Article ID: 1003-6326(2005)02-0400-04

Effect of Ag(Ti) underlayers on CoCrPt thin film media

GAO Feng-ju(高凤菊)1 , SUN Hui-yuan(孙会元)1, 2, FENG Shun-zhen(封顺珍)1,

YU Hong-yun(于红云)1, JIA Lian-zhi(贾连芝)1, PAN Cheng-fu(潘成福)1,

ZHOU Hong-juan(周鸿娟)1, NIE Xiang-fu(聂向富)1, SUN Yu-ping(孙玉平)2

(1. College of physics, Hebei Normal University, Shijiazhuang 050016, China;

2. Key Laboratory of Materials Physics, Institute of Solid State Physics, Chinese Academy of Sciences, Hefei 230031, China)

Abstract: The nanocomposite films of CoCrPt/Ag were prepared by DC and RF magnetron sputtering onto glass substrates and subsequent annealing. Magnetic and structure properties of these films have been investigated in detail. Vibrating sample magnetometer(VSM), X-ray diffraction(XRD) and scanning probe microscope (SPM) were applied to study the magnetic properties and microstructure. Magnetic properties such as coercivity(Hc) are strongly dependent on the thickness of Ag and the annealing temperature. When the thickness of Ag underlayer is 20nm, the coercivity reaches the maximum of 2200×79.578A/m. The XRD patterns show that the CoCrPt films are hcp structure lying on the film plane. The SPM images show that small and uniform magnetic grains are isolated by Ag. The effect of Ti underlayer on the magnetic properties is also investigated. These features make CoCrPt/Ag nanocomposite films very attractive for the next-generation of high-density recording.

Key words: CoCrPt/Ag(Ti); nanocomposite films; magnetron sputtering; coercivity CLC number: O484.4; O484.5

Document code: A

1 INTRODUCTION

Many works have been done in recent years on Co-based granular alloys for potential applications as recording magnetic media[1-5]. The ideal granular media should consist of small and uniform grains. High anisotropy magnetic grains embedded in a robust non-magnetic matrix are required. High coercivity, large squareness and negative nucleation field are very important for magnetic recording films.The addition of Pt to the recording layer can increase the anisotropy field by 33% and Ku by 11%[6]. However, excessive addition of Pt to CoCr-based thin film media decreases the Cr segregation at the grain boundary[7]. It is generally agreed that the segregation of nomagnnetic elements to the boundaries of the columnar grains also can lead to high coercivity and low media noise. So the introduction of new underlayer has been proposed. Many different underlayers such as Ti[8], SiO2[9], Ta[10], CrTi[11], CoTb[12], CrMo[13] and Cr[14], have been reported in the literatures. The results indicate magnetic properties strongly depend on the crystallographic relationship between the magnetic layer and the underlayer. The industry is still in the process of searching for a better underlayer.

Ag has been reported to be a successful underlayer for FePt and CoPt granular films. Ag has a low surface energy, it can move to the surface and embed the FePt particles suppressing coalescence. So the particles are magnetically isolated[15]. The existence of Ag is proven to be essential for the development of texture, even at a volume fraction as small as 10%[15].

Ag may be useful as underlayer for CoCrPt media, however it is largely unknown about that so far. Our study focuses on improving the magnetic properties such as the coercivity and decreasing the exchange coupling by using Ag underlayer. We found Ag underlayer increases the coercivity of CoCrPt nearly about 2000×79.578A/m. In addition, we will also report the effect of Ti underlayer on the magnetic properties and the microstructure of CoCrPt films.

2 EXPERIMENTAL

The films of CoCrPt (25nm)/Ag(t nm) (t varied from 0 to 80nm) were deposited on glass substrates at room temperature. The CoCrPt layer was deposited by RF sputtering. The Ag(Ti) layer was deposited by DC magnetron sputtering. The base pressure was lower than 2×10-5Pa and the Ar pressure during the sputtering is 2Pa. The composition of the CoCrPt target (in mole fraction) was 72%Co-15%Cr-12%Pt. The samples were annealed at 350, 450, 550 and 650℃ for 30min. The films of CoCrPt (25nm)/ Ti (20nm) were prepared in the same condition. The in-plane magnetic properties were measured using a vibrating sample magnetometer(VSM). Structural properties were analyzed with an X-ray diffractometer(XRD) with CuKα radiation at room temperature. Surface morphology and magnetic domains were obtained with scanning probe microscope(SPM).

3 RESULTS AND DISCUSSION

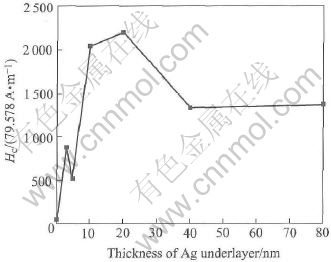

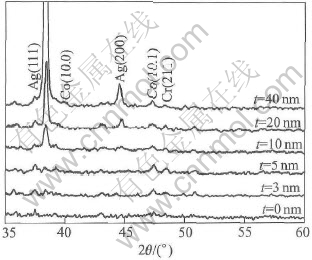

The XRD patterns of CoCrPt (25nm)/Ag (the thickness t varied from 0 to 40nm) annealed at 650℃ are shown in Fig.1. In all the XRD patterns, the Co(10.1) peak indicates that the structure of the CoCrPt films is hcp structure lying on the film plane, which is consistent with the result of the vibrating sample magnetometer(VSM). There is no peak of Ag when the thickness of Ag underlayer is 3 and 5nm, which indicates that the Ag underlayer is amorphous. As the thickness of Ag underlayer is 10nm, the (111) Ag peak appears. When the thickness of Ag underlayer is 20nm, the (200) Ag peak appears but it is very weak as the (111) Ag peak becomes more pronounced. In the same curve the Co(10.0) peak appears. When the thickness of Ag underlayer is 40nm, the (111) Ag peak and (200) Ag peak are stronger, implying the Ag underlayer becomes random.

Fig.1 XRD patterns of CoCrPt (25nm)/Ag (t nm) with different thickness of Ag

underlayer annealed at 650℃ for 30min

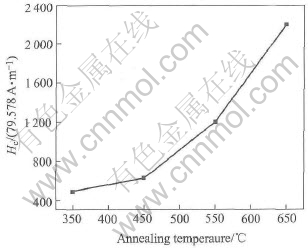

The coercivity varies with the thickness of the Ag underlayer as shown in Fig.2. It is found that the coercivity increases remarkably as the thickness of the Ag underlayer increases to 3nm. The increasing of the coercivity is due to the amorphous Ag increasing the physical separation between the magnetic grains. When the thickness of Ag underlayer is 20nm, the coercivity reaches the maximal value of 2200×79.578A/m because of the reduction of the intergrain interaction, which will be discussed later. When the thickness of Ag underlayer is 40nm the coercivity begins to decrease to 1340×79.578A/m. The coercivity does not change significantly for further increase of the thickness of Ag underlayer. This behavior can be attributed to the mixed phase of Ag underlayer.

]Fig.2 Coercivity Hc of CoCrPt (25nm)/Ag films annealed at 650℃

as function of thickness of Ag underlayer

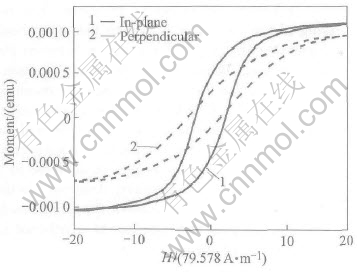

Moreover, we fabricated the CoCrPt (25nm)/Ag (20nm) the films by post-deposition annealing at different temperatures (350, 450, 550 and 650℃) as shown in Fig.3 and found that the coercivity increases with annealing temperature increasing. The film annealed at 650℃ for 30min can achieve a high coercivity of 2200×79.578A/m. Fig.4

Fig.3 Coercivity Hc of CoCrPt (25nm)/Ag (20nm) films as function of annealing temperature

Fig.4 In-plane and perpendicular hysteresis loop for CoCrPt (25nm)/Ag (20nm) films

annealed at 650℃

shows the hysteresis loop of CoCrPt (25nm)/Ag (20nm) annealed at 650℃ Post annealing may promote Ag further segregating and diffusing sufficient underlayer materials to the magnetic grain boundaries with a small amount into the interior of the magnetic grains, resulting in the increasing of the coercivity.

The in-plane coercivity of CoCrPt (25nm)/Ti (20nm) is 200×79.578A/m. We speculate that this behavior is because that the condition of the preparation is not suitable for Ti underlayer. A detailed investigation of Ti underlayer is under way.

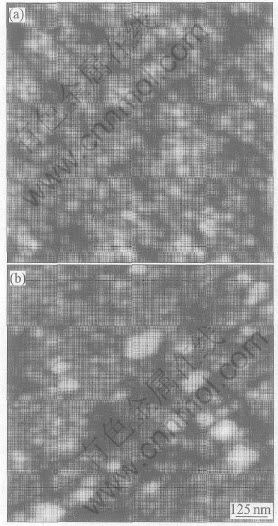

Fig.5 shows the AFM images of the film of CoCrPt (25nm)/Ag (20nm) annealed at 650℃ with the highest coercivity and CoCrPt (25nm) without Ag underlayer annealed at 650℃ for 30min. The average roughness Ra of the film of CoCrPt (25nm)/Ag (20nm) is 1.5nm. The Ra of the film of CoCrPt (25nm) is 2.2nm.It can be seen that the Ag underlayer (20nm) makes the grains small and uniform, which can be attributed to the effect of Ag underlayer. The average roughness Ra varies with the thickness of the Ag underlayer as shown in Fig.6. We can see that the Ag underlayer can make the surface smooth, but too sick underlayer is not helpful to the smoothness.

Fig.5 AFM images of CoCrPt (25nm)/Ag (20nm)(a) and CoCrPt (25nm)(b)

annealed at 650℃ for 30min

Fig.6 Ra of CoCrPt (25nm)/Ag films annealed at 650℃ as function of thickness of Ag underlayer

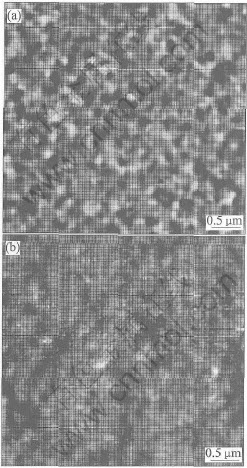

Fig.7 MFM images of CoCrPt(25nm)/Ag(20nm)(a) and CoCrPt(25nm)(b)

annealed at 650℃ for 30min

The MFM images of the films of CoCrPt (25nm)/Ag (20nm) annealed at 650℃ with the highest coercivity and CoCrPt (25nm) without the Ag underlayer annealed at 650℃ for 30min are shown in Fig.7. The dark and white regions represent the magnetic clusters in which the magnetic moments aligned in the same direction. The average cluster size of CoCrPt (25nm)/Ag (20nm) annealed at 650℃ is estimated to be about 150nm. It can be seen that the Ag underlayer affects the magnetic clusters size and distribution. Using Ag underlayer, the magnetic cluster structure becomes obviously finer compared with the sample without Ag underlayer. This result leads us to believe that Ag is segregated at grain boundaries of CoCrPt magnetic layer. The Ag segregation must be the cause of the magnetic isolation and the higher coercivity. Comparing the as-deposited film of CoCrPt (25nm)/Ag (20nm) with the post-annealing sample, the post-annealing sample has a fine and well-isolated domains contrast to the as-deposited samples. The post-annealing can also reduce the magnetic cluster size.

4 CONCLUSIONS

The granular hcp films of CoCrPt (25nm)/Ag( the thickness varied from 0 to 80nm) were deposited on glass substrates at room temperature. The samples were annealed at 350, 450, 550 and 650℃ for 30min. The structure of the CoCrPt films is hcp structure lying on the film plane. When the thickness of Ag underlayer is 20nm, the coercivity reaches the maximal value because of the perfect hcp structure and the reduction of the intergrain interaction. Ag underlayer makes the grains small and uniform. The coercivity increases with the annealing temperature and the films annealed at 650℃ for 30min can achieve a high coercivity of 2200×79.578A/m.

REFERENCES

[1] Delaunay J, Hayashi T, Tomita M. CoPt-C nanograinultar magnetic thin films [J]. Appl Phys Lett, 1997, 71(23): 3427-3429.

[2]Kubota Y, Folks L, Marinero E E. Intergrain magnetic coupling and microstructure in CoPtCr, CoPtCrTa, and CoPtCrB alloys [J]. Journal of Applied Physics, 1998, 84 (11): 6202-6207.

[3]Toney M F, Marinero E E, Doerner M F. High anisotropy CoPtCrB magnetic recording media [J]. Journal of Applied Physics, 2003, 94(6): 4018-4023.

[4]Platt C L, Howard J K, Roy A G, et al. Influence of stress on nucleation field of CoCrPt perpendicular media [J]. Journal of Applied Physics, 2002, 91(2): 772-774.

[5]Zeng H, Shan Z S, Liu Y, et al. Studies of the magnetic and reversal properties for thin CoCrTa films [J]. Journal of Magnetism and Magnetic Materials, 2002, 251: 283-291.

[6]Bolzoni F, Leccabue F, Panizzieri R. Magnetocrystastalline anisotropy and phase transformation in Co-Pt alloy [J]. IEEE Trans Magn, 1984, 20(5): 1625-1627.

[7]Mikami M, Djayaprawira D D, Domon H, et al. Study on increasing the coercivity of CoCrPtB media with high Pt content [J]. Journal of Applied Physics, 2002, 91(10): 7074-7076.

[8]Roy A G, Nuhfer N T, Laughlin D E. Postannealing effects on magnetic properties and microstructure of CoCrPt/Ti perpendicular recording media [J]. Journal of Applied Physics, 2003, 93(10): 8179-8182.

[9]Tateno Y, Katakura H, Igari T, et al. Magnetic anisotropy derived from interparticle interactions in CoCrPt/ SiO2 granular thin film longitudinal media[J]. Journal of Applied Physics, 2003, 93(5): 2804-2811.

[10]Roy A G, Laughlin D E. Effect of underlayers in improving the crystallographic texture of CoCrPt perpendicular recording media [J]. Journal of Applied Physics, 2002, 91(10): 8076-8078.

[11]Inaba N, Nakamura A, Yamamoto T, et al. Magnetic and crystallographic properties of CoCrPt thin films formed on Cr-Ti single crystalline underlayers[J]. Journal of Applied Physics, 1996, 79(8): 5354-5356.

[12]Uwazumi H, Shimatsu T, Sakai Y, et al. Recordingperformance and magnetization switching of CoTb/CoCrPt composite perpendicular media [J]. Journal of Applied Physics, 2002, 91(10): 8058-8060.

[13]Lai Chih-Huang, Chen Wei-Chuan, Tsai P H, et al. Effects of alloying additions in the CrMo underlayer on grain size ad magnetic properties of CoCrPt longitudinal media[J]. Journal of Applied Physics, 2003, 93(10): 8468-8470.

[14]Ajan A, Okamoto L. Crystallographic orientation of Cr in longitudinal recording media and its relation to magnetic anisotropy [J]. Applied Physics Letter, 2002, 81(8): 1465-1467.

[15]Shao Y, Yan M L, Sellmyer D L. Effects of rapid thermal annealing on nanostructure, texture and magnetic properties of granular FePt:Ag films for perpendicular recording [J]. Journal of Applied Physics, 2003, 93(10): 8152-8154.

Foundation item: Project(10274018) supported by the National Natural Science Foundation of China; Project(Z2001102) supported by the Key Foundation of Hebei Normal University; Project(2002116) supported by the Foundation of Hebei Provincial Education Department

Received date: 2004-11-25; Accepted date: 2005-01-18

Correspondence: SUN Hui-yuan, Professor; Tel: +86-311-6268020; E-mail: hysun@165e.com

(Edited by HE Xue-feng)