文章编号:1004-0609(2010)09-1759-07

预制体类型及孔隙结构对化学气相渗透TaC的影响

陈招科, 熊 翔, 李国栋

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:在分析和计算机准三维(2.5D)针刺整体炭毡、低密度炭毡孔隙结构的基础上,研究不同温度和压力下反应气体在上述预制体孔隙中的扩散行为、TaC的沉积速率及渗透深度。结果表明:在800~1000 ℃和60~400 Pa时,TaCl5气体在低密度炭毡中的有效扩散系数大于其在准三维针刺毡中的有效扩散系数。在800~950 ℃时,TaC在准三维针刺整体炭毡中的沉积速率大于其在低密度炭毡的沉积速率,但在950~1 000 ℃ 则刚好相反;在800 ℃和不同压力下,TaC在准三维针刺整体炭毡中的沉积速率均大于其在低密度炭毡中的沉积速率;TaC在低密度炭毡的沉积过程受表面反应控制和孔隙扩散控制的转变温度为950 ℃,而在准三维针刺整体毡中的转变温度则为900 ℃。在800 ℃和200 Pa时,TaC在不同预制体中的渗透深度均为100%,随着沉积温度的升高以及压力的升高(400 Pa)和降低(60 Pa),TaC在准三维针刺炭毡中的渗透深度显著降低,且明显小于同条件下其在低密度炭毡中的渗透深度。

关键词:TaC;化学气相渗透;孔隙结构;扩散;渗透深度

中图分类号: TB 332 文献标志码:A

Influence of preforms and pore structures on

chemical vapor infiltration of TaC

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China )

Abstract:The effects of deposition temperature and pressure on the diffusion behavior of TaCl5 vapor in the perform pores, and the deposition rats, infiltration depths of TaC in the performs were researched on the basis of theoretical analyses of the pore structures of 2.5D needle-punctured felts, low-density carbon felts. The results show that at 800-1 000 ℃ and 60-400 Pa, the effective diffusion coefficient of TaCl5 vapor in low-density felt is larger than that in 2.5D needle-punctured felt; at 800-950 ℃, the deposition rate of TaC in 2.5D needle-punctured perform is larger than that in the low-density perform, but it is opposite at 950-1 000 ℃. At 800 ℃ and 60-400 Pa, the deposition rate of TaC in 2.5D needle-punctured felt is larger than that in low-density felt. The change temperatures controlled by surface reactive kinetics and diffusion kinetics of pore in TaC-CVI process are 950 ℃ in low-density felts and 900 ℃ in 2.5D needle-punctured felts, respectively; at 800 ℃ and 200 Pa, the infiltration depths of TaC in 2.5D needle-punctured felts and low-density felts are all 100%, but decrease obviously with increasing temperature and variation of pressure. In addition, the infiltration depth of TaC in 2.5D needle-punctured felts is less than that in low-density felts.

Key words:TaC; chemical vapor infiltration; pore structure; diffusion; infiltration depth

TaC的熔点高达3 880~4 000 ℃[1],且具有硬度高、抗冲刷性能好、耐腐蚀和化学稳定性好等优点;同时,还具有优异的高温力学性能、抗高速气流(粒子流)冲刷性能、抗烧蚀性能,并与C/C材料具有良好的化学相容性及物理相容性[2]。当将TaC渗入炭纤维预制体中,形成TaC陶瓷基体[3]或TaC纤维表面涂层[4]时,该复合材料具有优良的超高温抗氧化性能和抗烧蚀性能。GIBSON等[5]利用三步化学反应工艺制备了Cf/TaC复合材料,但是其残余孔隙率高。KIM[6]用两种方法制备出石墨纤维增强TaC复合材料,但是其力学性能较差。

与热压烧结等工艺相比,用化学气相渗透(CVI)法制备纤维增强陶瓷基复合材料时所沉积的陶瓷基体不会损伤预制体。因此,CVI法被广泛用于多孔纤维预制体中沉积炭、SiC、BN以及其它难熔金属材料,并成为唯一得到实用且商业化生产的方法。法国Bordeaux大学、法国SEP公司、德国Karsluhe大学、美国Oak Ridge国家实验室、西北工业大学、中南大学等均对CVI法制备C/C复合材料、C/SiC复合材料开展了深入的研究[7-13]。目前,关于CVI工艺的研究主要集中在复合材料的致密化方面,其目的是为如何缩短CVI工艺时间以节约工艺成本;并通过理论分析反应气体在多孔预制体中的扩散传质、对流传质、沉积反应以及反应气体损耗等,建立化学气相浸渗过程模型。然而,这些研究均假设预制体的孔隙为细长圆孔且孔隙结构均匀一致。从航空航天实际应用较多的针刺整体炭毡来看,其内部孔隙结构并不均匀一致;因此,这些理论模型与实际情况相差甚远。

为了更好地在预制体中沉积出TaC基体,有必要详细研究针刺整体毡的孔隙结构以及其对化学气相渗透TaC的影响。本文作者在详细分析针刺整体毡孔隙结构的基础上,探讨反应气体在孔隙中的扩散行为,研究不同沉积温度和压力下TaC在多孔预制体中的沉积速率及渗透深度,并探讨TaC在多孔预制体中渗透/沉积过程的控制机制,为获得整体密度均匀,致密度较高的含TaC、SiC/TaC中间界面的C/C材料奠定基础。同时,还以低密度炭毡以及石墨纸为预制体或沉积基底,对比研究预制体类型及孔隙结构对TaC- CVI过程的影响。

1 实验

采用针刺整体毡(A,50 mm×10 mm×10 mm,0.56 g/cm3)、低密度炭毡(B,50 mm×10 mm×10 mm, 0.16 g/cm3)及柔性石墨纸(C,50 mm×10 mm×1 mm)作为预制体或沉积基底。针刺整体毡中炭纤维体积分数为0.32,其中无纬布层长纤维与网胎层短纤维体积比为0.85?0.15。低密度炭毡的炭纤维体积分数为0.09。

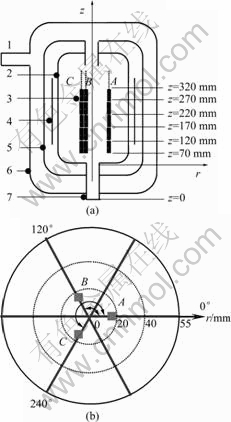

在沉积前,将针刺整体毡、低密度炭毡和柔性石墨纸进行超声清洗,然后110 ℃干燥以去除水分,最后,将3种(15个) 预制体或基底悬挂于反应器的保温区中。CVD反应器及样品装载示意图如图1所示。其中,5个针刺整体毡的放置位置为A(0?, z=70~320 mm);5个低密度炭毡的放置位置为B(120?, z=70~320 mm);5个柔性石墨纸基底的放置位置为C(240?, z=70~ 320 mm)。设定反应器中进气口位置为z=0 mm (见 图1)。

图1 CVD反应器及样品装载示意图

Fig.1 Schematic map of CVD reactor (a) and load of samples (b): 1—Gas outlet; 2—Graphite crucible; 3—Samples; 4— Graphite heater; 5—Heat preservation; 6—Stainless steel jacket; 7—Gas inlet

采用TaCl5-Ar-C3H6体系,在预制体中炭纤维表面或基底表面沉积TaC。工艺参数的研究范围主要设定为TaC-CVD过程受表面动力学控制的工艺参数范 围[14]。气体流速、滞留时间分别取沉积受表面反应控制的最大气体流速(40 cm/s)以及最小滞留时间(1.2 s);载气/稀释气体流量比取最小值(1/4);沉积温度及压力的研究范围分别为800~1 000 ℃和50~400 Pa。

利用精确度为0.1 mg的Adventure TM电子天平对样品进行称量;并以样品在单位面积和单位时间内的质量增加来表征沉积速率。

(1)

(1)

式中:r为沉积速率,mg/(cm2?h);mf为沉积后基底质量,mg;m0为沉积前基底质量,mg;Δm为基底沉积前后的质量变化,mg;A为基底的表面积,cm2;t为沉积时间,h。

TaC在纤维表面沉积后会使炭纤维表面的颜色变成黄色;在预制体里层,没有沉积TaC的炭纤维则为黑色;每次实验后,将样品沿横截面方向切开,测量横截面中黄色/黑色界面与预制体表层的距离,将此距离除以预制体厚度的一半获得渗透百分比,并用此百分比来表征渗透深度。用JEOL-6360LV型扫描电子显微镜(SEM)观察预制体的微观孔隙结构以及化学气相渗透后TaC的微观沉积形貌。

2 结果与讨论

2.1 预制体孔隙结构

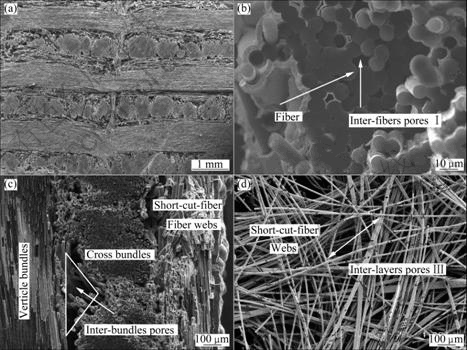

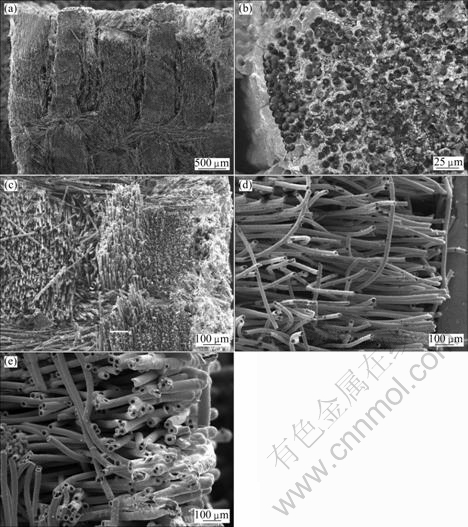

图2所示为针刺整体毡的微观结构及孔隙结构。

针刺整体毡的孔隙主要分为三类:一是纤维束内单丝纤维之间的I型束内孔隙;二是纤维束与纤维束之间的II型束间孔隙;三是网胎层内短纤维与短纤维之间的III型层间孔隙。12 k炭纤维束的截面为圆形,单丝的截面也为圆形,假设炭纤维束内的单丝按开启式排列[15],则可计算出束内I型孔隙的尺寸为4.8 μm;而II型孔隙的尺寸约为246.0 μm,III型层间孔隙尺寸则在300.0~400.0 μm。

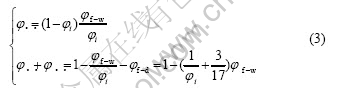

假设针刺整体毡中的纤维体积分数为φf,无纬布长纤维体积分数为φf-w,网胎中短纤维体积分数为φf-d,则有:

(2)

(2)

而其I型束内孔隙φⅠ、II型束间孔隙φⅡ和III型层间孔隙φⅢ的体积分数则为

式中:φf-w/φi为纤维束在针刺整体毡中所占体积分数。

经计算,纤维束内孔隙体积分数φⅠ=0.129。短纤维在网胎中所占体积比为ρn/ρc(ρn为网胎的密度,ρc为炭纤维的密度),而短纤维在准三维整体毡中所占体积分数为φf-d,可得网胎在毡体中所占体积比为φf-dρc/ρn;由此得出网胎层间Ⅲ型孔隙的体积分

图2 已渗透TaC的准三维针刺整体毡结构及孔隙结构照片

Fig.2 Microstructures of needle-punctured felt (infiltrated with TaC) and pore structure: (a) Microstructure; (b) Inter-fiber pores I; (c) Inter-bundle pores II; (d) Inter-layer pores III

数为

φⅢ=(1-ρn/ρc)×φf-d×ρc/ρn=0.426 (4)

纤维束间的Ⅱ型孔隙的体积分数为

(5)

(5)

低密度炭毡的密度为0.16 g/cm3,孔隙率为90.7%,平均孔隙尺寸为165.0 μm左右。

2.2 孔隙结构对反应气体在预制体中扩散的影响

经计算,TaCl5气体分子的碰撞直径(σ)为8~10 ?。根据平均分子速率和分子平均自由程公式可计算得出,在800 ℃和200 Pa时,TaCl5气体分子平均速率 为7.96 m/s,平均自由程λ为16~26 μm。根据Knudsen公式(

为7.96 m/s,平均自由程λ为16~26 μm。根据Knudsen公式( )(其中Kn为Knudsen数,d为孔隙直径),可知TaCl5气体分子在针刺整体毡的Ⅰ型孔隙、Ⅱ型孔隙、Ⅲ型孔隙以及低密度炭毡孔隙中的Knudsen数分别为3.33~5.40、0.065~0.106、0.040~0.065和0.097~0.158。由此可知,TaCl5气体分子在4种孔隙中的扩散均受混合扩散控制。

)(其中Kn为Knudsen数,d为孔隙直径),可知TaCl5气体分子在针刺整体毡的Ⅰ型孔隙、Ⅱ型孔隙、Ⅲ型孔隙以及低密度炭毡孔隙中的Knudsen数分别为3.33~5.40、0.065~0.106、0.040~0.065和0.097~0.158。由此可知,TaCl5气体分子在4种孔隙中的扩散均受混合扩散控制。

在充分考虑预制体孔隙尺寸、平均分子速率、平均分子自由程及Kn数的情况下,反应气体在孔隙中的有效扩散系数可以写为[8]

(6)

(6)

式中:α为扩散系数比值;xi为计算气体在混合气体中的体积分数;xj为第j种气体在混合气体中的体积分数;σi为第i种气体分子的碰撞直径;Mi, Mj为第i, j种气体分子的相对分子量。

(7)

(7)

在反应气体体系中,TaCl5和C3H6的体积分数非常小,因此,假设TaCl5和C3H6均在Ar中无限稀释,在计算TaCl5在Ar中的菲克扩散系数和扩散系数比值 时,忽略C3H6的作用,只考虑TaCl5和Ar的双元互扩散。因此,式(7)可简单化为

时,忽略C3H6的作用,只考虑TaCl5和Ar的双元互扩散。因此,式(7)可简单化为

(8)

(8)

取Ar的碰撞直径σAr为3.6 ?,摩尔质量MAr为36 g/mol;取TaCl5的碰撞直径σTaCl5分别为8 ?或10 ?,摩尔质量MTaCl5为358.5 g/mol,计算出 为4.453或5.062。由此可计算出不同温度压力下TaCl5气体在多孔预制体中的扩散系数,如图3所示。

为4.453或5.062。由此可计算出不同温度压力下TaCl5气体在多孔预制体中的扩散系数,如图3所示。

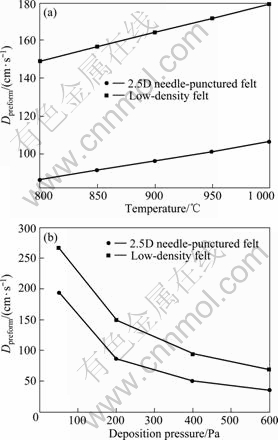

图3 不同温度和压力下预制体类型与扩散系数的关系

Fig.3 Diffusion coefficients of preforms as functions of deposition temperatures and pressures: (a) At 200 Pa and different temperatures; (b) At 800 ℃ and different pressures

由图3可知,TaCl5在多孔预制体中的有效扩散系数随温度的升高而增加,随沉积压力的升高而降低。同时,在不同温度和不同压力下,TaCl5在低密度炭毡中的有效扩散系数均大于其在整体毡中的有效扩散 系数。

2.3 不同温度下预制体类型及孔隙结构对TaC沉积速率及渗透深度的影响

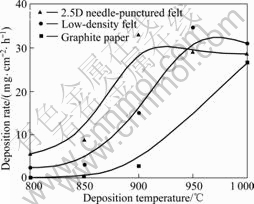

图4所示为200 Pa时不同温度下预制体类型对沉积速率的影响。

不同温度下预制体类型对沉积速率的影响非常大。在800~900 ℃,TaC在针刺整体毡中的沉积速率最大;在950~1 000 ℃,TaC在低密度炭毡中的沉积速率最大。同时,在石墨纸基底表面,随着温度的升高,TaC的沉积速率持续增加;在低密度炭毡中,沉积速率在800~950 ℃时急剧增加,在950 ℃时达到最大值,在1 000 ℃时反而减小;在针刺整体毡中,沉积速率在800~900 ℃时急剧升高,在900 ℃时达到最大值,在900 ℃以后沉积速率缓慢下降。

图5所示为不同温度下TaC在针刺整体毡和低密度炭毡中沉积20 h后的微观结构。

图4 200 Pa时不同温度下预制体类型对沉积速率的影响

Fig.4 Deposition rates of preforms or substrates at 200 Pa as functions of deposition temperatures

由图5(a),(b),(c)可知,在800 ℃时,TaC在针刺整体毡中的沉积比较均匀;在850 ℃,针刺整体毡表层没有结壳,但纤维束表层开始结壳;在900 ℃时,针刺整体毡表层开始结壳。由图5(d),(e)可知,在950 ℃时,TaC在低密度炭毡中的沉积比较均匀;但在 1 000 ℃时,预制体表层结壳。由此可知,当沉积温度大于950 ℃时,TaC在低密度炭毡的渗透/沉积过程已开始由孔隙扩散所控制。当沉积温度大于900 ℃时,TaC在针刺整体毡中的渗透/沉积过积开始由孔隙扩散控制。当TaC的渗透过程受孔隙扩散所控制时,大多数反应物在到达预制体中心前已经在表层孔隙处发生了沉积反应,并迅速封闭表层孔隙通道,阻止反应气体进入内部孔隙而沉积。受孔隙扩散控制是沉积速率随沉积温度的升高反而下降的主要原因。

当TaC的渗透沉积过程受表面动力学控制时,沉积速率主要与预制体比表面积有关;针刺整体毡的比表面积远远大于低密度炭毡以及石墨纸的比表面积,因此,在该预制体中沉积的TaC量最多,沉积速率最大。

图5 TaC在针刺整体毡及低密度炭毡中沉积20 h后的微观结构

Fig.5 Microstructures of low density felts and 2.5D needle-punctured felts after TaC deposition for 20 h: (a) 2.5D needle-punctured felt, 800 ℃; (b) 2.5D needle-punctured felt, 850 ℃; (c) 2.5D needle-punctured felt, 900 ℃; (d) Low-density felt, 950 ℃; (e) Low-density felt, 1 000℃

在受孔隙扩散控制时,预制体表层孔隙堵塞,预制体内反应气体浓度急剧下降,TaC可沉积的比表面积急剧减少,沉积速率较小。综合以上分析可知,TaC在石墨纸基底表面、低密度炭毡以及针刺整体毡中的沉积过程受表面反应控制和扩散(或孔隙扩散)的转变温度分别为1 000 ℃,950 ℃和900 ℃。

不同温度下TaC在针刺整体毡及低密度毡中的渗透深度如图6所示。TaC在针刺整体毡中的渗透/沉积深度要比其在低密度炭毡中的渗透/沉积深度小。结合图3(a)可知,TaCl5气体在针刺整体毡中的有效扩散系数较小,沉积过程更容易受反应气体在孔隙中的扩散所控制。当沉积温度为800 ℃时,TaC在低密度炭毡和针刺整体毡中的渗透深度都为100 %;随沉积温度的升高,TaC在两种预制体中的渗透深度均明显下降。这主要是温度的升高使TaC在多孔预制体中的渗透过程由受表面动力学控制逐渐转变为受孔隙扩散控制,反应气体无法渗入到预制体最里层的孔隙处发生沉积所致。

图6 TaC在针刺整体毡及低密度炭毡中渗透深度与温度的关系

Fig.6 Infiltration depths of TaC as functions of deposition temperatures in 2.5D needle-punctured felts (a) and low-density felts (b)

2.4 不同压力下预制体类型及孔隙结构对TaC沉积速率及渗透深度的影响

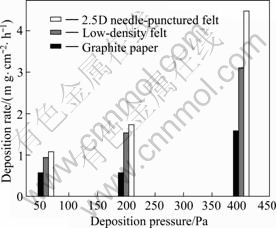

图7所示为800 ℃时不同压力(50~400 Pa)下预制体类型对沉积速率的影响。

在800 ℃时不同压力下预制体孔隙结构对沉积速率的影响较大。由于比表面积的关系,TaC在针刺整体毡中的沉积速率大于其在低密度炭毡和石墨纸上的沉积速率。同时,TaC在两种多孔预制体中的沉积速率均随沉积压力的增大而增加。结合图3(b)可知,随压力的升高反应气体在多孔预制体中的扩散速率下降;但图7表明,随压力的升高,沉积速率反而升高;表明在800 ℃时沉积速率受扩散速率的影响不大。

图7 800 ℃时不同压力下预制体类型对沉积速率的影响

Fig.7 Deposition rates of TaC at 800 ℃ as functions of deposition pressures

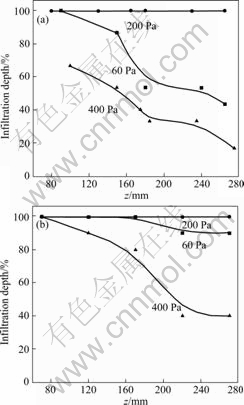

不同压力下TaC在低密度炭毡及针刺整体毡中的渗透深度如图8所示。在800 ℃、60~400 Pa下,TaC在低密度炭毡中的渗透深度要大于其在针刺整体毡中的渗透深度,这与反应气体在不同预制体中的扩散系数有关(见图3(b))。在沉积压力为200 Pa时,TaC在两种预制体中的渗透深度大部分均为100%,渗透深度较大;而在压力为60 Pa和400 Pa时,渗透深度明显下降。在60 Pa时,反应器中气体流速相对较快,反应气体来不及渗透到预制体最里层就被系统排出反应器;也就是说反应气体在 z=270 mm处可停留的时间较短(滞留时间较短),沉积过程较容易转移为受扩散所控制,渗透深度较小。当沉积压力为400 Pa时,在沉积位置为z=70 mm处渗透深度较小的主要原因是沉积压力的增大使沉积过程转变为受孔隙扩散所控制;而渗透深度随沉积位置的增加急剧减小则主要是损耗效应的影响。

图8 800 ℃时不同压力下TaC在多孔预制体中的渗透深度

Fig.8 Infiltration depths of TaC at 800 ℃ as functions of pressures in 2.5D needle-punctured felt (a) and low-density felt (b)

3 结论

1) 在不同温度和压力下,TaCl5气体在低密度炭毡中的有效扩散系数大于其在整体毡中的有效扩散系数。

2) TaC在石墨纸基底表面、低密度炭毡以及整体毡中的沉积过程受表面反应控制和扩散(或孔隙扩散)控制的转变温度分别为1 000 ℃,950 ℃和900 ℃;TaC在整体毡中的渗透深度要比其在低密度炭毡中的渗透深度小;且随着温度和沉积位置的升高,渗透深度明显下降。

3) 在不同压力下,TaC在整体毡中的沉积速率大于其在低密度炭毡和石墨纸上的沉积速率;在60 Pa和400 Pa时,渗透深度随着沉积位置的增加而减小;在200 Pa时, TaC在两种预制体中的渗透深度均为100 %。

REFERENCES

[1] 马福康, 邱向东, 贾厚生, 刘贵才. 铌与钽[M]. 长沙: 中南工业大学出版社, 1997: 19.

MA Fu-kang, QIU Xiang-dong, JIA Hou-sheng, LIU Gui-cai. Niobium and tantalum[M]. Changsha: Central South University of Technology Press, 1997:19.

[2] 李国栋, 熊 翔, 黄伯云. 温度对CVD-TaC涂层组成、形貌与结构的影响[J].中国有色金属学报, 2005, 15(4): 565-571.

LI Guo-dong, XIONG Xiang, HUANG Bai-yun. Effect of temperature on composition, surface morphology and microstructure of CVD-TaC coating[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 565-571.

[3] SAYIR A. Carbon fiber reinforced hafnium carbide composite[J]. Journal of Materials Science, 2004, 39(19): 5995-6003.

[4] US Ultramet. Fiber interface coatings [EB/OL]. http://www. ultramet.com/fiber_interface_coatings.html. 2009-10-22.

[5] GIBSON J O, GIBSON M G.. Production of carbon fiber-tantalum carbide composites: US 4196230[P]. 1980-04-01.

[6] KIM C, GRUMMON D S, GOTTSTEIN G. Processing and interface characteristics of graphite fiber reinforced tantalum carbide matrix composites[J ]. Scripta Metallurgica et Materialia, 1991, 25(10): 2351-2356.

[7] VISHAK S, SRINIVAS P. Optimization of isothermal-isobaric chemical vapor infiltration[J]. Computers Chem Engng, 1998, 22(Supple): S713-Sl76.

[8] GRIFFITHS S K, NILSON R H. Optimum conditions for composites fiber coating by chemical vapor infiltration[J]. J Electrochem Soc, 1998, 145(4): 1263-1272.

[9] OFORI J Y, SOTIRCHOS S V. Structural model effects on the predictions of chemical vapor infiltration models [J]. J Electrochem Soc, 1996, 143(6): 1962-1973.

[10] OFORI J Y, SOTIRCHOS S V. Investigation of the potential of forced-flow chemical vapor infiltration[J]. J Electrochem Soc, 1997, 144(1): 274-289.

[11] CHANG H C, GOTTLIEB D, MARION M, SHELDON B W. Mathematical Analysis and Optimization of Infiltration Processes[J]. Journal of Scientific Computing, 1998, 13(3): 303-321.

[12] SKAMSER D J. Model of chemical vapor infiltration using temperature gradients[J]. Journal of Materials Research, 1997, 12(3): 724-737.

[13] TAGO T, KAWASE M, LKUTA Y, HASHIMOTO K. Numerical simulation of the thermal-gradient chemical vapor infiltration process for production of fiber-reinforced ceramic composite[J]. Chemical Engineering Science, 2001, 56(6): 2161-2170.

[14] 陈招科, 熊 翔, 李国栋, 肖 鹏, 张红波, 尹 健, 黄伯云. 工艺参数对 CVI-TaC沉积速率的影响[J]. 中国有色金属学报, 2006, 16(12): 2047-2053.

CHEN Zhao-ke, XIONG Xiang, LI Guo-dong, XIAO Peng, ZHANG Hong-bo, YIN Jian, HUANG Bai-yun. Influences of process parameters on deposition rate of CVI-TaC[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 2047-2053.

[15] 李爱军. 碳/碳复合材料性能预测与 ICVI 工艺系统虚拟设计[D]. 西安: 西北工业大学, 2004.

LI Ai-jun. Prediction of C/C composite properties and virtual design of ICVI processes[D]. Xi′an: Northwestern Polytechnical University, 2004.

(编辑 杨 华)

基金项目:国家自然科学基金委员会创新研究群体科学基金资助项目(50721003);国家自然科学基金资助项目(50872154)

收稿日期:2009-06-09;修订日期:2010-06-08

通信作者:熊 翔,教授,博士;电话:0731-88836079;E-mail:xiong228@sina.com