文章编号:1004-0609(2008)12-2140-05

超声化学原位合成(Al3Zr+ZrB2)/A356复合材料的力学行为

张松利,赵玉涛,陈 刚,汪长勤

(江苏大学 材料科学与工程学院,镇江 212013)

摘 要:利用超声化学熔体原位反应技术合成颗粒增强(Al3Zr+ZrB2)/A356复合材料,通过SEM原位拉伸实验及其断裂表面研究分析复合材料的断裂行为。结果表明,复合材料的抗拉强度、屈服强度和伸长率分别达到403.61 MPa、343.98 MPa和8.9%,较未施加超声作用的复合材料分别提高16.09%、12.9%和32.83%;复合材料的室温拉伸断口SEM形貌表现出明显的韧窝断裂特征,为塑性断裂。裂纹的萌生机制主要有基体在滑移过程中的位错作用机制、内生Al3Zr和ZrB2颗粒脱落或破碎形成的空穴成核机制和基体缺陷诱发机制;由于内生增强颗粒微观分布上的不均匀性,当主裂纹扩展前方遇到颗粒密集区时,其扩展方向偏向颗粒贫化区,绕过颗粒密集区,并沿颗粒富集区与贫化区的界面向前扩展、延伸,形成宏观裂纹。

关键词:复合材料;超声化学;原位拉伸;力学行为

中图分类号:TB 331 文献标识码: A

Mechanical behaviors of (Al3Zr+ZrB2)/A356 composites synthesized via in situ ultrasonic chemistry reactions

ZHANG Song-li, ZHAO Yu-tao, CHEN Gang, WANG Chang-qin

(School of Materials Science and Engineering, Jiangsu University, Zhenjiang 212013, China)

Abstract: The particulates reinforcement (Al3Zr+ZrB2)/A356 composites were synthesized via ultrasonic chemistry melt in situ reactions, and the fracture behaviors were investigated by SEM in situ tensile observations and fracture surface characterizations. The results indicate that the tensile strength, yield strength and the elongation reach 403.61 MPa, 343.98 MPa and 8.9%, increase by 16.09%, 12.9% and 32.83% than those without ultrasonic assistance, respectively. The obvious dimple-crack characters on the SEM fracture surface of the composites were observed, and the fracture mechanism is plastic fracture. The crack initiation mechanisms are mainly the matrix dislocation actions mechanism during sliding, cavity formation mechanism due to the in situ Al3Zr and ZrB2 particle sloughing or bursting and the matrix defect induction mechanism. The crack growth is selective because of the non-uniform micro-distribution of the in situ particles. When the growing main cracks are faced to the particle-rich area, the growing direction is deflected to the particle-poor area, the cracks grow along the interface of the particle-rich area and the particle-poor area, and the macro-cracks are formed.

Key words: composites; ultrasonic chemistry; in situ tension; mechanical behavior

原位颗粒增强铝基复合材料因其具有高的比强度、比刚度,低的热膨胀系数,耐磨损,低成本等优点,同时由于其增强体在熔体内反应生成,具有尺寸小、界面洁净无污染、热稳定性好、且与基体界面相容性好等特点,已成为铝基复合材料研究中的重点[1?4]。但是,目前对铝基复合材料的熔体原位反应合成技术的研究还不够完善,主要表现在以下方面:反应体系少;熔体起始反应温度高,恶化铝液;熔体原位反应时间较长;增强颗粒的体积分数较低,粗化现象严重;增强颗粒在基体中的分布不够均匀,增强颗粒团聚等。因此,许多研究者探寻新的手段和工艺来促进原位熔体化学反应的反应速度和反应程度;提高生成增强相的形核率,抑制长大速度,细化晶粒;使所生成的增强颗粒在基体中均匀分布;改善增强颗粒与基体的润湿性,提高铝基复合材料的综合性能[5?7]。近年来,利用物理手段来控制和促进化学反应,是科技界十分关注的研究领域。由于大功率超声空化效应导致在液体内产生瞬间的局部高温和高压,可改变液相的物理化学(热力学和动力学)状态,使在通常情况下不能进行或难以进行的过程(如金属/陶瓷的润湿)得以进行或加速;声流效应所引发的搅拌和分散等作用可产生宏观和微观均匀化效应[8?11]。高能超声的这些效应可显著改善陶瓷颗粒与液体间的润湿性,并迫使其在液体中均匀分散,对金属基体组织还有除气、除渣作用[12?14]。因此,本文作者利用高能超声的声空化和声流效应,加快A356-(K2ZrF6+KBF4)体系熔体原位化学反应速度,超声化学原位反应合成内生颗粒增强(Al3Zr+ZrB2) /A356复合材料,同时使生成的颗粒在熔体中趋于均匀分布,并研究复合材料的断裂行为机制。

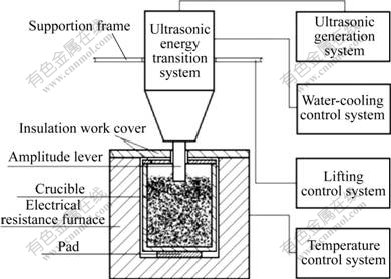

1 实验

实验原材料为工业用A356(Si7.39%、Mg0.37%、Ti0.15%、Fe≤0.16%、Cu≤0.05%、Mn≤0.10%、 Zn≤0.05%、Sn≤0.01%、Pb≤0.03%、其余为Al)铝锭,K2ZrF6和KBF4粉剂(纯度为99.8%)。先将K2ZrF6和KBF4粉剂放入250 ℃的干燥箱中烘烤3 h。然后,将A356合金锭放入石墨坩埚中,用电阻炉加热到熔化,加热至850 ℃,之后向熔体中加入铝液质量20%的K2ZrF6和KBF4粉剂(K2ZrF6与KBF4的质量比为2.25?1),用钟罩将反应物压入熔体中,同时,对铝熔体间歇施加功率为1.2 kW的高能超声场,实验装置如图1所示。反应结束后,经精炼扒渣,于720 ℃浇入金属型中,制得铸态内生颗粒增强铝基复合材料胚体。

图1 超声场下原位合成铝基复合材料的装置简图

Fig.1 Schematic diagram of fabrication apparatus of aluminum matrix composites under ultrasonic field

制取的样品在带有原位拉伸装置台的日本电子JXA?840型扫描电镜上进行微观组织结构分析和原位拉伸实验观察分析,拉伸性能实验在ESH?50型万能材料试验机上进行。

2 结果与讨论

2.1 物相分析

图2所示为A356-20%(K2ZrF6+KBF4)体系超声化学原位反应所制备的复合材料的XRD谱。根据参考文献[15?18],从图2中可以看出,复合材料出现了Al、Si、Al3Zr和ZrB2相的衍射峰,表明超声化学原位反应生成了Al3Zr和ZrB2增强相。

图2 A356-20%(K2ZrF6+KBF4)体系超声化学原位反应所制备复合材料的XRD谱

Fig.2 XRD pattern of as-prepared composites from A356-20%(K2ZrF6+KBF4) system via in situ ultrasonic chemistry reactions

2.2 微观组织

图3所示为在有无高能超声场下所制备的复合材料的SEM像。从图3中可以看出,间歇施加高能超声场后,所制备的复合材料增强相的颗粒数目增多,颗粒尺寸更加细小,在基体中分布更加均匀。

图3 A356-(K2ZrF6+KBF4)体系在有无高能超声场下所制备复合材料的SEM像

Fig.3 SEM images of as-prepared composites fabricated from A356-(K2ZrF6+KBF4) system: (a) Without high-energy ultrasonic assisting; (b) With high-energy ultrasonic assisting

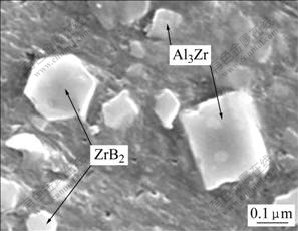

图4所示为间歇施加高能超声后A356-(K2ZrF6+ KBF4)体系所制备的复合材料的高倍SEM像。

图4 施加高能超声后A356-(K2ZrF6+KBF4)体系所制备的复合材料的高倍SEM像

Fig.4 High-magnified SEM images of composites fabricated from A356-(K2ZrF6+KBF4) system with high-energy ultrasonic assisting

从图4中可以看出,高能超声场下,内生Al3Zr的形貌为方块状或长方块状,周边比较钝圆,没有尖角出现,尺寸在0.1~0.3 μm之间,界面干净,没有杂物生成。内生ZrB2的形貌为方块状和六方块状,界面干净,周边钝圆,没有尖锐棱角出现,颗粒尺寸在0.1~0.2 μm之间,部分颗粒尺寸小于0.1 μm。

分析其原因,主要是因为对熔体施加高能超声波后,高能超声热效应,空化效应以及声流效应的综合协调作用加快了熔体原位化学反应速度,同时使生成的颗粒在熔体中趋于均匀分布。在声空化泡形成长大过程中,其尺寸迅速增大,导致内部的液体蒸发。空化泡的增大和内部液体的蒸发会从周围吸收热量,将导致空化泡表面的金属熔液的温度降低,造成局部过冷。对基体A356而言,可以在空化泡的附近形成晶核,使晶核的形核率增加,组织得到细化。在空化泡崩溃过程中,产生的强烈冲击波将会击碎初生晶体和正在长大的晶体,使之成为破碎的晶体质点,在声流的搅拌作用下,又使其弥散地分布于熔体中,相当于增加了外来核心,提高了形核率,同时抑制了晶体的成长,导致凝固后A356基体中树枝状Si相被打断呈颗粒状或者短棒状,α-Al晶粒变成细小的近圆形晶粒,如图5所示。当声空化泡崩溃时,在气泡的附近将会产生微射流。在一定频率下,微射流的结构取决于液体粘度与流动速度的大小,微射流的速度与声空化泡泡壁的运动速度成正比,并与声空化泡的半径成反比。由于声空化泡崩溃时的泡壁运动速度非常高, 而声空化泡的半径又很小,因此这一微射流的速度就比较大,这种瞬时的局部高速声流具有微观的搅拌作用对原位化学反应的进程及反应程度,细化晶粒,改善A356合金组织具有很大的作用。

图5 施加高能超声后A356-(K2ZrF6+KBF4)体系所制备的复合材料经过HF酸腐蚀后的SEM像

Fig.5 SEM images of composites synthesized from A356- (K2ZrF6+KBF4) system with ultrasonic assisting after eroding with HF acid: (a) Low-magnified structure; (b) High- magnified structure

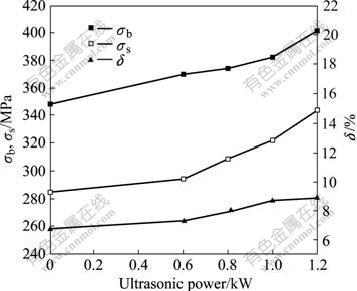

2.3 力学性能

图6所示为所制备复合材料的力学性能。由图6可见,施加高能超声后,(Al3Zr+ZrB2)/A356复合材料的抗拉强度σb、屈服强度σs和伸长率δ提高较未施加高能超声场时得到很大提高,分别达到403.61 MPa、 343.98 MPa和8.9%,较未施加超声作用的复合材料分别提高16.09%、12.9%和32.83%。这主要归因于高能超声的声空化效应和声流效应使得增强颗粒更细小、分布更加均匀,同时高能超声的除气除渣作用也使得复合材料的力学性能得以提高。

图6 A356-(K2ZrF6+KBF4)体系在高能超声功率作用下所制备复合材料的力学性能

Fig.6 Tensile, yield strength and elongation of composites fabricated from A356-(K2ZrF6+KBF4) system under high-energy ultrasonic

2.4 SEM断口形貌

图7 所示为A356-(K2ZrF6+KBF4)体系在有无高超声条件下所制备的复合材料的室温拉伸断口的SEM形貌。由图7(a)可以看出,复合材料的拉伸断口上分布着布着较多的脆性平坦区以及细密的撕裂棱,局部有一些小韧窝,其断裂型式表现为准解理加小部分韧窝的混合型断裂。随着高能超声的引入,复合材料拉伸断口的脆性平坦区逐渐减少变小,韧窝数量逐渐增多,解理断裂特征逐渐减弱,韧窝断裂特征逐渐增强,主要以细小韧窝居多,其断裂表现出明显的韧窝断裂特征。复合材料室温拉伸断口形貌随着高能超声的引入的变化趋势与前面分析的室温力学性能的变化是一致的。

图7 A356-(K2ZrF6+KBF4)体系在有无高超声条件下所制备复合材料的室温拉伸断口SEM形貌

Fig.7 SEM graphs of tensile fracture surfaces of composites fabricated from A356-(K2ZrF6+KBF4) system: (a) Without high-energy ultrasonic; (b) With high-energy ultrasonic

3 结论

1) A356-(K2ZrF6+KBF4)体系超声化学原位反应合成的复合材料增强相的颗粒数目较多,在基体中分布均匀、界面干净、周边钝圆,没有尖锐棱角出现;内生Al3Zr的形貌为方块状或长方块状,尺寸在0.1~0.3 μm之间;内生ZrB2的形貌为方块状和六方块状,尺寸在0.1~0.2 μm之间,部分颗粒尺寸小于0.1 μm。

2) A356-(K2ZrF6+KBF4)体系超声化学原位反应合成的(Al3Zr+ZrB2)/A356复合材料的抗拉强度σb、屈服强度σs和伸长率δ提高较未施加高能超声场时得到很大提高,分别达到403.61 MPa、343.98 MPa和8.9%,较未施加超声作用的复合材料分别提高16.09%、12.9%和32.83%。复合材料的室温拉伸断口SEM形貌表现出明显的韧窝断裂特征,为塑性断裂。

3) A356-(K2ZrF6+KBF4)体系超声化学原位反应合成的(Al3Zr+ZrB2)/A356复合材料的裂纹萌生机制主要有滑移过程中的位错作用机制、颗粒脱落或破碎形成的空穴成核机制和基体缺陷诱发机制;由于内生增强颗粒微观分布上的不均匀,裂纹的长大是有选择性的,当主裂纹扩展前方遇到颗粒密集区时,扩展方向偏转,偏向颗粒贫化区,绕过颗粒密集区,并沿颗粒富集区与贫化区的界面向前扩展、延伸,形成宏观 裂纹。

REFERENCES

[1] ROY D, GHOSH S, BASUMALLICK A, BASU B. Preparation of Fe-aluminide reinforced in situ metal matrix composites by reactive hot pressing[J]. Mater Sci Eng A, 2006, 415(1/2): 202?206.

[2] ZHAO Yu-tao, LI Zhong-hua, CHENG Xiao-nong, DAI Qi-xun, CAI Lan. In-situ synthesized (Al3Zr+ Al2O3)p/A356 composites by direct melt reaction in Al-Zr-O system[J]. Trans Nonferrous Met Soc China, 2003, 13(4): 769?773.

[3] ZHU He-guo, WANG Heng-zhi, GE Liang-qi, CHEN Shi, WU Shen-qing. Formation of composites fabricated by exothermic dispersion reaction in Al-TiO2-B2O3 system[J]. Trans Nonferrous Met Soc China, 2007, 17: 590?594.

[4] ZHAO Yu-hou, ZHOU Jin-en, YAN Wen. Aluminum matrix composite reinforced by in-situ formed intermetallic Al3Ti[J]. Trans Nonferrous Met Soc China, 2002, 12(4): 643?648.

[5] TSUNEKAWA Y, OKUMIYA M, SUZUKI H, GENMA Y. Preparation of in-situ reinforced composites using ultrasonic vibration and selective incorporation of reinforcements by magnetic field[J]. Aluminum Transactions (USA), 2000, 2(1): 1?10.

[6] ZHANG Song-li, ZHAO Yu-tao, CHEN Gang, CHENG Xiao-nong. Microstructures and dry sliding wear properties of in-situ (Al3Zr+ZrB2)/Al composites[J]. J Mater Proce Tech, 2007, 184(1/3): 201?208.

[7] WAN H, PAN J, YANG D. In situ aluminium matrix composite prepared by ultrasonic vibration[C]// Tenth International Conference on Composite Materials Ⅱ: Metal Matrix Composites Whistler. British Columbia, Canada, 1995: 161?167.

[8] 潘 蕾, 陶 杰, 陈照峰, 刘子利. 高能超声在颗粒/金属熔体体系中的声学效应[J]. 材料工程, 2006, 1: 35?37, 42.

PAN Lei, TAO Jie, CHEN Zhao-feng, LIU Zi-li. Acoustic effect of high intensity ultrasonic in particles/metal melt[J]. J Mater Eng, 2006, 1: 35?37, 42.

[9] 冯 若, 李化茂. 声化学及应用[M]. 合肥: 安徽科技出版社, 1990.

FENG Ruo, LI Hua-mao. Sonochemistry and its application[M]. Hefei: Anhui Science and Technology Press, 1990.

[10] JIAN X, XU C, MEEK T, HAN Q. Effect of ultrasonic vibration on the solidification structure of A356 alloy[J]. Trans American Foundry Society, 2005, 113(113): 131?137.

[11] 周衡志, 李子全, 陈建康, 胡孝昀. 纳米CeO2p/Zn-4.5%Al复合材料的高能超声制备及其力学性能[J]. 中国有色金属学报, 2007, 17(5): 757?762.

ZHOU Heng-zhi, LI Zi-quan, CHEN Jian-kang, HU Xiao-yun. Preparation and mechanical properties of nano-CeO2p/Zn- 4.5%Al composite materials by high-power ultrasonic technology[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(5): 757?762.

[12] HUANG Y P, LI D H, WANG R, HUANG W. An improvement way of the wet ability between particles and aluminum matrix of MMCp produced by casting[J]. Foundry Tech (China), 2004, 25: 17?18.

[13] XU Han-bin, JIAN Xiao-gang, MEEK THOMAS T, HAN Qing-you. Degassing of Aluminum alloys using ultrasonic vibration[J]. Mater Lett, 2004, 58(29): 3669?3673.

[14] YANG Yong, LAN Jie, LI Xiao-chun. Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy[J]. Mater Sci Eng A, 2004, 380(1/2): 378?383.

基金项目:江苏省高技术研究资助项目(BG2005026);高等学校博士学科专项科研基金博士点基金资助项目(20060299006);江苏省“六大人才高峰”资助项目(06-D-021);江苏大学高级人才资助项目(1283000349)

收稿日期:2008-04-15;修订日期:2008-07-25

通讯作者:赵玉涛,教授,博士;电话:0511-88791947;E-mail: zhaoyt@ujs.edu.cn.

(编辑 陈爱华)