Precipitates identification in R2PdSi3 (R= Pr, Tb and Gd) single crystal growth

XU Yi-ku1, 2, LIU Lin1, Wolfgang L?SER2, GE Bing-ming1

1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. IFW Dresden, Leibniz-Institut for Solid State and Materials Research, Dresden 01171, Germany

Received 8 December 2010; accepted 26 April 2011

Abstract: Floating zone method with optical radiation heating was applied to growing a class of R2PdSi3 (R=Pr, Tb and Gd) single crystals due to its containerless melting and high stability of the floating zone. One serious problem during the single crystal growth, precipitates of secondary phases, was discussed from the following four parts: precipitates from the raw materials and preparation process, precipitates formed during the growing process, precipitates in the melts and precipitates in the grown crystals. Annealing treatment and composition shift can effectively reduce the precipitates which are not formed during the crystallization but precipitated on post-solidification cooling from the as-grown crystal matrix because of the retrograde solubility of Si.

Key words: floating zone technique; single crystal growth; rare earth compound; precipitate

1 Introduction

In the past few years, much attention has been paid to ternary R2PdSi3 intermetallic compounds (R=Rare earth) which show a wide variety magnetic orderings [1-2]. The floating zone (FZ) method with optical radiation heating is applied to growing this class of compounds due to its containerless melting and high stability of the floating zone. Another benefit of the radiation heating method is the applicability of high pressures of the Ar atmosphere in the growth chamber, which reduces the evaporation loss and enables the growth of the compound containing the volatile element. Measurements on single crystalline R2PdSi3 specimens have revealed considerable anisotropy of the magnetic behavior [3-9], giant negative magnetoresistance [3, 6-7] and even magnetocaloric properties [6].

One serious problem in R2PdSi3 single crystal growth using FZ method is the control of precipitates, which is even inevitable in strictly speaking. SOUPTEL et al [10] discussed oxygen precipitates caused by starting components of the master alloy and the insert gas in crystal growth using FZ method. GRAW et al [11] grew Ce2PdSi3 single crystal with CeSi and CeSi2 precipitates by FZ method using radio frequency inductive heating. Till now, no systemic information on precipitates can be found. In this work, the precipitates formed during the preparation and growth process using optical floating zone method were discussed in four different types. Efficient ways of avoiding precipitates were also elaborated.

2 Experimental

Pure elements (?99.9%, mass fraction) supplied by several companies were adopted as initial components. Lumps of rare earth elements (Pr, Tb and Gd) were mechanically polished from crude to shiny surfaces in an argon gas glove box system, which can effectively eliminate the oxide layer and reduce oxygen contamination of the growing crystals. Appropriate portions of Pd and Si from bulk pieces were arc-melted to a Pd-75%Si (molar fraction) alloy in a Zr-gettered Ar atmosphere on a water-cooled copper hearth. Then the button was co-melted with the rare earth element in a Hukin-type copper cold-crucible several times to homogenize the alloy and finally cast into a copper mould. The rods obtained were in size of d6 mm×(60-80) mm and used as feed rods by the FZ method.

The FZ crystal growth process with radiation heating was performed in a laboratory type apparatus URN-2-ZM (MPEI, Moscow) with a vertical double ellipsoid optical configuration and a 5 kW air-cooled xenon lamp positioned at the focal point of the lower mirror [12]. The growth process proceeded in a vacuum chamber under 0.1 MPa flowing Ar atmosphere purified with a Ti-getter furnace leaving oxygen traces <1×10-6. Feed rod and seed rod with the same composition were attached to the upper stock and lower stock hanging in the chamber separately. The growth process was maintained by synchronous vertical downward motion of the upper and lower stock. Asymmetric counter-rotation of crystal (30 r/min) and feed rod (10 r/min), and growth rates from 3 to 5 mm/h were applied to growing crystals. The operating temperature of the floating zone and longitudinal temperature profiles were measured in situ with a two-color pyrometer using a stroboscopic method, which enabled a proper control of the growth process [13].

Microstructure and crystal perfection of samples were investigated by optical microscopy in a polarization microscope Axiovert 25 equipped with a Carl Zeiss digital camera and scanning electron microscopy (SEM) Philips XL 30. The composition of crystals was characterized by electron probe microanalysis (EPMA) applying the EDX-mode.

3 Results and discussion

3.1 Precipitates from raw material and preparation process

Low content of impurities in intermetallic raw material is high desirable for practical application. But the problem is that even high purity elements certified by the supplier may contain high amounts of oxygen, hydrogen or nitrogen trace elements. It is a particular problem for intermetallics containing rare earth elements, because it is normal that even commercially available elements with 99.9% purity may contain 0.5%-2.5% oxygen, which is not specified by most companies [10].

Rare earth elements have an affinity to oxygen which can be dissolved in the intermetallic matrix or form oxide layers with a higher stability. The oxidation rates are extremely rapid which make the rod preparation process rather difficult. It is inevitable to get some oxides of ROx type in the feed/seed rods even if special attention is paid during the rods preparation steps such as polishing of rare earth elements and rod casting.

In Pr2PdSi3 feed rod (Fig. 1(a)) and crystal (Fig. 1(b)), a tiny amount of ROx and Fe are detected and proved by EDX. Fe is an impurity from the Pr raw element and PrOx is recognized as reaction with oxygen in the surrounding atmosphere.

Fig. 1 SEM image of Pr2PdSi3 feed rod (a) and crystal (b)

3.2 Precipitates formed during growing process

At elevated temperatures, a silicothermic reaction of the metal oxides with Si can result in the formation of volatile SiO in the melt as

?

? (1)

(1)

where M is a metal. This effect is especially pronounced for R-containing binary and ternary silicides with melting temperatures higher than 1 500 °C. SiO evaporates from the molten zone and can condensate at the cold walls of the growth chamber.

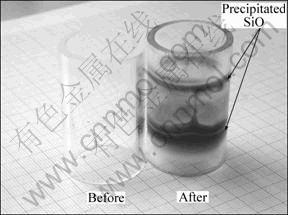

A steady SiO flow from the melt is induced even in the case of thermodynamically more stable R-oxides. This reduction of metal oxides can be observed visually at the very beginning of the FZ growing processes when solid oxide particles whirl on the surface of the floating zone. These solid particles can disappear after the exposure of the melt to the flowing Ar gas for about 30 min, leaving a clean melt surface. The evaporated SiO is often observed visually during crystal growth of R-silicides as brownish coloured powder at the quartz walls of the crystal growth chamber (Fig. 2). It reduces the optical transparency of the quartz of the growth chamber and the efficiency of the optical heating [10].

3.3 Precipitates in melt

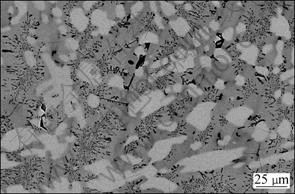

The evaporation of SiO from reaction (1) gives rise to the changes of the crystal stoichiometry associated with the drift in the melt. The microstructure shown in Fig. 3 proves that the composition of the zone deviates from the initial stoichiometric composition. The section comprises dendrites of Pr2PdSi3 principal phase along a dark matrix of the PrPd2Si2 phase [9], which is composed of (23.2±0.5)% Pr, (28.6±0.5)% Pd and (48.2±0.5)% Si (molar fraction) with a tetragonal Al4Ba type structure, and inclusions of tiny Si particles. That is, the melt composition of the traveling zone is gradually enriched in Pd with progressing growth. Normally, during the growth of the class of R2PdSi3 intermetallic compounds, RPd2Si2 is formed in the last quenched zone [9, 14].

Fig. 2 Photo of quartz tubes of growth chamber before and after crystal growth [10]

Fig. 3 SEM image of last quenched zone after Pr2PdSi3 growth process displaying Pr2PdSi3 main phase (bright), Pd-rich PrPd2Si2 phase (dark grey) and Si (black)

3.4 Precipitates in grown crystals

The uncontrolled composition change of the molten zone can also lead to morphological instability of the growth interface and the precipitation of secondary phases with subsequent nucleation of new grains and cracking. The SEM images shown in Fig. 4 indicate the different morphologies (block and strip) of TbSi precipitates in as-grown Tb2PdSi3 single crystal matrix. The black features in Fig. 4(a) were proved to be cracks.

The R2PdSi3 single crystals often exhibit different types of RSi precipitates in form of oriented striations in the single crystalline matrix. A thorough inspection of Gd2PdSi3 crystal reveals that it contains a minor volume fraction of platelets with very small thickness of the binary RSi phase (Fig. 5(a)). It can be concluded that they are not formed during the crystallization but precipitation on post-solidification cooling from the as-grown crystal matrix because the retrograde solubility of Gd and Si in the Gd2PdSi3 matrix is analogous to other members of this class of intermetallics [9, 15]. After annealing at 1 100 °C for 20 h and subsequent quenching, the volume fraction of precipitates is reduced (Fig. 5(b)). In a subsequent crystal growth attempt, the feed rod composition changes from 33.3% Gd-16.7% Pd-50% Si to 33.1%Gd-16.9%Pd-50%Si. A Gd2PdSi3 crystal nearly free of GdSi precipitates is achieved (Fig. 5(c)), which stresses the importance of small shifts of the feed rod composition for improving the crystal perfection. The composition of the crystal 34.0% Gd-16.0%Pd- 50.0% Si is determined by EPMA.

Fig. 4 SEM images of secondary phase precipitates in as-grown Tb2PdSi3 single crystal matrix: (a) Blocky RSi particle; (b) Strip RSi precipitate

Fig. 5 SEM images showing GdSi precipitates (bright striations) within Gd2PdSi3 single crystal matrix: (a) As-grown state [15]; (b) After annealing at 1 100 °C for 20 h; (c) As-grown state of crystal grown from Pd-rich feed rod

4 Conclusions

1) The FZ method with optical radiation heating is applied to the class of R2PdSi3 (R=Pr, Tb and Gd) compounds. The perfection of the grown crystals is highly affected by the precipitates. Oxides of the ROx and some other impurities may exist in high purity raw materials. SiO evaporation at elevated temperatures due to silicothermic reaction can effectively reduce oxygen content in the melt and the crystal. Pd-rich phase appeared in the last quenched zone in the form of RPd2Si2 phase is caused by the accumulation of Pd in the melt and slight Pd deviation in the crystal.

2) The crystal matrix contains platelet-like precipitates of RSi phase which arise from the retrograde solubility of the R2PdSi3 matrix and can be diminished by the growth from Pd-rich melt compositions and annealing treatments.

Acknowledgments

The authors would like to express their appreciation to D. WIZENT for his assistance in crystal growth and X-ray experiments, A. TERESIAK for X-ray phase analyses, and S. M?LLER-LITVANYI for crystal characterization and special thanks to D. SOUPTEL for the support in the work.

References

[1] KOTSANDIS P A, YAKINTHOS J K, GAMARI-SEALE E. Magnetic properties of the ternary rare earth silicides R2PdSi3(R=Pr, Nd, Gd, Tb, Dy, Ho, Er, Tm and Y) [J]. Journal of Magnetism and Magnetic Materials, 1990, 87(1-2): 199-204.

[2] MALLIK R, SAMPATHKUMARAN E V, PAULOSE P L. Large low temperature magnetoresistance and magnetic anomalies in Tb2PdSi3 and Dy2PdSi3 [J]. Solid State Communications, 1998, 106(3): 169-172.

[3] SAHA S R, SUGAWARA H, MATSUDA T D, SATO H, MALLIK R, SAMPATHKUMARAN E V. Magnetic anisotropy, first-order-like metamagnetic transitions, and large negative magnetoresistance in single-crystal Gd2PdSi3 [J]. Physical Review B, 1999, 60(17): 12162-12165.

[4] SAHA S R, SUGAWARA H, MATSUDA T D, AOKA Y, SATO H, SAMPATHKUMARAN E V. Magnetic, thermal and transport properties of single crystals of antiferromagnetic kondo-lattice Ce2PdSi3 [J]. Physical Review B, 2000, 62(1): 425-429.

[5] SAMPATHKUMARAN E V, BITTERLICH H, IYER K K, L?SER W, BEHR G. Magnetic behaviour of single crystal Ho2PdSi3 [J]. Physical Review B, 2002, 66: 52409/1-3.

[6] MAJUMDAR S, SAMPATHKUMARAN E V, PAULOSE P L, BITTERLICH H, L?SER W, BEHR G. Anisotropic giant magnetoresistance, magnetocaloric effect, and magnetic anomalies in single crystalline Tb2PdSi3 [J]. Physical Review B, 2000, 62(21): 14207-14211.

[7] MAJUMDAR S, SAMPATHKUMARAN E V, PAULOSE P L, BITTERLICH H, L?SER W, BEHR G. Magnetic and transport behaviour of single crystalline Dy2PdSi3 [J]. Physical Review B, 2001, 64(1): 012418-012421.

[8] FRONTZEK M, KREYSSIG A, DOERR M, ROTTER M, BEHR G, L?SER W, MAZILU I, LOEWENHAUPT M. Magneto-crystalline anisotropy in R2PdSi3 (R=Tb, Dy, Ho, Er, Tm) single crystals [J]. Journal of Magnetism and Magnetic Materials, 2006, 301(2): 398-406.

[9] XU Yi-ku, L?SER W, BEHR G, FRONTZEK M, TANG Fei, B?CHNER B, LIU Lin. Crystal growth of the Pr2PdSi3 intermetallic compound [J]. Journal of Crystal Growth, 2010, 312(12-13): 1992-1996.

[10] SOUPTEL D, L?SER W, GRUNER W, BEHR G. Oxygen as impurity in crystal growth of intermetallics [J]. Journal of Crystal Growth, 2007, 307(2): 410-420.

[11] GRAW G, BITTERLICH H, L?SER W, BEHR G, FINK J, SCHULTZ L. Constitution and crystal growth of RE2TMSi3 intermetallic compounds [J]. Journal of Alloys and Compounds, 2000, 308(1-2): 193-199.

[12] SOUPTEL D, L?SER W, BEHR G. Vertical optical floating zone furnace: Principle of irradiation profile formation [J]. Journal of Crystal Growth, 2007, 300(2): 538-550.

[13] BEHR G, L?SER W, SOUPTEL D, FUCHS G, MAZILU I, CAO Chong-de, K?HLER A, SCHULTZ L, B?CHNER B. Crystal growth of rare earth-transition metal borocarbides and silicides [J]. Journal of Crystal Growth, 2008, 310(7-9): 2268-2276.

[14] MAZILU I, TERESIAK A, WERNER J, BEHR G, CAO Chong-de, L?SER W, ECKERT J, SCHULTZ L. Phase diagram studies on Er2PdSi3 and ErPd2Si2 intermetallic compounds [J]. Journal of Alloys and Compounds, 2008, 454(1-2): 221-227.

[15] XU Yi-ku, FRONTZEK M, MAZILU I, L?SER W, BEHR G, B?CHNER B, LIU Lin. Floating zone crystal growth of selected R2PdSi3 ternary silicides [J]. Journal of Crystal Growth, 2011, 318(1): 942-946.

R2PdSi3 (R=Pr, Tb和Gd)单晶生长沉淀

徐义库1, 2,刘 林1,Wolfgang L?SER 2,葛丙明1

1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 德国莱布尼兹固态及材料科学研究所,德累斯顿 01069

摘 要:利用具有无坩埚、高稳定性等特性的光辐射悬浮区熔法,制备R2PdSi3(R=Pr, Tb和Gd)单晶。从原材料和试样制备过程、单晶生长过程、熔体内部以及单晶基体4个方面研究单晶制备过程中一个很重要的现象,第二相沉淀。采用退火热处理方法以及给料棒成分微调法可以有效减少凝固后期冷却过程中由于Si溶解度降低析出的条纹状RSi(R = Pr, Tb 和Gd)沉淀。

关键词:悬浮区熔;单晶生长;稀土元素化合物;沉淀

(Edited by FANG Jing-hua)

Foundation item: Project (2008629045) supported by the China Scholarship Council (Constructing High-Level University Project)

Corresponding author: XU Yi-ku; Tel: +86-29-88490195; Fax: +86-29-88492227; E-mail: xuyiku23@hotmail.com

DOI: 10.1016/S1003-6326(11)61030-3