Structures,properties and responses to heat treatment of deformation processed Cu-15%Cr composite powders prepared by mechanical milling

来源期刊:中国有色金属学报(英文版)2002年第5期

论文作者:刘京雷 刘祖岩 王尔德 线恒泽

文章页码:837 - 840

Key words:Cu-Cr alloy; deformation processed composite; mechanical milling

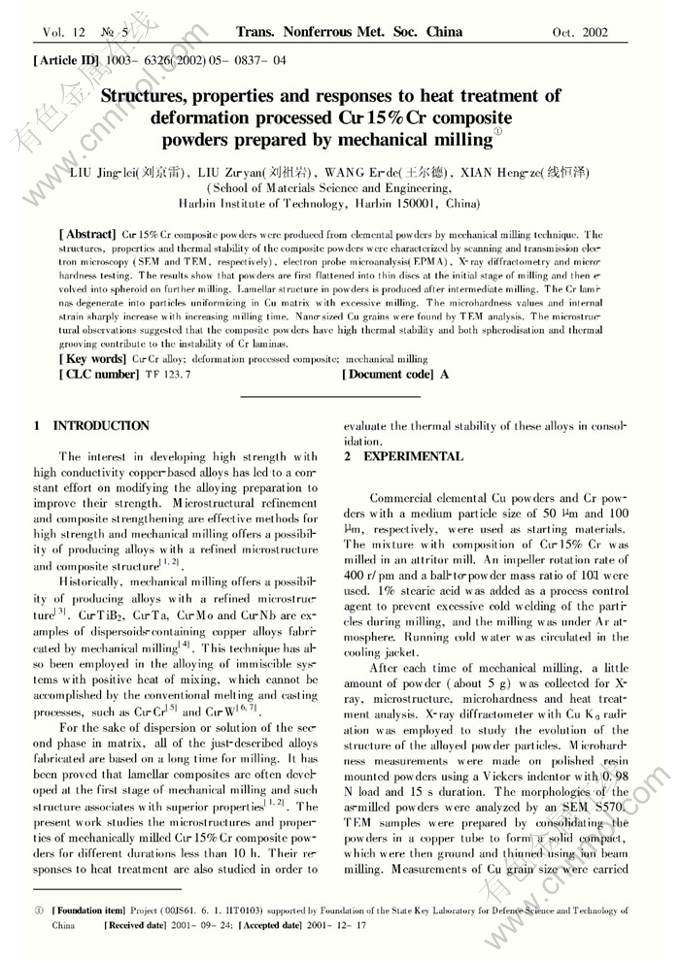

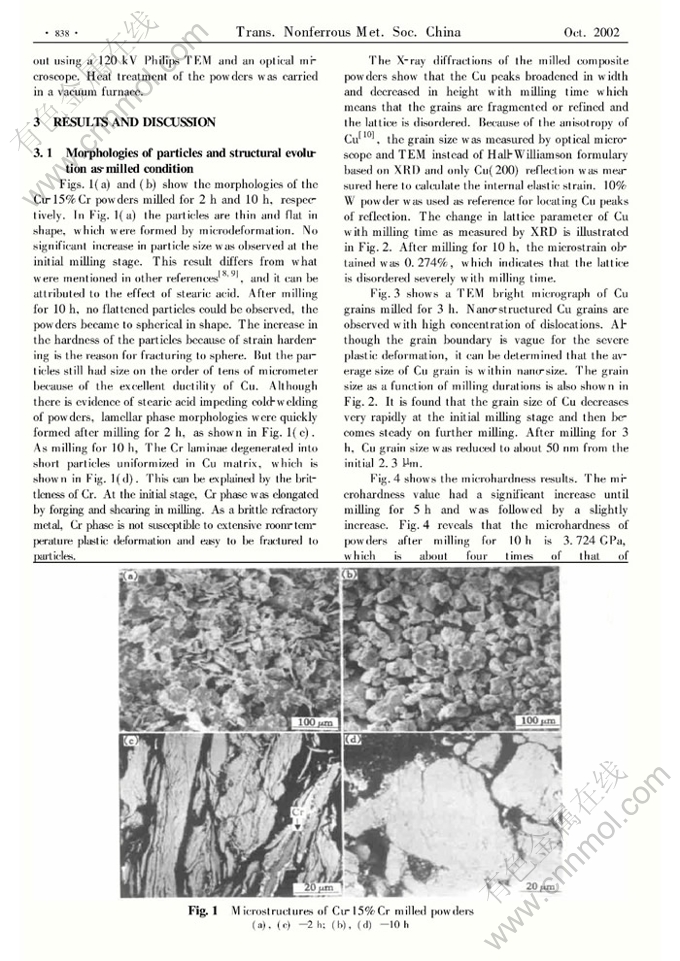

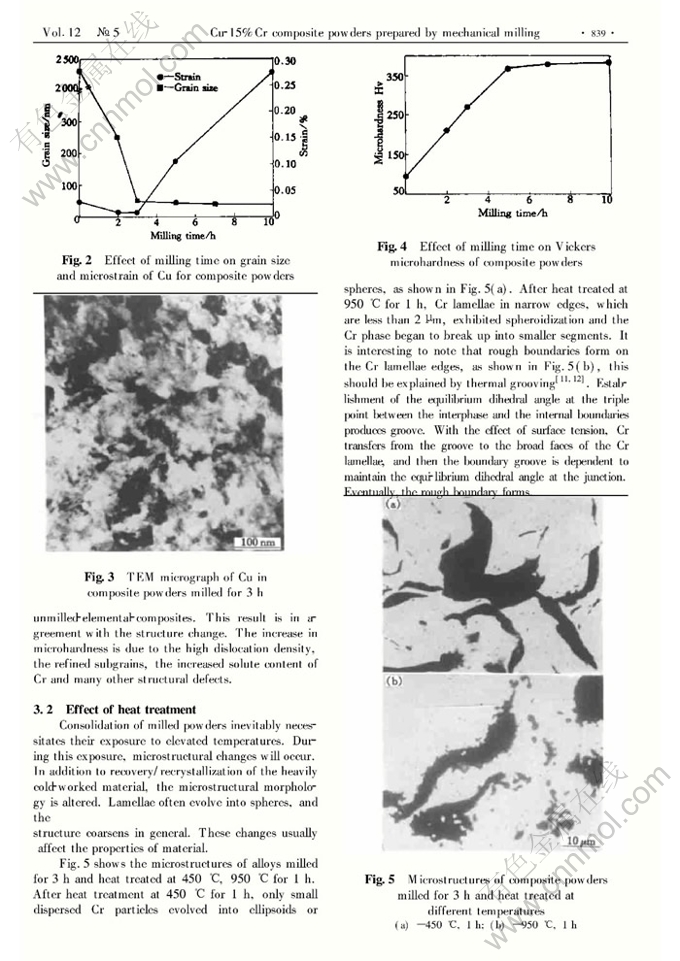

Abstract: Cu-15%Cr composite powders were produced from elemental powders by mechanical milling technique. The structures, properties and thermal stability of the composite powders were characterized by scanning and transmission electron microscopy (SEM and TEM, respectively), electron probe microanalysis(EPMA), X-ray diffractometry and microhardness testing. The results show that powders are first flattened into thin discs at the initial stage of milling and then evolved into spheroid on further milling. Lamellar structure in powders is produced after intermediate milling. The Cr laminas degenerate into particles uniformizing in Cu matrix with excessive milling. The microhardness values and internal strain sharply increase with increasing milling time. Nano-sized Cu grains were found by TEM analysis. The microstructural observations suggested that the composite powders have high thermal stability and both spherodisation and thermal grooving contribute to the instability of Cr laminas.