文章编号:1004-0609(2012)06-1624-08

[111]取向镍基单晶合金的组织结构与蠕变行为

苏 勇1, 2,田素贵1,于莉丽1,于慧臣3,张 姝1,钱本江1

(1. 沈阳工业大学 材料科学与工程学院,沈阳 110870;

2. 沈阳化工大学 机械工程学院,沈阳 110142;

3. 北京航空材料研究院,北京 100095)

摘 要:通过蠕变曲线的测定及微观组织形貌观察,研究[111]取向镍基单晶合金在高温低应力条件下的组织结构与蠕变行为。结果表明:经完全热处理后,[111]取向单晶合金的组织结构是立方γ′相以共格方式嵌镶在γ基体中,并沿 方向规则排列;在1 040~1 080 ℃、137~180 MPa的温度和应力范围内,该取向单晶合金表现出明显的温度和施加应力敏感性。蠕变期间,γ′相沿与应力轴呈一定角度形成筏状组织,蠕变后期在近断口区域筏状γ′相发生粗化和扭折。[111]取向单晶合金在蠕变期间的变形特征是位错在γ基体通道中运动和剪切筏状γ′相,由于形变量较大,较多位错切入筏状γ′相后使其形成亚晶结构,其中,蠕变后期大量位错切入筏状γ′相导致合金的蠕变抗力降低,是合金发生蠕变断裂的主要原因。

方向规则排列;在1 040~1 080 ℃、137~180 MPa的温度和应力范围内,该取向单晶合金表现出明显的温度和施加应力敏感性。蠕变期间,γ′相沿与应力轴呈一定角度形成筏状组织,蠕变后期在近断口区域筏状γ′相发生粗化和扭折。[111]取向单晶合金在蠕变期间的变形特征是位错在γ基体通道中运动和剪切筏状γ′相,由于形变量较大,较多位错切入筏状γ′相后使其形成亚晶结构,其中,蠕变后期大量位错切入筏状γ′相导致合金的蠕变抗力降低,是合金发生蠕变断裂的主要原因。

关键词:单晶镍基合金;[111]取向;蠕变;组织演化;亚晶;变形特征

中图分类号:TG132.3 文献标志码:A

Microstructure and creep behavior of [111] orientation single crystal nickel-based superalloy

SU Yong1, 2, TIAN Su-gui1, YU Li-li1, YU Hui-chen3, ZHANG Shu1, QIAN Ben-jiang1

(1. School of Materials Science and Engineering, Shenyang University of Technology, Shenyang 110870, China;

2. School of Mechanical Engineering, Shenyang University of Chemical Technology, Shenyang 110142, China;

3. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: By means of the measurement of creep curves and microstructure observation, the microstructure and creep behavior of a [111] orientation single crystal nickel-base superalloy were investigated under the conditions of high temperatures and low stresses. The results show that, after full heat-treatment, the microstructure of [111] oriented single crystal nickel-base superalloy consists of the cuboidal γ′ phase embedded coherently in the γ matrix, and regularly arranges along the  orientations. In the temperature and stress ranges of 1 040-1 080 ℃ and 137-180 MPa, the superalloy displays an obvious sensibility to the applied temperatures and stresses. During the tensile creep, the cuboidal γ′ phase in the alloy is transformed into the rafted structure at a certain angle relative to the direction of the applied stress. Furthermore, the coarsening and distorting of the rafted γ′ phase occurs in the region near the fracture at the latter stage of creep. The deformation features of the [111] orientation single crystal superalloy during creep are that the slipping of the dislocations is activated in the γ matrix channels and dislocations shear into the rafted γ′ phase. The significant amount of dislocations shear into the rafted γ′ phase, due to the bigger strain occurred to the alloy, to form the subgrain structure during high-temperature creep. In the latter stage of creep, large number of dislocations shear into the rafted γ′ phase for decreasing the creep resistance, which is thought to be the main reason for the creep rupture of the alloy.

orientations. In the temperature and stress ranges of 1 040-1 080 ℃ and 137-180 MPa, the superalloy displays an obvious sensibility to the applied temperatures and stresses. During the tensile creep, the cuboidal γ′ phase in the alloy is transformed into the rafted structure at a certain angle relative to the direction of the applied stress. Furthermore, the coarsening and distorting of the rafted γ′ phase occurs in the region near the fracture at the latter stage of creep. The deformation features of the [111] orientation single crystal superalloy during creep are that the slipping of the dislocations is activated in the γ matrix channels and dislocations shear into the rafted γ′ phase. The significant amount of dislocations shear into the rafted γ′ phase, due to the bigger strain occurred to the alloy, to form the subgrain structure during high-temperature creep. In the latter stage of creep, large number of dislocations shear into the rafted γ′ phase for decreasing the creep resistance, which is thought to be the main reason for the creep rupture of the alloy.

Key words: single crystal nickel-base superalloy; [111] orientation; creep; structure evolution; subgrain; deformation feature

单晶镍基合金中无晶界,已消除了高温条件下的晶界弱化现象,因此,具有优良的高温性能,并已被广泛应用于制作燃气涡轮机和航空发动机中的叶片部件[1-3]。在离心力作用下,蠕变损伤是单晶镍基高温合金主要的失效方式[4-6]。

单晶合金固有的晶体学特性决定了其蠕变行为的各向异性,蠕变各向异性的程度受温度的影响很大,人们发现温度越高,取向对蠕变反应的影响越小[7-9]。一些学者已经致力于研究和评估晶体取向对单晶合金的蠕变行为的影响,并试图确定造成这种各向异性的晶体滑移系。温度较低时,晶体的单晶体的滑移系为 ;而温度较高时,晶体滑移系转变为

;而温度较高时,晶体滑移系转变为 [10-12]。

[10-12]。

KEAR和PIEARCEY[13]对第一代镍基单晶合金MAR-M200进行的实验表明,在760~871 ℃温度范围内,接近 和

和 取向合金的蠕变抗力要明显好于接近

取向合金的蠕变抗力要明显好于接近 取向合金的蠕变抗力[13]。他们也发现,晶体取向在982 ℃时对于蠕变寿命的影响要小得多。实验结果也显示,在760 ℃时,

取向合金的蠕变抗力[13]。他们也发现,晶体取向在982 ℃时对于蠕变寿命的影响要小得多。实验结果也显示,在760 ℃时, 取向合金的蠕变寿命最好;然而在872 ℃和982 ℃时,

取向合金的蠕变寿命最好;然而在872 ℃和982 ℃时, 取向合金表现出最好的蠕变寿命。LEVERANT和KEAR[14]研究偏离

取向合金表现出最好的蠕变寿命。LEVERANT和KEAR[14]研究偏离 方向18°范围内的MAR-M200单晶镍基合金在760 ℃温度下的蠕变行为。其中,他们对合金3个阶段的蠕变机制进行研究,并且注意到第一和稳态蠕变阶段的蠕变速率按照如下顺序增长:

方向18°范围内的MAR-M200单晶镍基合金在760 ℃温度下的蠕变行为。其中,他们对合金3个阶段的蠕变机制进行研究,并且注意到第一和稳态蠕变阶段的蠕变速率按照如下顺序增长: 取向、

取向、 /

/ 边界、

边界、 /

/ 和

和 /

/ 边界之间的取向、

边界之间的取向、 /

/ 边界。MACKAY和MAIER[15]对取向偏离

边界。MACKAY和MAIER[15]对取向偏离 方向25°以内的第一代镍基单晶合金MAR-M247在774 ℃下的蠕变行为进行研究,结果表明合金取向靠近赤面投影三角形的

方向25°以内的第一代镍基单晶合金MAR-M247在774 ℃下的蠕变行为进行研究,结果表明合金取向靠近赤面投影三角形的 /

/ 边界比靠近

边界比靠近 /

/ 边界具有更长的蠕变寿命。这些结果与MAR-M200合金的蠕变行为一致[13-14],唯一的不同是MAR-M247在接近

边界具有更长的蠕变寿命。这些结果与MAR-M200合金的蠕变行为一致[13-14],唯一的不同是MAR-M247在接近 取向时的蠕变寿命最好,而MAR-M200在接近

取向时的蠕变寿命最好,而MAR-M200在接近 取向时的蠕变寿命最好。CARON等[16]研究了晶体取向对第一代镍基单晶合金CMSX-2在760 ℃、750 MPa条件下蠕变寿命的影响。实验结果显示,当晶体接近

取向时的蠕变寿命最好。CARON等[16]研究了晶体取向对第一代镍基单晶合金CMSX-2在760 ℃、750 MPa条件下蠕变寿命的影响。实验结果显示,当晶体接近 取向时,合金的蠕变寿命最好,但与MAR-M200和MAR-M247合金不同,CMSX-2合金在接近

取向时,合金的蠕变寿命最好,但与MAR-M200和MAR-M247合金不同,CMSX-2合金在接近 取向时的蠕变寿命非常短。而且,在偏离

取向时的蠕变寿命非常短。而且,在偏离 取向20°时并没有像MAR-M200和MAR-M247合金那样引起蠕变寿命的急剧降低[13-15]。

取向20°时并没有像MAR-M200和MAR-M247合金那样引起蠕变寿命的急剧降低[13-15]。

MATAN等[17]研究了晶体取向稍微偏离 方向的第二代镍基单晶合金CMSX-4的蠕变行为。他们的研究表明,在750 ℃条件下,蠕变第一阶段的应变较大,而且很大程度上取决于晶体取向偏离赤面投影三角形中

方向的第二代镍基单晶合金CMSX-4的蠕变行为。他们的研究表明,在750 ℃条件下,蠕变第一阶段的应变较大,而且很大程度上取决于晶体取向偏离赤面投影三角形中 /

/ 边界的程度。然而在950 ℃时,蠕变第三阶段占主要地位,而且蠕变第一阶段应变很小。他们发现在950 ℃蠕变各向异性程度要小一些。GUNTURI等[18]研究CMSX-4合金在750 ℃条件下的蠕变行为。研究发现,当晶体取向偏离

边界的程度。然而在950 ℃时,蠕变第三阶段占主要地位,而且蠕变第一阶段应变很小。他们发现在950 ℃蠕变各向异性程度要小一些。GUNTURI等[18]研究CMSX-4合金在750 ℃条件下的蠕变行为。研究发现,当晶体取向偏离 方向时,晶体取向远离

方向时,晶体取向远离 /

/ 边界的合金具有较短的蠕变寿命,而接近

边界的合金具有较短的蠕变寿命,而接近 /

/ 边界的合金具有相对较长的蠕变寿命。ZHANG等[19]通过研究发现,对某第一代镍基高温合金而言,在975 ℃、255 MPa条件下,其蠕变断裂特性是晶体实际取向偏离[001]取向程度的函数。

边界的合金具有相对较长的蠕变寿命。ZHANG等[19]通过研究发现,对某第一代镍基高温合金而言,在975 ℃、255 MPa条件下,其蠕变断裂特性是晶体实际取向偏离[001]取向程度的函数。

尽管[001]取向单晶合金具有制备工艺简单,高温力学性能及蠕变性能优良等特点,已广泛用于制作航空发动机的热端叶片部件[20-21]。但在实际生产过程中,制备的叶片部件与[001]取向不可避免地存在一定程度的偏差,同时,叶片部件本身具有复杂的结构,如错综复杂的冷却通道等,导致叶片部件在工作时实际的叶片部件承受的离心力的方向总是偏离[001]取向,有时甚至还很大。为了更好地理解单晶合金的蠕变行为,研究非[001]取向的单晶合金的蠕变行为对镍基单晶高温合金的设计和制备具有重要意义[22]。

据此,本文作者对[111]取向单晶镍基合金进行了蠕变性能测定及组织形貌观察,考察其高温低应力条件下的蠕变特征,结合组织形貌的SEM和TEM观察,研究了[111]取向单晶合金在高温拉应力蠕变期间的定向粗化规律及对蠕变性能的影响,试图为合金的开发与应用提供理论依据。

1 实验

在真空感应炉中熔炼母合金锭,采用籽晶法在高温度梯度真空定向凝固炉中,将母合金制备成[111]取向的单晶合金试棒,制备出[111]取向单晶合金的取向差在7°以内。制备出的单晶镍基合金的化学成分如表1所列。在箱式电阻炉中将[111]取向单晶合金试棒进行完全热处理,其选取的热处理工艺如下:(1 250 ℃,4 h,AC)+(870 ℃,32 h,AC)。

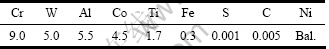

表1 单晶镍基合金的化学成分

Table 1 Chemical composition of single crystal nickel-base superalloy (mass fraction, %)

[111]取向单晶合金经完全热处理后,采用线切割将合金试棒沿 晶面、

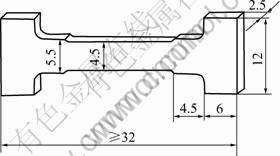

晶面、 晶面切取板状拉伸蠕变样品,试样的横断面为4.5 mm×2.5 mm,标距为11.0 mm,应力轴方向为[111]取向,样品的示意图如图1所示。

晶面切取板状拉伸蠕变样品,试样的横断面为4.5 mm×2.5 mm,标距为11.0 mm,应力轴方向为[111]取向,样品的示意图如图1所示。

图1 拉伸蠕变试样尺寸

Fig. 1 Schematic diagram of tensile creep sample (mm)

将试样的表面机械抛光后,置入GWT504型高温持久/蠕变试验机中,分别在相同应力(137 MPa)不同温度(1 040、1 070和1 080 ℃)和相同温度(1 040 ℃)不同应力(160和180 MPa)5种实验条件下,测定蠕变曲线。将蠕变前/后的[111]取向单晶合金经机械研磨和抛光后,使用100 mL HCl+80 mL H2O+20 g CuSO4腐蚀剂,对抛光后的样品进行化学腐蚀,在SEM下观察组织形貌,并将蠕变断裂后的试样制成d=3 mm的TEM样品,进行微观形貌观察,观察合金在蠕变期间γ′、γ两相的组织演化规律及变形特征,探讨合金在蠕变期间的变形机制。

2 结果与分析

2.1 合金的蠕变特征

将[111]取向单晶合金在高温不同条件下测定蠕变曲线,如图2所示,其中在不同温度施加137MPa条件下,测定的蠕变曲线示于图2(a),可以看出,在1 040 ℃合金具有较短的蠕变初始阶段,较低的稳态应变速率和较长的蠕变寿命,稳态蠕变时间持续93 h后,其应变量仅为3.33%。蠕变进入第三阶段后,应变速率逐渐增大,直至发生蠕变断裂,其蠕变寿命达134 h。随温度提高到1 070 ℃,合金在稳态蠕变期间的应变速率提高到4.677 9×10-4 h-1,稳态蠕变阶段的时间相应缩短,蠕变寿命降低到65 h;随温度进一步提高到1 080 ℃,合金的蠕变寿命已降低到45 h。

合金在1 040 ℃施加不同应力条件下测定的蠕变曲线如图2(b)所示,随施加应力提高到160 MPa,与137 MPa相比较,合金的应变速率略有提高,蠕变寿命缩短到65 h;随施加应力进一步提高到180 MPa,蠕变寿命降低到40 h。

图2 在不同条件下[111]取向单晶镍基合金的蠕变曲线

Fig. 2 Creep curves of [111] orientation single crystal nickel- based superalloy under different conditions: (a) Applied different temperatures under 137 MPa; (b) Different applied stress at 1 040 ℃

2.2 蠕变激活能及应力指数

合金在高温施加载荷的瞬间,产生瞬间应变,随蠕变进行,位错密度增加,由于应变硬化作用,致使应变速率减小,一旦蠕变进入稳态阶段,合金的应变速率保持恒定,其应变速率可由Dorn定律表示:

(1)

(1)

式中: 为稳态阶段的应变速率;A为与组织结构有关的常数;

为稳态阶段的应变速率;A为与组织结构有关的常数; 为施加的应力;n为表观应力指数;R为摩尔气体常数;T为绝对温度;Qa为表观蠕变激活能。

为施加的应力;n为表观应力指数;R为摩尔气体常数;T为绝对温度;Qa为表观蠕变激活能。

在高温低应力蠕变期间,位错攀移是合金的蠕变机制,在热激活作用下位错发生攀移越过g ?相,或异号刃位错相遇而消失,使合金的蠕变得以进行,其中,热激活对位错的攀移起到重要作用。因此,可用激活能定量评价位错攀移克服阻力所作的功。

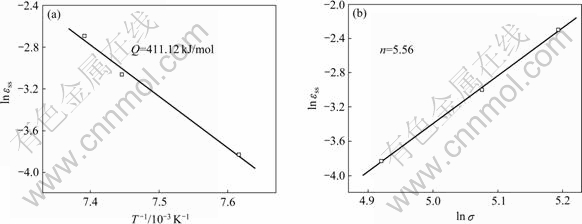

根据图2中不同条件下测定的蠕变曲线,测算出合金在稳态蠕变期间的应变速率,将合金在不同条件下的应变速率与施加温度、应力的关系分别示于图3(a)和(b)。由此,在实验的温度和应力范围内,测算出该合金在稳态蠕变期间的蠕变激活能和应力指数分别为:Q=411.12 kJ/mol和n=5.56。

2.3 在蠕变期间的组织演化

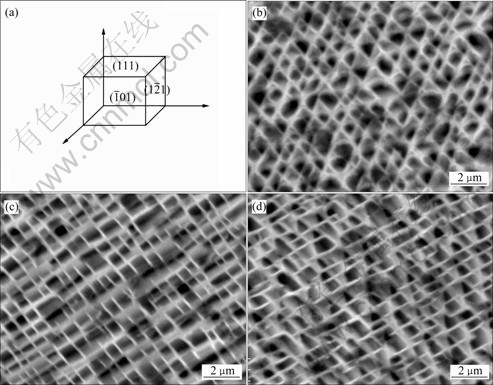

[111]取向单晶合金经完全热处理后,分别沿 、(111)和

、(111)和 晶面切割成板状蠕变样品,样品的宽面为

晶面切割成板状蠕变样品,样品的宽面为 晶面,其样品不同晶面的组织形貌如图4所示。

晶面,其样品不同晶面的组织形貌如图4所示。

在无应力状态下,单晶胞各晶面的示意图如图4(a)所示,γ′相在 、(111)和

、(111)和 晶面的形貌分别示于图4(b)、(c)和(d),可以看出,在(111)晶面,γ′相呈现类三角形或六角形形貌,如图4(b)所示,在

晶面的形貌分别示于图4(b)、(c)和(d),可以看出,在(111)晶面,γ′相呈现类三角形或六角形形貌,如图4(b)所示,在 晶面,γ′相沿与应力轴方向呈近45°角以长方形形貌规则排列,如图4(c)中白色箭头所示。在

晶面,γ′相沿与应力轴方向呈近45°角以长方形形貌规则排列,如图4(c)中白色箭头所示。在 晶面,γ′相仍然沿斜下方呈现长方形形貌,如图4(d)中白色箭头所示,其特征是沿与施加应力轴方向呈约53°角排列。由此可以看出:γ′相在空间仍然沿

晶面,γ′相仍然沿斜下方呈现长方形形貌,如图4(d)中白色箭头所示,其特征是沿与施加应力轴方向呈约53°角排列。由此可以看出:γ′相在空间仍然沿 取向规则排列,呈现立方体形貌,立方γ′相的边缘尺寸约为0.4 μm,且均匀分布。

取向规则排列,呈现立方体形貌,立方γ′相的边缘尺寸约为0.4 μm,且均匀分布。

图3 稳态期间合金的应变速率与施加温度、应力的关系

Fig. 3 Relationship among strain rates, applied temperatures and stresses during steady state creep: (a) Relationship between strain rate and temperatures; (b) Relationship between strain rate and applied stresses

图4 [111]取向单晶合金经完全热处理后不同晶面的组织形貌

Fig. 4 Morphologies of [111] orientation single crystal nickel-based superalloy on different crystal planes after fully heat-treatment: (a) Schematic diagram of cubic cell; (b) (111) plane; (c)  plane; (d)

plane; (d)  plane

plane

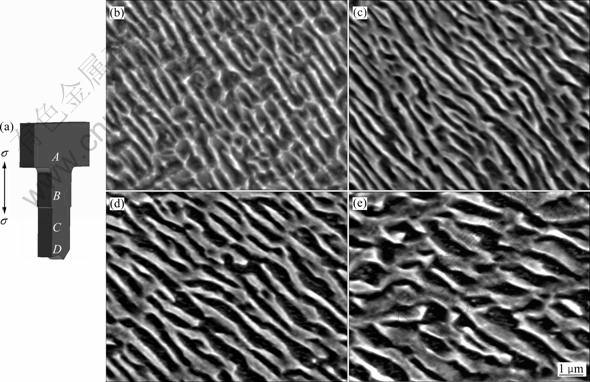

合金在拉伸蠕变期间发生了明显的组织演化,使其γ′相在(010)晶面沿[001]和[100]方向形成层片结构的筛网状筏形结构(有关[111]取向单晶合金在拉伸蠕变期间的组织演化与分析已另文发表)。而在 面观察,γ′相沿与[111]应力轴方向呈一定角度形成筏状结构,如图5所示。拉伸蠕变期间,在样品的不同位置或区域,承受不同的应力,特别是观察点区域距断口的距离不同,合金的受力状态不同,并导致合金在不同部位具有不同的组织形貌。在1 040 ℃、137 MPa条件下,[111]取向单晶合金蠕变134h断裂后,距断口不同位置γ′相的形貌,如图5所示。其中,照片中的黑色区域为γ′相,灰色及白色区域为γ基体相。

面观察,γ′相沿与[111]应力轴方向呈一定角度形成筏状结构,如图5所示。拉伸蠕变期间,在样品的不同位置或区域,承受不同的应力,特别是观察点区域距断口的距离不同,合金的受力状态不同,并导致合金在不同部位具有不同的组织形貌。在1 040 ℃、137 MPa条件下,[111]取向单晶合金蠕变134h断裂后,距断口不同位置γ′相的形貌,如图5所示。其中,照片中的黑色区域为γ′相,灰色及白色区域为γ基体相。

图5(a)所示为观察样品位置的示意图,区域A为非受力区,在该区域已有部分γ′相转变成筏状结构,且沿样品的轴线方向约37°角规则排列,如图5(b)所示;在受力区域,γ′相均已形成筏状形貌,但在不同区域筏状γ′相具有不同的形貌,在远离断口的区域B,筏状γ′相沿轴线方向呈37°角排列,且γ′相厚度尺寸均匀,如图5(c)所示;随离断口的距离减小至区域C,其γ′相的厚度尺寸略有增加,在离断口较近的区域C,虽然γ′相仍保持筏状形貌,但筏状g?相的取向与应力轴夹角已增加到近45°,且γ′相粗化程度增加,γ基体相由B区域的0.3 μm增加到C区域的0.5 μm,如图5(d)所示;在近断口的D区域,如图5(e)所示,γ和γ′相的厚度尺寸均已增加到约0.8 μm,筏状γ′相的形貌已转变成与应力轴成55°,且长度尺寸减小,并呈波浪状形貌。

如果认为样品离断口的距离减小发生缩径,使合金的变形量增大,则根据不同位置的形貌特征分析认为:随合金应变量的增加,合金中原来连续的筏状γ′相,因应变增加而发生扭曲或折断,同时,随合金变形程度的增加,近断口区域发生位错的交替滑移,使筏状γ′相扭曲程度增加,致使原筏状γ′相取向与应力轴的夹角,由37o逐渐转动倾斜至与应力轴成55o角,并呈现波纹状形貌。

图5 在1 040 ℃、137 MPa条件下[111]取向合金蠕变断裂后不同区域的组织形貌

Fig. 5 Morphologies of rafted γ′ phase in different regions after [111] orientation alloy crept up to fracture under applied stress of 137 MPa at 1 040 ℃: (a) Schematic diagram of observing regions; (b) Region A; (c) Region B; (d) Region C; (e) Region D

2.4 蠕变期间的变形特征

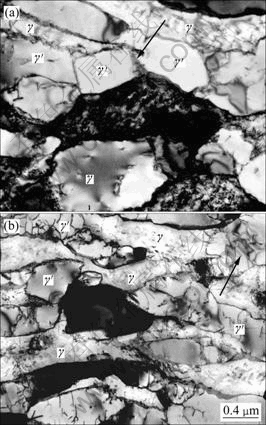

在1 040 ℃、137 MPa条件下[111]取向单晶合金蠕变不同时间的微观组织形貌如图6所示,合金蠕变50 h后的组织形貌,如图6(a)所示,可以看出,相已连接成筏状,但仍有部分γ′相保持立方形貌,且在γ/γ′两相界面存在不规则位错网,如图中黑色箭头所示。在相同条件下蠕变134h断裂后,合金的微观组织形貌如图6(b)所示,合金中的γ′相已完全形筏,且合金中筏状γ′相的扭曲程度增大,γ′相筏形化取向与应力轴成55 o夹角,如图5(e)所示,蠕变后期,由于形变量较大(如图2所示),故有较多位错切入筏状γ′相。随蠕变进行,切入γ′相的位错发生束集,使其形成亚晶结构,其亚晶之间存在较小的取向差,故显示不同的衬度,如6(b)所示。其中,基体通道承受最大剪应力易于位错滑移是使合金具有较大应变的主要原因。蠕变后期,筏状γ′相内有较多位错的事实表明,该合金已失去蠕变抗力。

图6 在1 040 ℃、137 MPa条件下[111]取向单晶合金蠕变不同时间的微观组织

Fig. 6 Microstructures after alloy crept for different times under applied stress of 137 MPa at 1 040 ℃: (a) 50 h; (b) Crept for 134 h up to fracture

3 讨论

在[111]取向的单晶镍基合金中,其组织结构仍是立方γ′相以共格方式嵌镶在γ基体相中,并沿 取向规则排列。若[111]取向单晶合金无取向差,单晶合金沿[111]取向施加拉应力时,立方γ′相各晶面对称受力,切应力值相等,各基体通道及在立方γ′相界面产生对称的应变能密度变化,且其值相等,故在蠕变期间,立方γ′相不发生筏形化转变。但实际上实验使用合金具有6°的取向差,由于取向差的作用,在高温施加拉应力的蠕变期间,合金中的立方γ′/γ两相界面发生不对称应变,其立方γ′相各晶面的晶格可发生扩张或压缩应变,其中立方γ′相六面体不同界面产生的应变能密度变化作为驱动力,可促使发生元素的定向扩散及γ′相的定向生长,其晶格扩张较大的晶面可诱捕较大半径的Al、Ti原子,促使其沿该晶面的法线方向定向生长,成为图5所示的组织形貌。

取向规则排列。若[111]取向单晶合金无取向差,单晶合金沿[111]取向施加拉应力时,立方γ′相各晶面对称受力,切应力值相等,各基体通道及在立方γ′相界面产生对称的应变能密度变化,且其值相等,故在蠕变期间,立方γ′相不发生筏形化转变。但实际上实验使用合金具有6°的取向差,由于取向差的作用,在高温施加拉应力的蠕变期间,合金中的立方γ′/γ两相界面发生不对称应变,其立方γ′相各晶面的晶格可发生扩张或压缩应变,其中立方γ′相六面体不同界面产生的应变能密度变化作为驱动力,可促使发生元素的定向扩散及γ′相的定向生长,其晶格扩张较大的晶面可诱捕较大半径的Al、Ti原子,促使其沿该晶面的法线方向定向生长,成为图5所示的组织形貌。

由于实验选用合金的施加应力轴与[111]取向存在6°的取向偏差,在高温施加载荷的蠕变期间,[111]取向单晶合金中3个 取向的基体通道受力不等,致使不同基体通道的应力分布发生不对称变化,γ′相将沿着具有较大应力及较大应变能密度变化的基体通道生长形成筏状组织。

取向的基体通道受力不等,致使不同基体通道的应力分布发生不对称变化,γ′相将沿着具有较大应力及较大应变能密度变化的基体通道生长形成筏状组织。

在高温蠕变期间,[111]取向单晶合金中γ′相形成筏状之后,其γ基体通道与施加应力轴方向呈近45°角排列,承受最大剪切应力,因此,合金具有较大的应变。随蠕变进行,合金的应变进一步增大,并逐渐在样品的中间区域出现缩颈,缩颈区域承载的横截面积减小,使恒载拉伸的有效应力增加,可使筏状γ′相逐渐粗化。随缩颈区域形变量的增加,伴随有蠕变位错的交替滑移,其蠕变位错的交替滑移,使筏状γ′相发生扭曲及晶体转动[23],可改变原筏状γ′相的取向直至转变为近似与应力轴成55°角的形貌,如图5(e)所示。

在蠕变后期,形变位错切入γ′及γ基体相的数量增加,在高温热激活的作用下,发生位错的束集,形成位错胞及亚晶结构,因而,在合金的不同区域存在具有取向差的亚晶结构,如图6(b)所示。

4 结论

1) 在实验的温度和应力范围内,[111]取向合金对施加温度和应力具有较强的敏感性,测算出合金的蠕变激活能和应力指数分别为:Q=411.12 kJ/mol和n=5.56,其稳态蠕变期间的变形机制为位错的攀移。

2) 经完全热处理后,[111]取向单晶合金的组织结构仍是立方γ′相以共格方式嵌镶在γ基体中,并沿 方向规则排列;在高温拉应力蠕变期间,γ′相沿与应力轴呈一定角度形成筏状组织,蠕变后期在近断口区域,筏状γ′相发生粗化和扭曲,随应变增加,粗化和扭曲程度加剧,直至呈现波浪状形貌。

方向规则排列;在高温拉应力蠕变期间,γ′相沿与应力轴呈一定角度形成筏状组织,蠕变后期在近断口区域,筏状γ′相发生粗化和扭曲,随应变增加,粗化和扭曲程度加剧,直至呈现波浪状形貌。

3) 在蠕变期间,[111]取向单晶合金的变形特征是位错在γ基体通道中运动和剪切筏状γ′相,由于形变量较大,较多位错切入筏状γ′相后,发生位错束集,使其形成亚晶结构;其中,基体通道承受最大剪应力易于位错滑移是使合金具有较大应变速率的主要原因。

REFERENCES

[1] TIAN Su-gui, ZHANG Shu, LIANG Fushun, LI A-nan, LI Jing-jing. Microstructure evolution and analysis of a single crystal nickel-based superalloy during compressive creep[J]. Materials Science and Engineering A, 2011, 528(15): 4988-4993.

[2] 夏永发, 金玉龙. 镍基单晶高温合金γ′颗粒[111]取向加载的粗化趋势[J]. 东北大学学报: 自然科学版, 2008, 29(7): 1053-1056.

XIA Yong-fa, JIN Yu-long. Directional coarsening trend of γ′-particles of nickel-base single crystal superalloy under load in [111] orientation[J]. Journal of Northeastern University: Natural Science, 2008, 29(7): 1053-1056.

[3] LIU L, HUANG T W, ZHANG J, FU H Z. Microstructure and stress rupture properties of single crystal superalloy CMSX-2 under high thermal gradient directional solidification[J]. Materials Letters, 2007, 61(1): 227-230.

[4] REED R C, TAO T, WARNKEN N. Alloys-by-design: Application to nickel-based single crystal superalloys[J]. Acta Materialia, 2009, 57(19): 5898-5913.

[5] 马文有, 李树索, 乔敏, 宫声凯, 郑运荣, 韩雅芳. 热处理对镍基单晶高温合金微观组织和高温持久性能的影响[J]. 中国有色金属学报, 2006, 16(6): 937-944.

MA Wen-you, LI Shu-suo, QIAO Min, GONG Sheng-kai, ZHENG Yun-rong, HAN Ya-fang. Effect of heat treatment on microstructure and stress rupture life of Ni-base single crystal superalloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 937-944.

[6] ZHANG J, LI J G, JIN T, SUN X F, HU Z Q. Effect of Mo concentration on creep properties of a single crystal nickel-base superalloy[J]. Materials Science and Engineering A, 2010, 527(13/14): 3051-3056.

[7] NABARRO F R N. Creep in commercially pure metals[J]. Acta Materialia, 2006, 54(2): 263-295.

[8] HAN G M, YANG Y H, YU J J, SUN X F. Temperature dependence of anisotropic stress-rupture properties of nickel-based single crystal superalloy SRR99[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(8): 1717-1721.

[9] 田素贵, 于莉丽, 张 殊, 于慧臣, 钱本江, 肖 丽. 晶体取向对镍基单晶合金蠕变行为的影响[J]. 中国有色金属学报, 2011, 21(2): 356-363.

TIAN Su-gui, YU Li-li, ZHANG Shu, YU Hui-chen, QIAN Ben-jiang, XIAO Li. Influence of crystal orientations on creep behaviors of single crystal nickel-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 356-363.

[10] LEVERANT G R, KEAR B H, OBLAK J M. Creep of precipitation-hardened nickel-base alloy single crystals at high temperatures[J]. Metallurgical and Materials Transactions B, 1973, 4(1): 355-362.

[11] ZHANG J X, WANG J C, HARADA H, KOIZUMI Y. The effect of lattice misfit on the dislocation motion in superalloys during high-temperature low-stress creep[J]. Acta Materialia, 2005, 53(17): 4623-4633.

[12] RAE C M F, REED R C. Primary creep in single crystal superalloys: Origins, mechanisms and effects[J]. Acta Materialia, 2007, 55(3): 1067-1081.

[13] KEAR B H, PIEARCEY B J. Tensile and creep properties of single crystals of nickel-base superalloy MAR-M200[J]. Transactions of the Metallurgical Society of the American Institute of Mechanical Engineers, 1967, 239(8): 1209-1215.

[14] LEVERANT G R, KEAR H B. The mechanism of creep in gamma prime precipitation-hardened nickel-base alloys at intermediate temperatures[J]. Metallurgical and Materials Transactions B, 1970, 1(2): 491-498.

[15] MACKAY R A, MAIER R D. The influence of orientation on the stress rupture properties of nickel-base superalloy single crystals[J]. Metallurgical and Materials Transactions A, 1982, 13(10): 1747-1754.

[16] CARON P, KHAN T, NAKAGAWA Y G. Effect of orientation on the intermediate temperature creep behavior of Ni-base single crystal superalloys[J]. Scripta Metallurgica, 1986, 20(4): 499-502.

[17] MATAN N, COX D C, CARTER P, RIST M A, RAE C M F, Reed R C. Creep of CMSX-4 superalloy single crystals: Effects of misorientation and temperature[J]. Acta Materialia, 1999, 47(5): 1549-1563.

[18] GUNTURI S S K, MACLACHLAN D W, KNOWLES D M. Anisotropic creep in CMSX-4 in orientations distant from  [J]. Materials Science and Engineering A, 2000, 289(1/2): 289-298.

[J]. Materials Science and Engineering A, 2000, 289(1/2): 289-298.

[19] ZHANG S H, ZHANG J, LOU L H. Anisotropic creep rupture properties of a Nickel-base single crystal superalloy at high temperature[J]. Journal of Materials Science and Technology, 2011, 27(2): 107-112.

[20] 温志勋, 苟文选, 岳珠峰. 镍基单晶裂纹扩展路径研究[J]. 稀有金属材料与工程, 2007, 36(9): 1549-1553.

WEN Zhi-xun, GOU Wen-xuan, YUE Zhu-feng. Crack propagation paths and fracture of Ni-based single crystal[J]. Rare Metal Materials and Engineering, 2007, 36(9): 1549-1553.

[21] YU X F, TIAN S G, WANG M G, ZHANG S, LU X D, CUI S S. Creep behaviors and effect factors of single crystal nickel-base superalloys[J]. Materials Science and Engineering A, 2009, 499(1/2): 352-359.

[22] PRASAD S, RAJAGOPAL K R, RAO J. A continuum model for the anisotropic creep of single crystal nickel-based superalloys[J]. Acta Materialia, 2006, 54(6): 1487-1500.

[23] CHATTERJEE D, HAZARI N, DAS N, MITRA R. Microstructure and creep behavior of DMS4-type nickel based superalloy single crystals with orientations near  and

and  [J]. Materials Science and Engineering A, 2010, 528(2): 604-613.

[J]. Materials Science and Engineering A, 2010, 528(2): 604-613.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50571070)

收稿日期:2011-06-13;修订日期:2011-11-01

通信作者:田素贵,教授,博士;电话:024-25494089;传真:024-25496768;E-mail: tiansugui2003@163.com