高强铝合金水浸搅拌摩擦焊接的温度场模拟

来源期刊:中国有色金属学报(英文版)2013年第4期

论文作者:张会杰 刘会杰 于雷

文章页码:1114 - 1122

关键词:铝合金;水浸搅拌摩擦焊接;温度场;模拟

Key words:aluminum alloy; underwater friction stir welding; temperature field; modeling

摘 要:应用三维热源模型对水浸搅拌摩擦焊接的温度场进行模拟分析。通过分析水介质的汽化特征,阐明水浸搅拌摩擦焊接的边界条件。在模拟中考虑了材料性能与温度的相关性。搅拌摩擦焊接试验的结果表明,模拟结果与温度场的真实值具有较高的拟合程度。温度场的模拟结果表明,尽管水浸搅拌摩擦焊接的轴肩面热流密度比常规搅拌摩擦焊接的高,但水浸接头的最高峰值温度明显比常规接头的低。水浸接头的高温分布区间显著变窄,焊缝各区热循环也得到了有效控制。

Abstract: The thermal modeling of underwater friction stir welding (FSW) was conducted with a three-dimensional heat transfer model. The vaporizing characteristics of water were analyzed to illuminate the boundary conditions of underwater FSW. Temperature dependent properties of the material were considered for the modeling. FSW experiments were carried out to validate the calculated results, and the calculated results showed good agreement with the experimental results. The results indicate that the maximum peak temperature of underwater joint is significantly lower than that of normal joint, although the surface heat flux of shoulder during the underwater FSW is higher than that during normal FSW. For underwater joint, the high-temperature distributing area is dramatically narrowed and the welding thermal cycles in different zones are effectively controlled in contrast to the normal joint.

Trans. Nonferrous Met. Soc. China 23(2013) 1114-1122

Hui-jie ZHANG, Hui-jie LIU, Lei YU

State Key Laboratory of Advanced Welding and Joining, School of Materials Science and Engineering, Harbin Institute of Technology, Harbin 150001, China

Received 23 February 2012; accepted 26 June 2012

Abstract: The thermal modeling of underwater friction stir welding (FSW) was conducted with a three-dimensional heat transfer model. The vaporizing characteristics of water were analyzed to illuminate the boundary conditions of underwater FSW. Temperature dependent properties of the material were considered for the modeling. FSW experiments were carried out to validate the calculated results, and the calculated results showed good agreement with the experimental results. The results indicate that the maximum peak temperature of underwater joint is significantly lower than that of normal joint, although the surface heat flux of shoulder during the underwater FSW is higher than that during normal FSW. For underwater joint, the high-temperature distributing area is dramatically narrowed and the welding thermal cycles in different zones are effectively controlled in contrast to the normal joint.

Key words: aluminum alloy; underwater friction stir welding; temperature field; modeling

1 Introduction

Friction stir welding (FSW) is a new and promising welding process that can produce high-quality joints of heat-treatable aluminum alloys [1-3]. However, the thermal cycles exerted on the samples still resulted in the reduction of mechanical properties of the joints due to the coarsening and dissolution of strengthening precipitates [4-7]. Therefore, it is possible to improve the strength of normal friction stir welded joints by accelerating the heat dissipation. In order to do this, external liquid cooling has been applied to samples during FSW. FRATINI et al [8,9] performed FSW of AA7075-T6 aluminum alloy with a flow of water followed by the moving tool during the welding. The tensile strength of the joint was found to be higher than that obtained in normal condition. Underwater friction stir welding of 2219-T6 aluminum alloy was carried out by LIU et al [10-12]. It was demonstrated to be available for strength improvement of the joint by limiting the coarsening and dissolution of strengthening precipitates. In fact, the strength improvement by the cooling action is resultant from the controlling of temperature histories and thermal cycles. Therefore, illuminating the temperature field of the cooled joints is beneficial to clarifying the essence of in-process-cooling FSW. Because of the experiment restrictions on the temperature measurements at deformed zones, it is necessary to develop a numerical model to predict the thermal history in FSW. Nevertheless, a limited number of works have attempted to tackle this problem. FRATINI et al [9] simulated the temperature histories of a FSW process under external liquid cooling, in which the coolant was modeled as water flux behind the tool, and the results revealed that the cooling effect resulted in a reduction of thermal flow adjacent to the tool. In Ref. [13], friction stir processing was simulated with in-process-cooling from the backing plate by computational fluid dynamics analysis. It was found that the temperature below the pin zone can be reduced by 80 °C with using liquid nitrogen at high flowing rate; however, cooling from backing plate had minor effects on the heat generated at shoulder interface. Previous investigations have illustrated the characteristics of temperature distributions during the FSW with external liquid cooling on the top or bottom surfaces of workpieces. However, the cooling effect exerted on the whole workpiece through the thickness direction has never been reported in the published literatures. This study aims to explore the temperature histories of underwater friction stir welding (FSW), in which the whole workpiece was kept immersion in the water environment during the welding.

2 Experimental

The base metal (BM) was a 7.5 mm-thick 2219-T6 aluminum alloy plate with 300 mm in length and 100 mm in width. The chemical compositions (mass fraction, %) of the BM are Cu 6.48, Mn 0.32, Fe 0.23, Ti 0.06, V 0.08, Zn 0.04, Si 0.49, Zr 0.2 and Al balance. FSW experiments were carried out under two kinds of conditions. One was in air, and the other was under water. For the convenience of statement, the FSW performed in air was defined as normal FSW, while the one performed under water was defined as underwater FSW. The joints (welds) formed under these two conditions were called normal and underwater joints (welds), respectively. FSW was performed along the longitudinal direction of the samples using an FSW machine (FSW-3LM-003).

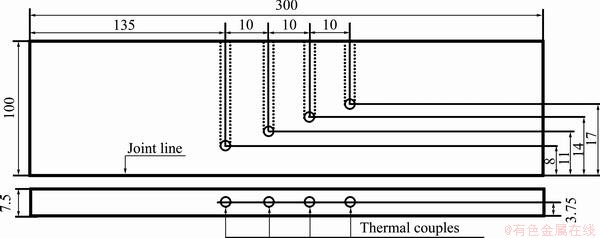

The welding tool consisted of a 22.5 mm-diameter shoulder and a conical right-hand screwed pin with the length of 7.4 mm and the median diameter of 7.4 mm. During the FSW, a 2.5° tilt angle and an axial load of 4.6 kN were applied to the welding tool. The rotation speed, welding speed and axial load for both normal and underwater FSW were 800 r/min, 100 mm/min and 4.6 kN, respectively. K-type thermocouples were used to measure the temperature of the samples during FSW. The measured locations were started at the heat affected zone (8 mm from the weld center) and then extended to the BM at the weld mid-thickness on the advancing side. The space was 3 mm between the adjacent measured locations. The exact locations of the thermal couples are shown in Fig. 1.

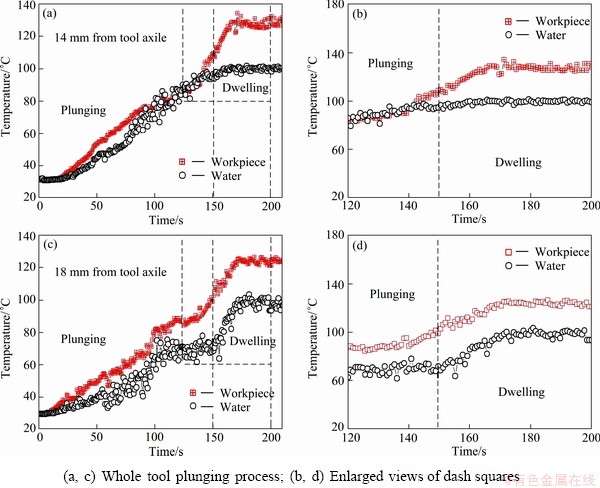

Under water environment, tool plunging experiment was also conducted to understand the vaporizing behavior of water during underwater FSW. The tool was plunged into the workpiece at a rotation speed of 800 r/min and a feeding speed of 3 mm/min, and then kept for a certain time after the shoulder contacted the top surface of workpiece. The temperatures of the top surface of workpiece and the corresponding water were measured. The measured locations were 14 mm and 18 mm away from the weld center.

3 Weld formation and vaporizing characteristics of water during underwater FSW

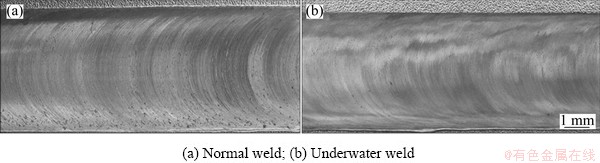

Figure 2 shows the weld appearances formed under different welding conditions. It can be seen that the width of the underwater weld is slightly smaller than that of the normal weld, which should be attributed to the lower level of material plastic flow. In addition, the underwater weld exhibits smoother appearance than the normal one due to the lower extent of oxidation in the water environment.

Fig. 1 Exact locations of thermal couples (Unit: mm)

Fig. 2 Weld appearances formed under different welding conditions

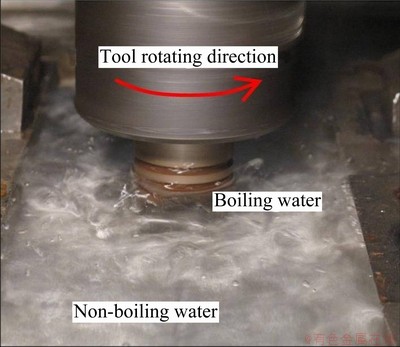

Fig. 3 Boiling characteristics of water at steady state of tool plunging period

Figure 3 shows the boiling characteristics of water at the steady state of tool plunging experiment in water environment. Apparently, the water around the tool can be divided into two parts, i.e. the boiling water and the non-boiling water. The border of both regions is rather unclear. An interesting phenomenon can be observed from the thermal cycles shown in Fig. 4. The water does not boil when the temperature of the top surface of workpiece reaches 100 °C, as normally expected, but begins to boil when the temperature of workpiece reaches a higher value of 120 °C. Generally, there exists a temperature difference between the heating surface and the adjacent water, which is called as boiling surplus temperature. When the water is at the static state and the heating rate is low, the surplus temperature is about 5 °C [14]. However, in current situation, the surplus temperature of water reaches a high value of 20 °C. The reason for this is that the water around the tool is not in a static state but flows annularly during underwater FSW. This enhances the heat dissipation from water and thus increases the boiling surplus temperature.

Fig. 4 Thermal cycles of top surface of workpiece and corresponding water

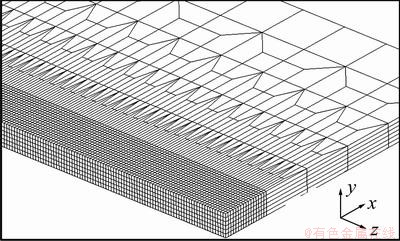

Fig. 5 Grid mesh for model

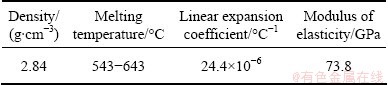

Table 1 Thermal-physical properties of material varying slightly with temperature [15]

4 Mathematical model

4.1 Thermal model and governing equations

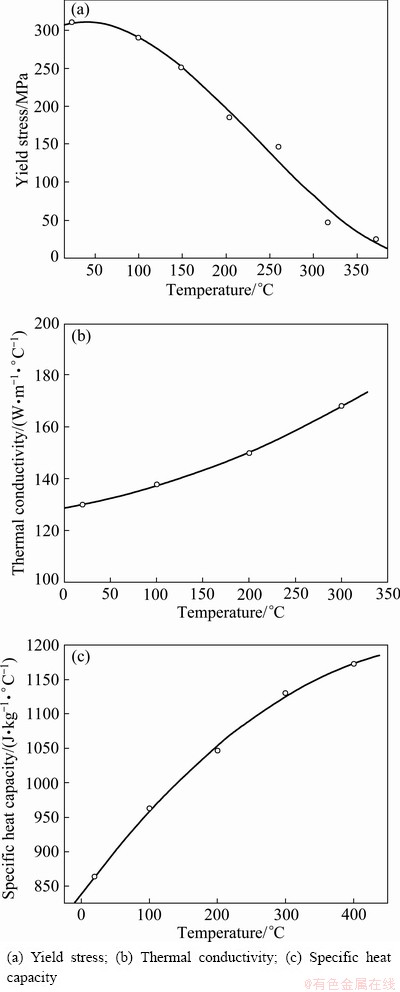

The two plates to be welded are assumed to be identical, so only one plate is meshed. A non-uniform grid mesh is generated for the calculation by using the MSC MARC software. The mesh is fine near the weld line and becomes coarse away from the weld line (see Fig. 5). The thermal-physical properties of BM are given in Table 1 and Fig. 6. It should be noted that the yield stress, thermal conductivity and specific heat capacity are temperature-dependent because they vary significantly with temperature, and the properties that cannot be attained from the literatures are deduced from the corresponding fitting curves.

The temperature distribution during FSW was determined by solving the governing equation for heat conduction:

(1)

(1)

where ρ is the density; c is the specific heat capacity; t is the time; T is the current temperature; q(x, y, z, t) is the rate of internal heat generation; kx, ky and kz are the thermal conductivities along three directions and are considered to be identical for isotropic material. In the modeling process of the temperature history, the moving heat source is represented by moving the heat generation of the nodes in each computational time step.

4.2 Heat generation

The total heat generation arising from tool/workpiece interface is given by the following relationship [16]:

(2)

(2)

where ω is the tool rotation speed; r is the distance from tool axis; τyield(T) is the temperature-dependent yield stress. In this heat generation model, the temperature- dependent yield stress is the only factor that affects the heat input. The temperature data at each increment time are used to evaluate the yield stress. The solidus temperature for 2219-T6 is 532 °C [15] at which the yield stress is set to be zero.

Fig. 6 Material properties varying greatly with temperature [15]

4.2.1 Heat generation from tool shoulder

The heat flux generated at the shoulder/workpiece interface (qs) can be directly described from Eq. (2),

,

,  (3)

(3)

where R1 is the radius of tool shoulder and R2 is the radius of tool pin at the shoulder.

Some of the heat generated at the shoulder/workpiece interface is transported into the tool material during FSW. The ratio of the heat that enters the workpiece to the heat transported into the tool can be deduced from this formula [17]:

(4)

(4)

In the FSW of aluminum alloys, the temperature at the shoulder/workpiece interface is generally concentrated in the range of 400-500 °C [3,4]. Therefore, the thermo-physical properties of the tool and the workpiece at 450 °C are substituted to Eq. (4), which leads to an f value of 0.77.

4.2.2 Heat generation from tool pin

For the convenience of finite element calculation, the heat generated by the pin/workpiece interface is averaged on the whole pin volume. The volume heat flux from the tool pin, as an internal heat source during the modeling, can be described by the following equation:

(5)

(5)

where Q2 and Q3 are the heats generated from the side and bottom surfaces of tool pin, respectively. Considering the tool geometry, the volume heat flux of tool pin is finally simplified as

(6)

(6)

4.3 Initial and boundary conditions

4.3.1 Initial condition

The normal and underwater FSWs have the same initial boundary conditions for the calculations of temperature fields:

=298 K (7)

=298 K (7)

4.3.2 Boundary condition at shoulder/workpiece interface

The heat flux boundary condition for the workpiece at the shoulder/workpiece interface is expressed as

(8)

(8)

4.3.3 Convection boundary conditions

The convection boundary condition for all the surfaces of workpiece is

(9)

(9)

where h is the convection coefficient.

In most of the previous investigations, the surfaces of workpiece exposed to the atmosphere were allocated a convection coefficient of 10-30 W/(m2·°C) for thermal modeling of normal FSW of aluminum alloys [17-21]. Based on this, the convection coefficient is set to be 15 W/(m2·°C) for the top and side surfaces of the plates in this study.

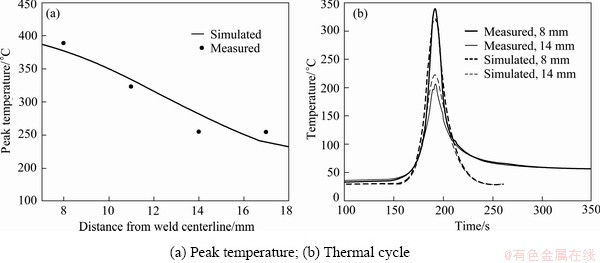

Heat transfer through the contact between workpiece and backing plate is complex and uncertain because of the uncertainty of the contact gap conductance. In previous investigations, this boundary condition was commonly simplified as the convection condition and the effective convection coefficient was mostly concentrated in the range of 200-1000 W/(m2·°C) [19-21]. For the normal FSW in the present study, six different convection coefficients 100, 200, 400, 600, 800 and 1000 W/(m2·°C) are chosen to make calculations in the temperature field separately, and it is found that when the convection coefficient between workpiece and backing plate is set to be 200 W/(m2·°C), the predicted profile generally shows good agreement with the magnitude and shape of the experimental profile, as shown in Fig. 7. The relatively low predicted temperature at the initial stage can be explained as follows. During the modeling, the temperature of air is set at a constant value (25 °C), but in fact, the temperature of the air near the workpiece is increased during the welding due to the gradual accumulation of heat input. For this reason, the heat dissipation is weakened compared with that in the practical situation, and thus the modeling temperature shows higher values than the experimental data at the temperature rise period.

Regarding the underwater FSW, the heat dissipation conditions for all sides of the workpiece are different from those under normal condition. For the top surface near welding tool, the contact water is in the boiling state under the effect of elevated temperature (above 120 °C), leading to intense heat transfer between the workpiece and the boiling water. While for the other surfaces exposed to the non-boiling water, the heat is dissipated from the workpiece by natural convection of water. Therefore, prior to every step of simulation, the temperature of each node should be detected first, based on which the appropriate heat transfer coefficient is chosen and exerted on the node. Besides, the convection coefficient between workpiece and backing plate is also different from that of normal FSW because the contact gap is filled with water during underwater FSW. After many trail experiments, it is found that when the convection coefficients of non-boiling water, boiling water and the interface of workpiece and backing plate are respectively chosen as 850, 3000 and 1000 W/(m2·°C), the modeling results yield very good agreement with the experimental measurements (see Fig. 8).

5 Results and discussion

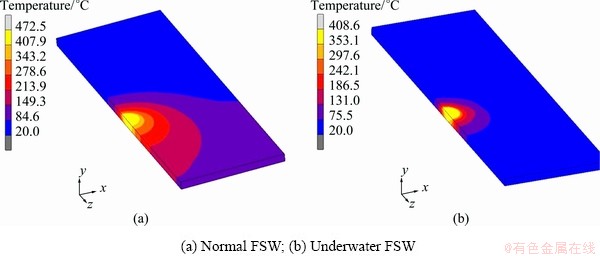

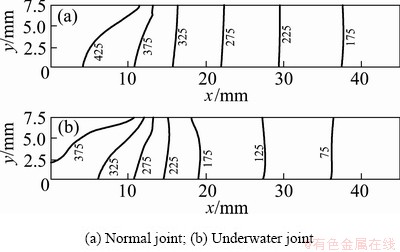

The maximum peak temperature of the normal joint is 472.5 °C, while that of the underwater joint is only 408.6 °C (see Fig. 9), significantly lower than that of normal joint; in addition, the high-temperature distributing area is remarkably narrowed in contrast to the normal joint.

Fig. 7 Modeling and test results of temperature histories of normal FSW

Fig. 8 Modeling and test results of temperature histories of underwater FSW

Fig. 9 Temperature distributions in quasi-steady state of welding process

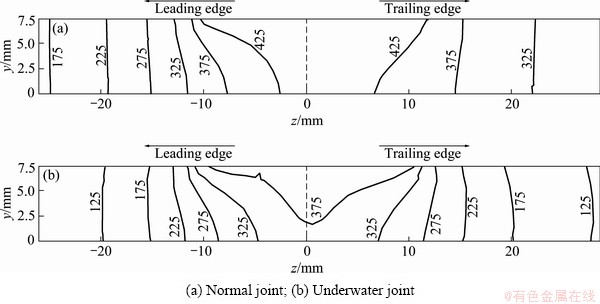

Figure 10 shows temperature distributions on the longitudinal section of the joints (yOz, x=0). Notably, the temperature distributions at the leading and trailing edges of the tool are asymmetrical with respect to the tool axis for normal FSW. The temperature at trailing edge is relatively high and exhibits low gradient. This should be attributed to the gradual accumulation of heat input behind the tool during the welding. In contrast, the isothermals of underwater FSW severely move towards the tool axis, and the moving extent at the trailing edge is larger than that at the leading edge. For this reason, the underwater FSW presents higher temperature gradient at both tool trailing and leading edges than the normal FSW; furthermore, the temperature distributions are more symmetrical with respect to the tool axis between the both edges.

Fig. 10 Temperature distributions on longitudinal section of joints (vertical dash line represents tool axis)

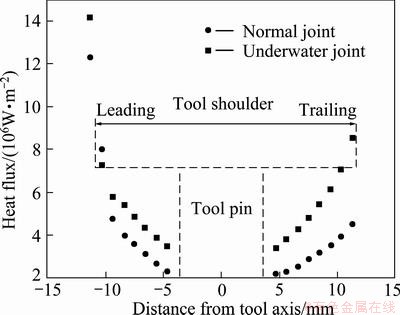

For both normal and underwater joints, the surface heat flux of tool shoulder is higher at the leading edge than at the trailing edge (see Fig. 11). During the welding process, the leading edge of shoulder first interacts with the “cold” base material. The relatively high yield stress allows intense friction heating to generate at the shoulder/workpiece interface according to Eq. (3). When the base material is transferred from the leading edge back to the trailing edge, it gradually becomes soft, which weakens the interaction between tool shoulder and base material; consequently, the surface heat flux of shoulder is decreased. From this point of view, the higher surface heat flux during underwater FSW is then easily understood. Just because the heat absorption capacity of water is rather higher than that of air, the maximum peak temperature of underwater joint is lower instead than that of normal joint.

Fig. 11 Distributions of surface heat flux of tool shoulder along joint line

Figure 12 reveals the peak temperature distributions on the cross section of the joints. Similar to that occurs on the longitudinal section, the isothermals of underwater joint also remarkably move towards the tool axis in contrast to the normal joint. The moving extent is the largest at the lower part and the smallest at the upper part of the joint. This means that the lower part experiences the largest cooling effect during underwater FSW. In Ref. [11], the results showed that the mechanical properties of the underwater joint were improved in contrast to the normal joint, and the improved level was the largest at the lower part and the smallest at the upper part. From the modeling result of temperature field, the intrinsic reason for this can be illustrated. The integral cooling effect of water effectively controls the thermal cycle at the lower part of joint, and thus improves the mechanical properties of the whole joint.

Fig. 12 Temperature distributions on cross section of joints

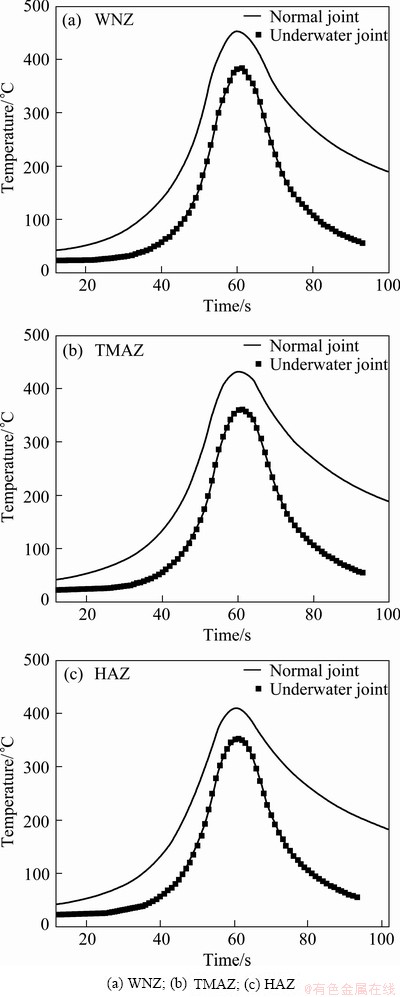

Figure 13 plots the time-temperature history profiles of different zones of both normal and underwater joints including weld nugget zone (WNZ), thermal mechanically affected zone (TMAZ) and heat affected zone (HAZ). As the tool passes by, the temperature of different zones of normal joint is gradually increased to the peak value and then shows a slow cooling rate. While for the underwater joint, the peak temperature of different zones is all lower than the corresponding value of the normal joint; in addition, the thermal cycle exhibits larger heating and cooling rates, leading to a shorter high temperature dwelling time. The controlling of thermal cycle by water cooling weakens the precipitate coarsening and dissolution in the thermal mechanically affected zone and heat affected zone, and consequently improves the hardness values of these two regions, and finally the mechanical properties of the whole joint [10].

Fig. 13 Thermal cycle of different zones of welds

6 Conclusions

1) The water around the tool can be divided into two parts according to its vaporizing characteristics, i.e. the boiling water and the non-boiling water. The test results indicate that the surplus temperature of water reaches 20 °C during underwater FSW.

2) The thermal modeling of underwater FSW was conducted with considering the temperature-dependent properties of the material. The experimental values validate the efficiency of the thermal model.

3) For underwater FSW, the surface heat flux of shoulder is higher than that for normal FSW. However, the maximum peak temperature of underwater joint is still considerably lower than that of normal joint due to the severe heat absorption capacity of water. Additionally, compared with the normal joint, the underwater joint exhibits a narrower high-temperature distribution area and lower welding thermal cycles in different zones.

References

[1] JOHNSEN M R. Friction stir welding takes off at Boeing [J]. Welding Journal, 1999, 78 (2): 35-39.

[2] JOELJ D. The friction stir welding advantage [J]. Welding Journal, 2001, 80(5): 30-34.

[3] MISHRA R S, MA Zong-yi. Friction stir welding and processing [J]. Material Science and Engineering R, 2005, 50(1-2): 1-78.

[4] THREADGILL P L, LEONARD A J, SHERCLIFF H R, WITHERS P J. Friction stir welding of aluminum alloys [J]. International Materials Reviews, 2009, 54(2): 49-93.

[5] SIMAR A,  Y, de MEESTER B, DENQUIN A, PARDOEN T. Microstructure, local and global mechanical properties of friction stir welds in aluminium alloy 6005A-T6 [J]. Material Science and Engineering A, 2008, 486(1-2): 85-95.

Y, de MEESTER B, DENQUIN A, PARDOEN T. Microstructure, local and global mechanical properties of friction stir welds in aluminium alloy 6005A-T6 [J]. Material Science and Engineering A, 2008, 486(1-2): 85-95.

[6] STARINK M J, SESCHAMPS A, WANG S C. The strength of friction stir welded and friction stir processed aluminium alloys [J]. Scripta Materialia, 2008, 58(5): 377-382.

[7] DIXIT V, MISHRA R S, LEDERICH R J, TALWAR R. Influence of process parameters on microstructural evolution and mechanical properties in friction stirred Al-2024(T3) alloy [J]. Science and Technology of Welding and Joining, 2009, 14(4): 346-355.

[8] FRATINI L, BUFFA G, SHIVPURI R. In-process heat treatments to improve FS-welded butt joints [J]. International Journal of Advanced Manufacturing Technology, 2009, 43(7-8): 664-670.

[9] FRATINI L, BUFFA G, SHIVPURI R. Mechanical and metallurgical effects of in process cooling during friction stir welding of AA7075-T6 butt joints [J]. Acta Materialia, 2010, 58(6): 2056-2067.

[10] LIU Hui-jie, ZHANG Hui-jie, HUANG Yong-xian, YU Lei. Mechanical properties of underwater friction stir welded 2219 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1387-1391.

[11] LIU Hui-jie, ZHANG Hui-jie, YU Lei. Homogeneity of mechanical properties of underwater friction stir welded 2219-T6 aluminum alloy [J]. Journal of Materials Engineering and Performance, 2011, 20(8): 1419-1422.

[12] ZHANG Hui-jie, LIU Hui-jie, YU Lei. Microstructure and mechanical properties as a function of rotation speed in underwater friction stir welded aluminum alloy joints [J]. Materials and Design, 2011, 32(8-9): 4402-4407.

[13] ALBAKRI A N, ALJOABA S Z, KHRAISHEH M K. Modelling of friction stir processing with in process cooling using computational fluid dynamics analysis [C]//SELIGER G, KHRAISHEH M M K, JAWAHIR I S. Advances in Sustainable Manufacturing: Proceedings of the 8th Global Conference on Sustainable Manufacturing. Berlin, Springer-Verlag, 2011: 99-105.

[14] PITTS D, SISSOM L. Schaum’s outline of theory and problems of heat transfer [M]. New York: McGraw Hill, 1998: 194.

[15] ZWILSKY K M, LANGER E L. ASM handbook volume 2, Properties and selection: Nonferrous alloys and special-purpose materials [M]. ASM International, 2001: 300-313.

[16] SCHMIDT H B, HATTEL J H. A thermal-pseudo-mechanical model for the heat generation in friction stir welding [C]//Proceedings of the 7th International Symposium on Friction Stir Welding. Awaji Island, Japan: TWI Ltd, 2008: S2B-P4.

[17] BASTIER A, MAITOURNAM M H, van K DANG, ROGER F. Steady state thermomechanical modelling of friction stir welding [J]. Science and Technology of Welding and Joining, 2006, 11(3): 278-288.

[18] HILGERT J, SCHMIDT H N B, dos SANTOS J F, HUBER N. Thermal models for bobbin tool friction stir welding [J]. Journal of Materials Processing Technology, 2011, 211(2): 197-204.

[19] CHAO Y J, QI X. Thermal and thermo-mechanical modeling of friction stir welding of aluminum alloy 6061-T6 [J]. Journal of Materials Processing and Manufacturing Science, 1998, 7(2): 215-233.

[20] HAMILTON C, DYMEK S, SOMMERS A. A thermal model of friction stir welding in aluminum alloys [J]. International Journal of Machine Tools & Manufacture, 2008, 48(10): 1120-1130.

[21] JACQUIN D, de MEESTER B, SIMAR A, DELOISON D, MONTHEILLET F, DESRAYAUD C. A simple eulerian thermomechanical modeling of friction stir welding [J]. Journal of Materials Processing Technology, 2011, 211 (1): 57-65.

张会杰, 刘会杰, 于 雷

哈尔滨工业大学 材料科学与工程学院,现代焊接与连接国家重点实验室,哈尔滨 150001

摘 要:应用三维热源模型对水浸搅拌摩擦焊接的温度场进行模拟分析。通过分析水介质的汽化特征,阐明水浸搅拌摩擦焊接的边界条件。在模拟中考虑了材料性能与温度的相关性。搅拌摩擦焊接试验的结果表明,模拟结果与温度场的真实值具有较高的拟合程度。温度场的模拟结果表明,尽管水浸搅拌摩擦焊接的轴肩面热流密度比常规搅拌摩擦焊接的高,但水浸接头的最高峰值温度明显比常规接头的低。水浸接头的高温分布区间显著变窄,焊缝各区热循环也得到了有效控制。

关键词:铝合金;水浸搅拌摩擦焊接;温度场;模拟

(Edited by Hua YANG)

Foundation item: Project (2010CB731704) supported by the National Basic Research Program of China; Project (51175117) supported by the National Natural Science Foundation of China; Project (2010ZX04007-011) supported by the National Science and Technology Major Project of China

Corresponding author: Hui-jie LIU; Tel: +86-451-86413951; Fax: +86-451-86416186; E-mail: liuhj@hit.edu.cn

DOI: 10.1016/S1003-6326(13)62573-X