Dry sliding wear behavior and mechanism of AM60B alloy at 25-200 ℃

来源期刊:中国有色金属学报(英文版)2011年第12期

论文作者:杨子润 魏敏先 赵玉涛 王树奇

文章页码:2584 - 2591

关键词:镁合金;干滑动磨损;氧化;摩擦层;磨损机制

Key words:magnesium alloy; dry sliding wear; oxidation; tribo-layer; wear mechanism

摘 要:针对AM60B合金在环境温度25~200 ℃、载荷12.5~300 N的条件下进行干摩擦磨损实验。结果表明:随着载荷的增大,磨损率增加;从轻微磨损到严重磨损的转变的临界载荷分别为25 ℃时275 N,100 ℃时150 N,200 ℃时75 N。在低载荷(<50 N)下,200 ℃下的磨损率低于25 ℃和100 ℃的。在轻微磨损阶段,磨损机制为磨粒磨损、氧化磨损和剥层磨损。当轻微磨损到严重磨损的转变开始时, 剥层磨损发挥主要作用,剥层磨损是从基体内部发生的剥落。随后, 塑性挤出磨损作为严重磨损出现,同时伴随着从轻微磨损到严重磨损的转变。厚的、硬的摩擦层通过限制磨面的塑性变形来阻碍从轻微磨损到严重磨损的转变。

Abstract:

Dry wear tests under atmospheric conditions at 25-200 ℃ and loads of 12.5?300 N were performed for AM60B alloy. The wear rate increases with increasing the load; the mild-to-severe wear transitions occur under the loads of 275 N at 25 ℃, 150 N at 100 ℃ and 75 N at 200 ℃, respectively. However, as the load is less than 50 N, the wear rate at 200 ℃ is lower than that at 25 ℃ or 100 ℃. In mild wear regimes, the wear mechanisms can be classified into abrasive wear, oxidation wear and delamination wear. Delamination wear prevailed as the mild-to-severe wear transition starts to occur; the delamination occurs from the inside of matrix. Subsequently, plastic-extrusion wear as severe wear prevails accompanied with the transition. The thick and hard tribo-layer postpones the mild-to-severe wear transition due to restricting the occurrence of massive plastic deformation of worn surfaces.

YANG Zi-run1, WEI Min-xian2, ZHAO Yu-tao2, WANG Shu-qi2

1. School of Materials Engineering, Yancheng Institute of Technology, Yancheng 224051, China;

2. School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China

Received 6 December 2010; accepted 31 March 2011

Abstract: Dry wear tests under atmospheric conditions at 25-200 ℃ and loads of 12.5-300 N were performed for AM60B alloy. The wear rate increases with increasing the load; the mild-to-severe wear transitions occur under the loads of 275 N at 25 ℃, 150 N at 100 ℃ and 75 N at 200 ℃, respectively. However, as the load is less than 50 N, the wear rate at 200 ℃ is lower than that at 25 ℃ or 100 ℃. In mild wear regimes, the wear mechanisms can be classified into abrasive wear, oxidation wear and delamination wear. Delamination wear prevailed as the mild-to-severe wear transition starts to occur; the delamination occurs from the inside of matrix. Subsequently, plastic-extrusion wear as severe wear prevails accompanied with the transition. The thick and hard tribo-layer postpones the mild-to-severe wear transition due to restricting the occurrence of massive plastic deformation of worn surfaces.

Key words: magnesium alloy; dry sliding wear; oxidation; tribo-layer; wear mechanism

1 Introduction

Magnesium alloys have been largely overshadowed by aluminum alloys for a long time. However, they are becoming one of the important lightweight materials in the last few decades. Magnesium alloys maintain a significant usage in machine, aerospace, automotive, space and nuclear energy due to their low densities, high specific buckling resistances, high specific strength, good damping capacities, good manufacturing and recycling capabilities [1-5]. The wear is a serious problem when magnesium alloys are subjected to sliding motion. The research about the wear of magnesium alloys has received significant attention in recent years. AM60B alloy is one of the widely used magnesium alloys and possesses an excellent toughness and ductility. However, the research about the wear of AM60B alloy has been sparsely reported till now.

AN et al [6] investigated the dry sliding wear of AZ91 and Mg97Zn1Y2 alloys. They considered that there were five wear mechanisms for magnesium alloys, namely abrasion wear, oxidation wear, delamination wear, thermal soften and melting. The superior wear resistance of magnesium alloy was attributed to the thermal stability of intermetallic compounds. ABDEL-WAHAB [7] studied the dry sliding wear behavior of hot deformed AZ61 alloy. The wear mechanisms were classified into two main wear regimes, the mild wear regime and severe wear regime. SHARMA et al [8] and HUANG et al [9] also shared the same viewpoint. But they pointed out that the severe wear should include the transfer of material. AUNG et al [10] studied the effect of sliding speed on the wear behavior of AZ91D alloy. Abrasive wear, oxidation wear and delamination wear prevailed at the sliding speeds of 0.01, 0.1 and 1.0 m/s, respectively. Recently, DAS et al [11] studied the wear behavior of AZ31 alloy, and considered that the oxidation wear prevailed at the low temperature; the plastic-deformation prevailed at the elevated temperature.

The aim of the present work is to study the effect of ambient temperature and load on the wear behavior and mechanism of AM60B alloy. The morphology, composition and structure of worn surfaces were examined. The wear behavior and wear mechanism of AM60B alloy at 25-200 ℃ were explored, and the relationship between the tribo-layer and the mild-severe wear transition was clarified.

2 Experimental

The dry wear tests were performed on a pin-on-disk high-temperature wear tester (MG-200 type). The pin specimens made from commercial AM60B alloy were machined to 6 mm in diameter and 12 mm in length. Because Mg-Fe was a popular sliding couple in engineering, commercial AISI 10 steel (HB171) was selected as the counterface, which was machined to 70 mm in diameter and 10 mm in thickness. The same test parameters were used for all samples: normal load of 12.5-300 N; 0.5 m/s of the sliding speed; 600 m of sliding distance; 25, 100 and 200 ℃ of the ambient temperatures.

All data on wear were measured from pins. Prior to the test, pins and disks were polished with 600 grit SiC paper and degreased. The pins were cleaned with acetone and dried before and after the test and then weighed for the wear loss using a balance with an accuracy of 0.01 mg. The wear rate was calculated through the mass loss divided by the density of the alloy and the sliding distance.

The morphology, composition and phase of worn surfaces were analyzed using an AMRA-1000B type scanning electron microscope (SEM) equipped with Inca Energy 350 type energy-dispersive spectrum (EDS), and a D/Max-2500/pc type X-ray diffractometer (XRD) respectively. The micro-hardness was measured using a HVS-1000 type digital micro-hardness tester with a load of 0.098 N and a holding time of 20 s.

3 Results and analyses

3.1 Wear rate

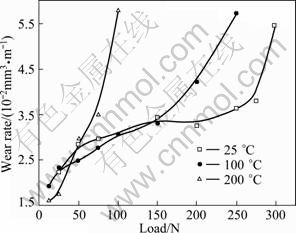

The wear rates of AM60B alloy as a function of the load at 25, 100 and 200 ℃ are shown in Fig. 1. The wear rate increased with increasing the load under different ambient temperatures. There existed the critical loads, under which the wear rate started to increase rapidly. In other words, the wear transition from mild wear to severe wear occurred. It can be observed that the mild-to-severe wear transition occurred at almost same wear rate range around (3-4)×10-2 mm3/m, that was reported by CHEN and ALPAS [12]. The critical loads decrease with increasing the ambient temperature, and were identified to be about 275 N at 25 ℃, 150 N at 100 ℃ and 75 N at 200 ℃, respectively.

Fig. 1 Wear rate as function of load and ambient temperature for AM60B alloy at 25, 100 and 200 ℃, respectively

Under the loads lower than 50 N, the wear rate at 200 ℃ was lower than those at 25 and 100 ℃. It is clear that in this case, the wear under different ambient temperatures fell in the mild wear regime. This seems to be contrary to the popular viewpoint that the transition from mild wear to severe wear was controlled by the critical surface temperature [6, 12, 13].

3.2 Phase and morphology of worn surfaces

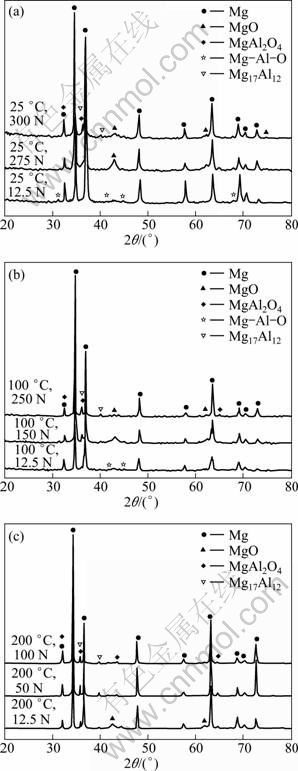

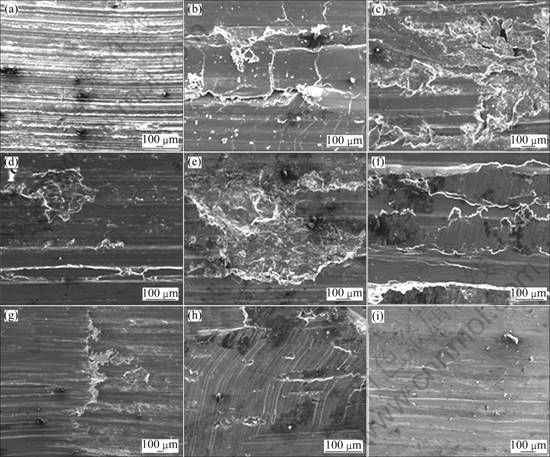

XRD patterns of the worn surfaces of AM60B alloy under various ambient temperatures and loads are shown in Fig. 2. It can be observed that tribo-oxides appeared on the worn surfaces except for Mg and Mg17Al12 phases. At 25 ℃, trace Mg-Al-O phase appeared under a lower load; MgO and trace Mg-Al-O existed under the higher loads. At 100 ℃, trace Mg-Al-O also appeared under a low load; the tribo-oxides were MgO and trace MgAl2O4 under a load of 150 N. As the load reached 250 N, MgAl2O4 turned to be a predominated oxide with trace MgO. At 200 ℃, the tribo-oxides were obviously different from those at 25 and 100 ℃ under the lower loads, and the tribo-oxides were MgO and trace MgAl2O4. As the load increased, MgAl2O4 turned to be a predominant tribo-oxide. It can be suggested that the oxides formed on worn surfaces roughly according to an order of Mg-Al-O, MgO and MgAl2O4 with increasing the ambient temperature and normal load. Table 1 summarizes the component and amount of tribo-oxides on the worn surfaces of AM60B alloy under various conditions. It must be noted that at 25 and 100 ℃, the amount of tribo-oxides increased with increasing the load, but significantly reduced when the wear entered the severe wear regime. However, at 200 ℃, the amount of tribo-oxides reduced with increasing the load.

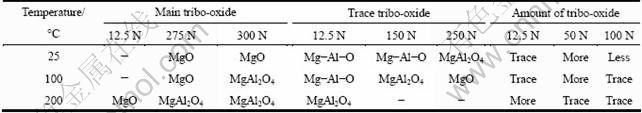

The morphologies of the worn surfaces of AM60B alloy under different ambient temperatures and loads are shown in Fig. 3. Under the lower loads, many deep grooves along the sliding direction presented at 25 ℃ (Fig. 3(a)). As the ambient temperature increased, delamination craters appeared with shallow grooves (Figs. 3(d) and (g)). It is clear that at 200 ℃, relatively smooth worn surface was covered by tribo-oxide layer.

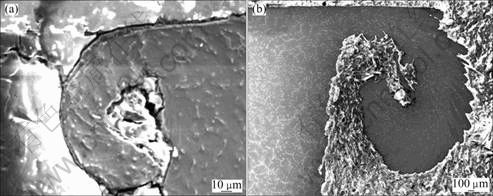

As the load increased, the delamination significantly increased with the delamination crater enlarging at 25 and 100 ℃ (Figs. 3(b) and (e)). At 200 ℃, the plastic deformation and plastic yield started to appear besides a small amount of delaminated regions (Fig. 3(h)). As the load further increased, the obvious plastics deformation and fracture occurred at 25 and 100 ℃ (Figs. 3(c) and (f)). However, at 200 ℃, there was merely a gross plastic flow without fracture because of the low flow strength at high temperature, thus the worn surface turned to be smoother (Fig. 3(i)). Especially, a large extrusion edge appeared on the tip of the worn surface (Fig. 4(b)), compared with a small one under 25 N (Fig. 4(a)).

Fig. 2 XRD patterns of worn surfaces of AM60B alloy under various conditions: (a) 12.5, 275 and 300 N at 25 ℃; (b) 12.5, 150 and 250 N at 100 ℃; (c) 12.5, 50 and 100 N at 200 ℃

3.3 Section morphology of worn surfaces

The section morphology of worn surfaces of AM60B alloy under various conditions was investigated, as shown in Fig. 5. Under the lower loads, the tribo-layer thickened with increasing the ambient temperature (Figs. 5(a), (d) and (g)). Especially, the thickness of the tribo-layer reached 30 μm at 200 ℃ (Fig. 5(g)), which was substantially thicker than 5 μm at 25 ℃ and 12 μm at 100 ℃. As the load increased, the morphology of tribo-layer greatly changed. At 25 ℃, the increased load detached and thickened the tribo-layer (Figs. 5(b) and (c)). It is clear that the detached tribo-layer appeared. This means that the tribo-layer not only formed on the worn surface, but also appeared on the subsurface. At 100 ℃, the increased load significantly thinned the tribo-layer on the worn surface. More importantly, the delamination occurred in the matrix on subsurface, where there existed crack and the oxide mixture inside crack (Figs. 5(e) and (f)). At 200 ℃, the tribo-layer almost could not be found under the loads of 50-100 N ( Figs. 5(h) and (i)).

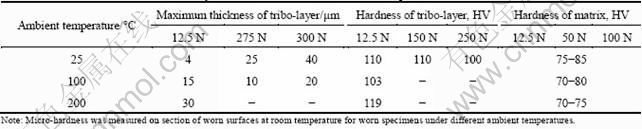

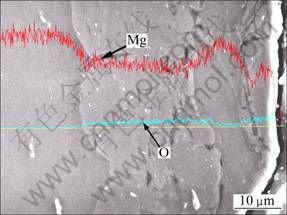

The existence of tribo-layer would be expected to substantially affect the wear behavior, which depended on the component and property of tribo-layer. The X-ray energy dispersive line scanning analysis result for the section of worn surface is illustrated in Fig. 6. It is observed that the tribo-layer contained relatively higher oxygen and lower magnesium than the matrix. Hence, the tribo-layer was the mixture of oxide and matrix, as shown in XRD pattern (Fig. 2). It is clear that the tribo-layer was a mechanical mixing layer (MML), as reported by SHARMA et al [8] and WANG et al [14]. The thickness and hardness of tribo-layer at the various sliding conditions are summarized in Table 2. It must be noted that the hardness of tribo-layer was obviously higher than the alloy matrix. Undoubtedly, the hard, thick mechanical mixing layer would cause the variation of wear behavior and mechanisms.

Table 1 Component and amount of tribo-oxides on worn surfaces of AM60B alloy under various conditions

Fig. 3 Morphologies of worn surfaces of AM60B alloy under various conditions:(a) 25 ℃, 12.5 N; (b) 25 ℃, 275 N; (c) 25 ℃, 300 N; (d) 100 ℃, 12.5 N; (e) 100 ℃, 150 N; (f) 100 ℃, 250 N; (g) 200 ℃, 12.5 N; (h) 200 ℃, 50 N; (i) 200 ℃, 100 N

Fig. 4 Plastic extrusion edges of AM60B alloy under loads of 25 N (a) and 100 N (b) at 200 ℃

4 Discussion

4.1 Wear mechanisms and delamination wear

The wear transition from mild wear to severe wear of AM60B alloy occurred with increasing load under different ambient temperatures. The wear transition undoubtedly resulted in the change of wear mechanisms. ABDEL-WAHAB [7] classified the wear mechanisms of AZ61 alloy into the mild wear and severe wear and emphasized the severe wear controlled by a mass of plastic deformation and plastic yield. CHEN and ALPAS [12] further classified the wear mechanisms into oxidation wear and delamination wear for the mild wear and the severe plastic deformation and melting wear for the severe wear. AN et al [6] identified five wear mechanisms for AZ91D alloy: abrasion, oxidation, delamination, thermal softening and melting. HUANG et al [9] studied the wear behavior of AZ91D and AM60B alloys. They indicated that fatigue wear and abrasive wear were the predominant wear mechanisms for AM60B alloy and delamination wear, adhesive wear and abrasive wear for AZ91D alloy.

Fig. 5 Section morphologies of worn surfaces of AM60B alloy under various conditions: (a) 25 ℃, 12.5 N; (b) 25 ℃, 275 N; (c) 25 ℃, 300 N; (d) 100 ℃, 12.5 N; (e) 100 ℃, 150 N; (f) 100 ℃, 250 N; (g) 200 ℃, 12.5 N; (h) 200 ℃, 50 N; (i) 200 ℃, 100 N

Table 2 Hardness and thickness of tribo-layer under various loads and ambient temperatures

Fig. 6 Line scanning analysis of section for worn surface of AM60B alloy under load of 300 N at 25 ℃

The wear mechanisms under various sliding conditions could be derived through the analysis for phase, morphology and composition of worn surfaces. At 25 ℃, under the lower load, many deep grooves appeared on the worn surfaces. In this case, there was a tribo-layer of 5 μm on the worn surface. It is clear that abrasion wear and oxidation wear were predominated wear mechanisms. As the load increased to 275 N, the tribo-layer thickened and delamination craters increased. In this case, oxidation wear and delamination wear were predominated wear mechanisms. As the load increased to 300 N, a mass of detached tribo-layer means the appearance of a severe delamination wear. Hence, the severe delamination wear and plastic extrusion are predominant wear mechanisms.

At 100 ℃, under the lower load, a few delamination craters and a relatively thick tribo-layer appeared on the worn surface. It is clear that oxidation wear prevailed. As the load increased to 150 N, the delamination craters on the worn surface enlarged, and the tribo-layer significantly thinned. The delamination occurred in the matrix at subsurface. In this case, oxidation wear and delamination wear prevailed. As the load further increased to 250 N, obvious plastic flow appeared, and the delamination deepened on subsurface. It is clear that delamination wear and plastic extrusion are predominant wear mechanisms.

At 200 ℃, under a load of 25 N, a few delamination craters and shallow grooves presented and a thick tribo-layer appeared on the smooth worn surface (Fig. 3 (g) and Fig. 5(g)). This is a typical oxidation wear. As the load increased to 50 N, the plastic flow and a few fracture marks appeared on the worn surface. The tribo-layer was totally eradicated because a relatively massive deformation resulted in the delaminating of tribo-layer. As the load further increased to 100 N, a totally plastic flow occurred on the worn surface. In this case, the plastic extrusion prevailed.

In summary, as the load increased at different ambient temperatures, the transition from mild wear to severe wear occurred accompanied with the severe delamination and massive deformation. This is agreement with the reported research results [7-9]. In our test, the mild wear regimes can be classified into abrasive wear, oxidation wear and delamination wear. As the tribo-layer is thin under lower loads and ambient temperatures, abrasive wear prevailed. Usually, abrasive wear and oxidation wear prevailed together. It is clear that oxidation wear always prevailed in mild wear regimes. The prior researches reported the delamination wear prevailed in mild wear regimes, but did not clarify the delamination pattern [7-10]. We found that delamination wear prevailed as the load or/and ambient temperature reached a relatively high level, at which the transition from mild wear to severe wear started to occur. Especially, the delamination pattern was found to delaminate from inside the matrix at subsurface. It is clear that delamination wear belongs to a fatigue wear. In this case, the wear depends on strength and toughness of subsurface as well except for the role of the tribo-layer. Higher strength and toughness of subsurface would delay the initiation of cracks, thus reducing delamination. There existed a crack and the oxide mixture inside the crack on the section of the worn surface (Figs. 5(e) and (f)). The EDS analysis result of wear debris could further prove the delamination pattern, as shown in Fig. 7. It can be observed that the upper side of the plate debris presented relatively high oxygen, but low oxygen in the delaminated side.

Fig. 7 Morphology (a) and compositions (b, c) of wear debris for AM60B alloy under load of 250 N at 100 ℃: (a) Morphology; (b) Upper side of debris; (c) Delaminated side of debris

4.2 Tribo-layer and oxidation wear

During sliding of magnesium alloy, more or less tribo-oxides appeared on the worn surfaces. ZHANG et al [15] investigated the friction and wear behavior of Mg-Zn-Y quasicrystal materials and found the tribo-oxide to be MgO. CHEN and ALPAS [12] found that the tribo-oxide was MgO in the mild wear of AZ91 alloy, but its amount was little in the severe wear. ABDEL-WAHAB [7] investigated the wear behavior of AZ61 alloy processed by the warm deformation (extrusion and rolling) during drying sliding. They pointed out that the tribo-oxide was ZnO, which only appeared in the mild wear regime. But AUNG et al [10] observed several tribo-oxides during the wear process. At 0.01 m/s, the main tribo-oxides were Mg-Al-O and MgO2 in abrasion wear. At 0.1 m/s and 1.0 m/s, the tribo-oxides were MgO and MgAl2O4, respectively, in oxidation wear. In the severe wear regime, the content of tribo-oxide was very low.

In our experiment, XRD analysis results of the worn surfaces show that various tribo-oxides appeared. The oxide component of worn surfaces changed in the order of Mg-Al-O, MgO and MgAl2O4 with increasing the loads and ambient temperatures (Table 1). There was no MgO2 phase but only Mg-Al-O phase under the lower ambient temperatures and loads. At 200 ℃, the tribo-oxides were MgO and MgAl2O4.

During sliding, under the normal load and friction force, the particles of oxides and Mg were mechanically mixed and pressed into the worn surfaces to form the so-called MML. The thickness of tribo-layer even reached 30-40 μm under the lower loads at 200 ℃ (Fig. 5(g)). More importantly, the tribo-layer presented higher hardness than the alloy matrix (Table 2). Undoubtedly, the tribo-layer would affect the wear behavior.

WANG et al [14] pointed out that as the tribo-layer exceeded a certain thickness, it significantly affected the contact conditions and wear rates due to its greater stiffness and hardness compared with the substrate. SHARMA et al [8] also indicated that the wear rate and surface damage could be minimized if the plastic deformation at the contact interfaces was prevented. The tribo-layer withstanding high stress without the plastic deformation or fracture of the matrix was very effective in reducing wear. Obviously in our study, the tribo-layer took a great part in preventing from wear. This depended on the thickness and hardness of the tribo-layer. The thick and hard tribo-layer is expected to definitely result in a low wear rate.

The tribo-layer was thickened and compacted with increasing the ambient temperature. Under the low loads of 12.5-25 N, the tribo-layer could stably exist on the worn surface to forbid the plastic deformation of the substrate. Thus, the mild wear prevailed under the ambient temperature of 200 ℃ and the low loads of 12.5-25 N. In this case, oxidation wear should be the predominant wear mechanism. Consequently, the wear rate at 200 ℃ was lower than that at 25 or 100 ℃. Although the tribo-layer at 25 and 100 ℃ did not thicken and consolidated as much as at 200 ℃. The produced tribo-oxides would reduce wear more or less. Hence, oxidation wear always prevailed in the mild wear regime.

5 Conclusions

1) The wear rate increases with increasing the load; the mild-to-severe wear transition occurs under a load of 275 N at 25 ℃, 150 N at 100 ℃ and 75 N at 200 ℃, respectively. However, as the load is less than 50 N, the wear rate at 200 ℃ is lower than that at 25 or 100 ℃.

2) A tribo-layer (MML) is found to form on worn surface during wear. The MML contains oxides of Mg-Al-O, MgO and MgAl2O4, and has obvious influences on the wear behavior and mechanism.

3) The mild wear regimes can be classified into abrasive wear, oxidation wear and delamination wear. Abrasive wear prevailed as the tribo-layer was thin; oxidation wear always exists. Delamination wear prevailed as the load or/and ambient temperature reaches a relatively high level with the delamination occurring from the inside of the matrix.

4) The delamination wear and plastic-extrusion wear successively prevail companied with the mild-to-severe wear transition. The thick, hard tribo-layer postpones the mild-to-severe wear transition due to restricting massive plastic deformation of worn surfaces.

References

[1] CHEN Dong-feng, DONG Xuan-pu, ZHANG Xiong, FAN Zi-tian. Mg alloy surface alloying layer fabricated through evaporative pattern casting technology [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(12): 2240-2245.

[2] DING Wen-jiang, WU Yu-juan, PENG Li-ming, ZENG Xiao-qin, LIN Dong-liang, CHEN Bin. Research and application development of advanced magnesium alloys [J]. Materials China, 2010, 29(8): 37-45. (in Chinese)

[3] SONG Peng-fei, WANG Jing-feng, PAN Fu-sheng. Research status and prospect of high strength wrought magnesium alloys [J]. Ordnance Material Science and Engineering, 2010, 33(4): 85-90. (in Chinese)

[4] HE Yun-bin, PAN Qing-lin, QIN Yin-jiang, LIU Xiao-yan, LI Wen-bin, CHIU Yu-lung, CHEN J J J. Microstructure and mechanical properties of ultra-fine grain ZK60 magnesium alloy processed by equal channel angular pressing [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2274-2282. (in Chinese)

[5] GUO Feng, LI Peng-fei, GAO Xia, XU Juan. Study on solid solution and aging process of AZ91D magnesium alloy with cerium [J].Journal of Rare Earths, 2010, 28(6): 948-951.

[6] AN J, LI R G, LU Y, CHEN C M, XU Y, CHEN X, WANG L M. Dry sliding wear behavior of magnesium alloys [J]. Wear, 2008, 265(1-2): 97-104.

[7] ABDEL-WAHAB E M. Dry sliding wear behavior of hot deformed magnesium AZ61 alloy as influenced by the sliding conditions [J]. Materials Science and Engineering A, 2008, 473(1-2): 330-335.

[8] SHARMA S C, ANAND B, KRISHNA M. Evaluation of sliding wear behaviour of feldspar particle-reinforced magnesium alloy composites [J]. Wear, 2000, 241(1): 33-40.

[9] HUANG W J, HOU B, PANG Y X, ZHOU Z R. Fretting wear behavior of AZ91D and AM60B magnesium alloys [J]. Wear, 2006, 260(11-12): 1173-1178.

[10] AUNG N N, ZHOU W, LIM L E N. Wear behaviour of AZ91D alloy at low sliding speeds [J]. Wear, 2008, 265(5-6): 780-786.

[11] DAS S, MORALES A T, ALPAS A T. Microstructural evolution during high temperature sliding wear of Mg-3%Al-1%Zn (AZ31) alloy [J]. Wear, 2010, 268(1-2): 94-103.

[12] CHEN H, ALPAS A T. Sliding wear map for the magnesium alloy Mg-9Al-0.9Zn (AZ91) [J]. Wear, 2000, 246(1-2): 106-116.

[13] ZHANG J, ALPAS A T. Transition between mild and severe wear in aluminium alloys [J]. Acta Materialia, 1997, 45(2): 513-528.

[14] WANG Y, RAINFORTH W M, JONES H, LIEBLICH M. Dry wear behaviour and its relation to microstructure of novel 6092 aluminium alloy-Ni3Al powder metallurgy composite [J]. Wear, 2001, 251 (1-12): 1421-1432.

[15] ZHANG Y B, YU S R, LUO Y R, HU H X. Friction and wear behavior of as-cast Mg-Zn-Y quasicrystal materials [J]. Materials Science and Engineering A, 2008, 472(1-2): 59-65.

杨子润1, 魏敏先2, 赵玉涛2, 王树奇2

1. 盐城工学院 材料工程学院,盐城 224051;2. 江苏大学 材料科学与工程学院,镇江 212013

摘 要:针对AM60B合金在环境温度25~200 ℃、载荷12.5~300 N的条件下进行干摩擦磨损实验。结果表明:随着载荷的增大,磨损率增加;从轻微磨损到严重磨损的转变的临界载荷分别为25 ℃时275 N,100 ℃时150 N,200 ℃时75 N。在低载荷(<50 N)下,200 ℃下的磨损率低于25 ℃和100 ℃的。在轻微磨损阶段,磨损机制为磨粒磨损、氧化磨损和剥层磨损。当轻微磨损到严重磨损的转变开始时, 剥层磨损发挥主要作用,剥层磨损是从基体内部发生的剥落。随后, 塑性挤出磨损作为严重磨损出现,同时伴随着从轻微磨损到严重磨损的转变。厚的、硬的摩擦层通过限制磨面的塑性变形来阻碍从轻微磨损到严重磨损的转变。

关键词:镁合金;干滑动磨损;氧化;摩擦层;磨损机制

(Edited by LI Xiang-qun)

Foundation item: Project (51071078) supported by the National Natural Science Foundation of China; Project (AE201035) supported by the Research Fund of Key Laboratory for Advanced Technology in Environmental Protection of Jiangsu Province, China

Corresponding author: WANG Shu-qi; Tel/Fax: +86-511-88797618; E-mail: shuqi_wang@ujs.edu.cn

DOI: 10.1016/S1003-6326(11)61095-9