surface; (h) Ultrafine processing surface lubricated with A oil; (i) Ultrafine processing surface lubricated with B oil

Fig.4 Morphology of ultrafine processing surface lubricated with B oil

Fig.5 EDS of points on Fig.4: (a) Position 1; (b) Position 2; (3) Position 3

3.3 TEM analysis of repairing film

Ultrafine processing sample was cut longitudinally along the friction contact part, then the cross section of friction surface was analyzed by TEM, as shown in Fig.6. It is found that there is a repairing film with thickness of about 1 μm on the friction surface, and there are about 10 nm nanocrystals in the repairing film. Selected area electron diffraction (SAED) of nanocrystals shows that the nanocrystals are compounds of magnesium and iron oxide (including MgO, MgO4, Fe3O4), FeSi and Fe3O4 compound, FeSi and SiO2 compound, FeSi, AlFe and Fe3O4 compound and Fe3C, and so on, as shown in Fig.7. Elements Si, Mg, Al and O in the repairing film mainly come from HMS self-repairing material, and element C mainly comes from lubricant oil. These illuminate that the repairing course is a complex friction chemical reaction process. At the same time, a consolidating repairing film is generated on the friction surface eventually, which contains nanocrystals composed of Fe3C, MgO, FeSi, Fe3O4, SiO2 complexes.

Fig.6 TEM photograph of repairing film cross section

Fig.7 SAED images of repairing film cross section: (a) MgO, MgO4, Fe3O4; (b) FeSi and Fe3O4; (c) FeSi and SiO2; (d) FeSi, AlFe and Fe3O4; (e) Fe3C [301] zone axis electron diffraction pattern

4 Conclusions

1) In the lubrication process, HMS self-repairing material has a function on anti-friction, and improves the tribological state of friction pairs from boundary lubrication to mixed lubrication.

2) For 45# steel, HMS self-repairing material has obvious self-repairing abilities. The surfaces of friction pairs lubricated with the oil containing HMS self-repairing material are smooth. And a repairing film with typical repairing elements, such as Mg, Al, O, Si, on the friction pairs surface is formed and the film has nanocrystals composed of Fe3C, MgO, FeSi, Fe3O4 and SiO2 complexes.

3) Repairing film formation has a relation with the average diameter, adsorption, thermal phase change and replacement reaction of the HMS powder particles. HMS self-repairing material fills into the pits and micro- damage on friction surfaces through its unique strong adsorption of silicate. Under physical, chemical and thermal effects in the frictional process, the phase change and the replacement between friction pair and substrate material Fe ions take place, which forms the repairing film with chemical bonds.

4) The wear resistance of HMS self-repairing material has a relationship with the surface roughness of friction pairs and the average diameter self-repairing material particle. HMS self-repairing material can reduce the wear surface roughness. When the powder average diameter is close to the surface roughness value of friction pairs, the HMS self-repairing material shows friction reduction, anti-wear, and self-repairing properties. When the powder particle size is much larger than the surface roughness value Ra, the material can still reduce the friction coefficient, but a certain degree of grain abrasion occurs on the friction pairs surface.

References

[1] HISAKADO T, SUKIZOE T, YOSHIKAWA T. Lubrication mechanism of solid lubricants in oil [J]. Lubr Tech, 1983, 105: 245- 253.

[2] ZHANG Si-wei. Tribology of savings in China has great potential for industrial applications—To talk about the status quo of China’s industrial applications tribological investigation [J]. China Surface Engineering, 2008, 21(2): 50-51. (in Chinese)

[3] XU Bin-Shi, OU Zhong-wen, LIU Wei-min. In-situ synthesis and tribological behavior of nanometer ZnS [J]. Tribology, 2002, 22(42): 12-15.

[4] WANG Xiao-li, XU Bin-shi, XU Yi, YU He-long, SHI Pei-jing, LIU Qian. Preparation of nano-copper as lubrication oil additive [J]. Journal of Central South University of Technology, 2005(10): 203-206.

[5] SHI Pei-jing, XU Bin-shi, XU Yi, WANG Xiao-li, YU He-long. Tribological behavior of oil-soluble organo-molybdenum compound as lubricating additive [J]. Trans Nonferrous Met Soc China, 2004(10): 386-390.

[6] GUPTA B K, BHUSHAN B. Fullerene particle as an additive to liquid lubricants and greases for low friction and wear [J]. Lubrication Engineering, 1994, 50(7): 524-528.

[7] ALBERT V. The effect of graphite type, purity and concentration on the performance of a clay filled polyalphaolefin grease, based on four ball wear (ASTM D2269) with coefficient of friction, and load wear index (ASTM D2596) [J]. NLGI Spokesman, 2002, 65(12): 10-25.

[8] GAO Yu-zhou, ZHANG Hui-chen, XU Xiao-lei, WANG Liang, CHEN Wen-gang. Formation mechanism of self-repair coatings on the worn metal surface using silicate particles as lubricant oil additive [J]. Lubrication Engineering, 2006(10): 39-42.

[9] ZHANG Bo, XU Bin-shi, XU Yi, WANG Xiao-li. Research on the tribological performance of micro-and nano-phyllosilicate mineral lubricating material [J]. China Surface Engineering, 2009, 22(1): 29-32, 36. (in Chinese)

[10] YAN Yan-hong, XIAO Hong, YANG Yu-lin. Influence of the self-repairing additive concentration on tribology properties of cast iron/cast iron friction pair [J]. China Surface Engineering, 2008, 21(3): 35-39. (in Chinese)

[11] XU Yi, YU He-long, ZHAO Yang, SHI Pei-jing, XU Bin-shi. Study on tribological properties of stratified silicate self-repair materials [J]. China Surface Engineering, 2009, 22(3): 58-61. (in Chinese)

[12] JIN Yuan-sheng. In situ mechanochemical reconditioning of worn ferrous surfaces [J]. Tribology International, 2004, 37(7): 561-567.

[13] QIAO Yu-lin. Nano-particles Lubrication and self-repairing technology [M]. Beijing: National Defense Industry Press, 2005: 70-75.

[14] LIU Wei-min, CHEN Shuang. Study on the tribological behavior of the surface-modified ZnS nanoparticles in liquid paraffin [J]. Wear, 2000, 238(2): 120-124.

[15] CHEN Shuang, LIU Wei-min, YU Lai-gui. Preparation of DDP-coated PbS nano particles and investigation of the antiwear ability of the prepared nanoparticles as additive in liquid paraffin [J]. Wear, 1998, 218(2): 153-158.

[16] YANG Yu-lin, YAN Yan-hong, ZHANG Rui-jun, REN Hao. Influence of wear time on metal wear self-repair and mechanism analysis [J]. Chinese Journal of Mechanical Engineering, 2008, 44(10): 172-176. (in Chinese)

[17] ZHANG Bo, XU Bin-shi, XU Yi, ZHANG Bao-sen. Effect of magnesium silicate hydroxide on the friction behavior of ductile cast iron pair and the self-repairing performance [J]. Journal of the Chinese Ceramic Society, 2009, 37(4): 492-496. (in Chiense)

[18] POGODAEV L I, BUYANOVSKII I A, KRYUKOV E Y. The mechanism of interaction between natural laminar hydrosilicates and friction surfaces [J]. Journal of Machinery Manufacture and Reliability, 2009, 5(38): 476-484.

[19] LIU Jia-jun. The material wear mechanism and anti-wear [M]. Beijing: Tsinghua University Press, 1993: 25-27. (in Chinese)

[20] Wen Shi-zhu, Huang Ping. Tribological theory [M]. Beijing: Tsinghua University Press, 2002: 75-82. (in Chinees)

[21] Bharat Bhushan. Introduction to tribology [M]. Beijing: China Machine Press, 2007: 132-140. (in Chinese)

(Edited by HE Yun-bin)

Foundation item: Projects(50735006, 50904072) supported by the National Natural Science Foundation of China; Project(2007CB607601) supported by the National Basic Research Program of China

Received date: 2010-07-01; Accepted date: 2010-10-27

Corresponding author: XU Bin-shi, Professor; Tel: +86-10-66718541; E-mail: xubinshi@vip.sina.com