半固态A356合金微观组织特征对充型能力的影响

谭建波1, 2, 邢书明1, 李立新2, 李增民2, 李 讯2, 曹凤江2

(1. 北京交通大学 机械与电子控制工程学院, 北京 100044;

2. 河北科技大学 材料科学与工程学院, 石家庄 050054)

摘 要: 采用电磁搅拌法制备了具有不同微观组织特征的半固态A356合金浆料, 用图像分析软件对浇注前浆料金相试样的初生相微观组织特征进行了测定, 利用间接挤压铸造方法铸造阿基米德螺旋线试样, 以挤压成形后的螺旋线试样长度衡量充型能力, 通过多元回归, 建立了半固态A356合金初生相微观组织特征与充型长度之间的数学表达式。 结果表明: 半固态浆料充型能力不仅与初生相微观组织特征参数有关, 微观组织特征参数的交互作用对充型能力的影响也较大。 利用该表达式可以对半固态浆料充型能力进行预测, 进而指导半固态浆料制备参数设计、 间接挤压铸造工艺设计和缺陷预测。

关键词: 半固态 A356合金; 挤压铸造; 微观组织; 充型能力 中图分类号: TG146.4

文献标识码: A

Influences of microstructure characteristics of semi-solid A356 alloy on filling ability

TAN Jian-bo1, 2, XING Shu-ming1, LI Li-xin2,

LI Zeng-min2, LI Xun2, CAO Feng-jiang2

(1. College of Mechanical and Electronic Control Engineering,Beijing Jiaotong University, Beijing 100044, China;

2. College of Materials Science and Engineering,Hebei University of Science and Technology, Shijiazhuang 050054, China)

Abstract: The method of electromagnetic strring was adopted to produce the semi-solid A356 alloy slurry which has different microstructure characteristic, the image analysis software was used to mensurate the microstructure characteristics of the primary phase of slurry metallographic specimen before pouring, and the indirect squeeze casting method was used to produce the archimedean spiral line sample, accordingly the length of spiral line sample after squeeze forming was used to weigh the filling ability, the mathematic representation between the microstructure characteristics of primary phase of semi-solid A356 alloy slurry and filling length via multivariant regression was setup. The result indicates that the filling ability of semi-solid slurry not only has the relation with the microstructure characteristic parameter of primary phase, but is also affected by the interaction of microstructure characteristic parameter greatly. This expression can forecast the filling ability of semi-solid slurry, and then guide the semi-solid slurry produce parameters design, indirect squeeze casting craft design and failure prediction.

Key words: semi-solid A356 alloy; squeeze casting; microstructure; filling ability

合金的充型能力直接关系到零件能否完整成形以及所得零件表面粗糙度的高低, 所以一直是材料成形领域关注的基本问题[1-5]。 由于半固态合金是含有非枝晶的固液混合物, 与液态合金充型相比, 其充型能力除受铸型材料、 浇注工艺和成形方法影响外, 还与半固态合金中的固相率、 晶粒形状和晶粒尺寸等有很大关系。 国内外不少学者研究了工艺参数对充型能力的影响作用和规律[1-8], 但半固态合金自身的微观结构对充型能力的影响还未引起足够重视。 微观流变学原理表明, 内部微观结构是流变行为的决定因素, Fan和Chen[9-12]、 Kato等[13]的实验研究也证明了这一点, 但微观结构与浆料充型能力之间的定量关系尚不清楚。 本文作者采用实验测定的方法, 研究了在挤压铸造条件下半固态A356合金浆料的微观组织特征对充型能力的影响规律, 并回归分析得到了其微观组织特征与充型能力的实验规律。

1 实验

1.1 材料

实验选用工业上常用的A356合金, 其化学成分(质量分数, %)为: Si7.14, Mg0.29, Fe0.12, Ni0.18, Cu0.13, Zn0.08, Mn0.09, Al余量。

1.2 实验方法

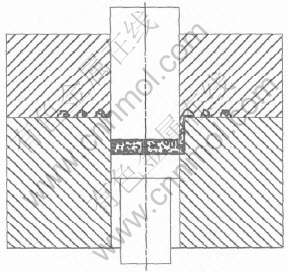

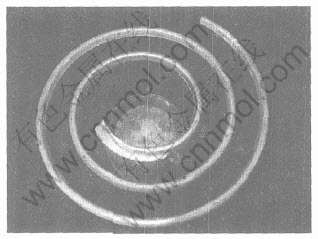

半固态浆料的微观组织特征可通过保温温度控制和搅拌工艺参数进行间接控制。 因此, 本文采用电磁搅拌法制浆, 通过改变搅拌频率、 输出电压及保温温度, 制备出具有不同微观组织特征的半固态A356合金浆料。 再将制备出的浆料浇入预热的阿基米德螺旋线试样模具压室内, 在固定的成形参数下进行间接挤压成形。 成形设备为2000kN半固态模锻机, 挤压模具示意图如图1所示。 挤压成形工艺参数均为: 模具预热温度300℃、 充型压力95MPa、 充型速度55mm/s、 保压时间8s、 浇注量1300g(控制压室中浇入半固态浆料的高度)。 待螺旋线试样凝固后, 顶出试样, 量取充型长度, 作为浆料充型能力的表征参数。 成形的螺旋线试样如图2所示。

图1 螺旋线挤压模具示意图

Fig.1 Sketch map of spiral line squeeze mould

图2 螺旋线试样照片

Fig.2 Photo of spiral line sample

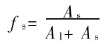

在半固态浆料浇入模具前用取样器舀取少量浆料, 进行水淬, 制取金相试样后拍照, 用图像分析软件测定液、 固相的平均面积, 以及初生相颗粒的平均周长、 平均尺寸。 固相率fs和形状因子Fc的定义如下[14, 15]:

式中 As为固相面积; Al为液相面积; P为晶粒平均周长; A为晶粒平均面积。 Fc=1时, 所有晶粒为完整球状。

2 结果与讨论

2.1 初生相微观组织特征参数及充型长度

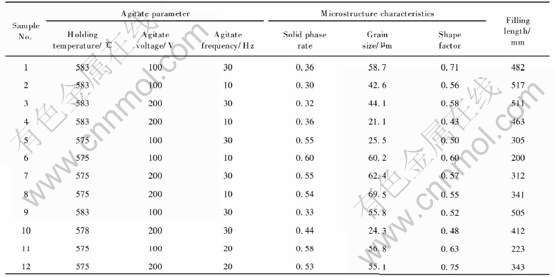

半固态 A356合金浇注前的微观组织如图3所示。 其中白色相为初生α相, 它在水淬过程中尺寸、 形态基本保持不变, 黑色组织为液相在水淬过程中的转变产物。 可以看出, 各次实验半固态浆料的微观组织特征存在明显差异, 如表1所列。 初生相固相率的变化范围为0.30~0.60, 形状因子为0.43~0.75, 晶粒平均尺寸为21.1~69.5μm。 相应地, 在充型条件相同的条件下, 充型长度也出现了明显差异, 充型长度最大与最小值之差高达317mm。 这些结果充分说明了半固态浆料的微观组织特征对充型能力有显著影响。

图3 半固态 A356合金浇注前的微观组织

Fig.3 Microstructures of semi-solid A356 alloy before pouring

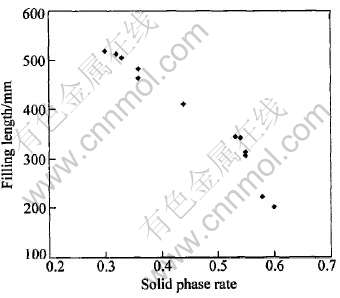

由表1的数据可以看出, 固相率对充型长度的影响比较明显, 随着固相率的增加, 充型长度减小, 固相率与充型长度的关系如图4所示。 其它微观组织特征参数对充型长度的影响规律比较复杂, 不能直接建立固相率、 形状因子和晶粒尺寸与充型长度的关系, 需要进行多元回归分析。

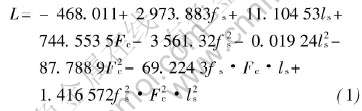

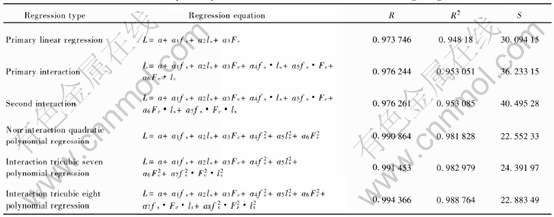

2.2 多元回归

为了得到半固态浆料的微观组织特征与充型长度的定量关系, 利用Excel程序对表1中的实验数据进行了多项式多元回归, 回归类型有: 一次线性回归、 一级交互作用、 二级交互作用、 无交互作用的二次多项式回归、 有交互作用的六次七项式回归、 有交互作用的六次八项式回归, 回归结果见表2。 从回归过程来看, 不考虑微观组织特征交互作用的线性回归, 即充型长度与固相率、 形状因子和晶粒尺寸为线性关系, 其回归系数最小, 标准误差较大, 回归方程: L=814.4338-966.262fs+0.092492ls+9.200327Fc。 由此方程可以看出, 充型长度随固相率的增大而减小, 随晶粒尺寸、 形状因子的增大而增大。 这与文献[9, 13]中表观黏度随固相率的增大而减小, 随晶粒尺寸、 形状因子的增大而增大的研究结果一致。 考虑一级交互作用的线性回归系数增大, 但标准误差增大; 二级交互的多元回归, 回归系数增大, 标准误差继续增大; 无

表1 浇注前初生相微观组织特征及充型长度

Table 1 Primary phase microstructure characteristics and filling length before pouring

图4 固相率与充型长度的关系

Fig.4 Relation between solid phase rate and filling length

交互作用的六次多项式回归, 回归系数继续增大, 标准误差减小; 有交互作用的六次八项式回归, 回归系数最大, 回归精度最高。 这说明固相率、 形状因子和晶粒尺寸对充型长度影响的交互作用是不能忽视的。

综合6种回归方程可见, 含一级和二级交互作用的六次八项式回归方程精度最高。 其回归系数: R=0.994366; R2=0.988764, 标准误差: S=22.88349, 回归平方和: U=138246, 残差平方和: Q=1570.96。 显著性检验: F=33.00032>F0.01(8, 3)=27.489, 回归特别显著。 预测半固态浆料充型能力的回归方程为

2.3 微观结构特征参数对充型长度的影响

2.3.1 固相率的影响

对式(1)进行分析, 第二项和第五项之和可化简为(2973.883-3561.32fs)×fs, 当固相率fs〈0.835时, 随着固相率的增加, 充型能力下降, 充型长度减小。 这一实验结果可以通过半固态浆料黏度公式[10]解释

式中 η为半固态浆料黏度; η0为液相黏度; Φeff为有效固相分数。

由式(2)可以看出, 随着固相率的增加, 有效固相分数Φeff增大, 浆料的表观黏度增大, 充型能力下降, 充型长度减小。 由于式(1)为流变成形的回归方程, 用固相率fs=0.835作为界限值是可以的。

2.3.2 晶粒尺寸的影响

式(1)中第3项和第6项之和可化简为(11.10453-0.01924ls)×ls, 当晶粒尺寸ls〈288.58μm时, 随着晶粒尺寸的增大, (11.10453-0.01924ls)×ls增大, 即充型长度增加。 这是因为当晶粒尺寸ls〈288.58μm时, 随着晶粒尺寸的增大, 比表面积越小, 晶粒之间聚集的趋势越弱, 被晶粒聚集体所包裹的液相越少, 聚集体之间的自由液态合金就相应增多, 整个浆料流动时所遇阻力减小, 表观黏度降低[9], 充型长度增加。

表2 半固态浆料微观组织特征对充型长度影响的回归分析

Table 2 Regression analysis of influence of semi-solid alloy slurry microstructure characteristic to filling length

2.3.3 形状因子的影响

式(1)中第4项和第7项之和可化简为(744.5535-87.7889Fc)×Fc, 由于Fc≤1, 经分析(744.5535-87.7889Fc)×Fc数值随Fc的增大而增大, 即充型长度随着形状因子数值的增大而增大。 由于形状因子反映了初生相的颗粒形态, 形状因子的数值越大, 初生相越接近球形, 初生相颗粒中包裹的液相就越少, 表观黏度降低[9], 充型长度增加。 上述分析仅仅是考虑了微观结构特征参数对充型长度的独立影响, 但从回归过程、 回归方程来看, 仅这样考虑是不够的, 还需分析微观结构特征参数间的交互作用对充型长度的影响。

2.4 微观结构特征参数间的交互作用

由式(1)前7项可见, 尽管充型长度随着初生相固相率的增大而减小、 随晶粒尺寸和形状因子数值的增大而增大, 但从式(1)后两项简化式(1.416572fs·ls·Fc-69.2243)fs·ls·Fc发现, 由于一般情况下fs·ls·Fc>1(如取fs=0.3, ls=12, Fc=0.3), f2s·l2s·F2c>1, 充型长度随着3个特征参数乘积的增大而增大, 而且, 增加幅度较大。 这说明, 半固态浆料充型长度不仅与初生相的3个微观组织特征参数的数值大小有关, 还与3个微观组织特征参数乘积的平方关系密切。 如前面所分析, 形状因子的数值将直接影响浆料中有效固相体积分数的数值, 晶粒尺寸直接影响晶粒聚集体大小, 微观组织特征参数的交互作用对半固态浆料表观黏度影响较大, 对充型能力的影响也是不容忽视的。

3 结论

1) 半固态浆料充型能力不仅与初生相微观组织特征参数有关, 还与微观组织特征参数乘积的平方关系密切。 建立了半固态浆料初生相微观组织特征参数与充型长度之间的数学表达式。

2) 半固态浆料微观组织特征参数的交互作用对充型能力影响较大, 半固态浆料制备阶段应严格控制固相率、 晶粒尺寸和形状因子参数值。

3) 利用回归方程可以对半固态浆料充型能力进行预测, 进而指导半固态浆料制备参数设计、 间接挤压铸造工艺设计和缺陷预测。

REFERENCES

[1]XING Shu-ming, ZHANG Li-zhong, ZENG Da-ben. Mold-filling ability of semisolid alloy[J]. Journal of University of Science and Technology Beijing, 2002, 9(4): 253-257.

[2]ZHANG Tie-jun, GUO Jing-jie, SU Yan-qing, et al. Effect of traveling magnetic on mould-filling length of the A357 melt during casting thin walled plate[J]. Journal of Materials Science and Technology, 2003, 19(1): 43-46.

[3]Kulasegaram S, Bonet J, Lewis J, et al. High pressure die casting simulation using a lagrangian particle method[J]. Communication in Numerical Methods in Engineering, 2003, 19(9): 679-687.

[4]张海英. 半固态合金熔体充型能力研究[D]. 北京: 北京交通大学, 2005.

ZHANG Hai-ying. Mold Filling Ability of Semisolid Alloy[D]. Beijing: Beijing Jiaotong University, 2005.

[5]Paul C, Mahesh P, Joseph H, et al. Modeling of cast systems using smoothed-particle hydrodynamics[J]. JOM, 2004, 56(3): 67-70.

[6]邢书明, 张励忠. 白口铸铁磨球半固态挤压铸造工艺参数设计[J]. 铸造, 2002, 51(7): 431-434.

XING Shu-ming, ZHANG Li-zhong. Process parameters design of semi-solld squeeze casting for producing white cast iron milling ball[J]. Foundry, 2002, 51(7): 431-434.

[7]杨卯生, 徐宏, 毛卫民. 铝合金半固态触变充型过程的计算机模拟[J]. 北京科技大学学报, 2002, 24(2): 181-185.

YANG Mao-sheng, XU Hong, MAO Wei-min. Simulation on filling process of semi-solid aluminum alloy casting[J]. Journal of University of Science and Technology Beijing, 2002, 24(2): 181-185.

[8]肖泽辉, 罗吉荣, 吴树森. AZ91D半固态流变压铸成形的研究[J]. 热加工工艺, 2004(2): 41-42.

XIAO Ze-hui, LUO Ji-rong, WU Shu-sen. Study on seni-solid rheoforming die casting for AZ91D alloy[J]. Hot Working Technology, 2004(2): 41-42.

[9]Fan Z, Chen J Y. Modelling of rheological behaviour of semi-solid metal slurry part 2-steady state behaviour[J]. Materials Science and Technology, 2002, 18(3): 243-249.

[10]Chen J Y, Fan Z. Modelling of rheological behaviour of semi-solid metal slurry part 1-theory[J]. Materials Science and Technology, 2002, 18(3): 237-242.

[11]Chen J Y, Fan Z. Modelling of rheological behaviour of semi-solid metal slurry(part 3)—transient state materials behaviour[J]. Materials Science and Technology, 2002, 18(3): 250-257.

[12]Fan Z, Chen J Y. Modelling of rheological behaviour of semi-solid metal slurry(part 4)—effects of particle materials morphology[J]. Materials Science and Technology, 2002, 18(3): 258-267.

[13]Kato A, Flemings M C. Viscosity of semi-solid A357 in the transirnt high shear rate regime[A]. Proceeding of the 6th S2P[C]. Turin, 2000. 477-482.

[14]Kopp R, Shimahara J. State of S & D and future trends in semi-solid manufacturing[A]. Proceeding of the 7th S2P[C]. Tsukuba: Japan Society for Technology of Plasticity, 2002. 57-66.

[15]Liu Y Q, Fan Z. Magnesium alloy selection for semi-solid metal processing[A].Proceeding of the 7th S2P[C]. Tsukuba: Japan Society for Technology of Plasticity, 2002. 587-592.

(编辑陈爱华)

基金项目: 河北省教育厅基金资助项目(2003217); 北京交通大学科研基金资助项目(230-12)

收稿日期: 2005-09-06; 修订日期: 2005-12-12

通讯作者: 谭建波, 教授; 电话: 0311-88613229; E-mail: tanjian1998@163.com