文章编号:1004-0609(2008)03-0465-06

渗碳工艺对WC-Co梯度硬质合金的梯度结构和硬度的影响

肖逸锋1, 2,贺跃辉1,丰 平1,谢 宏1, 3,马自省1, 3,张丽娟1,黄自谦1,黄伯云1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 湘潭大学 机械工程学院,湘潭 411105;

3. 株洲硬质合金集团有限公司,株洲 412000)

摘 要:对缺碳硬质合金采用渗碳处理制备梯度硬质合金,利用显微组织分析和维氏硬度测试等方法,研究渗碳工艺对梯度硬质合金的梯度结构和硬度的影响。结果表明:渗碳处理后随着渗碳时间延长,梯度层厚度增大,长时间渗碳还会出现梯度结构消失现象;渗碳时表面层WC晶粒长大,且渗碳时间越长晶粒长大越严重;渗碳后梯度硬质合金的表面硬度明显提高;渗碳后合金的表面硬度明显高于烧结态合金的表面硬度;随着渗碳时间的延长,合金表面硬度先增大后减小;合金的硬度在截面上沿梯度方向呈连续梯度变化,合金表面层因WC含量较高、钴含量较低而具有较高的硬度,中间层因钴含量较高、WC含量较低,其硬度较低。

关键词:WC-Co硬质合金;梯度结构;渗碳;硬度

中图分类号:TF 124.5;TG 135.5 文献标识码:A

Effects of carburizing process on gradient structure and

hardness of WC-Co gradient cemented carbides

XIAO Yi-feng1, 2, HE Yue-hui1, FENG Ping1, XIE Hong1, 3, MA Zi-xing1, 3,

ZHANG Li-juan1, HUANG Zi-qian1, HUANG Bai-yun1

(1. State Key Laboratory of Powder Metallurgy , Central South University , Changsha 410083, China;

2. School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China;

3. Zhuzhou Cemented Carbide Group Ltd., Zhuzhou 412000, China)

Abstract: Gradient cemented carbides were prepared by carburizing carbon-deficient cemented carbides. The effects of carburizing processes on the gradient structure and hardness of WC-Co gradient cemented carbides were investigated by optical microscopy, scanning electron microscopy and Vickers hardness test. The results show that the thickness of gradient structure increases with prolonging of carburizing time and the gradient structure disappears after long time carburizing. WC grains in the surface layer grow after carburizing and the growth degree increases with carburizing time. The surface hardness of as-carburized alloys is obviously higher than that of as sintered alloys, which increases firstly then decreases with prolonging carburizing time. The hardness of as-carburized alloys in the cross section varies continuously and gradiently along gradient direction, namely the hardness is higher in the surface layer for higher WC content and lower cobalt content, which is lower in the middle layer for higher cobalt content and lower WC content.

Key words: WC-Co cemented carbides; gradient structure; carburizing; hardness

由于硬质合金的耐磨性能和韧性是一对相互矛盾的性能,在许多服役条件下,传统的均匀结构硬质合金则表现出明显的劣势[1-3]。例如,地质矿山用硬质合金钻具这类要求钻齿表面耐磨和整体耐冲击,传统均匀结构硬质合金通常不能满足此种工作条件,而硬质合金中的脆、韧两相含量呈梯度分布是解决此类问题的主要途径[4]。将此类材料制备成梯度结构,在满足使用要求的前提下,有利于降低热应力、抑制应力集中、提高冲击韧性和断裂韧性[3-4]。

含WC+Co+η三相结构的硬质合金渗碳处理可以制备具有梯度结构的硬质合金[5-6]。这种硬质合金的成分和显微组织在空间均形成梯度分布:表层一定深处的η已经完全消失,而合金的芯部仍然保持WC+Co+η的三相结构;表面钴含量较低,中间层钴含量最高,芯部的钴含量为名义成分。本文作者在业已制备出梯度硬质合金的基础上,进一步研究渗碳工艺对合金的梯度结构和硬度的影响。

1 实验

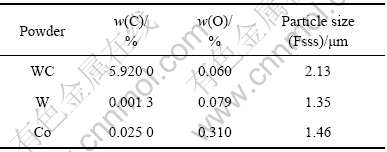

实验所用的WC粉、W粉和Co粉的性能见表1。将WC粉、Co粉和W粉配制成低于化学计量碳含量的WC-6Co混合料, 总碳含量的设计值为5.30%(质量分数)。混合料加入适量聚乙二醇和酒精,通过湿磨、喷雾干燥、制粒后采用单向模压的方法压制成长条状的样坯,压制压力为100 MPa。采用脱成形剂和烧结一体炉在1 440 ℃低压烧结60 min,烧结后试样的尺寸为6.5 mm×5.25 mm×21 mm。分析测试后再将余样等分埋入碳黑中,在通有流动氢气的还原炉中进行1 430 ℃渗碳处理,渗碳时间分别为40、60、80、100、120和140 min。

表1 原料粉末的性能

Table 1 Performance of raw powders

所有待测试样的表面和横切面进行抛光处理。采用Leica公司的MeF3A金相显微镜和Q550图像分析仪,以及扫描电子显微镜(JSM-6360LV)进行微观结构观察与测量。

硬度测试按GB/T4340.1—1999《金属维氏硬度试验 第1部分:试验方法》进行。采用FV-700维氏硬度仪测定其表面硬度,实验力为29.42 N;采用Leica公司的MHT-4显微硬度仪测定沿梯度方向的硬度变化规律,实验力为0.98 N。测量压痕对角线的长度,由式1可计算得到试样的维氏硬度(HV)

2 结果与分析

2.1 梯度硬质合金的显微组织特征

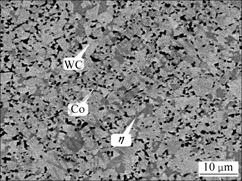

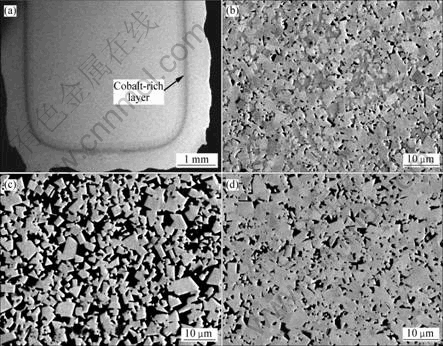

图1所示为试样经1 440 ℃低压烧结60 min后的显微组织。因试样5.30%的总碳含量远低于其化学计量(5.76%),X射线衍射研究表明合金中生成Co6W6C和Co3W3C两种η相[7]。烧结试样再经1 430 ℃渗碳80 min处理后,合金横截面显微组织如图2所示。由图2(a)可见合金中形成明显的富钴层,横截面可以分为表面区、中间富钴区和芯部这3个区域。图2(b)~(e)给出3个区域显微组织的细节:相比于烧结态的缺碳硬质合金,芯部组织变化不大,依然是含η相的WC+Co+η的三相组织;表层和中间层的η相则已经完全消失,为WC+Co两相组织;定量分析表明,表层和富钴层的Co相体积分数分别为10.161%和33.803%。

图1 烧结态缺碳硬质合金的显微组织

Fig.1 Microstructure of as-sintered WC-6Co carbon-deficient cemented carbides showing WC, Co and η phase (bright, dark and gray phases refer to WC, Co and η phase, respectively)

图2 梯度硬质合金横截面的显微组织

Fig.2 Microstructures of cross section of gradient cemented carbides (Volume fraction of cobalt phase in (b), (c) and (d) is about 4.513%, 33.803% and 10.161%, respectively): (a) Micrograph morphology of cross section; (b) Core; (c) Cobalt-rich layer; (d) Surface layer

刘咏等[8-10]从扩散热力学和动力学详细讨论梯度结构的形成机理,认为钴梯度的形成主要受碳扩散和WC晶粒长大导致的液相流动的影响。渗碳处理初期,表层由于碳势较高,先于内部出现液相,溶解在液相中的η相与扩散进来的C原子发生式(2)和(3)的η相分解反应[8],反应区的η相消失,分解出WC和Co。反应生成的WC通过溶解—析出机制在表层较粗的WC颗粒上析出,导致WC晶粒的长大并伴随表层出现更多的液相,反应界面的两边形成较大的液相浓度差。同时,为了降低体系的自由能,在表层液相中碳浓度梯度的作用下,η相分解出的W原子开始向表层迁移并与溶解于液相中的C原子结合形成WC,引起表层的 WC含量增加,并在表层WC颗粒上析出使表面的WC晶粒长大。W原子向合金表面迁移留下的体积缺陷被液相钴所填补,从而在合金WC+Co两相区与WC+Co+η三相区之间形成富钴层。可见,W原子向合金表面迁移也是梯度结构形成的原因之一。

2.2 渗碳时间对梯度结构位置的影响

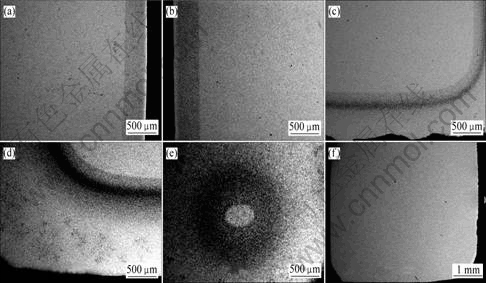

图3所示为1 430 ℃渗碳不同时间后合金的横截面显微组织。由图3可知,渗碳40 min或60 min时,富钴区已经形成并有一定的宽度但钴浓度不高,表面区较窄;随着渗碳时间的延长,富钴层钴浓度逐渐增大,富钴层逐渐向内部推移,表面区厚度随之增加,至120 min时接近于最大值,之后继续延长渗碳时间则会出现富钴层消失的现象;合金富钴层由外及里钴含量逐渐由低变高,后由高又逐渐变低,即在合金中,粘结相含量的变化是连续过渡的。

图3 1 430 ℃渗碳不同时间后试样横截面的显微组织

Fig.3 Morphologies of cross section of samples carburized at 1 430 ℃ for different time: (a) 40 min; (b) 60 min; (c) 80 min; (d) 100 min; (e) 120 min; (f) 140 min

如前分析,短时渗碳时由于碳扩散量有限,仅使表层较窄范围内的η相发生分解,因此富钴区钴浓度不高。随着渗碳时间延长,碳扩散使得合金一定厚度处的η相分解,析出的Co相由于液相迁移而聚集在两相区与三相区之间,时间越长富钴层离表层越远且钴浓度越高。对于本实验样品来说,渗碳120 min几近极限,继续延长渗碳时间,在之后的不长时间内芯部的η相就会完全消失。这时芯部的钴含量最大,随后则会由于钴浓度梯度的存在,芯部的钴向外扩散,所以渗碳140 min后富钴层已经消失。

2.3 渗碳时间对表面层组织的影响

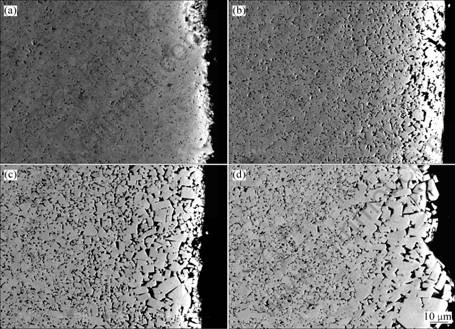

图4所示为1 430 ℃渗碳不同时间后合金表层的显微组织。由图4可见,渗碳处理后表层WC晶粒 产生了一定程度的聚集、长大现象,且渗碳时间越长,长大越严重,并且伴随钴池的形成。

图4 1 430 ℃渗碳不同时间后试样表层的显微组织

Fig.4 Microstructures of surface layer of gradient cemented carbides carburized at 1 430 ℃ for different time: (a) 60 min; (b) 80 min; (c) 100 min; (d) 120 min

前期研究[6]表明,合金内部的WC和η相随着渗碳时间的延长也会出现聚集长大,这与表层WC晶粒长大的机理不一样。表层WC晶粒的长大除了受渗碳时间的影响外,主要还在于碳含量的影响。UPADHYAYA等[11]曾经报道,碳含量强烈地影响WC晶粒的长大,随着碳含量的提高,合金的组织有粗大化的倾向。渗碳处理过程中,表层的碳含量高于内部的碳含量,表层形成液相的温度较芯部低,其液相的数量(体积分数)也比芯部多,这样必然会引起表层WC晶粒长大;同时,渗碳时间的延长进一步促使表层WC晶粒粗化。

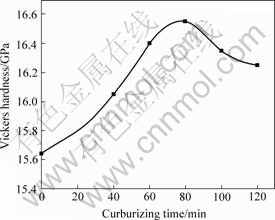

2.4 渗碳时间对表面硬度的影响

图5所示为1 440 ℃低压烧结60 min后再经1 430 ℃分别渗碳40、60、80和100 min后试样表面硬度变化规律。由图5可见:渗碳后的梯度硬质合金的表面硬度明显高于未经过渗碳的烧结态硬质合金的硬度;随着渗碳时间的增加,合金的表面硬度值先增大后减小。

图5 渗碳时间对梯度硬质合金表面硬度的影响

Fig.5 Effect of carburizing time on surface hardness of gradient cemented carbides

根据MILMAN等[12]的解释,硬质合金的硬度与WC晶粒大小、钴含量以及合金各相性能之间存在式(4)所述的Hall-Petch关系:

由式(4)~(6)可知,WC-Co 硬质合金的硬度与合金中硬质相WC的晶粒度、粘结相的含量等微观组织结构的特征参数有关。一般来说,WC-Co硬度合金的硬度随钴含量的增加或WC晶粒尺寸的增大而降低[14]。渗碳处理后,合金的硬度受两个因素的影响:表面钴含量的降低导致的硬度增加和WC晶粒的长大导致的硬度降低。短时间渗碳时,由于WC晶粒的长大不显著,前者占主导地位,合金的表面硬度相应增加,并随渗碳时间的延长而增高;当渗碳时间较长时,如图4所示,由于合金表面的WC晶粒长大和粘结相的聚集,导致表面硬度降低。实验同时表明,渗碳处理后,合金表面硬度始终保持在较高的数值,确保了其耐磨性的要求。

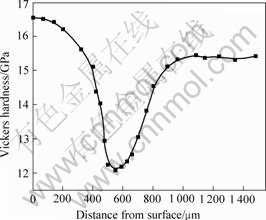

2.5 梯度方向的硬度分布

图6所示为1 440 ℃低压烧结60 min后经1 430 ℃渗碳80 min处理制得的梯度硬质合金用显微硬度方法测定的维氏硬度沿梯度方向的变化规律。由图6可知:沿梯度方向合金的硬度也是梯度分布的,合金表面和芯部均具有较高的硬度,外表面的维氏硬度值超过16.5 GPa,芯部的维氏硬度在15.2~15.5 GPa之间,而中间富钴带的维氏硬度最低只有12.2 GPa。

图6 梯度硬质合金截面显微维氏硬度沿梯度方向的变化

Fig.6 Variation of Vickers hardness of cross section along gradient direction for gradient cemented carbides

由图2和3 可知, 渗碳处理后在合金的内部空间形成钴含量连续变化的梯度结构,上述关于硬质合金硬度的分析说明这是导致合金硬度曲线呈连续变化的主要原因。合金表面WC含量较高而钴含量较低,因而具有较高的硬度和耐磨性;合金的中间富钴层钴含量较高而WC含量较低,因而硬度较低而韧性较好。

3 结论

1) 缺碳硬质合金渗碳处理后形成钴含量梯度分布的结构;随着渗碳时间延长,梯度层厚度增大,对于小试样长时间渗碳还会出现梯度结构消失现象;渗碳处理后表层WC晶粒出现不同程度的长大,且渗碳时间越长晶粒长大越严重。

2) 渗碳后合金的表面硬度明显高于烧结态的表面硬度;随着渗碳时间的增加,表面硬度值先增大后减小。

3) 合金的硬度在截面上沿梯度方向呈连续梯度变化,合金表面层因WC含量较高、钴含量较低,具有较高的硬度;中间层因钴含量较高、WC含量较低,其硬度较低。

REFERENCES

[1] ?KERMAN J, FISCHER U K R, HARTZELL E T. Cemented carbide body with extra tough behavior. US 5453241[P]. 1995-09-26.

[2] DROUGGE L. Tool of cemented carbide for cutting, punching or nibbling. US 5235879[P]. 1993-08-17.

[3] FISCHER U K R, HARTZELL E T, ?KERMAN J. Cemented carbide with a binder phase gradient and method of making the same. US 4820482[P]. 1989-04-11.

[4] LENGAUER W, DREYER K. Functionally graded hardmetals[J]. J Alloys Comp, 2002, 338(1/2): 194-212.

[5] 羊建高, 王海兵, 刘 咏, 张林秋, 李 芳, 龙郑易. 碳含量对矿用硬质合金梯度结构形成的影响[J]. 中国有色金属学报, 2004, 14(3): 424-428.

YANG Jian-gao, WANG Hai-bing, LIU Yong, ZHANG Lin-qiu, LI Fang, LONG Zheng-yi. Influence of carbon content on formation of gradient structure of cemented carbide for mining[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(3): 424-428.

[6] 张 立, 陈 述, 熊湘君, 黄伯云, 张传福. 双相结构功能梯度WC-Co合金的微观组织结构与小负荷维氏硬度[J]. 中国有色金属学报, 2005, 15(8): 1194-1199.

ZHANG Li, CHEN Shu, XIONG Xiang-jun, HUANG Bai-yun, ZHANG Chuan-fu. Microstructure and Vickers hardness of functionally graded WC-Co cemented carbide with dual phase structure[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1194-1199.

[7] 肖逸锋, 贺跃辉, 丰 平, 谢 宏, 张丽娟, 黄自谦, 黄伯云. 碳含量对缺碳硬质合金组织和性能的影响[J]. 中国有色金属学报, 2007, 17(1): 39-44.

XIAO Yi-feng, HE Yue-hui, FENG Ping, XIE Hong, ZHANG Li-juan, HUANG Zi-qian, HUANG Bai-yun. Effects of carbon content on microstructure and properties of carbon-deficient cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 39-44.

[8] 龙郑易, 刘 咏, 贺跃辉, 肖逸锋, 周永贵, 李 芳. 渗碳时间对梯度硬质合金显微组织和抗弯强度的影响[J]. 中国有色金属学报, 2007, 17(2): 326-330.

LONG Zheng-yi, LIU Yong, HE Yue-hui, XIAO Yi-feng, ZHOU Yong-gui, LI Fang. Effects of carburizing time on microstructure and transverse rupture strength of graded cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(2): 326-330.

[9] LIU Yong, WANG Hai-bing, LONG Zheng-yi, LIAW P K, YANG Jian-gao, HUANG Bai-yun. Microstructural evolution and mechanical behaviors of graded cemented carbides[J]. Mater Sci Eng A, 2006, 426: 346-354.

[10] LIU Yong, WANG Hai-bing, YANG Jian-gao, HUANG Bai-yun, LONG Zheng-yi. Formation mechanism of cobalt gradient structure in WC-Co hard alloy[J]. J Mater Sci Lett, 2004, 39: 4397-4399.

[11] UPADHYAYA A, SARATHY D, WAGNER G. Advances in alloy design aspects of cemented carbides[J]. Mater Des, 2001, 22(6): 511-517.

[12] MILMAN Y V, CHUGUNOVA S, GONCHBARUCK V, LUYCKX S, NORTHROP I T. Low and high temperature hardness of WC-6wt%Co alloys[J]. Inter J Refract Met Hard Mater, 1997, 15(1/3): 97-101.

[13] MILMAN Y V, LUYCKX S, NORTHROP I T. Influence of temperature, grain size and cobalt content on the hardness of WC-Co alloy[J]. Inter J Refract Met Hard Mater, 1999, 17(1/3): 39-44.

[14] LARSSON C, OD?N M. Hardness profile measurements in functionally graded WC-Co composites[J]. Mater Sci Eng A, 2004, 382: 141-149.

基金项目:国家自然科学基金资助项目(50323008)

收稿日期:2007-07-18;修订日期:2007-12-10

通讯作者:贺跃辉,教授,博士;电话:0731-8836144;E-mail: yuehui@mail.csu.edu.cn

(编辑 龙怀中)